Are you tired of waiting for super glue to dry?

It’s a real pain, especially when you’re in a hurry to fix something or finish a DIY project. But guess what?

There are actually some pretty cool tricks to make super glue dry faster. I kid you not.

In this blog post, we’ll spill the beans on these tried and true methods that will speed up the drying process of super glue. Say goodbye to wasted time and hello to getting things done in a flash.

So, let’s jump right in and find out how you can make super glue dry faster.

How Does Super Glue Work?

Contents

- 1 How Does Super Glue Work?

- 2 Factors That Affect Drying Time of Super Glue

- 3 Cleaning the Surfaces to Expedite the Drying Process

- 4 Applying a Thin Layer of Glue for Faster Drying

- 5 Using Catalysts or Activators to Speed Up the Process

- 6 Applying Heat to Accelerate the Curing Process

- 7 Following Manufacturer’s Instructions for Optimal Results

- 8 Benefits of Speeding Up Drying Time

- 9 Conclusion

Super glue, also known as cyanoacrylate adhesive, is a remarkable adhesive that is widely used in various applications. It is the go-to solution for fixing broken items or bonding materials together. But how does this powerful adhesive actually work?

At its core, super glue is made up of cyanoacrylate monomers. These tiny molecules contain carbon, hydrogen, and oxygen atoms and have a low viscosity, allowing the glue to flow effortlessly into small cracks and gaps.

When super glue comes into contact with a surface, it reacts with the moisture present on that surface. The water molecules in the air or on the material’s surface trigger a rapid polymerization reaction. This reaction causes the monomers to link together, forming long chains of molecules called polymers.

The polymerization process happens incredibly fast, generating heat as a byproduct. This heat further accelerates the reaction, allowing the glue to bond within seconds or minutes. The reaction continues until all the available monomers have linked together, resulting in a solid and rigid bond.

The bond formed by super glue is impressively strong due to the tightly arranged polymer chains. It creates an instant and durable connection between surfaces, making it ideal for quick repairs or projects that require immediate adhesion. The strength of the bond also enables super glue to withstand high levels of stress and tension.

To ensure the best results when using super glue, it is important to work with clean and dry surfaces. Any moisture or contaminants can interfere with the bonding process and weaken the bond. So, before applying super glue, make sure to clean and prepare the surfaces properly.

Factors That Affect Drying Time of Super Glue

Super glue, the mighty adhesive hero, can swoop in and save the day by bonding materials together in seconds. But have you ever wondered what factors affect its drying time? In this blog post, we will delve into the fascinating world of super glue and explore the key factors that can influence how quickly it dries. Get ready to uncover the secrets behind achieving rapid bonding with this incredible adhesive.

Temperature:

Temperature is a game-changer when it comes to super glue’s drying time. Higher temperatures, like the heat of a hairdryer or a warm environment, accelerate the chemical reactions during the curing process. Embracing some warmth can make all the difference if you’re in a hurry to see your bond solidify.

Humidity:

Moisture in the air can be both a friend and a foe when working with super glue. High humidity levels prolong drying time as moisture interferes with the curing process. On the other hand, low humidity speeds up drying as there is less moisture present to hinder bonding. To create an optimal environment for quick drying, consider working in a well-ventilated area or using a dehumidifier to reduce humidity.

Bonding Surfaces:

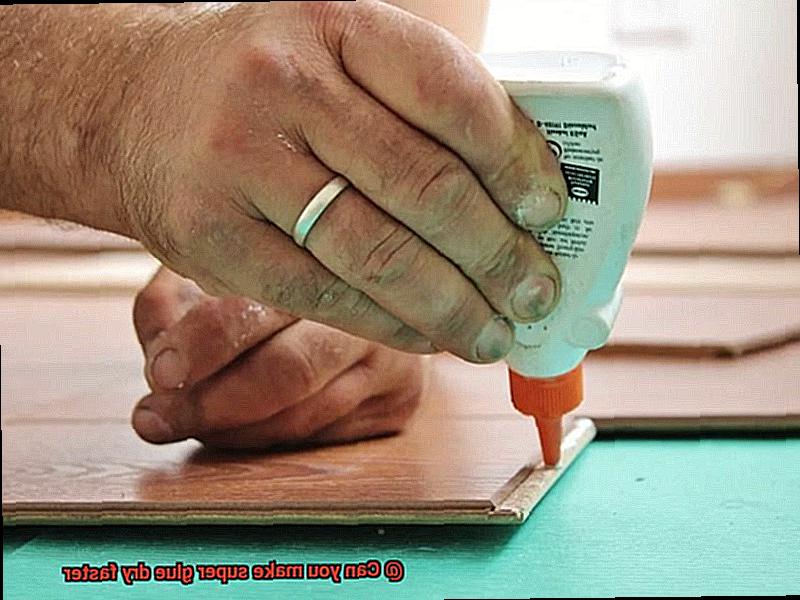

The surfaces being bonded play a significant role in drying time. Porous materials like wood or fabric tend to absorb some adhesive, slowing down the process. In contrast, non-porous materials such as metal or glass allow for quicker drying since the glue remains on the surface. Clean and smooth surfaces provide better adhesion and faster drying times compared to dirty or rough surfaces. So, ensure your surfaces are clean and choose your materials wisely for faster bonding.

Amount of Glue Applied:

Less is more when it comes to applying super glue. Excessive amounts create thicker layers that take longer to cure fully. For faster drying, apply a thin and even layer of adhesive. Remember, super glue is designed to bond quickly in thin layers, so avoiding excess glue not only speeds up drying time but also ensures a strong bond.

Type and Brand of Glue:

Not all super glues are created equal. Different formulations and brands may have varying drying times due to differences in chemical composition. Some glues prioritize quick drying, while others focus on flexibility or strength. When selecting a super glue, consider the intended application and choose a product that aligns with your time requirements.

Cleaning the Surfaces to Expedite the Drying Process

When it comes to using super glue, ensuring a speedy drying process is key. And one often overlooked step that can make all the difference is cleaning the surfaces before applying the adhesive. By taking the time to clean and prepare the surfaces properly, you can expedite the drying process and achieve a stronger bond. Let’s dive into why this step is so crucial and how to do it effectively.

First and foremost, any dirt, dust, grease, or moisture on the surfaces can seriously hinder the bonding process and slow down drying time. Imagine trying to stick two pieces of broken glass together with super glue, only to find that there’s a layer of grime preventing them from properly adhering. Frustrating, right? That’s why cleaning is so important.

To clean non-porous surfaces like glass, metal, or plastic, you’ll want to arm yourself with some isopropyl alcohol or acetone. These powerful cleaning agents will swiftly wipe away any contaminants. Soak a clean cloth or cotton swab with your chosen solution and give those surfaces a gentle wipe-down. You’ll be amazed at how much cleaner they become, instantly improving the bonding potential.

But what about porous surfaces like wood or fabric? Fear not. Warm soapy water is your best friend in this case. Grab a sponge and give those surfaces a good scrub to remove any dirt or debris that might interfere with the bonding process. Once you’re done, make sure to rinse them thoroughly to remove any soap residue that could affect the adhesive properties of the super glue.

Now that your surfaces are squeaky clean, it’s time to take it up a notch. Grab some sandpaper and lightly sand those bad boys. This step creates a slightly rougher texture on the surfaces, providing more surface area for the glue to adhere to. This extra grip means faster drying time and a stronger bond. Just be careful not to go overboard and damage your precious materials.

- One last thing before we’re done – dust. Those pesky little particles can be a real buzzkill when it comes to super glue. So, grab a soft brush or some compressed air and give those surfaces a final cleaning sweep. This will ensure that your surfaces are free from any lingering debris that could compromise the adhesive’s effectiveness.

- So there you have it – the importance of cleaning surfaces before applying super glue. Not only does it expedite the drying process, but it also ensures a stronger bond and a more durable result. Next time you’re faced with a DIY emergency, remember to clean like a pro and let that super glue work its magic in no time.

In summary, here are the key steps to cleaning surfaces to expedite the drying process:

- Identify the type of surface you’re working with – non-porous or porous.

- For non-porous surfaces, use isopropyl alcohol or acetone to wipe away contaminants.

- For porous surfaces, clean with warm soapy water and rinse thoroughly.

- Lightly sand the surfaces to create a rougher texture for better adhesion.

- Remove any dust particles with a soft brush or compressed air.

- Enjoy faster drying times and a stronger bond.

Applying a Thin Layer of Glue for Faster Drying

Today, we unveil a hidden secret that will revolutionize your crafting experience: the art of applying a thin layer of glue for lightning-fast drying. If you’ve ever yearned for speedy results, this is the answer you’ve been seeking.

Now, you may ponder how such a seemingly small adjustment can yield such remarkable results. The answer lies in the captivating science of evaporation. A thick layer of glue hinders the solvent within from evaporating completely, resulting in a sluggish drying process. However, by using a thin layer, more of the adhesive is exposed to the life-giving air, allowing the solvent to dissipate with astonishing swiftness. It’s like granting your glue a refreshing breath of air.

But how does one master this mystical technique? Begin by ensuring that the surfaces you wish to bond are pristine and dry. Any lurking dirt or moisture can meddle with the bonding process and impede drying time. Thus, seize a clean cloth or an alcohol wipe, and with unwavering determination, scrub away any impurities.

Next, arm yourself with a delicate brush or applicator and embark on the journey to spread the glue. Remember, steady hands are pivotal here. Gently press down to create a thin and uniform layer upon one of the surfaces. Beware the temptation to go overboard; we crave a whisper-thin layer, not an unruly mess.

Once your glue has been applied, join the two surfaces together and clasp them firmly for a fleeting moment. This ensures optimal contact between the materials and fosters a bond worthy of admiration. Picture it as giving your creation a gentle squeeze – but take heed. During this sacred time, movement and disturbance are forbidden; we yearn for unyielding alignment and unwavering strength.

It is crucial to note that various super glue types and brands boast different drying times. Some may dry within the blink of an eye, while others may require a handful of minutes. Always consult the manufacturer’s instructions for precise drying times and sage recommendations.

But wait, there’s more. Temperature and humidity wield influence over the hastiness of super glue’s drying process. Warmer temperatures and lower humidity levels serve as catalysts for swift drying. Thus, if possible, toil in a well-ventilated oasis boasting controlled temperature and humidity conditions, and witness your projects come to life with unparalleled alacrity.

Now that you possess the secret of applying a thin layer of glue for expeditious drying, embrace your creative endeavors with newfound confidence and celerity. Yet, let us not forget the importance of safety precautions – shield thy skin and eyes from direct contact by donning gloves and safety glasses.

Using Catalysts or Activators to Speed Up the Process

If you’ve ever found yourself anxiously waiting for your glue to set, then this is the post you’ve been waiting for.

So, what exactly are catalysts and activators? They’re the superheroes of the glue world – substances that can be added to super glue to kickstart or accelerate the chemical reaction that occurs when it meets moisture. Let’s take a closer look at how these mighty helpers work their magic.

First up, we have the humble H2O – water. Believe it or not, water is a common catalyst used in super glue. When water is introduced, it reacts with the cyanoacrylate molecules in the glue, causing them to bond and dry faster. It’s like giving your glue a jolt of lightning.

But that’s not all. Acidic substances like vinegar or lemon juice also make great activators. The acid in these everyday items breaks down the cyanoacrylate molecules, allowing them to bond and dry at warp speed. It’s like sending your glue on a luxurious spa retreat.

And hold onto your hats because there’s even more. Some manufacturers have gone above and beyond by creating specialized activators tailor-made for their brand of super glue. These convenient activators are applied directly to one of the surfaces being bonded before applying the glue. Talk about efficiency.

However, before you go wild with these catalysts and activators, there’s an important caveat. While they can certainly speed up the drying process of super glue, they can also impact its overall strength and durability. Using too much activator or applying it incorrectly might weaken the bond or lead to adhesive failure. Not exactly what we want.

To avoid any sticky situations, always read and follow the instructions provided by the manufacturer when using catalysts or activators with super glue. And remember, it’s smart to test the strength and performance of your bonded materials after using a catalyst or activator.

Applying Heat to Accelerate the Curing Process

If you’re tired of waiting for your super glue to dry, then heat may just be the solution you’ve been looking for. Applying heat to super glue can significantly speed up the curing process and make it dry faster. But how does it work? Let’s break it down.

Firstly, heat increases the rate of chemical reactions that occur during the curing process. Super glue is made up of tiny molecules that need to bond together to create a strong adhesive. When heat is applied, it gives these molecules a bit of a kick, urging them to bond faster and form a stronger hold.

Secondly, heat helps to evaporate any solvents present in the glue. You know that distinct smell that super glue has? That’s the solvents evaporating. By applying heat, you’re effectively speeding up this evaporation process and allowing the glue to dry more quickly.

However, it is important to note that not all types of super glue can handle high temperatures. It’s crucial to check the instructions or manufacturer’s recommendations before applying heat. The ideal temperature range for accelerating the drying process is typically between 100-150 degrees Fahrenheit (38-65 degrees Celsius).

So how do you apply heat? You can use a hairdryer or a heat gun to blow hot air onto the glued area. Start with a low heat setting and gradually increase it if necessary, while closely monitoring the glued area. For larger projects, a hot air blower or a heat lamp can also be effective.

Remember to prioritize safety. Always work in a well-ventilated area, as some fumes may be released during the curing process. Additionally, be cautious of the materials you’re working with, as excessive heat can cause damage or even burn the glue.

Following Manufacturer’s Instructions for Optimal Results

For optimal results with your super glue, it’s crucial to follow the manufacturer’s instructions down to the last detail. Don’t dismiss those tiny words in fine print – they hold the key to unlocking your glue game’s true potential.

First and foremost, different brands of super glue have their own unique instructions and recommendations. So, take a moment to familiarize yourself with what the manufacturer suggests for their particular product. Let’s delve into why this is so vital:

- Ideal application conditions: The instructions will typically enlighten you on the perfect temperature and humidity levels for applying the glue. It may sound trivial, but trust me, it can make a world of difference. Following these recommended conditions can speed up drying time and enhance the bond’s effectiveness.

- Proper amount of glue: Ever wondered how much glue you should be using? Wonder no more. The manufacturer’s instructions will act as your trusty guide, indicating the right amount of glue for different materials and applications. By adhering to these guidelines, you’ll ensure that you’re not skimping or overdoing it, resulting in a rock-solid and swift bond.

- Safety precautions: Ah, safety first. The manufacturer may provide invaluable advice on necessary safety measures, such as wearing protective gloves or working in a well-ventilated area. Believe me, you don’t want any sticky mishaps on your hands or harmful fumes invading your lungs. Ignoring these instructions could have dire consequences.

Benefits of Speeding Up Drying Time

From increased productivity and improved efficiency to reduced risks and emergency repairs, faster drying super glue can revolutionize projects and operations in multiple industries.

Increased Productivity:

In industries like manufacturing and construction, time is money. By reducing the drying time of super glue, projects and repairs can be completed at a record pace. This boosts productivity and provides a competitive edge in the market.

Improved Efficiency:

Waiting for glue to dry is frustrating, especially when you have tight deadlines. Faster drying time minimizes waiting periods, allowing tasks to be completed more efficiently. This leads to increased output and cost savings, making projects more profitable.

Reduced Risk of Accidental Damage:

We’ve all experienced the frustration of smudging freshly applied glue. By accelerating the drying process, the risk of accidental damage or smudging is significantly reduced. This ensures cleaner and more precise results, saving time and effort in fixing mistakes.

Quicker Handling and Use:

In industries like automotive or electronics, immediate use or assembly is often necessary. Speeding up the drying time enables quicker handling and use of glued items, facilitating seamless integration into production processes. This saves valuable time and ensures smooth operations.

Efficient DIY Projects:

For DIY enthusiasts or hobbyists, faster drying time is a game-changer. It eliminates the need to wait for hours before progressing to the next step, allowing projects to be completed in a shorter timeframe. Say goodbye to long waiting periods and hello to quicker project satisfaction.

Emergency Repairs:

Accidents happen, and when something breaks unexpectedly, a quick fix is essential. Super glue with faster drying time allows for swift repairs in emergency situations. Whether it’s a broken vase or a snapped cable, fast-drying super glue can save the day and restore functionality in no time.

3oQMFWFbOw8″ >

Also Read: How To Make Super Glue Dry Faster

Conclusion

Unfortunately, it is not possible to make super glue dry faster.

Super glue is designed to cure and bond materials at a specific rate, and trying to speed up the drying process can compromise the strength and effectiveness of the adhesive. Patience is key when using super glue – allowing it ample time to dry will ensure a strong and durable bond.

So resist the temptation to rush the process and instead embrace the waiting game for optimal results.