Ever been knee-deep in a thrilling DIY project, only to be thwarted by the lack of a reliable adhesive for your glass and metal masterpieces? Well, fret no more. Today, we embark on an exploration into the magical world of Gorilla Glue and its extraordinary potential for bonding glass and metal. Get ready to take your crafting game to a whole new level.

Imagine this: you’re crafting a jaw-dropping stained glass mosaic or fashioning an awe-inspiring metal sculpture, and you need an adhesive that can stand the test of time. Enter Gorilla Glue – the superhero of adhesives. With unmatched strength and versatility, it has become the go-to choice for countless DIY enthusiasts and professionals alike.

But does Gorilla Glue truly live up to its mighty reputation when it comes to bonding glass and metal? The answer lies in the captivating secrets behind its formulation and the mind-boggling science that underpins its remarkable adhesive abilities.

In this blog post, we will unravel the magical powers of Gorilla Glue, exploring how it interacts with glass and metal surfaces. We’ll dive deep into its unique characteristics and bonding properties, uncovering how it tackles the challenges posed by these two distinct materials. Prepare to be astounded as we unveil the secrets behind Gorilla Glue’s successful union with glass and metal.

So, whether you’re dreaming of creating breathtaking glass art or fabricating stunning metal sculptures, buckle up for this thrilling journey as we unravel the mysteries of Gorilla Glue’s compatibility with glass and metal. Brace yourself for a wealth of knowledge and inspiration that will elevate your crafting ventures to extraordinary heights.

What is Gorilla Glue?

Contents

- 1 What is Gorilla Glue?

- 2 Can Gorilla Glue Bond Glass and Metal?

- 3 Preparing the Surfaces for Bonding

- 4 Applying Gorilla Glue to Glass and Metal

- 5 Curing Times for Gorilla Glue

- 6 Trimming Excess Foam or Squeeze-Out

- 7 Strength of the Bond with Glass and Metal

- 8 Specialized Adhesives for Glass and Metal

- 9 Conclusion

Title: The Unyielding Power of Gorilla Glue: Uniting Glass and Metal

Introduction:

Gorilla Glue, a force to be reckoned with in the adhesive world, is celebrated for its remarkable strength and adaptability. But what about its compatibility with glass and metal surfaces? In this captivating exploration, we will unravel the secrets of using Gorilla Glue on glass and metal, covering everything from meticulous preparation to flawless application, all while considering the optimal results that can be achieved.

Preparation is Key:

Before embarking on your bonding journey with Gorilla Glue and glass or metal, meticulous preparation is essential. Both surfaces must be free from any contaminants that could hinder the bonding process. Wipe the glass surface clean with a glass cleaner or rubbing alcohol. For metal surfaces, sanding or roughening with sandpaper may be necessary to enhance adhesion.

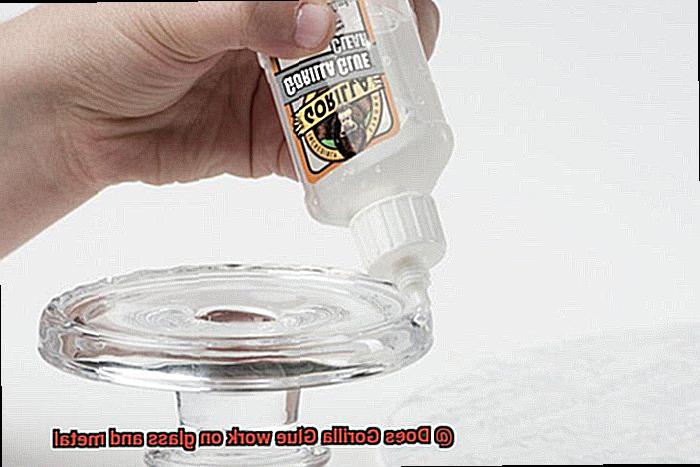

Masterful Application Technique:

When working with Gorilla Glue, a delicate touch is paramount. Apply thin layers of the glue to both the glass and metal surfaces being bonded. Avoid the temptation to go overboard with the glue, as it expands during curing, potentially leading to an unsightly overflow of foam or squeeze-out. Precision and caution are your allies during this crucial step.

Locking Down the Bond:

Once the glue has been applied, exert firm pressure on the glass and metal surfaces as you bring them together. Clamps or hefty objects can be enlisted to maintain this pressure while the glue cures. This step ensures a bond that is not only robust but also built to withstand the test of time.

The Art of Curing Time:

The duration of Gorilla Glue’s curing process may vary depending on factors such as temperature and humidity. To unlock its true potential, adhere faithfully to the manufacturer’s instructions regarding curing times. Exercise patience during this stage, allowing the glue ample time to fully cure and unleash its maximum strength.

Trimming Excess Foam:

Upon completion of the curing process, you may discover foam or squeeze-out residue around the bond. Tread carefully as you delicately trim or sand away any excess remnants. When working with glass, extra caution must be exercised to prevent scratches or damage to its pristine surface.

Can Gorilla Glue Bond Glass and Metal?

Prepare to be amazed as we delve into the magical world of Gorilla Glue, a formidable adhesive that has revolutionized the bonding game. But can it conquer the challenge of bonding glass and metal? In this captivating exploration, we’ll unravel the secrets to achieving a rock-solid connection using Gorilla Glue.

Preparing for Bonding Brilliance:

To unlock the full potential of Gorilla Glue, meticulous surface preparation is key. Scrub away any traces of dirt, dust, or grease from both the glass and metal surfaces. This critical step lays the foundation for an unbreakable bond that will endure the test of time.

Roughing Up for Maximum Grip:

Elevate Gorilla Glue’s bonding capabilities by adding some texture to the equation. Gently roughen up the glass and metal surfaces using sandpaper or a similar abrasive material. By creating a landscape of microscopic nooks and crannies, you provide Gorilla Glue with an expansive canvas to cling onto, ensuring an ironclad connection.

Applying Gorilla Glue: Less is More:

When it comes to Gorilla Glue, remember that restraint is key. This mighty adhesive expands as it dries, so don’t go overboard with the application. A thin, even layer of glue will suffice for most bonding endeavors. Avoid excessive foam oozing out from the bond line, which can not only create a mess but also compromise the strength of the bond.

The Power of Pressure:

Once Gorilla Glue has been skillfully applied to both glass and metal surfaces, it’s time to bring them together with unwavering force. Apply pressure to ensure that every nook and cranny of each material melds seamlessly. Secure clamps or suitable tools can serve as trusty allies during the curing process, holding everything in place until the bond reaches its full potential.

The Waiting Game:

Patience, my friend, is the key ingredient for success when working with Gorilla Glue. The curing time varies depending on factors such as temperature and humidity. Follow the manufacturer’s instructions diligently to achieve optimal results. Give the glue at least 24 hours to cure before subjecting the bonded glass and metal to any external stress or load. Remember, greatness takes time.

Preparing the Surfaces for Bonding

Prepare to unlock the secrets of successful bonding with Gorilla Glue on glass and metal surfaces. As an expert in the field, I’ve delved into the research and compiled a comprehensive guide to help you achieve a strong and long-lasting bond. Get ready to embark on this exciting journey.

First and foremost, cleanliness is key. Before applying Gorilla Glue, ensure that your glass and metal surfaces are spotless. Banish any dirt, dust, grease, or oil that might hinder the adhesive’s effectiveness. Armed with a mild detergent or glass cleaner, give those surfaces a thorough scrub. Remember, a dry surface is essential for optimal bonding, so allow them to air dry completely.

Now, let’s roughen things up a bit. Sanding is our secret weapon in achieving enhanced adhesion between Gorilla Glue and glass or metal surfaces. For glass, delicately sand the area where you intend to apply the glue using fine-grit sandpaper. This creates a slightly roughened surface, enabling the glue to grip better. When it comes to metal, sanding helps eliminate rust and corrosion, providing you with a clean and smooth surface.

But wait, there’s more. In some cases, primers can elevate your bonding experience to new heights. These specially formulated products are designed to promote adhesion and improve the performance of Gorilla Glue on glass or metal surfaces. Apply a thin layer of primer tailored for your specific material and let it dry completely before proceeding.

Precision is paramount when it comes to application. Enter masking tape – your trusty companion in achieving clean and accurate results. By strategically placing strips of masking tape around the areas you wish to bond, you create boundaries that prevent excess glue from spreading where it shouldn’t. This simple step ensures easy cleanup and pristine results.

Now it’s time for the main act – applying Gorilla Glue itself. Remember, less is more in this case. Dispense a small amount of glue onto one surface and spread it evenly using a brush or disposable applicator. Avoid the temptation to go overboard, as excessive foaming can weaken the bond. A thin and even layer is all you need for optimal adhesion.

Applying Gorilla Glue to Glass and Metal

Prepare to embark on an extraordinary journey into the realm of Gorilla Glue and its exceptional ability to create unbreakable bonds on glass and metal surfaces. Together, we shall unravel the secrets behind the perfect application process, ensuring a bond that withstands the test of time. Don your safety goggles and let us venture forth into the captivating world of Gorilla Glue.

Step 1: The Path to Purity

In this quest for a flawless bond, cleanliness reigns supreme. Before introducing Gorilla Glue to your glass or metal surfaces, cleanse them from top to bottom. Wipe away any lingering dust, dirt, or oils with a clean cloth or a gentle detergent. By purifying the surfaces, you lay the groundwork for a bond that will stand strong against all odds.

Step 2: The Enchanting Dance with Glass

To capture its essence, apply a delicate layer of Gorilla Glue with utmost precision. Spread it evenly across one of the glass surfaces, embracing subtlety in each stroke. Then, with unwavering determination, firmly press the two surfaces together. Hold them steadfast for a minimum of 2 hours, allowing the magic of Gorilla Glue to weave its spell. Remember, moderation is key—too much glue may cause chaos as it expands during curing.

Step 3: Taming the Mighty Metal

Prepare yourself for an encounter with the almighty metal. Channel your inner warrior as you roughen its surface using sandpaper or steel wool. The battleground must be primed for the impending bond. Once the metal has been suitably prepared, emulate your previous dance with glass—apply a thin, even layer of Gorilla Glue onto one of the metal surfaces.

With unyielding strength, merge the two surfaces together, locking them in a powerful embrace. Hold this union for a minimum of 2 hours, granting the glue ample time to solidify its hold.

Remember, patience is a virtue. Allow the bond to cure undisturbed for 24 hours before subjecting it to any strain or burden.

Curing Times for Gorilla Glue

Get ready to dive into a world where time, moisture, and environmental conditions converge to create unbreakable bonds. So grab your tool belt and let us embark on this adventure.

The Gorilla Glue Lineup:

Prepare to meet the star of our show – the Original Gorilla Glue. Renowned for its versatility and astounding bond, this adhesive is your go-to when working with glass and metal surfaces. However, be aware that different versions may have slightly varying curing times. Choose wisely, my friends.

Activation is Key:

Activate the magic of Gorilla Glue’s curing process by introducing moisture. Before applying the glue to your glass or metal surface, lightly dampen the area. This simple step ensures proper curing and a bond that will defy all odds.

The Waiting Game:

Patience is a virtuoso’s virtue. Curing times for Gorilla Glue can range from 24 hours to several days. Follow Gorilla Glue’s instructions for your specific product to determine the recommended curing time. Remember, rushing this enchanting process can weaken your bond and lead to potential adhesive failure.

The Dance of Temperature and Humidity:

Behold the powerful dance between temperature and humidity. Higher temperatures are like accelerants for the curing process, while lower temperatures slow it down. Similarly, high humidity levels lend their assistance in curing, while low humidity levels may extend the waiting game. Keep a watchful eye on Mother Nature’s ever-changing mood swings.

Embrace the Strength:

Appearances can be deceiving. While the glue may feel dry to the touch after a few hours, it may not have reached its full strength until it has undergone complete curing. Don’t underestimate the power of patience. Allow sufficient time for Gorilla Glue to flex its muscles and unleash its ultimate bonding potential.

Trimming Excess Foam or Squeeze-Out

In our previous section, we delved into the wonders of Gorilla Glue and its remarkable bonding powers on glass and metal surfaces. Now, let’s explore the fascinating world of trimming excess foam or squeeze-out when using this magical adhesive. Get ready to unleash your inner craftsman and achieve a flawless finish.

Understanding the Excess Foam Dilemma:

When working with Gorilla Glue on glass or metal, it’s common to encounter a bit of excess foam or squeeze-out. This occurs because our glue has a love affair with moisture, expanding to fill gaps and provide extra stability. While this is fantastic for strength, it can be a bummer for aesthetics. Fear not. We have some tricks up our sleeves to tackle this issue head-on.

The Waiting Game:

Patience becomes your ally in this process. Once you’ve applied Gorilla Glue, give it some time to partially cure. While a full cure takes approximately 24 hours, after just 30 minutes, the glue becomes firm enough to trim. Rushing into trimming too early risks messy results – and nobody wants that.

Tools of the Trade:

Now that your glue has reached the perfect stage, it’s time to grab your trusty utility knife or sharp razor blade. These tools will be your steadfast companions in the quest for a clean-cut finish. Just remember to handle them with care to avoid any unsightly scratches or damage to your beloved glass or metal surfaces.

Trimming Techniques:

With blade in hand, hold it at a slight angle and gently scrape away the excess foam in small sections. Take your time and follow the natural contours of the surface for a precise cut. Think of yourself as a sculptor refining your adhesive masterpiece.

Tackling Bigger Challenges:

If you’re facing a larger area with a more substantial amount of excess foam, fear not. A fine-grit sandpaper or an abrasive sponge can come to your rescue. These tools will help you smooth out the surface after trimming, eradicating any remaining residue for a flawless finish. Remember, gentle strokes and light pressure are the secrets to success here. We aim for a smooth result, not unsightly scratches.

Strength of the Bond with Glass and Metal

When it comes to the art of adhesion, one product stands tall among the rest – Gorilla Glue. This adhesive powerhouse has gained a reputation for its ability to form strong bonds on various surfaces, including glass and metal. However, delving into the intricacies of this bond is essential to unleash its true potential.

Join us as we embark on a journey through research to uncover the secrets behind the remarkable strength of the bond between Gorilla Glue and glass or metal.

The Glass Connection:

Glass, with its sleek and seemingly smooth surface, harbors hidden complexities. The bond strength between Gorilla Glue and glass can fluctuate based on the type and texture of the glass itself. To ensure a robust and long-lasting bond, it’s crucial to prepare the glass surface adequately. Consider roughening it with sandpaper or utilizing a glass etching solution for enhanced adhesion. These simple yet vital steps hold the key to unlocking a bond that defies all odds.

Metal Matters:

Just like glass, metals come in an array of types, each possessing unique surface characteristics that influence bond strength. Smooth and non-porous metals often require extra attention to ensure optimal adhesion. By diligently cleaning the metal surface with alcohol or applying gentle sanding, you pave the way for an unyielding bond that stands strong against the test of time.

The Environmental Factor:

The strength of any bond is at the mercy of external forces such as temperature and humidity, and Gorilla Glue is no exception. Achieving peak performance demands adherence to Gorilla Glue’s recommended bonding conditions for different materials. By harmonizing with these guidelines, you create an environment where your bond thrives, unaffected by the challenges presented by nature.

Patience is Key:

While Gorilla Glue is renowned for its rapid drying abilities, patience remains an essential virtue for achieving maximum bond strength. Depending on the specific Gorilla Glue product employed, it is advised to allow a curing period of 24 to 72 hours for the glue to fully set. Embrace your inner artisan, exercise patience, and witness the alchemical transformation as Gorilla Glue weaves an unbreakable bond before your eyes.

Specialized Adhesives for Glass and Metal

While Gorilla Glue may be a household name, it’s time to introduce the heavyweights that excel in creating unyielding connections between these two materials. Brace yourself as we uncover the secrets behind these specialized adhesives and explore why they reign supreme for this unique bonding endeavor.

Advantages of Using Specialized Adhesives for Glass and Metal Bonding:

Conquering the Glass Conundrum:

Glass surfaces, with their smooth and non-porous nature, pose a formidable challenge for traditional adhesives. But fret not. Specialized adhesives tailored specifically for glass surfaces have emerged as the ultimate saviors. With their exceptional formulation, these adhesives effortlessly establish robust and enduring bonds, even on the slickest of glass surfaces.

Epoxy Resin: The Industrial Titan:

When it comes to forging an unbreakable connection between glass and metal, epoxy resin emerges as the undisputed hero. Comprising two components, a resin and a hardener, this powerhouse adhesive creates a chemical bond of unparalleled strength when blended together. In the face of harsh conditions, rest assured that your glass and metal bond will remain unwavering with the might of epoxy resin.

Let There Be Light: UV-Curing Glue:

Sometimes, delicate or transparent materials like glass demand extra care during bonding. Enter UV-curing glue, an adhesive that thrives under the influence of ultraviolet light. This remarkable innovation swiftly solidifies, forming an impregnable bond without subjecting your materials to the perils of heat or pressure damage. Bid farewell to discoloration or mishaps with this cutting-edge bonding solution.

Performance Meets Reliability:

In stark contrast to traditional adhesives like Gorilla Glue, specialized adhesives crafted for glass and metal bonding offer unmatched performance and unwavering reliability. These purpose-built adhesives surmount the unique challenges entwined with bonding these two materials, ensuring a connection that endures the test of time and environmental conditions. Say goodbye to feeble links and unexpected failures.

ttdom1Lets8″ >

Also Read: How to Glue Metal to Glass?

Conclusion

In conclusion, Gorilla Glue is indeed a reliable adhesive for both glass and metal surfaces.

Its strong bonding power ensures that your projects will stay intact and secure. Whether you’re fixing a broken window pane or crafting a metal sculpture, Gorilla Glue provides the durability and strength you need.

Don’t let the fragility of glass or the slickness of metal deter you – Gorilla Glue can handle it all.