Today, we embark on a quest to unravel one of the most perplexing questions that has kept DIY enthusiasts scratching their heads: Can super glue really bond with Styrofoam?

Styrofoam, that magical polystyrene foam that’s practically made for crafting and modeling, has become an indispensable material in our creative repertoire. Its feather-light weight and exceptional insulation properties make it a dreamy choice for countless projects. And then there’s super glue, the superhero of adhesives, renowned for its unmatched strength and versatility. But can these two unlikely partners truly find common ground?

In this blog post, we’re here to demystify the age-old debate surrounding the compatibility of super glue with Styrofoam. Prepare to delve into the fascinating world of adhesive science as we uncover potential risks, explore helpful tips, and ultimately reveal whether this dynamic duo can create crafty magic together.

So, buckle up and get ready to unleash your inner glue guru.

What Is Styrofoam?

Contents

Styrofoam, a material you encounter in various aspects of your daily life, is much more than just a convenient packaging solution or craft material. Beyond its ubiquity, what exactly is Styrofoam, and what makes it so remarkable?

Styrofoam, though technically a brand name owned by The Dow Chemical Company, has become a popular term for expanded polystyrene foam (EPS foam). This versatile material is created by combining styrene with a blowing agent that expands the substance into its distinctive foam structure.

What sets Styrofoam apart is its closed-cell structure. The individual foam cells are sealed off from one another, giving Styrofoam its exceptional properties. This structure grants Styrofoam lightweight buoyancy, making it an ideal choice for packaging delicate items or ensuring their flotation in water. Moreover, it offers excellent thermal insulation capabilities, keeping buildings properly insulated and beverages at their desired temperatures.

Visually, Styrofoam is often characterized by its white color and smooth, glossy surface. It can be obtained in various forms such as sheets, blocks, balls, and custom-cut shapes. The material can be effortlessly cut with a sharp knife or molded using heat, such as with a hot wire cutter.

However, it is important to exercise caution when using certain adhesives with Styrofoam. Super glue, for instance, contains solvents that may dissolve or degrade the material. Additionally, the exothermic reaction during super glue’s curing process can generate heat, potentially causing the Styrofoam to melt or deform.

To mitigate these risks, it is generally recommended to avoid using super glue directly on Styrofoam. Instead, alternative adhesives like white craft glue or hot glue are often suggested for bonding purposes.

What Is Super Glue?

In the world of DIY projects, repairs, and crafting, having a reliable adhesive is essential. Enter super glue, also known as cyanoacrylate adhesive. This article will explore the ins and outs of super glue – what it is, how it works, and its limitations.

What is Super Glue?

Super glue is not your ordinary adhesive. It is a fast-acting, clear liquid that forms an incredibly strong and durable bond between various materials. The secret lies in its main ingredient – cyanoacrylate, an acrylic resin that undergoes polymerization when exposed to moisture in the air. This chemical reaction creates long chains of molecules, resulting in a rigid structure that holds materials together with remarkable strength.

Versatility at its Best:

One of the remarkable features of super glue is its versatility. It can bond an impressive range of materials, including plastics, metals, ceramics, leather, and wood. Whether you’re repairing a broken ceramic vase or creating intricate crafts with different materials, super glue is your go-to adhesive.

The Challenge with Styrofoam:

Ah, Styrofoam – that lightweight material commonly used for packaging and insulation. Unfortunately, super glue and Styrofoam don’t always see eye to eye. Styrofoam’s porous nature allows air and moisture to penetrate its surface, hindering the polymerization process of super glue. As a result, the bond may not be as strong or long-lasting as desired.

Specialized Solutions for Styrofoam Bonding:

But fear not. There are specialized glues available specifically designed for bonding Styrofoam. These glues contain unique ingredients that create a stronger bond with the porous material. They also have longer drying times to allow for better penetration into Styrofoam’s surface, ensuring a more reliable and secure bond.

Should You Use Super Glue on Styrofoam?

Super glue, also known as cyanoacrylate adhesive, is a popular choice for bonding various materials due to its fast-drying and strong adhesive properties. However, when it comes to Styrofoam, using super glue may not be the best option. In this blog post, we will explore why it is not recommended to use super glue on Styrofoam and provide alternative solutions for bonding this lightweight foam material.

Compatibility Issues:

Styrofoam, made from expanded polystyrene foam, is not compatible with many solvents or adhesives due to its chemical composition. Super glue contains cyanoacrylate, which can cause a chemical reaction that breaks down the polystyrene and leads to melting or deformation of the foam.

Weak Bonding:

While super glue creates a quick and strong bond between materials like metal or wood, it may not work as effectively on Styrofoam. The low-density structure of Styrofoam prevents the adhesive from fully penetrating the porous surface, resulting in a weaker bond.

Drying Time Challenges:

Super glue dries rapidly, often within seconds. This quick drying time can make it difficult to properly position or adjust the Styrofoam pieces before the adhesive sets. This may lead to misaligned or unevenly bonded Styrofoam, compromising the overall integrity of your project.

Recommended Alternatives:

For a safer and more reliable alternative, it is recommended to use adhesives specifically designed for polystyrene foam. These specialized glues are formulated to provide a secure bond without damaging or melting the foam. They are readily available in craft stores or online and offer better results when working with Styrofoam.

Potential Risks of Using Super Glue on Styrofoam

Today, we’re delving into a sticky topic that could save you from major crafting mishaps. Imagine this: you’re working on a project and reach for your trusty super glue to bond Styrofoam pieces together. But before you proceed, let’s discuss the potential risks involved in this adhesive choice.

Chemical Reaction Meltdown:

Super glue contains a powerful chemical called cyanoacrylate, renowned for its bonding capabilities. However, when it encounters Styrofoam, disaster can strike. The cyanoacrylate has the ability to cause the Styrofoam to melt or dissolve, resulting in deformed creations with compromised structural integrity.

Toxic Fumes Alert:

The combination of super glue and Styrofoam can release toxic fumes, including hydrogen cyanide. Inhaling these fumes may lead to respiratory issues or even poisoning. The level of toxicity varies depending on the brand of super glue used, necessitating caution during use.

Fast-Drying Woes:

Super glue’s rapid drying time can become a nightmare when working with Styrofoam. Once applied, there is limited time for adjustments or repositioning. Misalignment or uneven bonding can weaken the overall structure of the project.

Flexibility Matters:

Super glue lacks flexibility once dried, whereas Styrofoam is soft and flexible. This disparity in flexibility creates stress points on the Styrofoam, making it prone to cracks or breakage over time—especially when subjected to pressure or movement.

Skin Sticky Situation:

Accidental contact of super glue with skin can result in painful and challenging situations where fingers or body parts become stuck together. Separating them can be both painful and tricky. Therefore, it is crucial to take precautions and protect yourself when working with super glue.

In summary, using super glue on Styrofoam carries potential risks that can mar your crafting experience. To avoid these issues, it is best to explore alternative adhesive options specifically designed for Styrofoam or consult professionals with expertise in working with these materials.

Alternatives to Super Glue for Bonding Styrofoam

Before you reach for the dependable super glue, hold your horses. This article will explore the limitations of using super glue on Styrofoam and introduce you to some fantastic alternatives that will ensure your creations stand the test of time.

The Pitfalls of Super Glue:

While super glue may be the go-to adhesive for many projects, it can lead to disastrous results when bonding Styrofoam. The chemical reaction between super glue and Styrofoam can cause melting and structural deformities, leaving you with a less-than-desirable outcome. Additionally, the fast-drying nature of super glue leaves little room for adjustments or repositioning, making it challenging to achieve precise bonding.

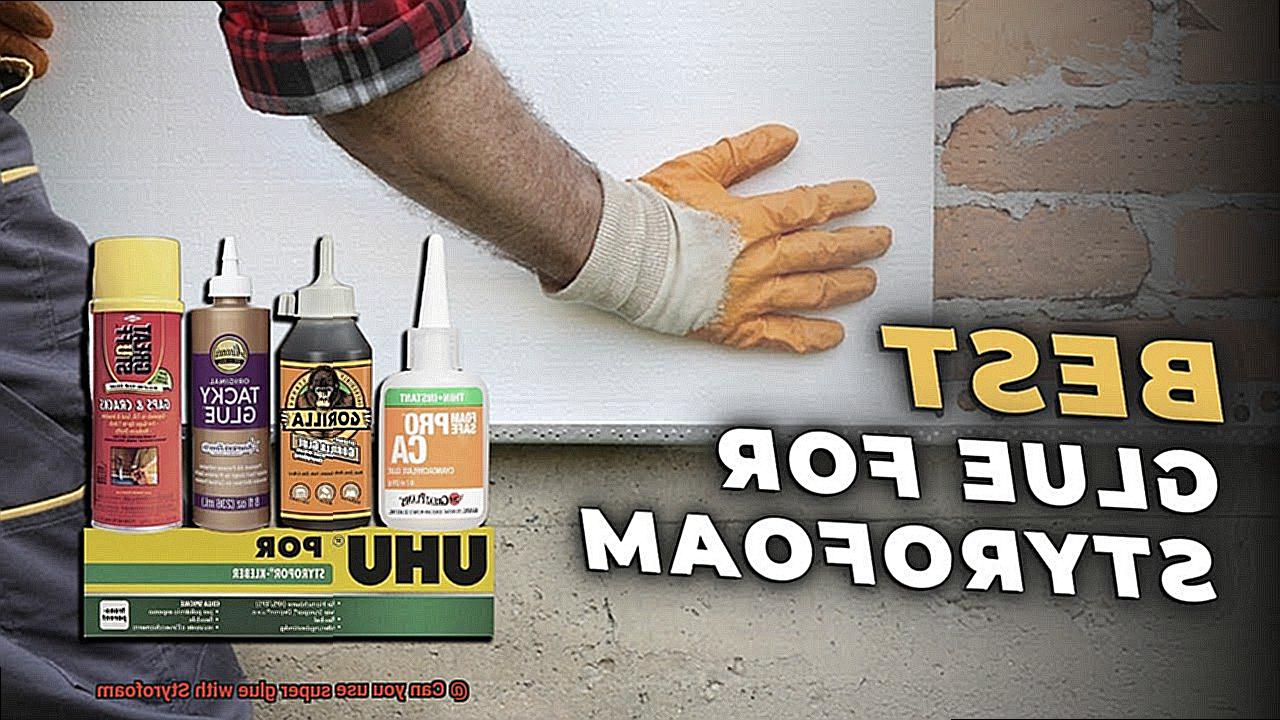

Styrofoam Glue:

Specialized glues formulated specifically for bonding Styrofoam are readily available in the market. These water-based glues have low viscosity, allowing them to penetrate the porous surface of Styrofoam and create a strong bond. They dry clear and remain flexible, ensuring your creations can withstand movement and stress.

Foam-Safe CA Glue:

Foam-safe cyanoacrylate (CA) glue is a variation of super glue designed to work with foam materials like Styrofoam. It has a slower curing time than regular super glue, which prevents damage to the porous surface of Styrofoam. This type of glue provides a strong bond and dries clear, making it an excellent choice for bonding Styrofoam.

Hot Glue:

Hot glue guns are a popular choice for bonding Styrofoam due to their convenience and quick-drying properties. The melted hot glue solidifies as it cools, creating a strong bond between Styrofoam pieces. However, take note of temperature limitations and moisture exposure, as hot glue may not be suitable for all Styrofoam projects.

Epoxy Resin:

Epoxy resin is a versatile adhesive that can be used to bond various materials, including Styrofoam. It consists of two components – resin and hardener – which need to be mixed before application. Epoxy resin provides a strong bond and offers excellent resistance to moisture and temperature fluctuations.

Double-Sided Tape:

For lightweight Styrofoam projects, consider using double-sided tape. This adhesive tape has adhesive on both sides, allowing for easy application and bond creation. It is a convenient option when you need a quick and mess-free solution.

How to Safely Use Super Glue with Styrofoam

While there are risks associated with using super glue directly on Styrofoam, proper preparation and technique can minimize these risks. In this guide, we will explore the steps you can take to safely use super glue with Styrofoam.

Prepare the Surface:

To ensure a strong bond, it’s crucial to clean the Styrofoam surface before applying super glue. Gently wipe the surface with a clean cloth or use a mild detergent to remove any dirt, dust, or oils. This step will help the glue adhere better and create a more secure bond.

Use Minimal Amounts:

Super glue is powerful and can expand when applied in excessive amounts, creating a mess. To avoid this, use a small amount of glue on one of the surfaces you want to bond. Remember, a little goes a long way, and you can always add more if needed. Using too much glue can weaken the bond and may cause damage to the Styrofoam.

Press and Hold:

Once you’ve applied the glue, press the two surfaces firmly together and hold them in place for a few seconds. This allows the glue to bond effectively. If possible, use clamps or weights to hold the surfaces together while the glue cures. Be careful not to apply too much pressure or twist the bonded surfaces, as it can weaken the bond or cause the Styrofoam to break.

Work Efficiently:

Super glue dries quickly, so it’s essential to work efficiently and accurately. Position the surfaces correctly before pressing them together because once bonded, repositioning may not be possible without damaging the foam. Plan your steps and ensure that everything is in place before applying the glue to avoid any mistakes.

Clean Up Excess Glue:

If you accidentally apply too much super glue or it spills onto unwanted areas, don’t panic. Use acetone or nail polish remover containing acetone to remove excess adhesive from the surface. Apply a small amount of acetone to a clean cloth and gently dab the affected area. Be cautious not to use too much acetone, as it can dissolve the Styrofoam if used excessively.

Safety Precautions:

When using super glue with Styrofoam, it’s crucial to work in a well-ventilated area to avoid inhaling fumes. Super glue fumes can be harmful, so it’s best to work in an open space or use a fan to improve air circulation. If possible, wear gloves and a mask for added protection. Additionally, remember that the bond strength of super glue on Styrofoam may not be as strong as on other materials, so avoid using it for applications that require high strength or load-bearing capabilities.

Pros and Cons of Using Super Glue with Styrofoam

When it comes to gluing Styrofoam, the use of Super Glue can be both advantageous and disadvantageous. Before embarking on any project involving this combination, it is essential to understand the pros and cons.

Let’s begin with the advantages. First and foremost, Super Glue is renowned for its strong bond. It creates a secure and durable connection between Styrofoam pieces, ensuring that your masterpiece stays intact. Additionally, Super Glue dries quickly, saving you precious time during small projects or repairs.

Versatility is another perk of Super Glue. Whether you’re working on a craft project or fixing a broken piece of Styrofoam, Super Glue can be a reliable option due to its compatibility with various materials. Furthermore, the precision applicators of Super Glue facilitate easy application, allowing for accurate bonding.

Now, let’s explore the disadvantages. One potential drawback of using Super Glue with Styrofoam is the risk of damaging the foam. The chemicals in Super Glue can react with Styrofoam, causing it to melt or dissolve. This can lead to deformities or loss of shape in your Styrofoam creation.

Another con is the limited flexibility that Super Glue offers once it dries. If you require the bonded Styrofoam pieces to bend or move without breaking, an adhesive with more flexibility may be a better choice.

It’s worth noting that Super Glue emits fumes that can irritate your eyes, nose, and throat. Therefore, it’s crucial to work in a well-ventilated area when using this adhesive. Additionally, the strong odor of Super Glue might not be ideal for enclosed spaces.

Lastly, once Super Glue has bonded two pieces of Styrofoam together, they are challenging to separate without causing damage. This lack of reusability can be a disadvantage if you need to disassemble or modify your project in the future.

NtOeJsBnFYE” >

Also Read: What Is the Best Glue For Styrofoam? – Glue Things

Conclusion

In conclusion, the debate surrounding the compatibility of super glue with Styrofoam continues to ignite passionate discussions among crafters and DIY enthusiasts. Styrofoam’s feather-light composition and incredible versatility make it a coveted material for countless projects. However, using super glue directly on Styrofoam can unleash a whirlwind of potential hazards, including melting, warping, feeble bonding, and even the release of toxic fumes.

To embark on a successful and secure bonding journey with Styrofoam, it is highly recommended to explore alternative adhesives that have been specifically formulated for this porous wonder. These specialized glues possess the remarkable ability to penetrate deep into the foam’s surface, forging an unbreakable bond without inflicting harm.

Consider options such as styrofoam glue, foam-safe cyanoacrylate (CA) glue, trusty hot glue guns, resilient epoxy resin, or dependable double-sided tape. Each of these alternatives boasts its own unique set of advantages and disadvantages; therefore, it is crucial to select the adhesive that aligns seamlessly with your project’s demands.

However, if you dare to defy convention and insist on employing super glue with Styrofoam despite its potential perils, there are precautions you can take to mitigate any adverse effects. Begin by meticulously preparing the surface before applying minimal amounts of glue. Once joined together, exert firm pressure upon the surfaces throughout the bonding process. Work swiftly and efficiently before the adhesive sets in stone. Should excess glue rear its sticky head, promptly banish it with a dash of acetone. And above all else, prioritize safety by engaging in your crafting endeavors within well-ventilated spaces.

By comprehending the limitations associated with using super glue on Styrofoam and exploring alternative adhesive avenues instead, you will ensure that your artistic ventures flourish with unwavering success and longevity.