When it comes to crafting a killer custom knife, the handle is just as crucial as the blade itself. And let me tell you, there’s this material called epoxy resin that’s been causing quite a stir in recent years. It’s tough, versatile, and offers endless creative possibilities. But does it really make a good knife handle? Buckle up as we dive into the nitty-gritty of strength, customization, and aesthetics to help you decide if epoxy resin is your knight in shining armor.

Pros:

Let me break it down for you – epoxy resin is one tough cookie. It can handle heavy-duty tasks like a champ, thanks to its impressive strength and stability. Rain or shine, this stuff won’t let you down. It laughs in the face of moisture, chemicals, and extreme temperatures, making sure your grip stays rock-solid no matter what Mother Nature throws at you. Oh, and did I mention that epoxy resin lets you unleash your inner Picasso? You can mix it with pigments, glitter, or even bits of wood or stone to create jaw-dropping designs that scream “look at me.”

Cons:

Here’s the deal – while epoxy resin may be strong as an ox most of the time, it can be a bit brittle compared to other handle materials like wood or micarta. So if you’re planning on going all Hulk-mode and smashing things left and right with your knife handle (please don’t), there’s a chance it could chip or crack under pressure if not reinforced properly. Plus, let’s not forget about time-consuming curing process involved here. You’ll need patience and precision when working with epoxy resin because getting that perfect finish requires attention to detail and temperature control skills.

Aesthetics and Feel:

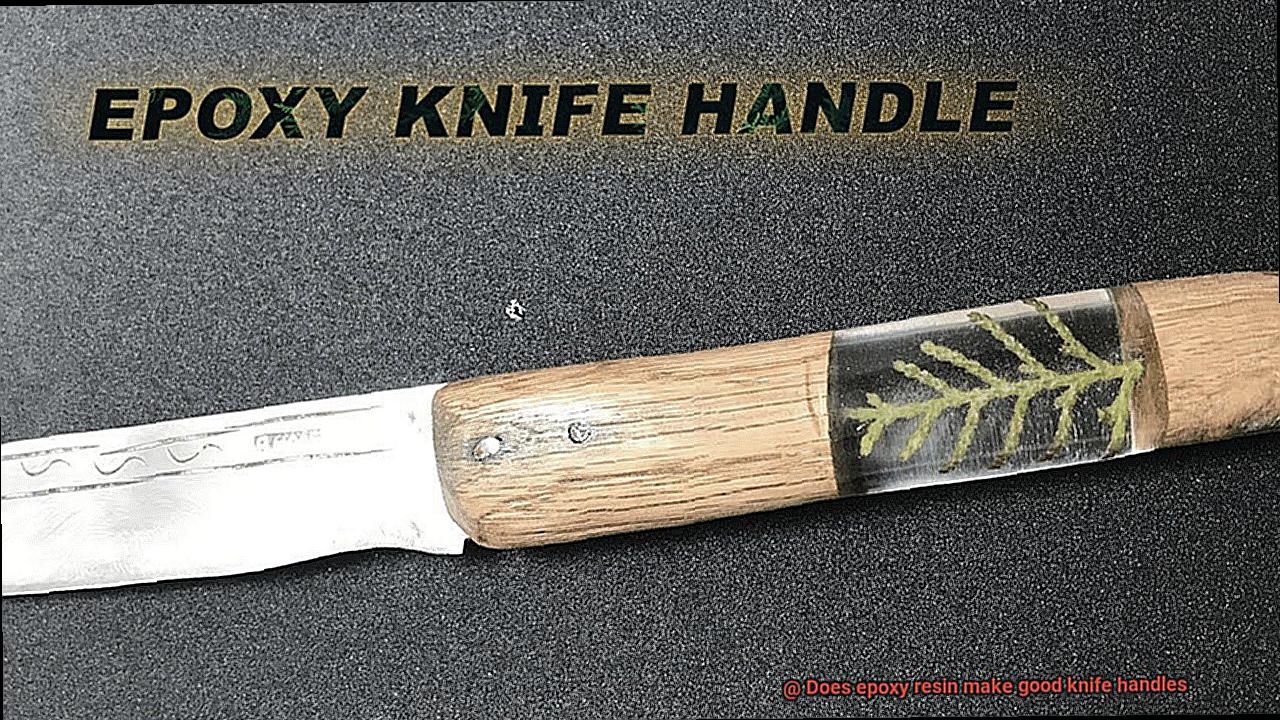

Picture this – imagine having a knife handle that’s a work of art. Well, with epoxy resin, that dream can become a reality. Its transparent nature allows you to embed tiny treasures, create mind-blowing patterns, or even trap delicate little plants and critters within the handle itself. It’s like carrying a piece of Mother Nature in your pocket. But hold up – some folks prefer the classic charm of traditional materials like hardwood.

They love the warmth, the grain, and the texture that only natural materials can provide. And hey, who can blame them?

Advantages of Epoxy Resin for Knife Handles

Contents

When it comes to the perfect knife, the handle plays a vital role in providing comfort, stability, and durability. While traditional handle materials like wood or plastic have their merits, epoxy resin is emerging as a game-changer in the world of knife handles. In this blog post, we will delve into the advantages of using epoxy resin for knife handles and why it’s worth considering for your next blade.

Advantage 1: Unmatched Durability

Epoxy resin is renowned for its exceptional strength and longevity. Unlike other handle materials that might chip, crack, or break under pressure, epoxy resin can withstand heavy-duty usage and resist wear and tear. Whether you’re slicing through tough cuts of meat or tackling outdoor adventures, an epoxy resin handle will stay solid and reliable.

Advantage 2: Water Warriors

Moisture can wreak havoc on some handle materials, leading to degradation and compromising the knife’s integrity. Epoxy resin, on the other hand, is impervious to water, making it the ideal choice for knives used in wet conditions or during cleaning. Say goodbye to swollen or warped handles and hello to a handle that can conquer any aquatic challenge.

Advantage 3: Chemical Resistance Superhero

Imagine a handle that can withstand exposure to various chemicals, solvents, and oils without flinching. That’s exactly what epoxy resin offers. From acidic foods to harsh cleaning agents, epoxy resin handles don’t corrode or degrade. Your knife will remain in tip-top shape no matter what substances it encounters.

Advantage 4: Customization Galore

Epoxy resin is a playground for creativity. With endless possibilities for customization, you can personalize your knife handle like never before. Mix in different pigments or additives to achieve a vast range of colors and effects. Pour it into molds of all shapes and sizes to create ergonomic and comfortable handles that fit your hand perfectly. The only limit is your imagination.

Advantage 5: Aesthetically Pleasing

Beyond its functional advantages, epoxy resin adds a touch of elegance to your knife. Its glossy and smooth finish gives the handle a professional and polished look. With the ability to incorporate various colors, patterns, or even embedded objects like wood or metal shavings, epoxy resin handles become true works of art that catch the eye and make a statement.

Customization and Aesthetics of Epoxy Resin Handles

Look no further. Epoxy resin handles are here to revolutionize your knife game. Not only do they offer unparalleled durability and resistance, but they also provide a wide range of customization options to suit your unique style. Let’s dive into the world of epoxy resin handles and discover how they can add a touch of elegance and individuality to your blades.

Unleash Your Creativity with Customization:

Epoxy resin handles offer endless possibilities for customization. With a plethora of colors, pigments, and metallic powders available, you can create mesmerizing patterns that reflect your personality. Whether you prefer vibrant bursts of color or subtle marbling effects, epoxy resin allows you to bring your vision to life. Plus, resin casting techniques enable you to embed objects like wood chips or stones, adding texture and charm to your handles.

Advantages That Stand the Test of Time:

Not only are epoxy resin handles visually stunning, but they also excel in durability. Resin is known for its exceptional strength, making it perfect for heavy-duty usage. Its resistance against water, chemicals, and oils ensures that your knife handle remains intact even in the harshest conditions. Say goodbye to worn-out handles and hello to longevity.

Aesthetics That Wow:

Epoxy resin handles possess an inherent aesthetic appeal that is hard to resist. The glossy finish achieved after polishing gives the handle a sleek and professional look that catches the eye. Moreover, by combining resin with other materials like wood or stabilized elements, you can create a captivating contrast between natural textures and the smoothness of the resin. This unique combination elevates the overall appearance of your knife, transforming it into a true work of art.

Showcasing Intricate Details:

Epoxy resin handles have a remarkable ability to preserve and highlight intricate details. Whether you opt for resin casting, marbling, or layering techniques, the result is a handle that showcases your craftsmanship and attention to detail. Sanding and polishing bring out the beautiful patterns and designs, ensuring that your knife handle becomes a conversation starter.

Resistance to Moisture and Chemicals

Epoxy resin is a game-changing material known for its exceptional resistance to moisture and chemicals. This makes it the perfect choice for knife handles, where durability and reliability are crucial.

One of the standout features of epoxy resin is its remarkable resistance to moisture. Unlike natural materials like wood or bone, epoxy resin doesn’t absorb water. This means that even if your knife handle gets wet during use or cleaning, it won’t swell, warp, or lose its shape. No matter how wet things get, your epoxy resin handle will remain stable and reliable.

But it’s not just moisture that epoxy resin can handle with ease. It also has an impressive resistance to a wide range of chemicals.

Oils, solvents, acids, alkalis – you name it, epoxy resin can take it. This is especially important for knife handles, which often come into contact with various substances during food preparation or outdoor activities.

With an epoxy resin handle, you don’t have to worry about degradation or reactions. Your handle will maintain its strength and integrity no matter what it encounters.

Another advantage of epoxy resin’s resistance to moisture and chemicals is its easy maintenance. Unlike some natural materials that require regular oiling or conditioning to prevent drying out or cracking, epoxy resin handles can be easily cleaned with mild soap and water. No special treatments or maintenance needed – just a simple clean and your handle will retain its original appearance and performance.

In addition to its functional benefits, epoxy resin handles also offer endless aesthetic possibilities. The versatility of epoxy resin allows for limitless creativity in design and color. Choose from a wide range of colors, add intricate details, or even incorporate other materials like wood or metal for a unique look. With an epoxy resin handle, you not only get exceptional performance but also a true work of art.

Thermal Resistance Properties

In the realm of knife handle materials, one material stands tall as the unyielding hero – epoxy resin. With its unparalleled thermal resistance properties, epoxy resin not only guarantees durability and reliability but also adds a touch of style to withstand even the most demanding kitchen challenges.

In this captivating blog post, we will delve into the molecular structure of epoxy resin, its remarkable ability to resist high temperatures, prevent cracks or fractures, and withstand the brutal force of thermal shock. Brace yourself for a journey into the world of thermal resistance properties.

The Molecular Fortress:

At the heart of epoxy resin’s invincibility lies its molecular fortress – a web of cross-linked polymer chains forming an unbreakable matrix. This unique molecular structure grants epoxy resin the power to maintain its shape and integrity even when exposed to extreme heat conditions, making it an unrivaled material for knife handles.

Heat Resistance:

Picture this – your cooking reaches scorching levels, but your epoxy resin knife handle remains cool and composed. That’s the magic of epoxy resin’s heat resistance. With minimal expansion or contraction under heat, this superhero material prevents cracks or fractures, ensuring that your knife handle triumphs over intense cooking sessions with unwavering strength.

Thermal Shock Resistance:

In the battle against thermal shock, epoxy resin emerges as an undefeated champion. Knife handles often encounter scalding surfaces or liquids, subjecting them to rapid temperature changes that can spell disaster. But fear not. Epoxy resin’s resilience against thermal shock transforms your knife handle into an impenetrable shield, ready to conquer any kitchen challenge that comes its way.

The Limitations:

Every hero has their limits, and epoxy resin is no exception. While it possesses exceptional thermal resistance properties, it is not invincible against extreme or prolonged exposure to high temperatures. To ensure the longevity of your epoxy resin knife handle, it is crucial to avoid direct contact with open flames or excessive heat sources, preserving its power for years to come.

Choosing the Right Ally:

To harness the full potential of epoxy resin as a knife handle material, one must carefully select the right ally – a high-quality resin that meets specific specifications. Different epoxy resins offer varying levels of thermal resistance, making it essential to choose a resin that aligns with your desired performance standards. In doing so, you unlock the true power of epoxy resin and elevate your knife handles to greatness.

Impact Resistance Considerations

When choosing a material for knife handles, impact resistance is of utmost importance. Enter epoxy resin, a superhero among materials known for its exceptional durability and strength. In this article, we will delve into the impact resistance considerations of using epoxy resin as a material for knife handles. We will explore different types of epoxy resins, their properties, advantages, and disadvantages compared to other materials. Get ready to unlock the secrets of this invincible hero.

Types of Epoxy Resins:

Epoxy resins come in various types, each with unique properties. Some resins are specifically formulated for high impact resistance, making them ideal for knife handles. These resins have a strong molecular structure with cross-linked polymer chains, allowing them to effectively absorb and distribute energy from impacts.

Advantages of Epoxy Resin:

One major advantage of epoxy resin is its excellent impact resistance. It can withstand heavy-duty tasks without compromising its structural integrity. Moreover, epoxy resin can be reinforced with materials like fiberglass or carbon fiber to further enhance its strength and rigidity.

Disadvantages of Epoxy Resin:

While epoxy resin provides good impact resistance, it may not be as resistant as certain metals or polymers. Therefore, it is important to consider the specific application and intended use of the knife when selecting epoxy resin as a handle material.

Tips for Readers:

To learn more about using epoxy resin for knife handles, consider these tips:

- Research different types of epoxy resins: Understand the specific properties and characteristics of different resins to select the most suitable one for your needs.

- Consider reinforcement options: Explore reinforcing your epoxy resin handle with materials like fiberglass or carbon fiber for even greater impact resistance.

- Seek expert advice: Consult experienced craftsmen or knife makers who have expertise in working with epoxy resin. They can provide valuable insights and tips for achieving the best results.

- Experiment and test: Before finalizing a design, create prototypes or test pieces to evaluate the impact resistance of your epoxy resin handle.

Cost Considerations

When it comes to cost considerations for using epoxy resin in knife handle projects, there are several factors to take into account. While the initial investment in epoxy resin may be higher compared to materials like wood or plastic, its long-term cost-effectiveness makes it a smart choice.

First and foremost, epoxy resin is known for its incredible strength and resistance to wear and tear. This means that knife handles made from epoxy resin are built to last. Unlike handles made from other materials, they won’t need to be replaced as frequently, resulting in savings over time.

Furthermore, epoxy resin is a superhero in battling moisture and chemicals. It stands strong in any environment, ensuring your knife handle stays intact without any damage or deterioration. With epoxy resin, you won’t have to worry about spending extra money on replacements due to water damage or exposure to harsh substances.

Maintenance is a breeze with epoxy resin handles. They’re easy to clean and maintain, requiring minimal effort and resources. Instead of wasting time fussing over their appearance, you can spend more time enjoying your knives.

In terms of customization, epoxy resin is like a chameleon. It can take on any color, pattern, or texture you desire. By simply mixing it with pigments or additives, you can create a unique look for your knife handles. There’s no need for additional expenses related to purchasing decorative materials – epoxy resin has got you covered.

To sum it up, while epoxy resin may have a higher upfront cost, its long-term benefits and durability make it a smart investment. With its incredible strength, resistance to moisture and chemicals, easy maintenance, and customization options, epoxy resin is a cost-effective choice for those seeking high-quality and long-lasting knife handles.

Craftsmanship Requirements

In this guide, we will explore the meticulous requirements for crafting knife handles with epoxy resin, unveiling a world of creativity and artistry that will leave you captivated.

Craftsmanship Requirements:

Choosing the Perfect Epoxy Resin:

- Opt for an epoxy resin with exceptional adhesion properties, ensuring a strong bond between the resin and the handle.

- Select a high-strength and durable resin, guaranteeing longevity and reliability for your knife handle masterpiece.

Preparing the Handle Material:

- Thoroughly clean the surface of the handle material, removing any impurities or oils that could hinder adhesion.

- Create an ideal bonding surface by roughening up the handle material through sanding or scoring, allowing the resin to adhere seamlessly.

Pouring and Shaping with Precision:

- Follow the manufacturer’s instructions to mix the epoxy resin, maintaining the perfect balance between resin and hardener.

- Pour the resin with finesse, ensuring an even distribution without any air bubbles that could compromise the handle’s structural integrity.

Carving and Finishing with Skill:

- Once cured, unleash your artistic prowess by carving, sanding, and polishing the epoxy resin handle to achieve your desired shape and smoothness.

- Use your skilled hands and keen eye for detail to create a comfortable grip that melds harmoniously with aesthetics.

Curing and Finishing Techniques:

- Exercise patience and allow ample time for the handle to fully cure, adhering to the recommended curing time provided by the manufacturer.

- Address any imperfections or rough spots through meticulous sanding and polishing techniques, culminating in a professional finish that exudes craftsmanship.

FjTXDR5mydk” >

Conclusion

In conclusion, epoxy resin is a fantastic choice for crafting knife handles. Before embarking on your next knife project, it’s important to take a few factors into account. Epoxy resin not only offers unparalleled durability but also boasts resistance against moisture and chemicals, making it an ideal option for handle materials. Say goodbye to worries about chipping or cracking during heavy-duty tasks – epoxy resin can handle it all.

But wait, there’s more. Epoxy resin opens up a world of creativity and customization options. With vibrant bursts of color, subtle marbling effects, or even embedded wood chips or stones, you can truly make your knife handle one-of-a-kind. And let’s not forget the glossy finish that polishing brings – it adds a touch of sleek professionalism that is sure to catch anyone’s eye.

However, it’s worth noting that compared to other materials like wood or micarta, epoxy resin can be slightly more brittle. If you plan on subjecting your knife handle to extreme force or impact, reinforcing it properly will help prevent any unwanted chipping or cracking.

Moreover, working with epoxy resin requires patience and precision due to its time-consuming curing process. Achieving that flawless finish demands meticulous attention to detail and impressive temperature control skills.

Ultimately, the decision of whether epoxy resin makes a good knife handle rests on personal preference and the intended use of the knife.