Ever found yourself in a sticky situation with a broken metal wire and no tools in sight? Fear not, because super glue is here to save the day. In this blog post, we’re diving deep into the world of using super glue on metal wire to see if it lives up to its legendary reputation.

Super glue, also known as cyanoacrylate adhesive, has always been hailed for its amazing bonding abilities. Its super strength and lightning-fast drying time have made it the go-to solution for countless repairs. But does it really work its magic on metal wire?

Sure, welding and soldering might be the traditional heroes of metal bonding, but super glue offers an intriguing alternative for certain situations. Its solvent-free formula creates a strong bond by reacting with moisture on the surface, causing a fancy process called polymerization that seals everything together. This special chemistry allows super glue to form tough connections, even on tricky materials like metal wire.

Wire-related projects often call for quick fixes that you can count on. Whether it’s fixing jewelry, delicate electronics, or getting crafty with DIY creations, you need a bond that’s secure and long-lasting. With its ability to create fast and strong bonds, super glue seems like the perfect contender for these scenarios.

Join us as we embark on a series of experiments to put super glue’s effectiveness with different gauges and types of metal wire to the test. Together, we’ll uncover the potential of this adhesive wonder, exploring its strengths and limitations along the way. Let’s find out if it truly lives up to its mythical powers.

So if you’ve ever wondered whether super glue and metal wire can make sparks fly in adhesive heaven, look no further. Dive into our blog and get ready to be amazed by the wonders of cyanoacrylate bonding.

What is Super Glue?

Contents

- 1 What is Super Glue?

- 2 What are the Different Types of Metal Wire?

- 3 How Does Super Glue Bond with Metal Wire?

- 4 Factors that Affect the Adhesion of Super Glue to Metal Wire

- 5 Preparing the Metal Wire Surface for Super Glue Application

- 6 Applying Super Glue to Metal Wire

- 7 Pros and Cons of Using Super Glue on Metal Wire

- 8 Alternatives to Using Super Glue on Metal Wire

- 9 Conclusion

Super glue, also known as cyanoacrylate adhesive, is a magical substance that possesses the power to securely bond metal wire and a wide range of other materials. This fast-acting adhesive is renowned for its ability to create strong and durable bonds in a matter of seconds. But what makes super glue so special?

At the heart of super glue lies its secret ingredient: cyanoacrylate. This powerful resin reacts with moisture in the air to initiate a rapid chemical reaction. When exposed to moisture, the liquid glue polymerizes and hardens almost instantly, creating an incredibly strong bond. It’s like witnessing a transformation from liquid to solid in the blink of an eye.

When it comes to bonding metal wire, choosing the right formulation of super glue is crucial. While most super glues can bond well with metal surfaces, some specialized varieties are specifically designed for enhanced adhesion to metals. These specialized formulas often contain additional additives or modifiers that improve their performance on metal substrates.

Before applying super glue to metal wire, it’s essential to prepare the surface properly. Cleanliness is key – ensure that the wire surface is free from contaminants and grease. A degreaser or rubbing alcohol can be used to remove any dirt or oxidation. For better adhesion, consider roughening the surface slightly using sandpaper or a file. This will provide more surface area for the glue to grip onto, resulting in a stronger bond.

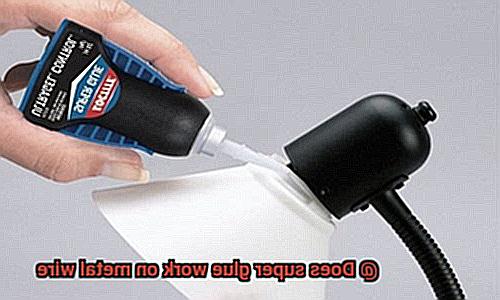

Applying super glue to metal wire requires precision and speed. Apply a small amount of glue onto one surface and firmly press the wire against it. Hold the pieces together for a few moments to allow the glue to set properly. Be mindful of the quick-drying properties of super glue – work swiftly and accurately to achieve optimal results.

While super glue can create strong bonds with metal wire, it’s important to consider the demands of your project. For heavy-duty applications or those involving constant movement, alternative adhesives like epoxy or solder may be more suitable. These adhesives offer stronger and more durable bonds, ensuring the longevity of your metal wire connections.

What are the Different Types of Metal Wire?

From the mighty powerhouse of steel wire to the lightweight wonder of aluminum wire, there is a wide range of types and uses to discover. Whether you’re a DIY enthusiast, jewelry maker, or simply intrigued by the versatility of metal wire, this guide will provide you with detailed insights into the various types and their applications.

Steel Wire: The Mighty Powerhouse

Steel wire is a true superhero in the world of metal wire. With its strength, durability, and resistance to corrosion, it is widely used in construction and manufacturing industries. Stainless steel wire fights rust and is ideal for outdoor applications, while carbon steel wire is perfect for heavy-duty projects due to its high tensile strength.

Copper Wire: The Electrical Wizard

Copper wire takes center stage as the electrical wizard. Known for its exceptional conductivity and flexibility, it is extensively used in electrical applications such as wiring systems, motors, and transformers. Electricians and engineers favor copper wire for its low resistance to electric current, while its soldering and brazing capabilities make it easy to work with.

Aluminum Wire: The Lightweight Wonder

When weight reduction is crucial, aluminum wire comes to the rescue. This lightweight wonder finds its place in industries where keeping things light is essential, such as aircraft and automotive manufacturing. Not only is aluminum wire lightweight, but it also boasts corrosion resistance, making it a top choice for outdoor use.

Brass Wire: The Versatile Beauty

Brass wire combines strength, corrosion resistance, and aesthetic appeal into one package. It finds its way into diverse applications like jewelry making, musical instruments, decorative items, and electrical connectors. Whether you’re creating stunning jewelry or adding artistic flair to your projects, brass wire has got you covered.

Nickel Wire: The Heat Champion

When it comes to high temperatures, nickel wire reigns supreme. With its heat resistance, corrosion resistance, and exceptional chemical resistance, it is the champion in high-temperature applications. From heating elements to automotive parts, nickel wire plays a vital role. Additionally, it is used in batteries, electronics, and various industrial components.

How Does Super Glue Bond with Metal Wire?

Super glue, also known as cyanoacrylate adhesive, is a remarkable adhesive that can bond various materials, including metal wire. But have you ever wondered how this powerful glue actually bonds with metal wire? Let’s take a closer look at the fascinating process.

Before applying super glue to metal wire, it’s crucial to prepare the surface properly. This involves cleaning the wire and ensuring it is free from any dirt, oil, or oxidation. Simply wipe the wire with a clean cloth and use a degreasing agent if necessary. This step ensures optimal bonding.

Now that the surface is ready, it’s time to apply the super glue. Use a small amount and apply it sparingly directly onto the metal wire. Be careful not to use excess glue, as it can spread onto unwanted areas.

When the super glue comes into contact with the metal wire surface, something magical happens. The adhesive begins to polymerize rapidly, forming strong chemical bonds with the metal surface. This is primarily due to the chemical composition of cyanoacrylate adhesives.

Cyanoacrylate adhesives contain molecules that have an affinity for reacting with moisture present on the metal wire’s surface. As the super glue reacts with this moisture, it undergoes a process called anionic polymerization. This causes the adhesive to harden and form robust bonds with the metal surface.

After applying super glue to the metal wire, patience is key. Allow sufficient time for the adhesive to fully cure. This typically takes a few minutes but can vary depending on the specific brand and type of super glue being used. During this curing process, further polymerization and cross-linking occur, resulting in an even stronger bond between the metal wire and the adhesive.

However, it’s important to note that not all types of metal wire may be compatible with super glue. Metals like aluminum or stainless steel can be less reactive with the adhesive, making it more challenging to achieve a strong bond. In such cases, roughening the surface of the wire using sandpaper or a file can increase its reactivity with the super glue.

Remember to also consider environmental conditions and intended application when using super glue for bonding metal wire. High temperatures or exposure to harsh chemicals can weaken the bond. So, always choose the right glue for the job and ensure proper surface preparation for a secure and durable bond.

Factors that Affect the Adhesion of Super Glue to Metal Wire

Super glue, also known as cyanoacrylate adhesive, possesses the remarkable ability to create strong bonds with metal wire. However, achieving optimal adhesion requires a deep understanding of the factors that influence the bonding process. In this article, we will delve into the key factors that affect the adhesion of super glue to metal wire, providing valuable insights on how to maximize its bonding potential.

Surface Cleanliness:

Cleanliness reigns supreme when it comes to super glue. Any trace of dirt, grease, or residue on the metal wire can act as a formidable barrier, impeding the glue from forming a strong bond. Before applying super glue, ensure that the metal wire is meticulously cleaned and free from any contaminants. A pristine surface allows for better contact between the glue and the metal, resulting in an unyielding bond.

Surface Roughness:

The roughness of the metal wire’s surface plays a pivotal role in adhesion. A smooth surface provides an array of contact points for the glue to cling onto, yielding a tenacious bond. Conversely, a rough or uneven surface can diminish the effectiveness of the bond. If your metal wire boasts a textured exterior, consider sanding or polishing it to enhance adhesion.

Temperature:

Temperature serves as another critical factor influencing super glue’s adhesion properties. Ideally, super glue thrives at room temperature (around 20-25 degrees Celsius or 68-77 degrees Fahrenheit). Extreme temperatures can meddle with the bonding process. Higher temperatures accelerate curing too hastily, while colder temperatures can halt or decelerate curing altogether. Thus, working within this controlled temperature range is vital.

Humidity:

Humidity levels in the environment wield considerable sway over super glue’s adhesion capabilities. Excessive humidity introduces moisture into the bonding equation, weakening the bond. To ensure optimal adhesion, it is advisable to work in an environment with moderate humidity levels. If necessary, employ a dehumidifier or air conditioning to maintain precise humidity control.

Type of Metal:

Different metals possess distinct surface properties that influence super glue’s adhesion. Some metals may harbor a natural oxide layer or coating that necessitates removal before applying the glue. Additionally, certain metals exhibit varying degrees of chemical reactivity, which can impact their compatibility with super glue. It is crucial to consider the specific characteristics of the metal wire being used and opt for an adhesive that harmonizes with that particular metal.

Application Technique:

The manner in which super glue is applied to the metal wire significantly impacts adhesion. An even and thin layer of glue ensures proper contact with the metal surface, fostering a robust bond. Over-application or excessive force during application can lead to excess glue seepage or uneven distribution, resulting in weakened adhesion. Employing a gentle touch and precision are paramount to achieving a durable bond.

Preparing the Metal Wire Surface for Super Glue Application

To create a secure and long-lasting bond with metal wire, proper preparation is essential. This article explores the necessary steps to ensure the surface is ready for super glue application. By following these guidelines, you can achieve a durable bond that will stand the test of time.

Step 1: Clean the Metal Wire Surface

Begin by removing any contaminants that could hinder the bonding process. Use a clean cloth or mild detergent solution to gently wipe the wire surface. Avoid harsh chemicals or abrasives that could damage the metal. This step ensures a clean surface for optimal adhesion.

Step 2: Thoroughly Dry the Wire

Moisture compromises super glue effectiveness, so it’s crucial to ensure the metal wire is completely dry before applying the adhesive. Allow the wire to air dry or use a clean cloth/paper towel to remove any lingering moisture. Remember, a dry surface guarantees maximum bonding strength.

Step 3: Enhance Adhesion (optional)

For an even stronger bond, consider roughening the metal wire’s surface slightly. Lightly sand the wire with fine-grit sandpaper or use a metal brush to create micro abrasions. These tiny scratches increase the surface area available for bonding, resulting in enhanced adhesion.

Step 4: Optional Metal Primer

To further enhance the bond, apply a metal primer designed specifically for super glue and metal surfaces. This specialized primer acts as a bonding agent, creating a stronger connection between the adhesive and the wire. Follow the manufacturer’s instructions carefully and allow sufficient drying time before applying super glue.

Applying Super Glue to Metal Wire

In this article, we will explore the implications of applying Super Glue to metal wire and how to achieve the best results.

First things first, cleanliness is key. Before applying Super Glue to your metal wire, make sure the surface is clean and free from any dirt, grease, or oxidation. A quick wipe with isopropyl alcohol or acetone should do the trick. This ensures that the glue can bond properly and securely.

Now that your wire is squeaky clean, it’s time to tackle any rough edges. If your metal wire has any jagged or rough areas, grab a file or sandpaper and smooth them down. This creates a smooth surface for the Super Glue to adhere to, resulting in a stronger bond.

When it comes to Super Glue, less is more. Only a small amount is needed to create a powerful bond. Applying too much can lead to excess glue oozing out and creating a messy appearance. So squeeze just a tiny drop onto the desired area of the metal wire.

Hold your wire in place for a few seconds to allow the glue to set and bond properly. Super Glue works fast, so make sure you align everything correctly before applying it because once it’s bonded, it’s difficult to reposition or adjust.

Now, let’s talk about the strength of that bond. Generally, Super Glue forms a strong bond with metals like steel, aluminum, and copper. However, it may not work as effectively on metals with low surface energy or those that are coated or treated with certain substances. In these cases, using a primer specifically designed for bonding metals can enhance the adhesion and durability of the bond.

It’s important to note that while Super Glue is strong, it’s not recommended for load-bearing or high-stress applications. So if you’re working on a heavy-duty project, you might want to explore other options. Additionally, moisture can weaken the bond, so keep the bonded area dry and avoid exposing it to water or excessive humidity.

Pros and Cons of Using Super Glue on Metal Wire

Super glue might just be the answer. With its fast-drying properties and versatile applications, it offers several advantages. However, it’s important to be aware of its limitations as well. In this article, we’ll explore the pros and cons of using super glue on metal wire, so you can make an informed decision for your projects.

Pros:

- Fast-Drying: Unlike other adhesives, super glue dries in a flash, allowing you to use the wire immediately. This is especially convenient when working on time-sensitive projects or needing instant gratification.

- Strong Bond: Super glue forms an unbreakable connection with metal surfaces, ensuring a secure attachment. This strength is particularly beneficial for delicate or intricate wire designs that require a trustworthy bond.

- Versatility: Whether it’s stainless steel, aluminum, or copper wire, super glue can handle it all. Its compatibility with various metals makes it a versatile option for different projects and applications.

- Resistance to Moisture and Heat: Super glue laughs in the face of moisture and heat, making it suitable for outdoor or high-temperature environments. It can withstand exposure to water, humidity, and extreme temperatures without compromising its adhesive strength.

- Accessibility and Affordability: Super glue is widely available at hardware stores, craft stores, and online platforms. Its affordability ensures that quality adhesives are within everyone’s reach, whether you’re a professional or a hobbyist.

Cons:

- Lack of Flexibility: While super glue creates an initially strong bond, it can become brittle over time. If the wire is subject to bending or flexing, the bond may weaken or break. This limitation makes it less suitable for applications where flexibility is crucial.

- Not Suitable for Heavy-Duty Applications: Super glue may not be the best choice for heavy-duty situations or applications involving significant stress or pressure on the wire. In such cases, alternative adhesives or mechanical fasteners may be necessary.

- Compatibility Issues: Different types of super glue may work better with specific metals than others. It’s essential to check the manufacturer’s recommendations or perform a small test before using super glue on metal wire to ensure compatibility and optimal results.

- Difficult Removal: Once super glue has dried, removing it without damaging the wire can be quite the challenge. This can become problematic if a mistake is made during the bonding process or if repositioning of the wire is required.

- Fumes and Irritation: Super glue emits fumes during the curing process that can irritate the eyes, nose, and throat. Using it in a well-ventilated area and taking necessary precautions to avoid direct exposure to the fumes is crucial.

Alternatives to Using Super Glue on Metal Wire

When it comes to bonding metal wire, relying solely on super glue may not provide the strength and durability you need. Fortunately, there are several adhesive-free alternatives available that offer secure and long-lasting connections. In this article, we will explore some of these alternatives, providing you with a range of options to choose from for your wire projects.

Soldering:

Soldering is a technique commonly used in electronics and jewelry making. By melting a metal alloy onto the wire, soldering creates a strong bond. This method requires a soldering iron, solder, and flux. With excellent conductivity and durability, soldering is ideal for projects that demand strength.

Epoxy Adhesive:

Epoxy adhesive is a two-part adhesive consisting of a resin and a hardener. When combined, they create a powerful and permanent bond. Applying epoxy to metal wire involves spreading a thin layer onto the surfaces and pressing them together. This versatile adhesive can securely bond different types of metal wires.

Heat Shrink Tubing:

Heat shrink tubing is a heat-sensitive material that tightly shrinks around the wire when heated. It not only provides insulation but also ensures secure bonding. Commonly used in electrical wiring applications, heat shrink tubing protects against moisture, dust, and other contaminants.

Wire Wrapping:

Wire wrapping involves wrapping a secondary wire or thread around the main wire, creating tension that holds them together. This technique is often used in jewelry making as it provides both decorative patterns and secure connections.

Mechanical Fasteners:

For projects requiring maximum strength and reliability, mechanical fasteners like screws, bolts, or clips can hold metal wires together effectively. These fasteners provide robust connections but may require additional tools and hardware.

Adhesive Tapes:

In temporary or non-load-bearing applications, adhesive tapes such as electrical tape or duct tape can be used to bond metal wires. While these tapes offer quick and easy bonding, they may not provide the same level of durability or strength as other methods.

w-iHL3tN__A” >

Also Read: Can You Super Glue Electrical Wires?

Conclusion

In conclusion, the answer to the question “Does super glue work on metal wire?”

is a resounding yes. Super glue has proven to be an effective adhesive when it comes to bonding metal wire.

Its strong and durable formula creates a secure bond that can withstand various conditions and pressures. Whether you’re repairing a broken piece of jewelry or creating a DIY project, super glue provides a reliable solution for attaching metal wires together.

So, next time you find yourself in need of joining metal wires, reach for that trusty tube of super glue and watch as it works its magic, bringing your creations together with precision and strength.