Woodworking projects can be a rollercoaster of emotions, especially when it comes to the strength of wood glue. We’ve all felt that sinking feeling when a weak bond leads to our hard work falling apart or groaning under pressure. But fret not – in this blog post, we’re diving deep into the world of wood glue to uncover its true strength and reliability.

Wood glue, also known as carpenter’s glue or PVA glue (Polyvinyl Acetate), is like a superhero adhesive specially made for bonding wood. It’s a go-to choice for DIY enthusiasts, craftsmen, and pros alike because it packs a serious punch in various woodworking applications.

The magic of wood glue lies in its ability to infiltrate the tiniest nooks and crannies of wood. As it seeps into the fibers, it creates an unbreakable connection by interlocking them together. This results in a joint that laughs in the face of time and stands tall against any challenge.

But here’s where things get even more impressive – wood glue isn’t just strong; it’s got flexibility for days. Once cured, this stuff remains unfazed by temperature swings, humidity, and everyday stresses that wooden wonders encounter. Whether you’re building furniture fit for royalty or crafting intricate sculptures that defy gravity, wood glue has your back with a hold that lasts for ages.

And here’s another secret weapon: wood glue isn’t limited to bonding wood-to-wood only. Nope. It can also join forces with other materials like metal, plastic, or ceramics. As long as you prep those surfaces properly and keep them squeaky clean, wood glue will create connections so sturdy they’ll make Superman jealous.

Now hold on tight because there are a few things to consider before jumping headfirst into gluing bliss. The strength of a wood glue joint can be influenced by factors like the type of wood, how well you prepare it, and your technique. These variables play a role in determining just how mighty that bond will be. So choose wisely, my friend, and pick the glue that’s perfect for your project.

In conclusion, wood glue absolutely holds strong when used right. Its superpower to penetrate deep into wood fibers and create an unbreakable bond makes it a trusted and reliable adhesive. So, next time you’re ready to tackle a woodworking adventure, reach for that trusty bottle of

Different Types of Wood Glue

Contents

Wood glue is an essential adhesive in woodworking projects. It helps to bond pieces of wood together, creating strong and durable joints. There are different types of wood glue available, each with its own unique characteristics and strengths. Understanding these different types can help you choose the right glue for your specific project.

PVA Glue

Polyvinyl acetate (PVA) glue, also known as white glue or carpenter’s glue, is one of the most common types of wood glue. It is water-based and dries clear, making it ideal for projects where appearance is important. PVA glue forms a strong bond with wood fibers and is suitable for both interior and exterior applications. It is easy to apply, non-toxic, and can be sanded and painted over once dry. However, PVA glue does not perform well in high-moisture environments and may not be suitable for outdoor projects exposed to the elements.

Polyurethane Glue

Polyurethane glue, also known as Gorilla Glue, is a popular choice for projects that require a strong bond. It is a waterproof adhesive that expands as it cures, filling in gaps and creating a tight bond between wood surfaces. Polyurethane glue is incredibly strong and can withstand extreme temperatures and moisture. However, it has a longer curing time and requires clamping during the drying process to ensure a secure bond.

Epoxy Glue: Epoxy glue consists of two components

Hide Glue

Hide glue, also known as animal glue, has been used for centuries in woodworking. It is made from the collagen in animal hides and bones and is available in both liquid and granular form. Hide glue offers excellent bond strength and is reversible, meaning it can be easily dissolved with heat or moisture for disassembling or repairing wood joints. However, it requires special preparation and application techniques, including heating the glue before use.

Cyanoacrylate Glue

Cyanoacrylate glue, commonly known as super glue, is a fast-setting adhesive that forms an instant bond when it comes into contact with moisture. While not specifically designed for woodworking, cyanoacrylate glue can be used to bond small wood pieces or for quick repairs. It is not suitable for large or load-bearing joints, as it tends to be brittle and may fail under stress.

In conclusion, understanding the different types of wood glue is essential for choosing the right adhesive for your woodworking project. PVA glue is versatile and suitable for general applications, while polyurethane glue provides waterproof properties. Epoxy glue offers exceptional strength and durability, hide glue allows for reversible repairs, and cyanoacrylate glue is ideal for quick fixes.

Preparing the Surfaces for Bonding

Preparing the surfaces for bonding with wood glue is a crucial step in ensuring a strong and durable bond. By following the steps and techniques outlined below, you can maximize the effectiveness of the wood glue and create long-lasting bonds.

First, it is important to clean the surfaces that need to be bonded. Any dirt, dust, or debris on the wood can hinder the effectiveness of the glue. Use a clean cloth or brush to remove any loose particles from the surface.

Next, sanding the surfaces is essential for creating a rough texture that allows the glue to adhere better. Smooth surfaces can prevent the glue from properly gripping the wood. Use sandpaper with a grit between 120-180 for effective sanding.

If the wood has any existing finishes like varnish or paint, it is important to remove them before applying wood glue. These finishes can create a barrier between the wood and the glue, reducing bond strength. Sanding or using a chemical stripper can help remove these finishes effectively.

In some cases, particularly with dry or porous wood, slightly moistening the surface can improve bond strength. However, be cautious not to over-moisten the wood as excessive moisture can weaken the bond.

Finally, applying sufficient pressure on the glued surfaces using clamps is vital for a strong bond. Clamping helps maintain consistent pressure across the entire bonded area and prevents any movement while the glue dries. Follow the manufacturer’s recommendations for clamping time and pressure.

By following these steps and techniques, you can prepare surfaces for bonding with wood glue effectively. It’s important to note that different types of wood glues may have specific instructions regarding surface preparation, so always refer to the product’s instructions for optimal results.

The Strength of Different Types of Wood Glue

Wood glue is a powerful adhesive that is widely used in woodworking projects to bond pieces of wood together. But does wood glue hold strong? As an expert in this field, I can confidently say that when used correctly, wood glue does indeed provide a strong and durable bond.

Types of Wood Glue:

There are various types of wood glue available on the market, each with its own unique characteristics and strengths. Some of the most common types include PVA (polyvinyl acetate) glue, epoxy glue, polyurethane glue, and hide glue.

PVA Glue:

PVA glue, also known as white or yellow glue, is the most popular type of wood glue. It is water-based and dries clear. PVA glue is known for its exceptional bonding strength and ease of use. It is suitable for most woodworking applications but may not be suitable for environments with high moisture or temperature fluctuations.

Epoxy Glue:

Epoxy glue is a two-part adhesive that consists of a resin and a hardener. When these components are mixed together, they create a bond that is incredibly strong and durable. Epoxy glue excels in providing resistance to moisture, heat, and chemicals. It is often used for bonding difficult-to-glue materials or in applications that require maximum strength.

Polyurethane Glue:

Polyurethane glue, commonly known as Gorilla Glue, is a versatile adhesive that forms a robust bond between wood surfaces. It expands as it cures, filling gaps and providing additional strength. Polyurethane glue is waterproof and can be used both indoors and outdoors. However, it requires moisture to cure properly and may necessitate clamping during the drying process.

Hide Glue:

Hide glue is a traditional type of wood adhesive made from animal collagen. It has been utilized in woodworking and instrument making for centuries. Hide glue offers exceptional strength and reversibility. It has a long open time, allowing for adjustments before it sets. However, hide glue requires heating and can be more challenging to work with compared to modern wood glues.

Factors Affecting Strength:

The strength of wood glue depends not only on the type of glue used but also on various factors. These factors include the quality of the wood surfaces being bonded, the clamping pressure applied during drying, and the curing time. It is essential to follow the manufacturer’s instructions and recommendations for each specific type of glue to achieve optimal strength.

Drying Time for Maximum Bonding Strength

Achieving maximum bonding strength in woodworking projects requires more than just slapping on some wood glue and calling it a day. One of the key factors that often gets overlooked is the drying time for the glue to reach its full potential. Let’s dive into why drying time is essential for creating strong and durable bonds.

First and foremost, drying time allows the wood glue to penetrate the wood fibers effectively. Wood glue is designed to seep into the pores of the wood, creating a solid connection that can withstand the test of time. Without adequate drying time, the glue may not have enough opportunity to make its way deep into the wood, resulting in weaker bonds.

But drying time isn’t just about penetration; it’s also about evaporation. Most wood glues are water-based, with water acting as a carrier for the adhesive chemicals. During the drying process, water evaporates, leaving behind the adhesive that binds the wood together. Rushing this process can lead to incomplete evaporation, leaving behind moisture that weakens the bond.

Moreover, proper drying time allows the bond strength to fully develop. While wood glue may feel dry to the touch after a few hours, it needs time to chemically react and harden. Prematurely subjecting joints to stress before complete curing can compromise the bond strength and potentially lead to failure.

Applying clamping pressure during drying is another crucial step in achieving maximum bonding strength. Clamping ensures that wood pieces remain in close contact while the glue cures, eliminating air gaps and enhancing bond strength. However, it’s important to note that clamps should only be removed once the glue has fully cured – rushing this step can undo all your hard work.

Different types of wood and applications may require varying drying times. Dense hardwoods or large, heavy pieces of wood generally need extended drying times due to their density or moisture content. It’s important to consider these factors and adjust your drying time accordingly to ensure optimal bonding strength.

Applying Pressure to Enhance the Bond

Applying pressure to enhance the bond between two pieces of wood is a crucial step in creating a strong and durable connection. By following a few key steps and considerations, you can ensure that the bond will withstand the test of time.

Firstly, it’s important to choose the right clamps for applying pressure. Consider using bar clamps, pipe clamps, or C-clamps that are appropriate for the size and shape of the wood pieces being glued. Having enough clamps to distribute pressure evenly across the joint is essential.

Before applying glue, prepare the surfaces by ensuring they are clean, dry, and free from any dust, debris, or previous finishes. This allows the glue to penetrate into the wood fibers effectively.

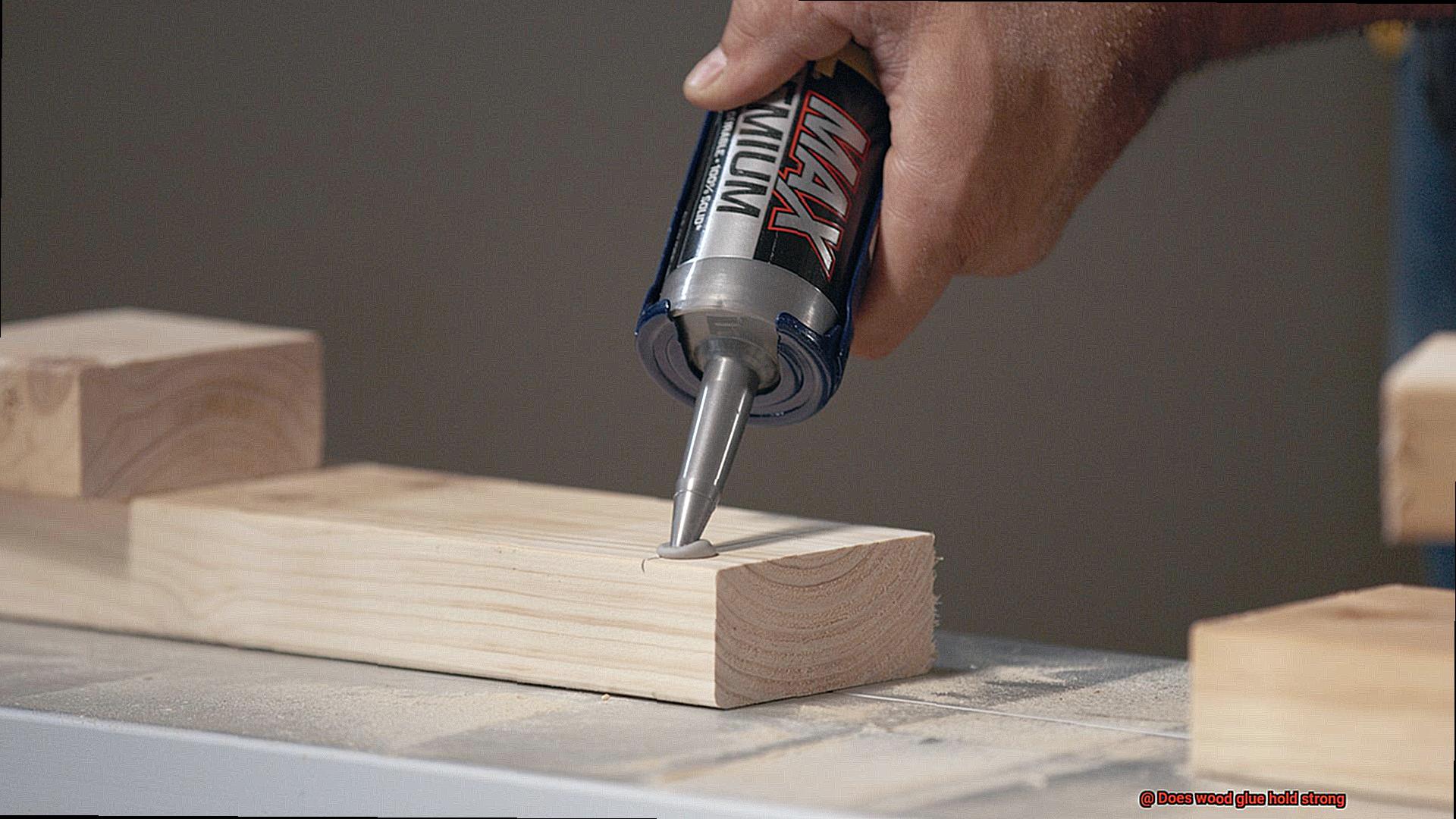

Next, apply an even layer of glue onto one of the wood surfaces using a brush or roller. Be careful not to use too much glue as excess can weaken the bond.

Once the glue is applied, carefully align the two wood pieces and press them firmly together. Take care to ensure they are properly aligned before proceeding with applying pressure.

If using clamps, position them along the joint and tighten gradually. Apply enough pressure to bring the wood pieces together without causing deformation or cracking. If clamps are not available or suitable for your project, consider using weights such as heavy books or sandbags to apply pressure evenly across the joint.

Allow sufficient drying and curing time as recommended by the glue manufacturer. Rushing this step can result in a weak bond.

After the recommended drying and curing time has passed, carefully remove the clamps or weights without disturbing the joint or applying sudden force that could weaken the bond.

Factors Affecting Wood Glue’s Strength

Wood glue, a versatile adhesive commonly used in woodworking projects, relies on several factors to achieve optimal strength. Understanding these factors and implementing proper techniques can ensure a reliable and durable bond between wood pieces.

The type of wood being glued is a significant factor in the strength of the bond. Different woods have varying densities and porosities, which affect how well the glue adheres to the surface. Hardwoods like oak or mahogany have a tighter grain structure and may require a stronger adhesive for a strong bond. Softwoods such as pine or cedar have a more open grain structure and can absorb more glue, resulting in a stronger bond.

Proper surface preparation is crucial for a strong bond. The wood surface must be clean, dry, and free from any contaminants like dirt, dust, or grease that can interfere with adhesion. Roughening the surface with sandpaper increases the contact area between the wood and glue, enhancing overall strength.

Achieving proper glue coverage is essential. Applying an even layer of glue ensures that all areas are adequately covered. Insufficient coverage can result in weak spots where the wood may separate over time, while excessive glue can lead to squeezing out during clamping, weakening the bond.

Applying adequate pressure during clamping promotes strong adhesion. Pressure ensures maximum contact between the wood and glue, allowing for better bonding. Insufficient pressure can result in gaps or voids in the glue line, reducing strength. Following manufacturer recommendations for clamping time and pressure specific to the type of wood glue being used is crucial.

Allowing sufficient curing time is vital for maximum strength. Different glues have varying curing times, so following manufacturer instructions is essential. Curing conditions like temperature and humidity also affect bond strength; extreme levels may interfere with the process and weaken the adhesive bond.

Tips for Using Wood Glue Effectively

Wood glue is a versatile adhesive commonly used in woodworking projects to create strong and durable bonds between pieces of wood. To ensure the wood glue holds strong, there are several tips and techniques that can be followed:

Surface Preparation

Before applying wood glue, it is crucial to properly prepare the surfaces being glued. This involves cleaning the surfaces and removing any dust, dirt, or previous finishes that could hinder the bond. Lightly sanding the surfaces creates a slightly rough texture, improving adhesive strength.

Even Application

Applying an even layer of glue on both surfaces being joined is essential for a strong bond. Using too little glue may result in a weak bond, while using too much can cause excessive squeeze-out and difficulties in clamping. Achieving the right balance ensures proper coverage and bonding.

Choosing the Right Glue

Selecting the appropriate type of wood glue for the project is important for optimal results. Different types of wood glues, such as PVA (polyvinyl acetate), epoxy, and cyanoacrylate (super glue), have varying strengths and weaknesses. PVA glue is commonly used for general woodworking applications and provides a strong bond when used correctly.

Clamping

Applying sufficient pressure during the drying process is crucial for a strong bond. Clamping the glued pieces together ensures maximum contact between the wood surfaces and even distribution of the glue. The use of clamps or other suitable methods is recommended to hold the pieces tightly together until the glue dries completely.

Temperature and Humidity

Environmental conditions play a significant role in the performance of wood glue. It is important to use wood glue within the recommended temperature range and avoid extreme humidity levels. High humidity can slow down drying and weaken the bond, while low humidity can cause rapid drying, compromising strength. Minimizing temperature fluctuations during drying minimizes potential cracking or weakening of the bond.

Conclusion

Wood glue is known for its strong bonding capabilities, making it a reliable choice for various woodworking projects.

Its adhesive properties ensure that the pieces of wood are securely held together, creating a sturdy and durable bond. Whether you’re working on intricate furniture designs or simple DIY crafts, wood glue proves its strength time and time again.

So, if you’re wondering if wood glue holds strong, the answer is a resounding yes.