Are you itching to tackle a DIY project with some trusty plywood?

Maybe you’ve caught yourself pondering, “Can you just glue plywood together?” It’s a tempting thought, isn’t it?

The idea of slapping on some adhesive and voila. Instant masterpiece.

But hold your horses, my friend. Before you rush into this sticky situation, let’s take a moment to really understand the ins and outs of gluing plywood.

We’ll dive deep into the realm of adhesives, explore the different types of glue that work best, examine the quality of plywood needed for successful bonding, and consider the intended use of your final creation. So grab your tool belt and get ready to embark on this enlightening journey as we uncover whether or not gluing plywood together is a genius move or an epic fail waiting to happen.

Let’s get stuck on this topic – in the best possible way.

What is Plywood?

Contents

Plywood, the unsung hero of construction and woodworking projects, is an engineered wood product made by bonding thin layers of wood veneer with a strong adhesive. In this article, we will explore the world of plywood and the crucial role of glue in creating durable and resilient structures.

Types of Glue:

Various types of adhesives are used in plywood production, each with its own unique properties and strengths. Here are some common types:

- Wood Glue: Also known as carpenter’s glue or PVA glue, wood glue is specifically formulated for woodworking applications. It penetrates the wood fibers, creating a strong bond between plies.

- Epoxy: Known for exceptional strength and resistance to moisture and heat, epoxy adhesives are commonly used in marine plywood or outdoor applications.

- Polyurethane Adhesive: Offering a combination of strength, flexibility, and water resistance, polyurethane adhesives are ideal for applications requiring a strong bond and moisture resistance.

- Construction Adhesive: Designed for heavy-duty bonding, construction adhesives excel at bonding plywood to various substrates such as concrete, metal, or plastic.

Reinforcement Methods:

While glue is crucial in bonding plywood, additional reinforcement methods ensure sturdy joints. Here are two common techniques:

- Mechanical Fasteners: Screws or nails used in conjunction with glue add extra reinforcement to plywood joints. These fasteners penetrate through the glued layers, preventing separation and increasing strength.

- Dowels or Biscuits: Inserted into pre-cut holes in plywood layers before gluing, dowels and biscuits align and strengthen joints, providing additional support.

Conclusion:

Glue is the backbone of plywood, providing strength, durability, and resistance to environmental factors. However, additional reinforcement methods like mechanical fasteners or dowels/biscuits are often necessary. Choosing the right glue for the application and following proper surface preparation and clamping techniques are crucial for optimal results.

What is Glue?

Glue, the unsung hero of construction and woodworking projects, is the secret ingredient that holds everything together, ensuring durability and resilience. Without glue, our creations would easily crumble into pieces.

So, what exactly is glue? It is a substance that bonds or joins materials together. Glue can be made from a variety of materials, such as natural substances like animal bones or synthetic compounds like chemicals. There are numerous types of glue available in the market, each with its own unique properties and uses.

Let’s explore some common types of glue and their applications:

- Wood Glue: Designed specifically for woodworking projects, wood glue provides a strong bond and effectively works on wood surfaces. Whether you’re building furniture or crafting intricate designs, wood glue is your go-to adhesive.

- Epoxy Adhesive: This versatile glue can bond a wide range of materials, including wood, metal, glass, and plastic. It forms an incredibly strong bond and is resistant to heat, water, and chemicals. Ideal for heavy-duty applications like automotive repairs or industrial projects.

- Super Glue: Also known as cyanoacrylate adhesive, super glue is a fast-acting adhesive that bonds quickly and securely. It works well on various materials, including plastic, metal, ceramic, and rubber. Perfect for small repairs and DIY projects around the house.

- Hot Glue: Popular for crafts and quick fixes, hot glue is applied in a molten state using a hot glue gun and solidifies as it cools down. It can bond a wide range of materials and provides a strong hold.

These are just a few examples of the many types of glue available. Each type has its own unique properties and uses, so it’s important to choose the right glue for your specific project.

Can You Just Glue Plywood Together?

Gluing plywood together can be a cost-effective and efficient method for various woodworking projects. However, determining whether it is suitable for your specific application requires careful consideration of several factors.

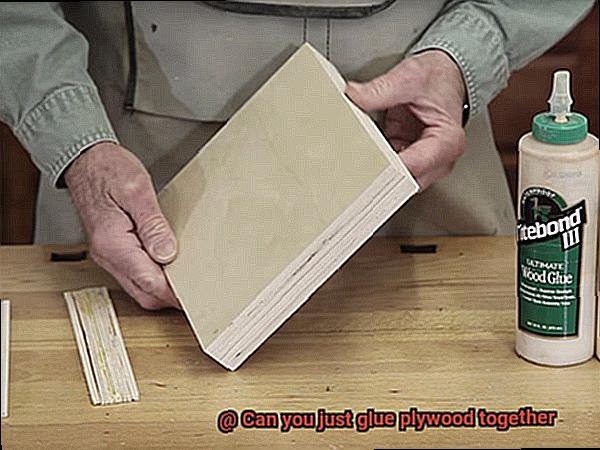

Firstly, the type of glue you choose is crucial in determining the strength and durability of the glued plywood. Common options include PVA glue, epoxy, and polyurethane glue. PVA glue, also known as wood glue, provides a strong bond but is not suitable for outdoor or moisture-exposed areas. Epoxy offers excellent bonding strength and resistance to moisture and temperature changes, making it ideal for marine applications. Polyurethane glue expands as it cures, filling gaps and creating a strong bond.

Surface preparation is another important factor to consider. Before gluing plywood together, ensure the surfaces are clean, dry, and free from contaminants that may affect bonding. Lightly sanding the surfaces can enhance adhesion.

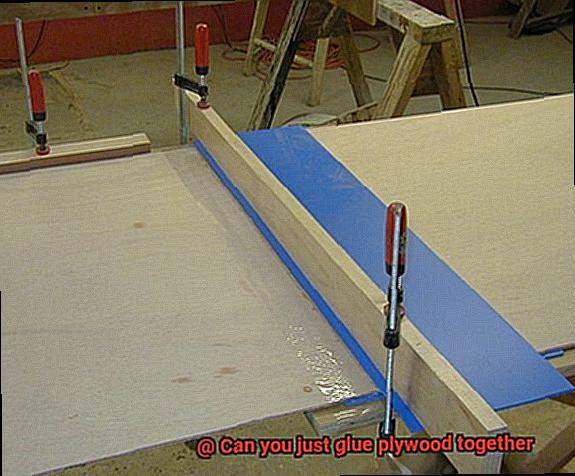

Proper clamping is essential to ensure even pressure distribution and prevent warping or gaps between the sheets. Position clamps at regular intervals along the glued joint and tighten sufficiently without causing excessive squeeze-out of the glue.

While gluing plywood together can be effective, additional reinforcement may be necessary in certain applications. Structural or load-bearing projects often require screws or nails for extra strength and stability.

Benefits of Using Glue for Joining Plywood

When it comes to joining plywood, glue is the unsung hero that holds it all together. This adhesive wonder provides a plethora of benefits that can elevate your woodworking projects to new heights. Let’s explore why glue is the ultimate solution for plywood joinery.

First and foremost, let’s talk about strength. When plywood is glued together, the bond created is incredibly strong and durable. In fact, it can be as robust as or even stronger than the wood itself. Say goodbye to wobbly joints and hello to stability and peace of mind.

The next benefit is the elimination of nails or screws. With glue, there’s no need to dig through a rusty old toolbox or worry about visible hardware sticking out like a sore thumb. Glued joints create a seamless finish that looks professional and polished – perfect for impressing your friends and family.

Flexibility is another fantastic advantage of using glue for plywood joinery. Unlike mechanical fasteners, glue allows for greater design freedom. You can create intricate shapes and curves without any limitations. Let your imagination run wild and bring those unique ideas to life.

Gluing plywood also reduces the risk of splitting or damaging the wood. We all know how frustrating it can be when a nail causes a split near the edge. With glue, that problem disappears. Your plywood will remain intact and structurally sound, giving you peace of mind and saving you countless headaches.

But wait, there’s more. Glued joints distribute stress evenly across the surface, making them incredibly strong and reliable. That means your creations can withstand pressure without breaking a sweat.

Moisture and humidity can wreak havoc on plywood, but not when you use glue for joinery. Glue creates a watertight seal that keeps water out and protects your plywood from damage. Whether you’re building outdoor furniture or kitchen cabinets, glued joints will keep your projects safe and sound.

Now let’s talk budget. Gluing plywood is a cost-effective option. There’s no need for fancy tools or expensive hardware – all you need is the right adhesive. Save some cash while still achieving professional results.

And here’s a fun fact: glued joints are reversible. Unlike nails or screws that can cause irreversible damage, glued joints can be easily disassembled when needed. It’s like a woodworking magic trick.

Last but not least, glue provides insulation properties. Say goodbye to unwanted heat or sound transfer between plywood pieces. Glued joints act as a barrier, keeping your projects cozy and quiet.

Types of Glue for Joining Plywood

Choosing the right glue for joining plywood is essential to ensure strong and durable joints in woodworking projects. With a variety of options available, it can be overwhelming to determine which glue is best suited for your specific needs. In this guide, we will explore the different types of glue commonly used for joining plywood, discuss their advantages and disadvantages, and provide helpful tips on how to use them effectively.

Wood Glue (PVA Glue):

Wood glue, also known as carpenter’s glue or PVA glue, is a popular choice for joining plywood. It is easy to use, readily available, and forms a strong bond when it dries. However, wood glue is not as resistant to moisture as some other adhesives, so it may not be suitable for projects exposed to water or high humidity.

To use wood glue effectively, apply an even layer on both surfaces to be joined and use clamps to hold them together until the glue dries completely. This will ensure a tight and secure bond.

Epoxy Glue:

Epoxy is a two-part adhesive that consists of a resin and a hardener. It offers exceptional strength and durability, making it ideal for heavy-load applications or outdoor projects exposed to harsh conditions. However, epoxy can be more expensive than other glues and requires careful mixing and application.

To achieve optimal results with epoxy glue, follow the manufacturer’s instructions for mixing ratios and curing times. Proper mixing ensures a strong bond, while proper application guarantees maximum strength and durability.

Polyurethane Glue (Gorilla Glue):

Polyurethane glue expands as it cures, creating a strong bond and filling gaps. It is waterproof and provides good resistance to heat and chemicals. However, polyurethane glue can be messy to work with and requires clamping during the curing process.

When using polyurethane glue, apply a thin layer on both surfaces, dampen one side with water, and clamp the pieces together until the glue cures. This technique ensures a secure bond and prevents any excess glue from seeping out.

Contact Cement:

Contact cement is commonly used for laminating plywood surfaces together. It provides an instant bond and does not require clamping. However, contact cement may not be as strong as other glues and may not be suitable for load-bearing applications.

To use contact cement effectively, apply a thin layer on both surfaces, allow it to dry until tacky, and firmly press the surfaces together. The instant bond makes it crucial to align the pieces correctly before pressing them together.

Additional Reinforcement Methods for Joining Plywood

Glue is the tried and true method for joining plywood, but there are additional reinforcement techniques that can take the strength and stability of these joints to new levels. In this comprehensive guide, we will delve into various methods beyond glue that can be employed to reinforce plywood joints, exploring their unique benefits and applications.

Mechanical Fasteners:

Mechanical fasteners, such as screws or nails, when combined with glue, offer an extra layer of reinforcement to plywood joints. By strategically placing these fasteners, one can maximize their effectiveness and enhance the overall strength and stability of the joint. It is crucial to select appropriately sized and positioned fasteners for optimal results.

Dowels:

Dowels are wooden rods that are inserted into pre-drilled holes in the plywood pieces being joined. By incorporating dowels with glue, the joint gains additional strength and becomes more resistant to separation under stress. This combination ensures a robust bond that withstands heavy loads.

Splines:

Ideal for joining plywood at right angles, splines are thin strips of wood inserted into grooves cut into the edges of the plywood pieces being joined. Splines significantly reinforce the joint, preventing flexing or breakage. This method finds particular utility in constructing cabinets or boxes where strength and stability are paramount.

Biscuit Joints:

Biscuit joints involve using small oval-shaped wooden biscuits inserted into slots cut into the plywood pieces being joined. These biscuits are coated with glue, allowing for secure bonding when the pieces are clamped together. Renowned for their strength and inconspicuousness, biscuit joints are popular in cabinetry and furniture making.

Reinforcing Plates:

In applications demanding exceptional strength, reinforcing plates made of metal or sturdy plastic can be incorporated alongside glue. These plates are affixed to the joint’s surface using screws or bolts, evenly distributing stress and minimizing the risk of failure. Reinforcing plates provide a robust solution for heavy-duty projects.

Factors Affecting the Strength and Durability of Glued Plywood Joints

When it comes to creating strong and durable plywood joints, glue is the unsung hero. But not all glue is created equal. From the type of glue used to the surface preparation, clamping pressure, curing time, environmental factors, and even the quality of plywood itself – every element plays a crucial role in determining the strength and durability of glued plywood joints. Let’s dive into these factors and unlock the secrets to achieving plywood joints that can withstand the test of time.

Type of Glue:

The choice of glue can make or break the strength of your plywood joint. Polyvinyl acetate (PVA), epoxy, urea-formaldehyde (UF), and phenol-formaldehyde (PF) are commonly used types of glue. Each has its own properties that influence bonding strength. Epoxy glue, known for its high strength and moisture resistance, provides a reliable option for projects exposed to water or humidity. On the other hand, PVA glue is popular for general woodworking projects due to its affordability and ease of use.

Surface Preparation:

To ensure a strong bond, proper surface preparation is vital. Clean, dry surfaces free from contaminants like dust or grease are essential. Sanding the surfaces creates a rough texture that allows glue to penetrate deeper into wood fibers, enhancing adhesion.

Clamping Pressure:

Applying adequate and evenly distributed clamping pressure during curing is crucial for strong joints. Insufficient pressure leads to poor adhesion, while excessive pressure can weaken bonds by squeezing out excess glue. A balance must be struck to achieve optimal results.

Curing Time:

Patience is a virtue when it comes to achieving maximum strength in plywood joints. Curing time varies based on glue type and environmental conditions. Following manufacturer instructions ensures the glue fully sets before subjecting joints to stress or load. Rushing this step can compromise the overall strength and durability of the joint.

Environmental Factors:

The environment in which plywood joints are exposed can impact their strength and durability. Moisture, temperature fluctuations, and UV radiation can weaken adhesive bonds over time. Choosing a glue suitable for the intended application and environmental conditions is essential. For outdoor projects, opt for waterproof or weather-resistant glues to ensure long-lasting performance.

Quality of Plywood:

Even the best glue cannot compensate for poor quality plywood. Plywood with voids or gaps between layers creates weak spots in joints. Opting for high-quality plywood with minimal defects ensures optimal results. Investing in good plywood is crucial for achieving strong and durable glued plywood joints.

lxGBflrWeN8″ >

Also Read: How To Glue Plywood Together?

Conclusion

In conclusion, the act of gluing plywood together is not just a casual affair—it requires careful consideration and attention to detail. Before embarking on this adhesive adventure, several factors must be taken into account.

The choice of glue is paramount in determining the strength and longevity of your plywood creation. Wood glue, epoxy, polyurethane glue, and construction adhesive are all contenders in this sticky game, each with its own unique properties and applications. To ensure success, select the appropriate glue based on the intended use of your final masterpiece.

But it doesn’t stop there—surface preparation plays a crucial role in achieving a solid bond. Cleanliness is key; surfaces must be free from any contaminants that could hinder adhesion. A touch of sanding can also work wonders in enhancing the connection between plies.

Proper clamping is an absolute must for even pressure distribution and to prevent any unsightly warping or gaps between sheets. Follow the instructions provided by the manufacturer for curing times, applying just enough pressure without causing excessive squeeze-out of glue.

While gluing plywood together can yield impressive results, certain applications may require additional reinforcement methods. Mechanical fasteners like screws or nails can provide an extra dose of strength and stability to joints. And for those seeking ultimate precision and alignment, dowels or biscuits inserted into pre-cut holes within the plywood layers will do just the trick.

Ultimately, glue serves as the backbone of plywood bonding—providing strength, durability, and resistance against environmental elements. By carefully selecting the right adhesive for your project and diligently following proper surface preparation and clamping techniques, you can transform simple sheets of plywood into breathtaking masterpieces.