Title: Crafting a Cutting Board: Is Regular Wood Glue Up to the Challenge?

Introduction:

Contents

- 1 What is Regular Wood Glue?

- 2 Why Is Regular Wood Glue Not Recommended for Cutting Boards?

- 3 Potential Toxicity Concerns of Regular Wood Glue

- 4 Inadequate Strength of Regular Wood Glue

- 5 Lack of Moisture Resistance with Regular Wood Glue

- 6 Specialized Adhesives for Cutting Board Construction

- 7 Waterproof and Food-Safe Epoxy as an Alternative to Regular Wood Glue

- 8 Established Woodworking Practices When Constructing a Cutting Board

- 9 Conclusion

Hey there, DIY enthusiasts. If you’re diving into the world of cutting board construction, you might be wondering if regular wood glue is up to snuff. I mean, it’s easy to find and cheaper than specialized adhesives. So, can you trust regular wood glue for your cutting board creation? Let’s roll up our sleeves and dig into the pros and cons while keeping safety in mind.

Pros:

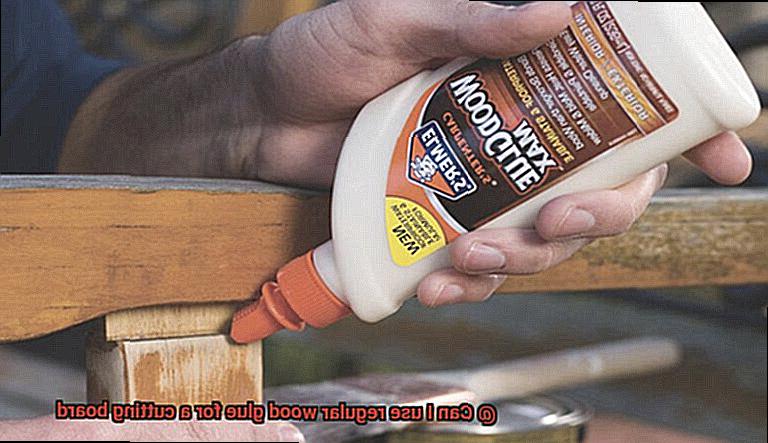

Regular wood glue, that nifty adhesive you can snag at your local hardware store, packs a punch when it comes to bonding wooden surfaces. It’s designed specifically for this purpose and offers a sturdy hold that can withstand all the slicing and dicing action. Plus, it dries clear as day, ensuring your cutting board shines with seamless beauty.

Cons:

Now let’s talk about the not-so-great parts. While regular wood glue generally gets the job done, it does have its downsides for cutting boards. First off, it might not be waterproof. That means excessive moisture could cause warping or damage over time – definitely not what we want in our trusty kitchen companion. Secondly, some wood glues contain chemicals that aren’t exactly food-friendly. To avoid any unwanted surprises, make sure you choose a food-safe glue labeled as non-toxic and suitable for kitchen use.

Safety Considerations:

Safety first. When making your cutting board dreams come true with wood glue, always opt for a food-grade adhesive that meets FDA regulations. These glues are specially formulated to be safe for direct contact with food – no worries about any funky substances seeping into your delicious meal prep. And hey, don’t forget to read those instructions like a pro before diving in. Also, work in a well-ventilated area and gear up with protective equipment just to be on the safe side.

In conclusion, regular wood glue can totally rock your cutting board project, delivering the strength and clarity you desire. Just remember to choose a food-safe, waterproof option and follow all safety guidelines for a sturdy, long-lasting, and secure cutting board. So go ahead and embrace the convenience of regular wood glue, but keep its limitations in mind as you embark on your next cutting board adventure.

What is Regular Wood Glue?

Woodworking and DIY projects are growing in popularity as more people discover the joy of creating beautiful and functional pieces with their own hands. Regular wood glue, also known as yellow glue or carpenter’s glue, is an essential tool for every woodworker and DIY enthusiast. In this blog post, we will explore the properties that make regular wood glue so popular and why it is a must-have for any woodworking project.

Strong bonding properties:

Regular wood glue is a specially formulated adhesive designed to bond wood surfaces effectively. Its unique combination of polymers, resins, and additives creates a powerful bond that penetrates the pores of the wood, resulting in a sturdy connection. This ensures that your woodworking projects remain strong and durable over time.

Ease of use:

Regular wood glue is water-based, making it incredibly easy to work with. Its liquid form allows for smooth application, ensuring even coverage on the surfaces being bonded. Additionally, it has a relatively fast drying time, allowing you to continue working on your project without prolonged waiting periods.

Water resistance:

Once fully cured, most regular wood glues become water-resistant or even waterproof. This makes them ideal for indoor applications where occasional exposure to moisture is expected, such as furniture or decorative items. However, it’s important to note that they may not perform well in extreme moisture or outdoor conditions.

Availability and versatility:

Regular wood glue is readily available in hardware stores, home improvement centers, and online retailers. It comes in various sizes to suit different project needs, from small bottles for occasional use to larger containers for professional applications. Whether you’re building furniture, repairing wooden structures, or crafting small decorative items, regular wood glue is versatile enough to handle it all.

Why Is Regular Wood Glue Not Recommended for Cutting Boards?

Today, we embark on a crucial journey into the realm of cutting board construction. While regular wood glue may be your trusted ally in most woodworking projects, it is essential to understand why it falls short when it comes to cutting boards. So, grab your favorite beverage, and let’s explore the perils of using regular wood glue for this specialized task.

Moisture Resistance:

Cutting boards are exposed to constant moisture, heat, and various food ingredients. Unfortunately, regular wood glue is ill-equipped to handle these elements. Over time, this type of glue may soften or break down, jeopardizing the structural integrity of your cherished cutting board.

Potential Toxicity:

Regular wood glue often contains chemicals that are not safe for consumption. When in contact with cutting board surfaces, these chemicals can leach into your food, posing a significant health risk. By opting for food-grade adhesives, you ensure that your culinary creations remain free from potentially hazardous substances.

Strength and Durability:

Cutting boards endure substantial pressure and stress during use. Regrettably, regular wood glue may not possess the necessary strength and durability to withstand these forces. This deficiency can lead to delamination or separation of the board’s components, resulting in an unreliable and potentially unsafe kitchen tool.

Temperature Resistance:

In a bustling kitchen environment, cutting boards frequently encounter hot pots, pans, and utensils. If the glue used in construction lacks temperature resistance, it may soften or even melt under high heat. Consequently, this can cause warping or complete failure of the cutting board structure—a less-than-ideal situation while preparing a delectable meal.

Potential Toxicity Concerns of Regular Wood Glue

Regular wood glue may seem like a convenient adhesive choice for constructing a cutting board, but it comes with potential toxicity concerns that should not be overlooked. This type of glue contains chemicals such as formaldehyde, a known carcinogen. Just imagine the horror of slicing your fresh vegetables on a cutting board glued with regular wood glue, only to have those harmful chemicals leach into your food. The health risks associated with this scenario are too serious to ignore.

Formaldehyde exposure can cause respiratory and eye irritation, as well as allergic reactions in some individuals. Prolonged contact with this toxic chemical can even lead to more severe health issues like asthma and cancer. But formaldehyde isn’t the only concern when it comes to regular wood glue. It may also contain solvents and volatile organic compounds (VOCs) that contribute to indoor air pollution when released into the air during the drying process.

Another worry arises from the possibility of small particles of glue mixing with your food while using a regular wood glue-bonded cutting board. Ingesting these particles can be harmful, especially if the glue contains toxic chemicals.

To address these concerns and ensure the safety of your cutting board, it is crucial to opt for food-safe wood glues specifically formulated for kitchen items like cutting boards. These glues are made without harmful chemicals and are designed to be non-toxic when in contact with food. Look for glues labeled as “FDA-approved” or “food-grade” to ensure their safety and compliance with kitchenware standards.

If you have already used regular wood glue on your cutting board and are concerned about its potential toxicity, it is advisable to avoid using it for cutting food. Instead, reserve it for decorative purposes or non-food-related projects.

Inadequate Strength of Regular Wood Glue

When it comes to creating our own cutting boards, many of us turn to regular wood glue as a seemingly convenient option. However, using regular wood glue can lead to disastrous consequences due to its inadequate strength. In this article, we will explore the causes behind the weakness of regular wood glue and why it is not suitable for use on cutting boards.

Moisture and Washing:

Regular wood glue is simply not designed to handle the constant exposure to moisture and frequent washing that a cutting board undergoes. Over time, the adhesive properties of regular wood glue can deteriorate, causing your cutting board to fall apart. Imagine the frustration and disappointment of seeing your hard work crumble before your eyes.

Weak Bond:

Unlike specialized food-safe glues that are designed specifically for cutting boards, regular wood glue fails to create a strong bond. This can result in gaps and uneven surfaces on your cutting board, making it unstable and unsafe to use. Picture yourself trying to chop vegetables on a wobbly surface – accidents waiting to happen.

Warping and Splitting:

The inadequate strength of regular wood glue can also cause your cutting board to warp or split over time. Exposure to excessive moisture or changes in temperature weakens the bond of the glue, leading to an unsightly and unusable cutting board. Your culinary masterpiece deserves better.

Food Safety Concerns:

In addition to its weak bond, regular wood glue may not be food-safe. This means it could potentially release harmful chemicals into your food, compromising your health and safety. Specialized food-safe glues are formulated to be non-toxic and safe for contact with food – a crucial aspect when it comes to preparing meals.

Lack of Moisture Resistance with Regular Wood Glue

Before we dive in, let’s address the elephant in the room: regular wood glue. While it has its place in general woodworking projects, it simply can’t handle the task of creating a durable and moisture-resistant cutting board. So, grab your aprons and let’s explore why regular wood glue won’t cut it for your culinary creations.

The Moisture Menace:

Imagine this: you’ve just finished preparing a mouthwatering feast on your beautiful homemade cutting board. Now, it’s time for cleanup. As you wash away the remnants of your culinary adventures, water seeps into the wood, wreaking havoc on your cutting board’s integrity.

Regular wood glue, or PVA glue, is ill-equipped to handle this constant exposure to moisture. Its adhesive properties weaken when faced with water, leading to joints that separate or break apart over time. Nobody wants their hard work falling apart like a souffle gone wrong.

Cleaning Catastrophes:

Regular wood glue crumbles under the pressure of cleaning agents too. The harsh chemicals found in these cleaners further deteriorate the already vulnerable bond created by regular wood glue. This leaves your cutting board even more susceptible to moisture damage and compromises its ability to withstand repeated washing and sanitization.

Enter the Heroes: Waterproof Wood Glue and Epoxy Resins:

There is a light at the end of this moisture-filled tunnel. FDA-approved waterproof wood glues and epoxy resins are here to save the day. These alternative adhesives are specifically formulated for waterproof and food-safe applications, ensuring they can withstand prolonged exposure to moisture without compromising strength or adhesive properties.

Waterproof wood glues offer a strong bond that can stand up to repeated water exposure. They resist water and maintain their adhesive properties, ensuring your cutting board remains intact and reliable for years to come.

On the other hand, epoxy resins provide another excellent option for creating a moisture-resistant bond in cutting board construction. With their two-component formula, they create a durable and waterproof bond that can handle regular cleaning and exposure to moisture. Say goodbye to warped and unsightly cutting boards.

Safety First:

When using alternative adhesives for cutting board construction, always follow the manufacturer’s instructions and ensure they are food-safe and approved for direct contact with food. After all, we want to savor our delicious creations without any health concerns.

Specialized Adhesives for Cutting Board Construction

Constructing a cutting board requires more than just skillful woodworking techniques. Choosing the right adhesive is crucial to ensure the longevity and durability of the finished product. Regular wood glue simply won’t cut it, as it lacks the necessary water resistance and strength required for a cutting board. In this article, we will explore the importance of using specialized adhesives for cutting board construction and highlight some of the advantages they offer.

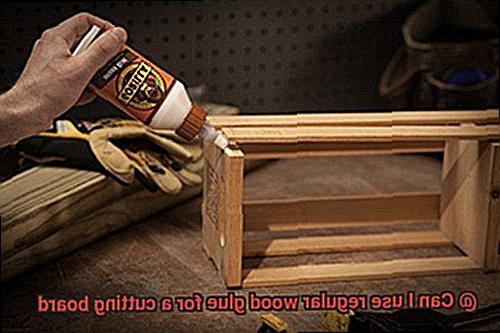

Epoxy Resin: The Mighty Bonding Agent

Epoxy resin stands as a mighty bonding agent favored by woodworkers for its exceptional strength and water resistance properties. It forms an unyielding bond between wood pieces, ensuring that your cutting board stays intact even with regular use and cleaning. With epoxy resin, your cutting board will withstand the test of time, enduring the demands of everyday kitchen tasks.

Food-Grade Polyurethane Glue: Safe and Reliable

For those seeking a safe and reliable adhesive option, food-grade polyurethane glue is an excellent choice. This non-toxic adhesive is expressly designed for direct contact with food, making it ideal for kitchen utensils like cutting boards. It provides a robust bond between wood pieces while offering exceptional resistance against moisture and temperature changes. With food-grade polyurethane glue, you can confidently prepare meals on a cutting board that is both safe and dependable.

Say No to Regular Wood Glues

Regular wood glues simply don’t have what it takes to withstand the rigors of cutting board construction. They lack the essential water-resistant properties that specialized adhesives offer. Over time, regular wood glues may degrade due to continuous exposure to moisture, compromising the structural integrity of your cutting board. To ensure the longevity and durability of your creation, it’s best to steer clear of regular wood glues when constructing a cutting board.

Waterproof and Food-Safe Epoxy as an Alternative to Regular Wood Glue

When it comes to constructing cutting boards, regular wood glue simply won’t suffice. That’s where the wonders of waterproof and food-safe epoxy come into play. This alternative adhesive offers a multitude of benefits that make it the perfect choice for your cutting board project.

First and foremost, let’s discuss strength. Waterproof epoxy is specifically designed to resist water penetration, creating a protective barrier that prevents warping, cracking, and the growth of bacteria. Cutting boards are constantly exposed to moisture and food, making this resistance crucial. Regular wood glue pales in comparison in this department.

While epoxy may be slightly pricier than regular wood glue, the durability and longevity it provides make it well worth the investment. Moreover, when it comes to your health and safety, skimping on a product that will be in direct contact with your food is simply not an option.

Speaking of safety, food-safe epoxy is formulated to be non-toxic and safe for contact with food. You can rest easy knowing that your cutting board won’t release any harmful chemicals or substances when cured, ensuring that your delicious meals remain uncontaminated.

Now, let’s delve into ease of use. Applying epoxy requires proper surface preparation, including thorough cleaning and sanding to create a rough surface for better adhesion. Once mixed according to the manufacturer’s instructions, you can effortlessly spread it evenly over the cutting board’s surface using a brush or applicator. Just remember to follow the recommended curing time and temperature specified by the manufacturer for optimal results.

However, it’s important to note that working with epoxy can be slightly trickier compared to regular wood glue. Precise mixing and application are essential, as any mistakes may be difficult to correct once the epoxy has cured. Additionally, keep in mind that epoxy may alter the appearance of the wood, giving it a glossy or glass-like finish. If you’re a fan of the natural look and feel of wood, this might be a downside for you.

Established Woodworking Practices When Constructing a Cutting Board

When it comes to constructing a cutting board, following established woodworking practices is crucial to ensure durability, safety, and longevity. By adhering to these practices, you can create a cutting board that not only functions well but also withstands the test of time.

- Choose the right wood: The choice of wood is essential for a cutting board. Hardwoods such as maple, walnut, and cherry are popular choices due to their durability and resistance to moisture and bacteria. These woods are less likely to scratch or warp, providing a sturdy surface for cutting.

- Prepare the wood: Before construction, it is important to mill the boards to the desired thickness and width. This step ensures uniformity and stability in the final product. Additionally, allow the wood to acclimate to its environment for a few days. This acclimation prevents warping or splitting of the boards once assembled.

- Use the right glue: Regular wood glue is not suitable for a cutting board. Instead, opt for a high-quality waterproof or food-safe glue that can withstand moisture and frequent washing. This type of glue ensures that your cutting board remains intact even when exposed to water.

- Apply glue evenly: To achieve a strong bond between the boards, apply the glue generously and evenly on the edges before clamping them together. Be sure to wipe away any excess glue with a damp cloth before it dries, as dried glue can be difficult to remove without damaging the wood.

- Clamp properly: Proper clamping is vital to ensure a tight bond between the boards. Use clamps to hold the boards firmly in place while the glue sets. Apply even pressure across the entire surface of the cutting board to prevent gaps or unevenness.

- Remove excess glue: Once the glue has dried, remove any excess glue by scraping or sanding it off. Take care not to damage the wood surface while doing so, as it can affect the overall appearance of the cutting board.

- Allow curing time: After assembly, give the cutting board ample time to cure. Let it sit undisturbed for at least 24 hours to allow the glue to fully dry and create a strong bond. This curing period ensures stability and longevity of the cutting board.

- Regular maintenance: To prolong the lifespan of your cutting board, regular maintenance is necessary. Apply food-grade mineral oil or beeswax regularly to keep the board moisturized and protected from drying out or cracking. This simple step helps maintain the wood’s natural beauty and prevents moisture absorption.

- Follow food safety guidelines: Proper cleaning and sanitation are crucial for a cutting board used in food preparation. Clean the board thoroughly after each use, using hot soapy water or a mild bleach solution. Use separate boards for different types of food to prevent cross-contamination. If the cutting board becomes heavily worn or damaged, it should be replaced to ensure food safety.

PVpX-MI3nvc” >

Also Read: How can I attach fabric to wood? – Glue Things

Conclusion

In conclusion, using regular wood glue for a cutting board is not recommended. While it may seem convenient and cost-effective, regular wood glue is not designed to withstand the demands of a cutting board. It lacks the necessary waterproof and food-safe properties that specialized cutting board glues possess.

When it comes to something as important as a tool used in food preparation, it’s crucial to prioritize safety and durability. Regular wood glue can deteriorate over time when exposed to moisture and repeated washing, compromising the integrity of your cutting board.

Furthermore, regular wood glue may contain harmful chemicals that can leach into your food, posing health risks. Cutting board glues are specifically formulated to be non-toxic and food-safe, ensuring that your meals remain uncontaminated.

Investing in a proper cutting board glue will provide peace of mind knowing that your cutting board is built to last and safe for use with food. These specialized glues offer superior bonding strength, resistance to water damage, and compliance with health and safety regulations.

So, while regular wood glue might seem like a quick fix or an easy solution, it’s best to stick with the appropriate adhesive specifically designed for cutting boards. Your cutting board deserves the best care possible to ensure its longevity and maintain its hygienic qualities.