Picture this: You’re cruising down the road, wind in your hair, tunes blaring, and then BAM.

A flat tire throws a wrench into your plans. Talk about a buzzkill.

This nifty little potion swoops in to save the day, patching up those pesky punctures and leaks faster than you can say “roadside assistance.”

Now, here’s the million-dollar question: does this magical elixir need time to dry before you can hit the road again? Well, strap yourself in because we’re about to dive deep into the world of tire sealant and uncover whether it needs a little drying time or if it’s ready for action straight away.

So, grab your popcorn (or maybe just a cup of coffee) and let’s get this show on the road.

Types of Tire Sealants and Their Drying Times

Contents

- 1 Types of Tire Sealants and Their Drying Times

- 2 Factors to Consider When Choosing a Tire Sealant

- 3 Instructions for Proper Usage

- 4 The Benefits of Using Tire Sealant

- 5 The Drawbacks of Using Tire Sealant

- 6 How to Know if Your Tire Has Been Sealed Properly

- 7 Troubleshooting Common Problems with Tire Sealants

- 8 Professional Repairs vs. DIY Solutions

- 9 Conclusion

These nifty products are designed to seal those annoying holes and keep your tires inflated. But before you rush out to buy one, it’s essential to understand the different types of tire sealants and their respective drying times. In this article, we’ll dive into the world of tire sealants and provide you with all the information you need.

Latex-Based Sealants:

The most common type of tire sealant is latex-based. Made from a liquid latex compound, these sealants transform into a flexible rubber-like substance when exposed to air. Latex-based sealants require patience, taking around 24 to 48 hours to fully dry and form a strong seal. So, if you’re planning on using this type of sealant, make sure to give it ample time to dry before hitting the road.

Synthetic-Based Sealants:

Synthetic-based sealants are another popular choice. These sealants are crafted from synthetic polymers that bond tightly with the tire surface, creating a secure seal. Unlike latex-based sealants, synthetic-based ones offer a shorter drying time, ranging from just a few hours to overnight. This makes them a great option if you’re in a hurry and need your tires fixed quickly.

Fiber-Based Sealants:

If you want a quick fix, fiber-based sealants are the way to go. These sealants contain tiny fibers or particles that swiftly plug up punctures and create a temporary patch. Fiber-based sealants work like magic, drying within minutes of application. So, if you find yourself with a flat tire on the side of the road, fiber-based sealants can get you back on track in no time.

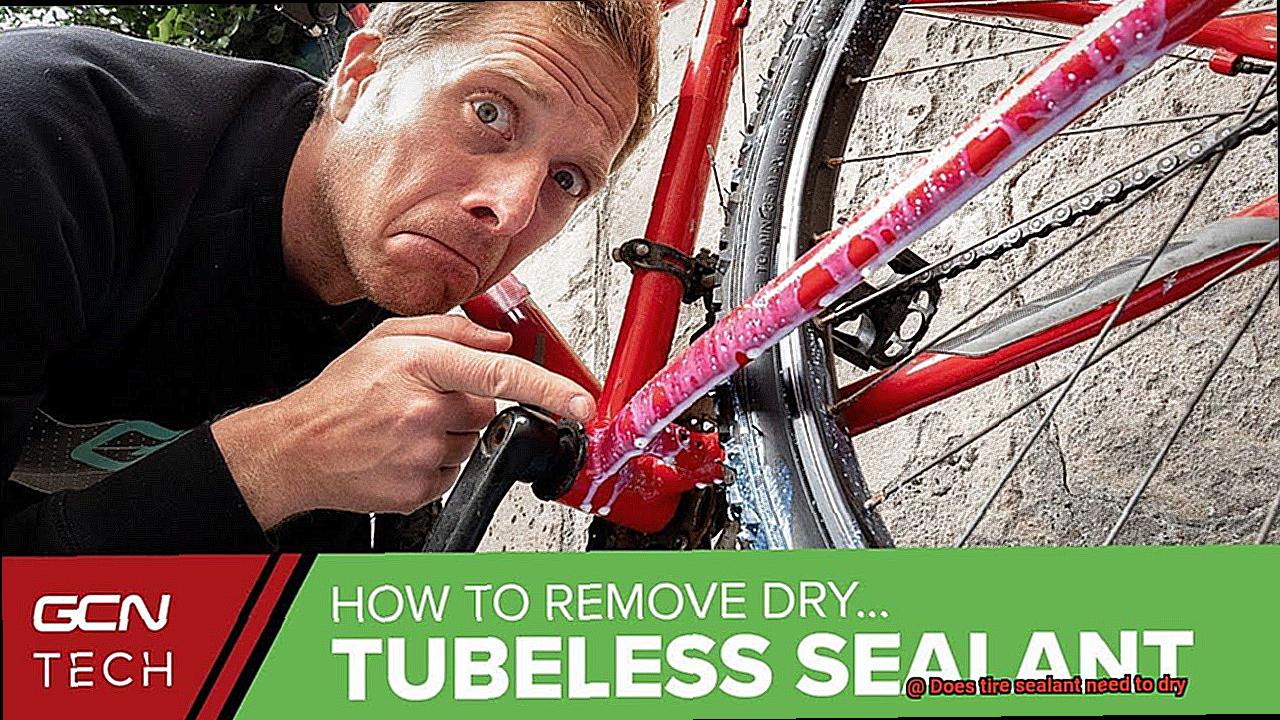

Specialized Sealants:

Some tire sealants are designed for specific types of tires, such as tubeless tires or those with inner tubes. These specialized sealants may have different compositions and drying times based on the specific requirements of the tire they are intended for. It’s crucial to read the manufacturer’s instructions carefully to ensure you choose the right sealant for your tire and follow the recommended drying time.

External Factors:

It’s important to consider external factors that can affect the drying time of tire sealants. Warmer temperatures generally speed up the drying process, while colder temperatures may prolong it. Additionally, humidity levels can also impact drying time. Higher humidity levels can slow down the drying process, so keep that in mind when applying tire sealant.

Conclusion:

In conclusion, tire sealants come in various types, each with its own composition and drying time. Latex-based sealants take 24 to 48 hours to fully dry, synthetic-based sealants dry within a few hours to overnight, and fiber-based sealants dry quickly within minutes. Specialized sealants cater to specific tire types, and external factors like temperature and humidity can also affect drying times. Remember to follow the manufacturer’s instructions for optimal results.

Factors to Consider When Choosing a Tire Sealant

Tire sealants are a lifesaver when it comes to dealing with punctures and leaks. But with so many options available, how do you choose the right one? In this article, we’ll discuss the essential factors to consider when selecting a tire sealant. By considering these factors, you can ensure that you make an informed decision that will keep your tires protected and provide peace of mind.

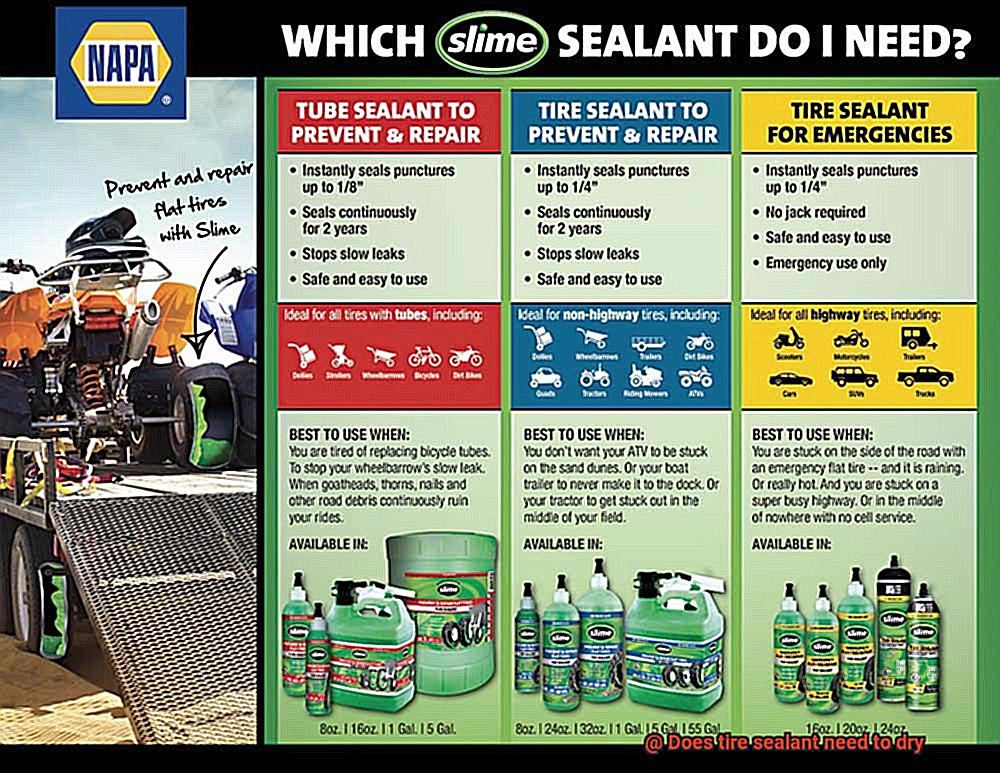

Compatibility with Tire Type:

- Ensure the sealant is compatible with your tire type (tubeless, tube-type, high-performance).

- Using an incompatible sealant can lead to subpar performance and potential tire damage.

Effectiveness:

- Look for a sealant with a proven track record in effectively sealing punctures and preventing leaks.

- Check customer reviews and conduct research to gauge effectiveness.

Sealing Capability:

- Consider the size of punctures the sealant can handle effectively.

- Some products are better suited for small punctures, while others can handle larger holes.

Durability:

- Evaluate the durability of the tire sealant.

- Some may require more frequent reapplications, especially in extreme weather or high-mileage situations.

- Opt for long-lasting sealants to save time and effort in the long run.

Installation Process:

- Consider the ease of installation.

- Some require complex procedures or special equipment, while others can be easily injected into the tire.

- Choose user-friendly sealants if you prefer a DIY approach.

Safety:

- Prioritize non-toxic and non-flammable sealants for safety during installation and use.

- Consider how the sealant may impact tire balance and stability.

Longevity:

- Consider how long the sealant remains effective once applied to your tires.

- Some may dry out or lose effectiveness over time, requiring more frequent reapplications.

- Choose long-lasting sealants to minimize maintenance and keep your tires protected.

Cost:

- Compare prices and evaluate value for money.

- Some sealants may be more expensive upfront but offer better performance and longevity.

- Others may be more budget-friendly but require more frequent reapplications.

Instructions for Proper Usage

Proper usage of tire sealant is vital to ensure its effectiveness and your safety. Let’s dive into the instructions step by step:

- Tire sealant application: Begin by removing the valve core, that tiny fellow at the center of your tire valve. Then, attach the sealant bottle to the valve stem and give it a good squeeze. Remember, each sealant may have specific application guidelines, so follow the manufacturer’s instructions closely.

- Allow for circulation: After applying the sealant, let it work its magic by allowing circulation. You can achieve this by taking your car for a spin or manually rotating the tire for a while. This ensures that the sealant is distributed evenly throughout the tire for maximum effectiveness.

- Drying time: Ah, the burning question – does tire sealant need to dry? Well, it depends on the type you’re using. Some sealants require a specific drying period before hitting the road again, while others don’t need any drying time at all.

- Follow manufacturer instructions: To play it safe, always read and follow the manufacturer’s instructions regarding drying time. They know their product best and want to ensure you get optimal performance and safety. For specific information on drying time, check the product label or contact the manufacturer directly.

- Factors affecting drying time: Keep in mind that factors like temperature and humidity can impact drying time. In general, higher temperatures and lower humidity levels speed up the process, while colder temperatures and higher humidity may prolong it.

- Post-application precautions: Once you’ve applied the sealant, take some post-application precautions. Check for leaks and monitor tire pressure regularly. If any issues arise, seek professional assistance to ensure your safety on the road.

Remember, tire sealant is your superhero sidekick, but it’s not a substitute for proper tire maintenance. So keep those tires inflated and treaded well for a smooth ride ahead.

The Benefits of Using Tire Sealant

Tire sealant is like a superhero for your tires, swooping in to save the day when you encounter a puncture. This remarkable substance quickly seals punctures and prevents air from escaping, allowing you to continue driving without the hassle of changing a tire or calling for roadside assistance. But the benefits of using tire sealant go beyond just sealing punctures.

First and foremost, tire sealant provides peace of mind in remote locations or situations where a spare tire is not readily available. It can seal multiple punctures, even if they occur in quick succession. So, whether you run over a sharp object or encounter a series of punctures, the sealant has your back.

But the benefits don’t stop there. Using tire sealant can actually improve your vehicle’s fuel efficiency. When your tires are properly inflated, they roll more easily and require less energy to move. By preventing air loss due to punctures, tire sealant helps maintain optimal tire pressure, leading to improved fuel efficiency. Save money at the pump while enjoying a smoother ride.

Not only does tire sealant improve fuel efficiency, but it can also extend the lifespan of your tires. Punctures and air loss can cause uneven wear on your tires, leading to premature deterioration. However, by preventing punctures and maintaining proper tire pressure, the sealant helps ensure that your tires wear evenly and last longer. Say goodbye to frequent tire replacements and hello to cost savings.

Speaking of saving money, using tire sealant is a cost-effective solution compared to replacing a damaged tire. The cost of purchasing and using a sealant is significantly lower than buying a new tire or paying for roadside assistance. Plus, having a tire sealant on hand allows you to quickly fix minor punctures yourself instead of waiting for professional help.

Safety is paramount when it comes to tires, and tire sealant can help with that too. A sudden loss of air due to a puncture can lead to loss of control over your vehicle, especially at high speeds. By sealing punctures and maintaining tire pressure, the sealant helps reduce the risk of accidents caused by tire blowouts or sudden deflation. Hit the road with confidence, knowing you have an added layer of protection.

And don’t worry, using tire sealant is a breeze. It is easy to use and requires minimal maintenance. Once injected into the tire, it spreads evenly and coats the inner surface, creating a protective layer. You don’t need to reapply it frequently, as it can last for months, providing continuous protection against punctures.

The Drawbacks of Using Tire Sealant

Tire sealant may seem like the ultimate solution to fixing punctures on the go, but it comes with several drawbacks that drivers need to be aware of. From potential imbalances in tires to messy aftermaths and limited effectiveness, using tire sealant may not be as convenient as it initially seems.

One major drawback of using tire sealant is the potential for an imbalance in your tires. The liquid sealant is distributed unevenly inside the tire, which can result in vibrations and a not-so-smooth ride. Imagine feeling like you’re on a roller coaster while driving down the highway – not exactly the kind of thrill you were hoping for.

The aftermath of using tire sealant can be messy and time-consuming. If the sealant leaks or spills during application, it can get all over your rim, tire sidewalls, and even your precious vehicle’s body. Cleaning up that sticky substance becomes a frustrating task that no one wants to deal with.

Moreover, tire sealant is not a permanent fix. While it may temporarily patch up small punctures, larger or more severe damage may require professional repair or even tire replacement. And here’s the kicker – some tire manufacturers may void your warranty if you’ve used sealant on your tires. So not only are you left with a temporary solution, but you also risk losing out on warranty coverage.

Let’s not forget about the impact on tire pressure monitoring systems (TPMS). The liquid sealant can clog or damage these sensors, resulting in inaccurate readings or worse, system failure. Monitoring tire pressure is crucial for safety reasons, so compromising the accuracy of TPMS can have serious consequences.

Furthermore, tire sealant is not suitable for all types of tires. Those high-performance or racing tires that you love? They may not be compatible with sealants due to their unique construction and materials. Using sealant on these tires could compromise their performance and safety, making it a risk that is simply not worth taking.

Last but not least, tire sealant may not be effective against certain types of punctures or damage. If the puncture is too large or if the sidewall of the tire is damaged, sealant may not be able to provide a sufficient or long-lasting repair. In these cases, seeking professional assistance becomes necessary, adding to the inconvenience and cost.

How to Know if Your Tire Has Been Sealed Properly

Tire sealants are a convenient solution for fixing small punctures without the need for tire replacement. However, ensuring that your tire has been sealed properly is crucial for safety and optimal performance. This article will explore five effective methods to determine if your tire has been sealed correctly.

Look for Leaks:

After applying the sealant, carefully inspect the tire for any signs of air escaping. Listen for hissing sounds and check for bubbles forming on the surface of the tire. These indications suggest that the sealant may not have been applied correctly or that there could be another puncture requiring attention.

Monitor Tire Pressure:

A properly sealed tire should maintain a stable and recommended tire pressure. Regularly check the tire pressure gauge and note any significant pressure drops over a short period. Such drops could indicate ineffective sealing of the puncture by the sealant.

Check for Bulges or Deformities:

Visually inspect the tire for any bulges or deformities. If the sealant was not evenly applied or did not completely fill the puncture, it may cause the tire to bulge or appear misshapen. This can have adverse effects on tire performance and stability.

Look for Excessive Sealant:

Examine the rim and sidewall of the tire for any residual sealant that may have dripped or leaked outside the puncture area. The presence of excessive sealant beyond the puncture area could signal an improper application or a larger issue with the tire itself.

Seek Professional Inspection:

When in doubt, it is always advisable to seek a professional inspection of your tire. Tire technicians are trained to identify potential issues with sealant applications and can provide guidance on whether reapplication is necessary or if further repairs are required.

Troubleshooting Common Problems with Tire Sealants

Tire sealants are a lifesaver when it comes to repairing punctures and preventing air leaks in tires. However, like anything else, they can sometimes present their own set of problems. In this article, we will explore common issues with tire sealants and provide troubleshooting tips to help you get the most out of your sealant.

Problem 1: Sealant does not fully dry or cure.

If you find that the sealant you applied is taking longer than expected to dry or cure, there are a couple of factors that could be at play.

- Excessive sealant application: Applying too much sealant can prolong the drying process. To remedy this, remove any excess sealant and ensure better air circulation to expedite drying.

- Temperature and humidity: Cooler temperatures and high humidity levels can also slow down the drying process. To counteract this, find a warm, well-ventilated area to place your tire and facilitate faster drying.

Problem 2: Using sealants on severely damaged or cracked tires.

It’s crucial to remember that tire sealants are designed for temporary repairs on minor punctures. If your tire is severely damaged or cracked, using sealants is not recommended. In such cases, it’s best to replace the tire rather than relying on sealants.

Problem 3: Residue from previous tire products interfering with sealant drying.

If you’ve previously used other products such as tire shine or protectant on your tires, the residue from these products can hinder the adhesive properties of the sealant and affect its ability to dry. Ensure you clean the tire thoroughly before applying the sealant to avoid any interference.

Professional Repairs vs. DIY Solutions

Dealing with tire problems can be a hassle, but fortunately, there are options available for fixing them. In this article, we will explore the pros and cons of professional repairs and DIY solutions for tire issues. By considering factors such as cost, time, difficulty, and safety, you will be able to determine which approach is best suited to your needs.

Professional Repairs: The Reliable Choice

- Thorough Inspection: Opting for professional repairs ensures that your tire undergoes a meticulous examination to identify the root cause of the problem. This comprehensive inspection allows for the addressing of any underlying issues, resulting in a more reliable and long-lasting solution.

- Advanced Sealant: Professionals utilize high-quality tire sealants specifically designed to withstand extreme temperatures and high pressures. These advanced formulas offer superior durability compared to DIY solutions, providing added peace of mind.

- Drying Time: After applying the sealant, it is crucial to allow sufficient drying time to promote proper adhesion and effectiveness. This process typically takes between 30 minutes to an hour, ensuring optimal results.

DIY Solutions: Convenience with Limitations

- Temporary Fix: DIY solutions using tire sealant kits offer a convenient option for minor punctures or leaks. However, it is essential to recognize that these repairs should only be considered temporary fixes rather than permanent solutions.

- Limited Inspection: DIY repairs do not involve a thorough inspection of the tire to identify underlying issues that may have contributed to the problem. Without addressing these potential causes, recurring problems may arise.

- Drying Time and Durability: DIY sealants may not possess the same level of durability or longevity as those used by professionals. Following the instructions provided with the kit, including allowing sufficient drying time before resuming regular use, is crucial.

jCkPjOdGlkk” >

Conclusion

The conclusion is clear: tire sealant does need to dry.

It’s not a quick fix that magically seals the puncture and allows you to hit the road immediately. No, it requires some patience and time for the sealant to dry properly and form a strong bond with the tire.

So, if you find yourself with a flat tire and decide to use sealant, be prepared to wait for it to dry before getting back on the road.