Wood glue – the unsung hero of woodworking projects. It’s that trusty adhesive that holds everything together, ensuring our creations withstand the test of time. But here’s the burning question: does wood glue lose its strength over time? Well, buckle up, because we’re about to debunk some common misconceptions and uncover the real story.

Before we dive into the juicy details, let’s get one thing straight – wood glue is designed to be a force to be reckoned with. It’s engineered for lasting strength and durability. However, just like any other material in this crazy world, there are factors that can influence its performance as time goes by. In this blog post, we’ll dig deep into the changes wood glue can experience over the years and explore the science behind its mighty grip.

So grab your favorite mug filled with piping hot coffee (or tea if that’s your jam), kick back in your comfiest chair, and prepare to have your mind blown by what you’re about to discover. Spoiler alert: the truth about whether wood glue loses its strength may surprise you more than a plot twist in your favorite thriller.

Factors That Can Contribute to Loss of Strength in Wood Glue

Contents

Wood glue is a staple in any woodworker’s toolkit, providing a strong and reliable bond for various woodworking projects. However, it’s important to understand the factors that can contribute to a loss of strength in wood glue over time. By being aware of these factors and taking the necessary precautions, you can ensure that your glued joints remain sturdy and durable.

Factor 1: Moisture:

Excessive moisture is one of the primary culprits behind weakened wood glue bonds. When wood glue comes into contact with moisture, it can break down and lose its adhesive properties. Water-based wood glues are particularly susceptible to moisture damage compared to solvent-based glues. To prevent this, it’s crucial to keep your glued surfaces dry and avoid exposing them to prolonged moisture.

Factor 2: Temperature:

Extreme temperatures can also impact the strength of wood glue. High temperatures can soften the glue, while low temperatures can make it more brittle. It’s essential to choose the appropriate type of wood glue that can withstand the temperature conditions your project will be exposed to. Additionally, avoid exposing glued surfaces to rapid temperature changes, as they can stress the bond and weaken it over time.

Factor 3: Aging:

As wood glue ages, its chemical composition may change, leading to a decrease in adhesive properties. Exposure to UV light can accelerate this aging process, further reducing its strength. To mitigate this factor, always check the expiration date on your wood glue bottles and store them in a cool, dark place to preserve their adhesive capabilities.

Factor 4: Improper Application:

The way you apply wood glue plays a significant role in the strength of the bond it creates. Uneven application or gaps between surfaces being bonded can result in weaker joints. Follow the manufacturer’s instructions for proper application techniques, including surface preparation and clamping requirements. This will ensure that your wood glue bonds are as strong as possible.

Factor 5: Incompatible Surfaces:

Different wood glues are formulated to work best with specific types of surfaces. Using the wrong type of wood glue for a particular surface can lead to a loss of strength in the bond. For example, water-based glues may not provide a strong bond on oily or resinous woods due to the natural oils present. Be sure to choose the appropriate wood glue for the surfaces you’re bonding to maximize strength.

Environmental Conditions

Wood glue is a versatile adhesive commonly used in woodworking projects, but its performance can be influenced by environmental conditions. In this article, we will delve into the role of temperature and humidity in determining the effectiveness of wood glue, providing valuable insights to woodworkers seeking durable and robust bonds.

Temperature’s Influence:

Temperature plays a critical role in the curing process of wood glue. Most wood glues are designed to cure at room temperature, typically around 70°F (21°C). However, deviations from this optimal range can affect the glue’s performance. Lower temperatures hinder the curing process, resulting in extended drying times and potentially weaker bonds. Conversely, higher temperatures expedite curing but may render the glue overly viscous, compromising its strength and workability.

Humidity’s Impact:

Humidity levels also exert a significant influence on wood glue effectiveness. As water-based adhesives, wood glues rely on moisture for proper curing. Yet excessive humidity can impede the drying process and weaken bonds. High humidity causes the glue to absorb into wood fibers, diminishing bonding strength and durability.

Different Types of Wood Glues:

It is crucial to note that not all wood glues respond equally to environmental conditions. Some specialized variants, such as waterproof or weatherproof glues, are formulated to withstand moisture exposure and temperature fluctuations without compromising their adhesive properties. These advanced wood glues offer enhanced versatility and reliability across various woodworking applications.

Best Practices for Optimal Bonding Strength:

To achieve optimal bonding strength with wood glue, it is essential to adhere to the manufacturer’s instructions regarding temperature and humidity conditions for application and curing. Additionally, storing wood glue in a cool, dry place away from extreme temperatures and humidity levels is highly recommended.

Aging

Aging, the relentless march of time, affects every aspect of the human body. From the first appearance of fine lines on our faces to the gradual decline in physical strength, aging is an inevitable and complex process. In this article, we will explore the intricacies of aging, delving into its various effects on our bodies. So, let’s embark on a journey through time and unravel the mysteries of aging.

The Biological Processes:

At a cellular level, aging involves a multitude of intricate biological processes. Telomeres, the protective caps at the ends of chromosomes, shorten with each cell division. As telomeres erode, cells gradually lose their ability to divide and replicate accurately. This phenomenon is known as cellular senescence and is a hallmark of aging.

The Visible Changes:

As time passes, visible changes become apparent on our bodies. Wrinkles etch themselves upon our skin like ancient hieroglyphs, a testament to a life well-lived. Our hair loses its vibrant hue and turns gray as pigment-producing cells decline in number. Additionally, age spots appear as a result of accumulated sun exposure over the years.

The Internal Transformations:

Internally, aging affects our organs and bodily functions. Our bones become more brittle, making us susceptible to fractures and osteoporosis. Vital organs such as the heart and lungs gradually lose their efficiency, leading to decreased cardiovascular capacity and respiratory function. Cognitive decline can also occur as brain cells degenerate and neural connections weaken.

The Role of Lifestyle:

Although aging is an inevitable process, certain lifestyle factors can influence its progression. Regular exercise has been shown to improve cardiovascular health and maintain muscle mass. A balanced diet rich in antioxidants can combat oxidative stress and slow down cellular damage. Adequate sleep and stress management techniques are also crucial for overall well-being.

Embracing Aging:

While aging presents its challenges, it is also a testament to the resilience and wisdom acquired over time. Embracing the aging process involves nurturing a positive mindset and focusing on self-care. Engaging in activities that stimulate the mind, maintaining social connections, and pursuing hobbies can enhance quality of life and promote healthy aging.

Improper Application

Wood glue is a remarkable adhesive that can create bonds of unmatched strength and durability. However, the key to unlocking its full potential lies in proper application. In this comprehensive guide, we will delve into the world of wood glue and reveal the secrets to avoiding weak joints and compromised adhesive strength. Prepare to embark on a journey where surfaces are meticulously prepped, ratios are perfectly balanced, drying time is respected, and clamping pressure is applied with precision. Let’s dive in.

Factor 1: Surface Preparation: The Foundation of Strong Bonds

To achieve robust wood glue joints, surface preparation is paramount. Begin by ensuring that the surfaces to be bonded are pristine – free from any contaminants such as dust, grease, or old adhesive residue. A thorough cleaning using a damp cloth and gentle sanding if necessary will pave the way for effective glue adhesion, guaranteeing unwavering strength and longevity.

Factor 2: Glue-to-Wood Ratio: Balancing Strength and Elegance

Wood glues come with specific guidelines regarding the ideal amount to be applied for optimal bonding strength. Too little glue can leave your joints vulnerable to separation, while excessive amounts can result in messy squeeze-out. The secret lies in finding the perfect harmony between strength and elegance. Follow the manufacturer’s recommendations for the appropriate glue-to-wood ratio, and witness your bonds flourish with both power and finesse.

Factor 3: Drying Time: Patience for Perfect Bonds

Patience is truly a virtue when it comes to wood glue application. Rushing the drying process or failing to allow sufficient time for the adhesive to cure can spell disaster for your joints. Respect the bond’s journey towards greatness by adhering strictly to the recommended drying time provided by the manufacturer. Take into account variables like temperature and humidity, which can influence drying time, and witness your bonds evolve into unyielding structures that defy the test of time.

Factor 4: Proper Clamping: Uniting Surfaces with Precision

During the curing process, clamping becomes the conductor orchestrating a symphony of adhesion. Applying proper clamping pressure ensures even distribution of the adhesive, leaving no room for gaps or weaknesses in your joints. Embrace the art of precision by applying sufficient and even clamping pressure, creating a symmetrical marriage between wood surfaces. With this level of attention to detail, weak joints will become a distant memory.

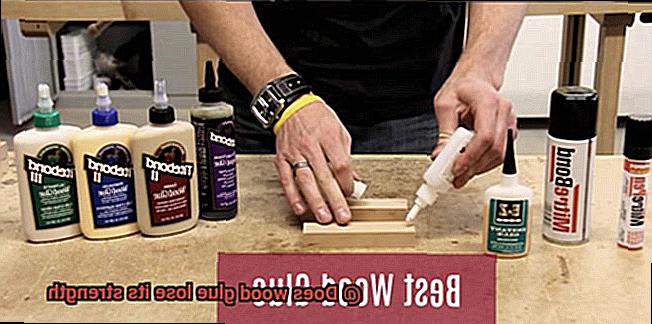

Choosing the Right Type of Glue for Your Project

When it comes to your project, whether it’s woodworking, crafting, or repairs, choosing the right type of glue is crucial for success. The glue you select can determine the strength and durability of your project, so it’s essential to understand the different options available and their specific uses.

- Wood Glue: Also known as carpenter’s glue or yellow glue, wood glue is specifically designed for bonding wood surfaces together. It forms a strong bond, dries clear, and can be sanded and painted over once dry. Wood glue is perfect for woodworking projects that involve joining pieces of wood.

- Epoxy Adhesive: For maximum strength and structural applications, epoxy adhesive is your go-to choice. It consists of a resin and hardener that need to be mixed together before use, creating an incredibly strong bond. Epoxy is also great for filling gaps and cracks in wood.

- Polyurethane Glue: If your project involves joining wood with other materials like metal or plastic, polyurethane glue is a versatile option. It creates a strong bond between different materials and can be used both indoors and outdoors. Additionally, polyurethane glue can expand to fill gaps while curing.

- General-Purpose Adhesives: Super glue or cyanoacrylate glue is perfect for quick repairs or projects that require instant adhesion. It has a fast-drying time and forms a strong bond quickly. However, it may not have the same long-term bonding strength as specialized woodworking glues.

When selecting a glue, always read the label and follow the manufacturer’s instructions for proper use. Consider factors such as clamping or curing time, durability, and the specific requirements of your project. Think about long-term durability if your project will be exposed to moisture or temperature changes.

Regular Maintenance and Care

Regular Maintenance and Care: Preserving the Strength of Wood Glue Bonds

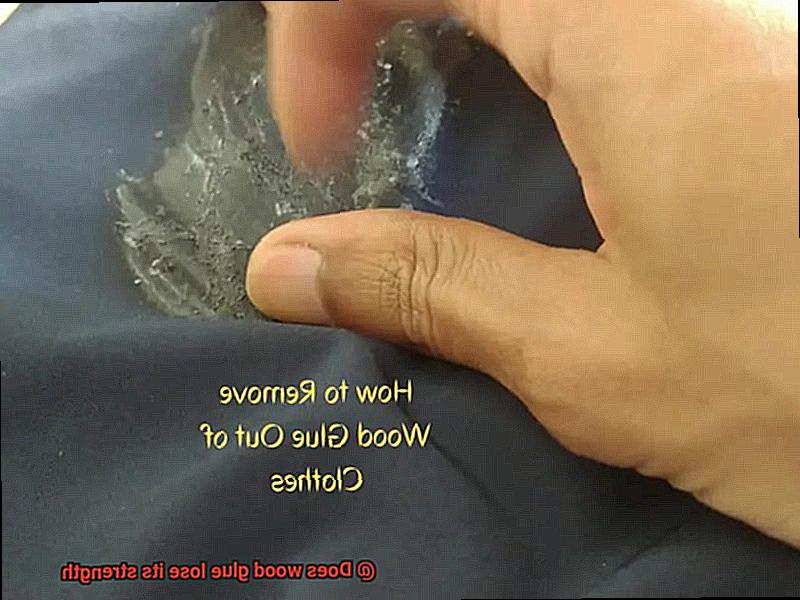

Wood glue is a remarkable adhesive that provides strong and durable bonds. However, like any other material, it requires regular maintenance and care to preserve its strength over time. By following a few simple practices, you can ensure that your wood glue bonds remain strong and secure for years to come.

- Cleanliness is Key: Before applying wood glue, thoroughly clean the surfaces to be bonded. Remove any dirt, dust, or grease that can interfere with the adhesive’s ability to create a strong bond. Use a mild detergent or solvent and wipe the surfaces clean with a lint-free cloth. This step ensures that the glue can penetrate and adhere properly.

- Apply Adequate Pressure: When bonding, apply sufficient clamping pressure to create a strong bond. This ensures that the glue spreads evenly across the surfaces, eliminating weak spots. Use clamps or suitable tools to maintain consistent and adequate pressure until the glue has fully cured.

- Allow for Proper Curing Time: Allowing sufficient time for the adhesive to dry and cure is vital for achieving maximum bond strength. Different types of wood glues have varying curing times, so follow the manufacturer’s instructions. Rushing the drying process can result in weakened bonds, so be patient and allow the glue to cure fully before subjecting it to stress.

- Protect from Moisture: Wood glue is not waterproof, so avoid direct contact with water or excessive humidity. This is especially important in outdoor applications or areas prone to moisture buildup. Applying a protective sealant or finish over the bonded surfaces adds an extra layer of protection against moisture.

- Regular Inspection and Maintenance: Regularly inspect your wood glue bonds for signs of deterioration or weakening. Check for cracks, gaps, or other visible damage and address them promptly. If needed, consult with a professional or follow appropriate repair procedures to ensure the longevity of the bond.

Minimizing Loss of Strength in Wood Glue Joints

However, as time passes, these joints may experience a decline in strength due to various factors. This article delves into essential tips and techniques that will minimize the loss of strength in wood glue joints, guaranteeing their longevity.

Choose the Perfect Glue:

Selecting the right type of wood glue for your specific project is paramount. Consider properties such as moisture resistance, temperature durability, and aging resilience. Different glues offer varying levels of protection against these factors, so choose wisely. Opt for waterproof or weather-resistant glues for projects exposed to moisture.

Meticulous Surface Preparation:

Before applying the glue, ensure that the surfaces are immaculately clean and devoid of debris. Eliminate dust, dirt, or remnants of old adhesives using sandpaper or a scraper. This meticulous step creates a pristine and smooth surface, optimizing glue adhesion.

Craftsmanship in Clamping:

Achieving strong and reliable joints necessitates precise clamping during the drying process. Apply even pressure across the entire glued area using clamps that deliver ample force without damaging the wood. This ensures a tight bond and prevents any gaps that may weaken the joint.

Temperature and Humidity Considerations:

Extreme temperatures can compromise the strength and make glue joints brittle. Adhere to the manufacturer’s recommendations regarding temperature and humidity conditions for optimal glue performance. Avoid working in excessively hot or cold environments to maintain joint integrity.

Delicate Application of Glue:

To attain maximum bond strength, apply a thin and even layer of glue on both mating surfaces. Excessive glue application can lead to poor adhesion and potential weakening of the joint. Remember, less is more.

Reinforce with Mechanical Fasteners:

In high-stress or load-bearing applications, bolster wood glue joints with mechanical fasteners such as screws or nails. This supplementary support provides extra strength and stability to the joint.

Regular Maintenance and Vigilance:

To prevent further loss of strength, regularly inspect your wood glue joints for signs of weakness or deterioration. Prompt repair or reinforcement can avert potential failures and ensure the longevity of your projects.

Optimal Storage:

Adhere to the manufacturer’s instructions for appropriately storing wood glue. Proper storage preserves the glue’s effectiveness and prevents premature degradation, ensuring optimal performance when you need it.

uaNckEMncQE” >

Also Read: Is Elmer’s glue waterproof after it dries?

Conclusion

In conclusion, wood glue is a steadfast adhesive capable of forging robust and enduring bonds. However, various factors can contribute to the gradual weakening of wood glue over time. Excessive moisture, unpredictable temperature fluctuations, the relentless march of age, improper application techniques, and the utilization of an unsuitable glue for specific surfaces can all undermine the bond’s resilience.

To mitigate the potential loss of strength in wood glue joints, it is imperative to exercise caution and adopt certain preventive measures. Keep your glued surfaces impeccably dry and shield them from prolonged exposure to moisture. Carefully select the appropriate type of wood glue that harmonizes with the temperature conditions your project will confront. Scrutinize the expiration date on your wood glue bottles diligently and safeguard their adhesive prowess by storing them in a cool, obscure abode. Adhere scrupulously to the manufacturer’s instructions for precise application techniques and ensure uniform clamping pressure for an unwavering bond. Optimize strength by employing the correct variant of wood glue for specific surfaces.

Moreover, regular maintenance and meticulous care are indispensable in preserving the potency of wood glue bonds. Thoroughly cleanse surfaces before applying glue, exert ample pressure during clamping procedures, allot sufficient time for proper curing, safeguard against encroaching moisture, and regularly scrutinize any telltale signs of deterioration to promptly address them.

By comprehending these factors and adhering to best practices, you can rest assured that your wood glue bonds will endure with unwavering strength for years on end.