They’re like the annoying cousin that shows up uninvited and wreaks havoc on your home. From soggy carpets to sky-high water bills, these sneaky leaks can turn your peaceful abode into a watery disaster zone. That’s where JB Weld comes in, folks – the superhero of adhesives, ready to save the day. But does it have what it takes to banish those pesky water leaks for good?

In this blog post, we’re diving deep into the world of JB Weld to see if it’s a true water leak sealing wizard or just another overhyped product. We’ll lay out all the facts so you can make an informed decision when faced with that stubborn dripping faucet or mysterious puddle around your pipes. So grab a cuppa, get comfy, and let’s find out if JB Weld really is the ultimate go-to solution for sealing water leaks.

What is JB Weld?

Contents

- 1 What is JB Weld?

- 2 Does JB Weld Seal Water Leaks?

- 3 Advantages of Using JB Weld for Sealing Water Leaks

- 4 Disadvantages of Using JB Weld for Sealing Water Leaks

- 5 How to Use JB Weld for Sealing Water Leaks

- 6 Tips for Applying JB Weld to Seal Water Leaks

- 7 When Not to Use JB Weld for Sealing Water Leaks

- 8 Alternatives to Using JB Weld for Sealing Water Leaks

- 9 Conclusion

When it comes to repairing and bonding, one name reigns supreme – JB Weld. This exceptional epoxy adhesive has earned a well-deserved reputation for its remarkable strength, versatility, and ability to tackle a vast array of materials. In this article, we will delve into the remarkable features and uses of JB Weld, unveiling why it has become the go-to solution for all your repair needs.

Features of JB Weld:

- Unmatched Strength: Once fully cured, JB Weld forms a bond that rivals the strength of steel. Its robust nature enables it to handle heavy-duty repairs and endure immense pressure.

- Incredible Versatility: Whether you’re working with metal, wood, plastic, ceramic, or even glass surfaces, JB Weld is your ultimate adhesive companion. It flawlessly fixes broken tools, patches up leaky pipes, and bonds different materials together with ease.

- Temperature Resistance: From chilling lows of -67°F (-55°C) to scorching highs of 500°F (260°C), JB Weld fearlessly withstands extreme temperatures. It won’t crack or weaken under the harshest heat or cold conditions.

- Waterproof Wonder: JB Weld creates a waterproof seal that can triumphantly withstand exposure to moisture. Say goodbye to those pesky leaks in pipes, tanks, and radiators.

- Effortless Application: Mixing the resin and hardener in equal parts is a breeze. Simply follow the instructions, apply the adhesive to the surface in need, and let it cure. It’s as simple as that.

Uses of JB Weld:

- Automotive Repairs: From fixing cracked engine blocks to repairing exhaust systems, JB Weld has become a trusted companion for automotive enthusiasts and professionals alike.

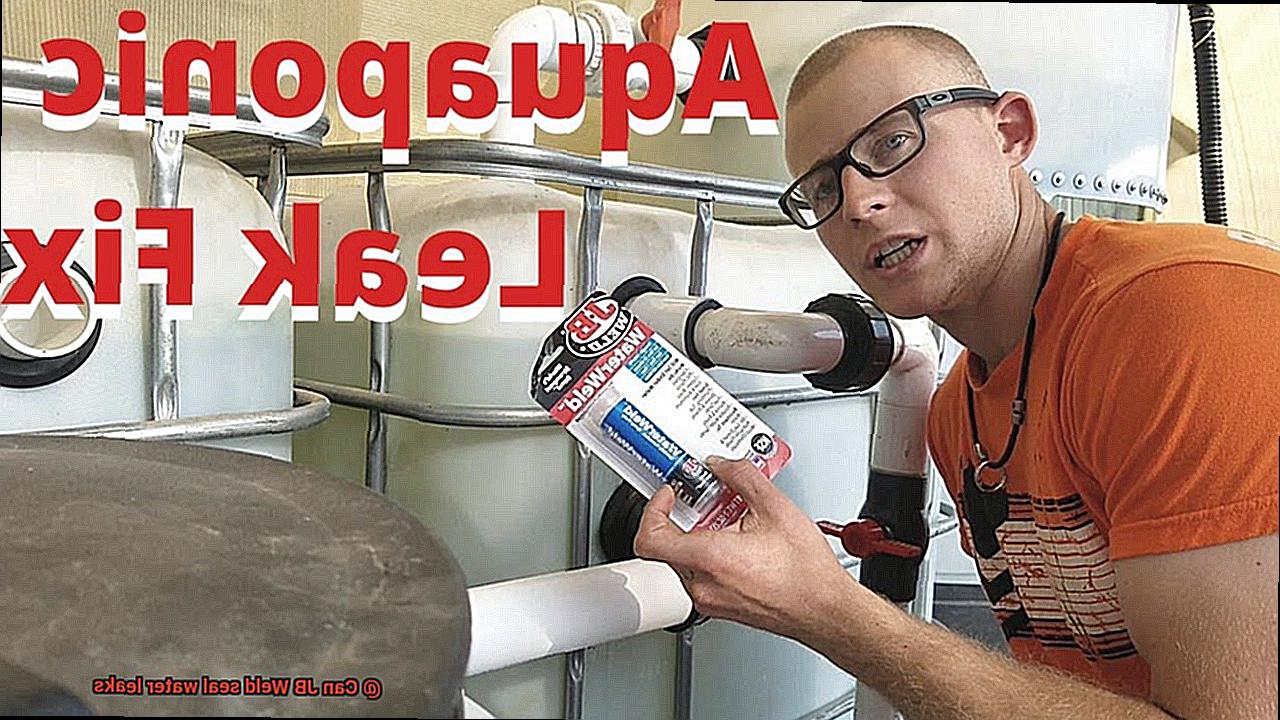

- Plumbing Fixes: Need to seal a leaky pipe? Look no further than JB Weld. Its water-resistant properties make it perfect for temporary fixes until you can seek professional assistance.

- Construction Projects: Whether you’re embarking on a DIY endeavor or undertaking a major construction job, JB Weld is your ultimate ally. It assists in bonding and repairing materials like wood, metal, and plastic with precision.

- Household Repairs: Broken ceramics, damaged furniture, or even a cracked shower tile? JB Weld to the rescue. It effortlessly saves the day, making your repairs seamless and durable.

Does JB Weld Seal Water Leaks?

If you’re tired of dealing with pesky water leaks in your pipes, tanks, or other water-containing structures, you’re not alone. Many people are looking for the best way to seal these leaks and prevent any further damage. One product that often comes up in these discussions is JB Weld, a popular epoxy adhesive known for its exceptional strength and versatility. But does JB Weld really seal water leaks?

The answer, my friends, is both yes and no. Let me explain.

JB Weld is not specifically formulated as a waterproofing product, but rather as a strong adhesive. However, don’t let that discourage you just yet. Due to its high strength and durability, JB Weld can still provide a temporary or even long-term seal for certain types of water leaks.

First, let’s talk about the factors that determine the effectiveness of JB Weld in sealing water leaks. The size and location of the leak play a significant role. For small cracks or holes in metal surfaces, JB Weld can often provide a reliable and long-lasting seal. Its ability to bond with various materials makes it a versatile option for many repairs.

However, for larger or more complex leaks, additional measures may be necessary. It’s crucial to thoroughly clean and prepare the surface before applying JB Weld to ensure proper adhesion. This means removing any dirt, grease, or rust that might interfere with the bond. Remember, preparation is key.

In some cases, reinforcing the repaired area with fiberglass or using specialized waterproofing products alongside JB Weld may be necessary. These additional measures can help enhance the seal and provide added protection against water damage.

It’s worth noting that JB Weld may not adhere well to certain plastics or rubber materials. So if you’re dealing with leaks in these types of materials, it’s wise to consult with a professional or consider alternative solutions specifically designed for those materials.

In conclusion, while JB Weld can be effective in sealing water leaks in certain situations, it’s essential to assess the specific circumstances and consider other factors before relying solely on this adhesive. Remember to clean and prepare the surface, evaluate the size and location of the leak, and consider additional measures if needed.

Advantages of Using JB Weld for Sealing Water Leaks

This incredible adhesive has the power to seal water leaks and provide a range of advantages that make it the go-to solution for DIY enthusiasts and professionals alike.

First and foremost, let’s talk about strength. JB Weld creates a bond that can withstand high pressure and temperature variations, making it perfect for sealing water leaks in various applications. Whether it’s a plumbing fixture, an automotive part, or even a boat hull, JB Weld can handle it all. Say goodbye to those worries about leaks causing damage or ruining your day.

Versatility is another major advantage of JB Weld. This adhesive can seal different types of leaks, from small cracks in pipes to holes in radiators or leaking tanks. It bonds with a variety of materials like metal, plastic, wood, and even concrete. So no matter what you’re dealing with, JB Weld has got your back.

Now let’s talk about ease of application. Using JB Weld is a breeze. Just mix equal parts of the resin and hardener, apply it to the area needing repair, and let it cure. It’s simple enough for anyone with basic DIY skills to tackle those leaks themselves. No need to call in the professionals or spend a fortune on repairs.

Once fully cured, JB Weld exhibits excellent resistance to water and various chemicals commonly found in plumbing systems or automotive environments. This means that once you’ve sealed a water leak with JB Weld, it’s going to stay sealed, even when exposed to moisture or corrosive substances. Talk about long-lasting results.

And let’s not forget about cost-effectiveness. Compared to other methods of sealing water leaks, JB Weld is an affordable option. A little goes a long way, so you won’t need to use excessive amounts of the product. By fixing leaks promptly with JB Weld, you can prevent potential damage that could lead to more extensive and expensive repairs in the future.

So there you have it, folks. The advantages of using JB Weld for sealing water leaks are clear: a strong and durable bond, versatility in sealing different types of leaks, easy application, resistance to water and chemicals, and cost-effectiveness. With JB Weld by your side, you can conquer those water leaks and prevent further damage.

Disadvantages of Using JB Weld for Sealing Water Leaks

JB Weld is often hailed as the superhero adhesive for sealing water leaks, but it’s important to understand its limitations and potential drawbacks. In this article, we’ll explore the disadvantages of using JB Weld for sealing water leaks, ensuring you have all the information needed to make an informed decision.

Limited Flexibility:

Once JB Weld cures, it becomes hard and rigid, lacking the flexibility needed to accommodate movement or expansion in repaired materials. This rigidity can lead to cracks or breaks in the bond, resulting in water leakage.

Limited Resistance to Chemicals and Solvents:

While JB Weld is known for its strength and durability, it may not hold up well against exposure to harsh chemicals or solvents commonly found in water systems. Over time, exposure to these substances can deteriorate the bond created by JB Weld, leading to recurring leaks or further damage.

Compatibility with Different Materials:

JB Weld is primarily designed for bonding metal surfaces and may have varying effectiveness when used on non-metal materials like plastic or ceramics. Ensuring compatibility with the specific material being repaired is crucial to avoid poor adhesion and ineffective sealing.

Challenging Application Process:

The application process of JB Weld requires thorough surface preparation, including cleaning and roughening up the surface for better adhesion. This can be time-consuming and may require specialized tools or equipment. Additionally, JB Weld has a significant curing time of at least 24 hours, which can be inconvenient in urgent situations.

Difficulty in Removal:

Once fully cured, JB Weld forms a strong bond that can be challenging to break if a repair needs to be undone or modified in the future. Removing JB Weld can be laborious and may cause additional damage or complications during the repair process.

How to Use JB Weld for Sealing Water Leaks

Today, we’re diving into the world of fixing water leaks like a pro by harnessing the power of everyone’s favorite superhero adhesive, JB Weld. Get ready to become a hero in your own home as we embark on this exciting journey.

First and foremost, let’s introduce our star player, JB Weld. Renowned for its exceptional bonding strength and versatility, this adhesive is the equivalent of having a superhero in a tube. Whether it’s automotive repairs or plumbing fixes, JB Weld can handle it all – including sealing water leaks. Prepare to be amazed.

Now, before we can save the day, we need to locate the source of the leak. Keep an eye out for water stains or follow the drip trail to pinpoint the trouble spot. Once you’ve identified it, it’s time to get down and dirty.

Arm yourself with cleaning supplies and give the area a thorough scrub. We want that surface squeaky clean, free from any dirt or grease that could hinder our mighty JB Weld bond. A little soap or rubbing alcohol will work wonders, ensuring our hero sticks like glue.

But wait, there’s more. To give JB Weld an ironclad grip, we need to roughen up the surface with sandpaper or a wire brush. Think of this step as priming our superhero for battle – we want that surface rough and ready for action.

Now comes the thrilling part – mixing our two-part epoxy adhesive. Follow the instructions on the packaging diligently, my friends. We are creating an extraordinary bond here, so precision is key. Trust me; this step is vital for success.

Once your JB Weld is thoroughly mixed, it’s time to apply it like a true superhero saving the day. Use a putty knife or a small brush to spread this magic potion evenly over the leaky area. Ensure you cover every nook and cranny, creating a protective shield against water invaders.

However, our journey has only just begun. Exercise patience, my fellow heroes, as we must allow our JB Weld to cure for 24 hours before exposing it to water or moisture. During this time, it grows in strength and establishes an impenetrable fortress against leaks. Remember, good things come to those who wait.

After the curing period is over, it’s time to inspect our handiwork. Check for any remaining leaks or signs of water seepage where it shouldn’t be. If you spot any trouble, fear not – simply apply another layer of JB Weld and repeat the curing process. Our superhero can handle it.

However, keep in mind that even superheroes have their limits. JB Weld may not be suitable for all types of leaks or materials. If you’re dealing with a severe leak or unsure about using JB Weld, don’t hesitate to call in the professionals. Sometimes even heroes need backup.

In conclusion, using JB Weld to seal water leaks is like having a superhero by your side. With careful preparation, precise mixing, and a dash of patience, you can rescue your home from pesky leaks. Remember to assess the severity of the leak and seek professional advice if needed.

Tips for Applying JB Weld to Seal Water Leaks

Water leaks can be a real headache, but fear not. With the right tools and techniques, you can take matters into your own hands and fix those pesky leaks. One popular option for sealing water leaks is using JB Weld, a versatile epoxy adhesive known for its strength and durability. In this guide, we’ll walk you through the steps of applying JB Weld to seal water leaks effectively.

Step 1: Prepare the Surface

Before applying JB Weld, it’s crucial to clean the surface thoroughly. Use a degreaser or strong soap to remove any dirt, oil, or grease that could hinder adhesion. Once clean, make sure to dry the surface completely. Any moisture or water residue may compromise the effectiveness of JB Weld.

Step 2: Mix the JB Weld

JB Weld comes in two tubes – one with epoxy resin and the other with a hardener. Follow the manufacturer’s instructions to mix the two components in the correct ratio. Proper mixing ensures optimal curing and maximum strength.

Step 3: Apply JB Weld Evenly

Using a disposable applicator or a small putty knife, apply a thin and even layer of mixed JB Weld to the area where the water leak needs sealing. Spread it evenly across the entire surface, ensuring complete coverage.

Step 4: Press Firmly and Hold

After applying JB Weld, press firmly on the repaired area to ensure good contact between the epoxy and the surface. Hold it in place for a few minutes to promote better adhesion and prevent displacement during curing.

Step 5: Allow Sufficient Curing Time

JB Weld requires time to cure properly and reach its maximum strength. Refer to the product instructions for specific curing times, which may vary depending on temperature and humidity levels. It’s essential to allow enough time for complete curing before exposing the repaired area to water or stressors.

Step 6: Test for Leaks

Once JB Weld has cured, test for leaks before considering the repair job complete. Fill the repaired area with water or apply pressure to the system and check for any signs of leakage. If leaks persist, additional layers of JB Weld may be required for a watertight seal.

When Not to Use JB Weld for Sealing Water Leaks

When it comes to sealing water leaks, JB Weld is a popular choice. However, there are certain situations where using JB Weld may not be the best option. Here are some scenarios to consider:

- High-pressure systems: If you’re dealing with a water leak in a system that operates under high pressure, JB Weld may not be able to handle the force. It’s important to use products specifically designed for high-pressure applications to avoid catastrophic leaks.

- Large or structural leaks: While JB Weld can work wonders for small cracks or holes, it may not be effective for big leaks. JB Weld simply isn’t designed to handle significant amounts of water flow. For major leaks, it’s best to call in professionals or explore other repair options.

- Incompatible materials: JB Weld may have trouble bonding with flexible or rubber-based materials. If your leak is happening in one of these materials, it’s best to seek out a product that is specifically formulated for bonding and sealing them.

- Constant exposure to water or moisture: Although JB Weld may initially do the job, over time, water can break down the epoxy bond and leave you wet and miserable. If your leak is in an area that’s constantly getting soaked, consider alternative solutions that are more resistant to water and moisture damage.

- Extreme temperature conditions: Temperature can affect the performance of JB Weld, causing it to become brittle or lose its adhesive properties. If you’re dealing with scorching hot or freezing cold conditions, it’s important to choose a product that can withstand the specific temperature range of your application.

Alternatives to Using JB Weld for Sealing Water Leaks

However, there are alternative options available that can offer unique benefits and address specific challenges that JB Weld may not be able to handle. Let’s explore some of these alternatives and discover their superhero-like qualities.

One alternative to JB Weld is epoxy putty. This trusty sidekick shares a similar composition and application process, but different brands may offer varying properties and strengths. For example, Loctite and PC Products are popular brands known for their high temperature resistance and excellent adhesion to various materials. So, if you’re dealing with extreme temperatures or need strong adhesion, epoxy putty might be the hero you’re looking for.

Another hero in the battle against water leaks is silicone sealant. This flexible and waterproof adhesive comes in various forms, such as tubes or liquid formulations, and can be applied using a caulking gun or brush. Silicone sealant is known for its ability to adhere to different surfaces and its exceptional flexibility, making it a versatile option for sealing water leaks.

If your leak resides in the realm of plumbing systems, plumber’s tape or pipe repair kits might be the heroes you need. These specialized solutions are designed specifically for fixing leaks in plumbing pipes and fittings. They provide a quick and effective way to address common plumbing leaks, acting as superheroes ready to swoop in and save the day.

Before you embark on your leak-sealing adventure, remember that each alternative has its own strengths and weaknesses. It’s important to choose the right one based on your specific needs. If you’re unsure about which option to choose or if the leak seems too overwhelming for a DIY fix, don’t hesitate to call in a professional for some backup.

dJRbcs16qao” >

Conclusion

In conclusion, JB Weld is an incredibly effective solution for sealing water leaks.

Its unique formulation and high-strength bond make it the go-to choice for DIY enthusiasts and professionals alike. Whether you’re dealing with a small crack or a larger hole, JB Weld can provide a reliable and long-lasting fix.

With its exceptional resistance to water pressure and temperature fluctuations, you can trust JB Weld to keep those leaks sealed tight.