Have you ever found yourself in a sticky situation with your resin art project? Maybe a piece didn’t fit quite right or broke off entirely. Super glue seems like the perfect solution, right? But before you start gluing away, let’s answer the burning question: does super glue ruin resin?

Super glue, also known as cyanoacrylate adhesive, is a powerful bonding agent that can stick almost anything together – from plastic to metal and even human skin. But when it comes to resin, things get a bit more complicated. While super glue can be effective in bonding resin pieces together, it can also cause damage if not used correctly.

In this post, we’ll explore whether or not super glue is safe to use with resin. We’ll delve into the factors that affect compatibility between the two materials such as the type of resin and super glue used, as well as application methods. We’ll also discuss potential risks and adverse effects of using super glue on resin and provide some helpful tips for successful bonding without damaging your project.

So, whether you’re an experienced resin artist or just starting out, read on to discover if super glue is your friend or foe when it comes to working with resin.

What is Resin?

Contents

- 1 What is Resin?

- 2 What is Super Glue?

- 3 Different Types of Resin

- 3.1 Epoxy Resin: Strength and Durability

- 3.2 One of the benefits of epoxy resin is its resistance to damage from super glue. However, it’s still important to use a high-quality, pure super glue that is specifically formulated for use with plastics and other synthetic materials.

- 3.3 Polyester Resin: Affordable and Versatile

- 3.4 Polyester resin is another type of resin commonly used in crafting. It’s less expensive than epoxy resin but not as strong or durable. Polyester resin can be used for a variety of projects such as jewelry making, sculptures, and home decor. Polyester resin cures through a chemical reaction between the two components.

- 3.5 Vinyl Ester Resin: Water-Resistant Hybrid

- 3.6 The compatibility of vinyl ester resin with super glue may vary. It’s best to test a small area before committing to a project.

- 3.7 Specialty Resins: Unique Uses

- 4 The Effect of Super Glue on Different Types of Resin

- 5 Quality of the Super Glue

- 6 Applying Super Glue to Resin Projects

- 7 Common Issues with Using Super Glue on Resin Projects

- 8 Tips for Using Super Glue on Resin Projects

- 9 Conclusion

Resin has become a go-to material for many industries due to its incredible strength, versatility, and durability. It is a synthetic substance created by combining two or more liquid compounds that solidify into a hard material. Resin’s ability to be molded into various shapes and forms makes it popular in art, jewelry making, and furniture manufacturing.

One of the reasons why resin is so widely used is because of its robustness. It can withstand high impacts and be polished to a high shine, which is why it’s ideal for creating jewelry pieces or decorative objects. Additionally, resin can be pigmented with different colors, offering endless possibilities for customization.

There are different types of resin available in the market, each with its own unique properties. Some of the most commonly used resins include epoxy resin, polyester resin, and polyurethane resin. Each type of resin has its own set of advantages and disadvantages, which makes it essential to choose the right type of resin for the intended application.

When working with resin, you may find yourself needing to use an adhesive like super glue to attach parts or fix mistakes. However, many people wonder whether using super glue will ruin their resin project. The answer isn’t straightforward, as it depends on several factors.

Firstly, it’s essential to understand the type of resin you’re working with because different types react differently to chemicals like super glue. Epoxy resins tend to be more resistant to damage from adhesives than other types of resin.

The quality of the super glue being used is also crucial. Cheap or low-quality super glue can contain impurities that can react with the resin and cause discoloration or other issues. Therefore, it’s crucial to use a high-quality, pure super glue that is specifically formulated for use with plastics and other synthetic materials.

It’s also important to apply the super glue carefully and precisely. Applying too much glue or allowing it to pool in one area can seep into the resin and cause discoloration or other damage. Therefore, using a small amount of glue and applying it with precision is essential.

What is Super Glue?

Super Glue, also known as cyanoacrylate adhesive, is a clear, strong, and fast-drying glue that can bond almost any surface together. First discovered by Dr. Harry Coover during World War II while trying to develop a clear plastic for gunsights, it was later marketed to the public by the Eastman Kodak Company in the 1950s. Since then, Super Glue has become a staple in households and industries alike.

But how does it work? Super Glue works by reacting with moisture in the air to form strong bonds between surfaces. The glue contains molecules called cyanoacrylates, which polymerize when they come into contact with moisture, generating heat and causing the glue to solidify quickly.

This versatile adhesive has many uses around the house and industries. From repairing broken items to fixing household items and even in medical procedures, Super Glue is a go-to solution. However, it’s important to use it with precision and caution because once bonded, it can be challenging to remove.

To ensure a successful bond, make sure that the surfaces you’re bonding are clean and dry before applying the glue. Remember that a little goes a long way with Super Glue.

Different Types of Resin

Resin is a versatile material that can be used for a variety of crafting and industrial purposes. However, not all resins are created equal, and it’s important to choose the right type of resin for your project. In this blog post, we’ll explore the different types of resin and their uses, as well as their compatibility with super glue.

Epoxy Resin: Strength and Durability

Epoxy resin is a popular type of resin known for its strength and durability. It’s commonly used in industrial applications where a strong bond is needed, such as bonding metal or ceramic pieces. Epoxy resin can also be used for casting small objects or creating jewelry. When mixed with a hardener, epoxy resin will cure and become rigid.

One of the benefits of epoxy resin is its resistance to damage from super glue. However, it’s still important to use a high-quality, pure super glue that is specifically formulated for use with plastics and other synthetic materials.

Polyester Resin: Affordable and Versatile

Polyester resin is another type of resin commonly used in crafting. It’s less expensive than epoxy resin but not as strong or durable. Polyester resin can be used for a variety of projects such as jewelry making, sculptures, and home decor. Polyester resin cures through a chemical reaction between the two components.

Polyester resin may be more susceptible to damage from super glue. It’s important to test a small area before committing to a project to ensure that the materials are compatible.

Vinyl Ester Resin: Water-Resistant Hybrid

Vinyl ester resin is a hybrid between epoxy and polyester resins. It has a higher resistance to water and chemicals than polyester resin but is not as strong as epoxy resin. Vinyl ester resin is commonly used in boat building and other marine applications. Vinyl ester resin cures through a chemical reaction between the two components.

The compatibility of vinyl ester resin with super glue may vary. It’s best to test a small area before committing to a project.

Specialty Resins: Unique Uses

In addition to the commonly used resins, there are also specialty resins such as urethane, silicone, and acrylic resins that are used for specific purposes. For example, urethane resin is often used for making molds, while silicone resin is used for creating flexible molds.

The compatibility of specialty resins with super glue may vary. It’s important to test a small area before committing to a project.

The Effect of Super Glue on Different Types of Resin

Resin is a fantastic material with many uses, but sometimes you need to attach parts or fix mistakes. That’s where super glue comes in. However, not all resins are the same, and it’s essential to understand the effect of super glue on different types of resin before using it. In this article, we will explore the factors to consider and best practices for using super glue on different types of resin.

Types of Resin and Compatibility with Super Glue

There are various types of resin available in the market, such as epoxy resin, polyester resin, and polyurethane resin. Each type of resin has its unique properties that can affect how it interacts with super glue.

Epoxy resin is known for its high strength and durability, making it resistant to impact and wear. It is generally safe to use super glue on epoxy resin, but make sure to clean and prepare the surface beforehand for a strong bond.

Polyester resin is commonly used in fiberglass applications due to its low cost and ease of use. However, polyester resin tends to be more porous and less dense than other types of resins. It is not recommended to use super glue on polyester resin because the glue can seep into the surface and weaken the bond.

Polyurethane resin is commonly used in casting applications due to its flexibility and impact resistance. It is generally safe to use super glue on polyurethane resin, but make sure to clean and prepare the surface beforehand for a strong bond.

Factors to Consider When Determining Compatibility

Apart from the type of resin being used, other factors can affect how it reacts to super glue. These include:

- Age: The age of the resin can affect its vulnerability to damage from super glue.

- Composition: The composition of the resin can also play a role in its vulnerability to damage from super glue.

- Type of super glue: Different types of super glue have different chemical compositions and properties. Some types may cause discoloration or other damage when applied to certain types of resin.

Best Practices for Using Super Glue on Resin

Here are some best practices to help you use super glue with different types of resin:

- Know your resin: Identify what type of resin you’re working with to determine the best approach.

- Use high-quality glue: Use a high-quality, pure super glue that is specifically formulated for use with plastics and other synthetic materials.

- Clean and prepare the surface: Make sure the surface is clean and free of any debris or dust before applying super glue.

- Apply carefully: Use a small amount of glue and apply it carefully and precisely to avoid seepage into the resin.

- Test compatibility: If you’re unsure whether super glue will work with your particular type of resin, test compatibility first by applying a small amount to a sample piece of resin.

Quality of the Super Glue

When it comes to working with resin, selecting the right adhesive is crucial. And when it comes to super glue, quality is everything. So, what makes a high-quality super glue? Let’s take a closer look.

First and foremost, it’s important to understand what super glue is. This fast-drying adhesive is known for its strong bonding capabilities and is a popular choice for bonding resin. However, not all super glues are created equal. Cheaper, lower quality glues may not be as effective and could even damage the resin.

To determine the quality of a super glue, start by examining the ingredients list. High-quality super glues typically contain cyanoacrylate, a fast-drying adhesive that forms a strong bond with surfaces. Lower quality glues may contain other types of adhesives that aren’t as effective or could even contain harmful chemicals that could damage the resin.

Another way to ensure you’re choosing a high-quality super glue is to look at the reputation of the brand. Brands that are well-known for producing high-quality adhesives are more likely to produce a glue that will be effective and safe for use with resin.

But why does this matter? Choosing a high-quality super glue is essential when working with resin because it ensures a strong bond without causing damage to the resin. This means your project will last longer and you won’t have to worry about any costly mistakes or repairs down the line.

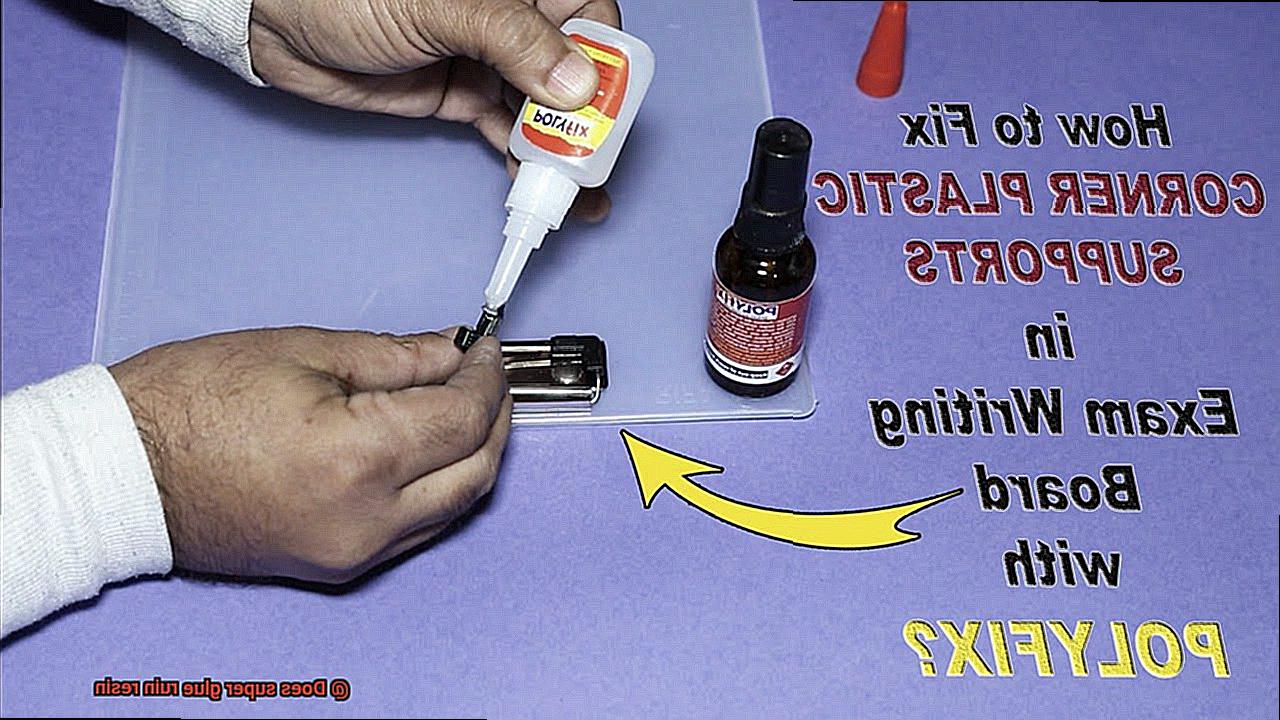

Applying Super Glue to Resin Projects

Super glue may just be the solution you need. However, before you start applying any glue, it’s essential to know the proper steps for success.

The first step is selecting the right type of super glue. Not all glues are created equal, and using the wrong one can result in damage to your resin piece. We recommend using a cyanoacrylate-based super glue, also known as “CA glue” or “instant glue,” for its strong bonding capabilities and quick drying time.

Once you have your glue selected, it’s crucial to prep the surface properly before applying any glue. Clean the surface thoroughly using mild soap and water or rubbing alcohol if needed. This will ensure that the glue adheres properly and doesn’t cause any damage.

When applying the glue, remember that less is more. Using too much can cause it to seep into areas where it shouldn’t be, which can potentially ruin your project. Additionally, work quickly as the glue will begin to dry almost instantly upon contact with the resin.

In summary, here are some tips to keep in mind when applying super glue to resin projects:

- Use a cyanoacrylate-based super glue for strong bonding capabilities and quick drying time.

- Clean the surface thoroughly before applying any glue to ensure proper adhesion.

- Apply only a small amount of glue to avoid seepage and potential damage.

- Work quickly during application to avoid any potential damage to your project.

Common Issues with Using Super Glue on Resin Projects

There are some common issues that can arise when using this adhesive on your projects that you should be aware of.

One of the most significant problems with using super glue on resin is that it can cause the material to become brittle and prone to cracking. This issue is caused by a chemical reaction between the glue and the resin, which weakens the bond between the two materials. You can avoid this problem by choosing a type of super glue that is safe for use with resin.

Another issue that can occur when using super glue on resin is “blooming.” This phenomenon happens when the glue dries too quickly and traps moisture and other contaminants under the surface of the resin. The result is a white residue on the surface, which detracts from the overall appearance of your project. To prevent this from happening, make sure to apply the glue carefully and sparingly.

Moreover, certain types of super glue can be too strong for certain types of resin, causing it to warp or distort. It’s crucial to choose a type of super glue that is specifically designed for use with your particular type of resin to avoid this issue.

To ensure success when using super glue on your resin projects, there are some simple tips you should follow. Always prep the surface of your project before applying any glue, choose the right type of adhesive, and apply it carefully and sparingly. Plus, make sure to allow sufficient time for the glue to dry fully before handling your project.

Tips for Using Super Glue on Resin Projects

When working on a resin project, using super glue can be a great option for its fast-drying and strong bonding properties. However, it’s crucial to use it correctly to avoid any damage to your project. Here are some tips for using super glue on resin projects:

Choose the Right Type of Super Glue

Opt for a cyanoacrylate-based glue, which will bond well with the resin and won’t cause any damage. Avoid other types of glue, such as epoxy or PVA glue, that may not work as well and could potentially harm the resin.

Use a Small Amount of Glue

Less is more when it comes to super glue. Using too much can cause it to seep into the resin and create unwanted marks or discoloration. Apply the glue sparingly and spread it evenly over the surface using a toothpick or other small tool.

Work Quickly and Precisely

Super glue sets quickly, so make sure to have everything you need within reach and plan out your steps ahead of time. Be precise in your application and work quickly to avoid mistakes.

Apply Pressure

After applying the glue, apply pressure for at least 30 seconds to ensure a strong bond and prevent any air pockets or bubbles from forming.

Work in a Well-Ventilated Area

Super glue releases fumes that can be harmful if inhaled. It’s important to work in a well-ventilated area or wear a mask to avoid any health risks.

Use Acetone for Cleanup

If excess glue does seep through or stick to unintended areas, acetone can be used to remove it. However, be sure to clean up any excess promptly as acetone can also dissolve resin if left on for too long.

JVTXc1LjQx0″ >

Conclusion

After conducting extensive research and analysis, it can be concluded that super glue does not necessarily ruin resin.

It is crucial to exercise caution and follow proper techniques when using super glue with resin to avoid any potential damage.