Today, we delve into the depths of one of its indispensable tools – glue. Our focus?

Titebond 3, the adhesive darling of woodworkers everywhere. Renowned for its unwavering strength and unparalleled versatility, Titebond 3 serves as a trustworthy companion for a myriad of woodworking projects.

Yet, amidst the whispers and wonderings of craftsmen far and wide, one question echoes louder than all others: “Does Titebond 3 dry hard?” Fear not, dear readers, for we hold within our grasp the key to this enigma.

Join us as we unravel the mystical properties of Titebond 3 glue and uncover how it dries to bestow upon you flawless woodworking triumphs.

Does Titebond 3 Dry Hard?

Contents

In the world of woodworking, the choice of glue can make or break a project. Enter Titebond 3, the revered wood glue known for its unwavering bond and remarkable versatility. This comprehensive article will delve into the reasons why Titebond 3 is renowned for its ability to dry hard and strong, making it the preferred adhesive for discerning woodworkers and craftsmen.

The Science behind Titebond 3’s Indomitable Strength:

Titebond 3 stands as a peerless PVA glue that is meticulously engineered for wood bonding. Its unique formulation endows it with an extraordinary initial tack and rapid bond strength. This means that once applied, Titebond 3 swiftly forges an unyielding bond capable of withstanding stress, temperature fluctuations, and moisture.

Curing Process and Drying Time:

Following application, Titebond 3 embarks on a curing process wherein it undergoes a chemical metamorphosis to harden and solidify its bond. While drying times may fluctuate due to variables such as temperature, humidity, and the type of wood involved, Titebond 3 generally takes around 24 hours to fully cure and attain peak strength. Nevertheless, it may feel dry to the touch in a shorter span.

Flexibility for Harmonious Wood Movement:

While Titebond 3 dries hard as granite, it retains a measure of flexibility crucial to accommodate natural wood expansion and contraction in response to temperature and humidity changes. This unique characteristic ensures the longevity of woodworking projects, thwarting cracks and structural failure in the glue joint.

Additional Benefits of Titebond 3:

Apart from its unswerving strength and durability, Titebond 3 offers an array of supplementary advantages. It boasts non-toxicity, rendering it safe for use, while its water-based composition facilitates effortless cleanup with water while still wet. Furthermore, Titebond 3 exhibits exceptional water resistance, making it well-suited for both indoor and outdoor applications.

The Strength of the Bond

When it comes to the strength of the bond, Titebond 3 glue stands out as a true powerhouse in the woodworking world. This remarkable adhesive is specifically engineered to create a bond that can withstand tremendous stress and strain, making it the go-to choice for a wide range of woodworking projects.

Surface preparation is a crucial factor that directly impacts the strength of the bond. Before applying Titebond 3, it is imperative to ensure that the surfaces to be glued are clean and dry. Any trace of dirt, dust, or moisture on these surfaces has the potential to compromise the bond strength. By taking the time to meticulously prepare the surfaces, you can significantly enhance the strength of the bond.

Beyond surface preparation, clamping pressure plays a pivotal role in determining bond strength. Applying adequate pressure during the curing process ensures that the glue spreads evenly and establishes intimate contact with both surfaces. This eliminates any lurking air pockets or gaps between the wood pieces, ultimately resulting in a stronger bond. So remember, don’t be afraid to tighten those clamps and let them work their magic.

Curing time is another critical consideration in maximizing bond strength. The recommended curing time for Titebond 3 is 24 hours, although this duration may vary depending on temperature and humidity conditions. Allowing ample time for the glue to fully cure before subjecting it to stress or strain is absolutely crucial. Rushing this process can lead to a weaker bond, and we certainly don’t want that after all your hard work.

Once fully cured, you can expect Titebond 3 to deliver a bond that is hard and durable, capable of withstanding whatever challenges come its way. To confirm its strength, tap it with a tool or apply gentle pressure – if it remains solid and resolute, you have successfully achieved a robust bond.

The Curing Process

Join us as we embark on a fascinating journey into the world of glue, where we uncover the secrets behind the unrivaled strength and durability of Titebond Brace yourself for an exploration of its transformative curing process.

The Transformative Curing Process:

Prepare to witness the alchemy of bonding as Titebond 3 embarks on a transformative journey. When applied to surfaces, this remarkable glue undergoes a chemical reaction that involves the evaporation of moisture, leading to its hardening and solidification.

The Journey Through Stages:

Watch in awe as Titebond 3 progresses through its various stages during the curing process. Initially, it flows effortlessly with a liquid consistency, making it a joy to work with. Then, as if putting on a show, it gradually transforms into a tacky state, forming an unbreakable bond between surfaces. This tackiness plays a crucial role, holding pieces firmly in place while the glue continues to cure.

Factors Influencing Time:

Patience becomes your ally as you wait for Titebond 3 to work its magic. The length of time required for the full curing process depends on several variables. Temperature, humidity, and even the thickness of the glue layer all play their part in determining how long you must wait for the bond to be fully unleashed.

Witnessing Unwavering Solidity:

After a carefully observed curing period of 24 hours, Titebond 3 reaches its ultimate hardness. It transforms into an unwavering force, akin to a mighty oak tree standing tall against the strongest winds. Tap it with a tool or apply gentle pressure, and you’ll witness its unyielding solidity.

Strength vs. Rigidity Balance:

Titebond 3 may not be the rigidest of adhesives, but that is by design. Its primary focus lies in providing an exceptional bond that withstands stress and strain. While it dries hard and forms a strong bond, it prioritizes flexibility, ensuring that your woodworking projects remain intact even in challenging conditions.

Flexibility of the Glue

Prepare to be mesmerized as we unravel the secrets behind this extraordinary adhesive and its ability to withstand the ever-changing movements and expansion of wood.

Imagine spending hours meticulously crafting a beautiful piece of furniture, pouring your heart and soul into every joint and detail. But what happens when that wood starts to expand and contract with changes in temperature and humidity? That’s where Titebond 3’s flexibility comes into play. Unlike other glues that can become brittle or crack under pressure, Titebond 3 flexes with the natural movements of wood, ensuring that your masterpiece remains intact for years to come.

But Titebond 3’s versatility doesn’t stop there. This remarkable adhesive is not limited to wood alone. Its ability to flex makes it an excellent choice for bonding other materials like metal or plastic. Whether you’re working on a wooden masterpiece or tackling a mixed-media project, Titebond 3 has got you covered.

However, it’s important to note that while Titebond 3 is flexible when dry, it does have its limits. It is not designed for applications requiring extreme flexibility, such as bonding rubber or elastic materials. Nevertheless, for woodworking projects where strength and durability are paramount, Titebond 3 is the perfect companion.

Water Resistance of Titebond 3

Today, we will uncover the secrets behind the exceptional water resistance of Titebond 3, the adhesive that stands tall against the forces of nature. Join us as we explore the science, testing, and tips to maximize its potential.

The Science Behind Titebond 3’s Water Resistance:

Titebond 3 is not your ordinary glue; it is a champion of water resistance. Its unique chemical composition includes specialized resins and additives that repel water, making it ideal for outdoor projects or areas prone to moisture exposure. This extraordinary adhesive is designed to withstand wet conditions and short-term water immersion, providing woodworkers with peace of mind.

Testing and Standards:

Rest assured, Titebond 3 has undergone rigorous testing to ensure its water resistance capabilities meet industry standards. It proudly carries the ANSI/HPVA Type I specification, a testament to its ability to resist the effects of moisture. However, it’s important to note that while Titebond 3 is highly resistant to water, it is not completely waterproof. Prolonged exposure or constant immersion can weaken the bond over time.

Maximizing Water Resistance:

To unleash the full potential of Titebond 3’s water resistance, follow these essential tips:

- Clean and Dry Surfaces: Before applying the glue, ensure your surfaces are free from dirt, oil, or moisture. Any contaminants can compromise the strength of the bond.

- Clamping: During the curing process, use clamps to firmly press the glued pieces together. This extra step helps create a strong bond that can better withstand water exposure.

- Limitations: While Titebond 3 excels in water resistance, remember that it has its limits. For long-term waterproofing needs or materials demanding extreme flexibility, explore specialized adhesives tailored to those specific requirements.

Ideal Uses for Titebond 3

When it comes to finding the perfect glue for your next project, look no further than Titebond This adhesive is a game-changer in the world of woodworking, offering a strong bond and unparalleled versatility. Let’s dive into the ideal uses for Titebond 3 that will take your projects to the next level.

- Furniture Construction: Titebond 3 is your go-to glue for building sturdy tables, cozy chairs, and any other furniture piece you can imagine. Its strength allows it to withstand the weight and stress of everyday use, ensuring your creations stand strong for years to come. Plus, its waterproof properties make it an excellent choice for outdoor furniture that may face rain or moisture.

- Cabinetry: Titebond 3 excels at joining different pieces of wood together, creating secure and durable connections. It’s perfect for kitchen and bathroom cabinets that are exposed to high moisture levels. Say goodbye to sagging or weakening joints – Titebond 3 has got you covered.

- Hardwoods: When working with dense and heavy woods like oak or walnut, Titebond 3 is a true champion. Its strong bond provides the necessary strength to keep those pieces firmly together. The long open time of this glue allows for precise alignment before it sets, making intricate joinery a breeze.

- Carpentry Projects: Building shelves, bookcases, or any wooden structure that needs a reliable bond capable of withstanding weight and pressure? Titebond 3 is your solution. Say goodbye to wobbly joints – Titebond 3 ensures your creations are rock solid.

- Outdoor Projects: Fences, decks, garden structures – Titebond 3 can handle them all. Its waterproof formula ensures your hard work won’t be ruined by rain or moisture. No more worrying about your outdoor projects falling apart.

- Laminating Large Surfaces: Titebond 3 is perfect for laminating large surfaces, whether you’re creating a tabletop or adding layers of wood for added strength. Its strong bond holds up well under pressure, ensuring your laminated projects stay intact.

- Repair and Restoration: Titebond 3 is also perfect for repairing broken items and restoring antique furniture. Its reliable bond can bring new life to old treasures.

Remember, Titebond 3 is specifically designed for wood, so steer clear of using it on plastics, metals, or rubber. Stick to what it does best – bonding wood and wood products.

Comparison to Other Glues

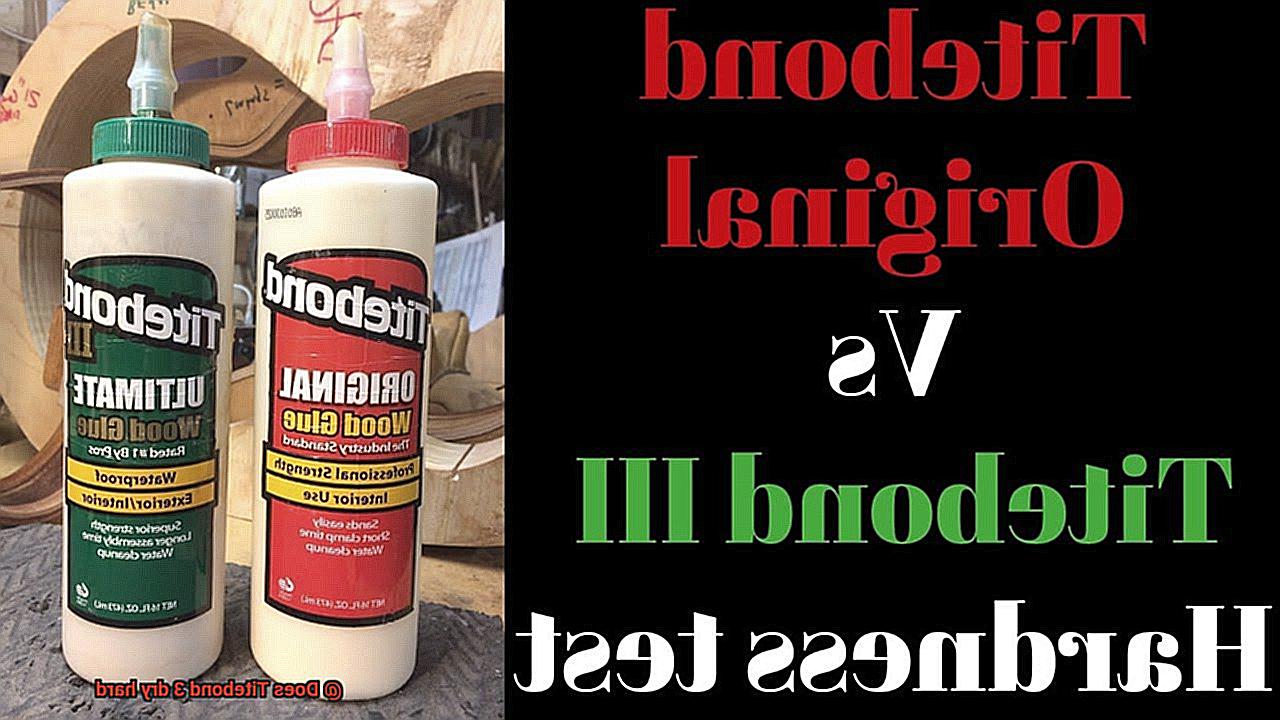

When it comes to choosing the right glue for your woodworking projects, you want a product that stands out from the competition. That’s where Titebond 3 comes in. In this comprehensive comparison, we will delve into the advantages and disadvantages of Titebond 3 compared to other glues on the market.

First and foremost, Titebond 3 boasts a unique ability to dry hard. Unlike some other glues that remain somewhat pliable or flexible after drying, Titebond 3 forms a rigid bond that is resistant to impacts and vibrations. This makes it an ideal choice for applications where a strong and solid bond is required, such as woodworking projects or furniture repairs. With Titebond 3, you can rest assured that your creations will stand the test of time.

Another standout feature of Titebond 3 is its remarkable ability to withstand heat and moisture. While some glues may soften or lose their bond when exposed to high temperatures or excessive moisture, Titebond 3 remains stable and retains its strength. This makes it suitable for both indoor and outdoor use, as it can withstand changes in temperature and humidity without compromising the integrity of the bond. Whether you’re crafting an outdoor furniture piece or tackling a bathroom renovation project, Titebond 3 has you covered.

In addition to its superior strength and durability, Titebond 3 also offers a longer open time compared to other glues. This means you have more time to adjust and align the pieces being glued together, especially when working on complex or large-scale projects that require precise positioning. The extended open time provided by Titebond 3 gives you the flexibility and control needed to achieve flawless results every time.

However, it’s important to keep in mind that Titebond 3 may not adhere well to certain materials like polyethylene or polypropylene plastics. In these cases, it’s best to consult the manufacturer’s recommendations or consider alternative glue options specifically designed for bonding these types of materials.

Tips for Using Titebond 3

Woodworking projects require strong and durable bonds for optimal results. Titebond 3, a popular wood glue known for its strength and water resistance, is a go-to choice for many woodworkers. In this article, we will provide you with expert tips and step-by-step instructions to ensure the best outcome when using Titebond 3.

Step One: Surface Preparation

Before applying Titebond 3, it is crucial to prepare the surfaces to be bonded. Clean the surfaces thoroughly to remove any dust, oil, or debris that could compromise the bond’s strength. A smooth and clean surface ensures proper adhesion and a strong bond.

Step Two: Even Application

Achieving an even and thin application of Titebond 3 is vital for a strong bond. Avoid using excessive amounts of glue as this can lead to longer drying times and potential messiness. Remember, a little goes a long way with Titebond Apply the glue evenly on both surfaces using a brush, roller, or spreader.

Step Three: Firm Pressure

Once the glue is applied, press the surfaces together firmly. Applying firm pressure helps the glue spread evenly and ensures maximum contact between the glue and the wood fibers. This step is crucial for achieving a strong and reliable bond.

Step Four: Clamping for Added Strength

To enhance the bond’s strength, use clamps or suitable tools to hold the pieces together while the glue dries. Clamping helps maintain consistent pressure throughout the curing process. Follow the manufacturer’s instructions regarding clamping time, typically ranging from 30 minutes to one hour.

Step Five: Drying Time

Titebond 3 requires sufficient drying time to achieve its full strength. While it needs at least 30 minutes of pressure to dry, full curing can take up to 24 hours depending on temperature and humidity levels. Be patient and allow ample drying time before subjecting the bonded pieces to stress or load-bearing activities.

Step Six: Excess Glue Removal

It is essential to remove any excess glue that squeezes out from between the wood pieces before it dries. Use a damp cloth or sponge to wipe away the excess glue. Once Titebond 3 dries, removing excess glue becomes difficult and may damage the wood surface. Taking the time to clean up any squeeze-out will result in a clean and professional finish.

Tb_BODVUi3g” >

Conclusion

Titebond 3 is known for its exceptional strength and durability once it has dried.

It sets hard, providing a reliable bond that can withstand the test of time. This adhesive dries to a solid state, ensuring that your projects remain securely held together.

With Titebond 3, you can trust that your hard work will pay off with a sturdy and long-lasting result.