Got a plumbing project in the works that involves ABS pipes? Unsure which primer to use to ensure a secure connection between the pipes and fittings? You might have heard whispers about using purple primer on ABS, but is it really a viable option?

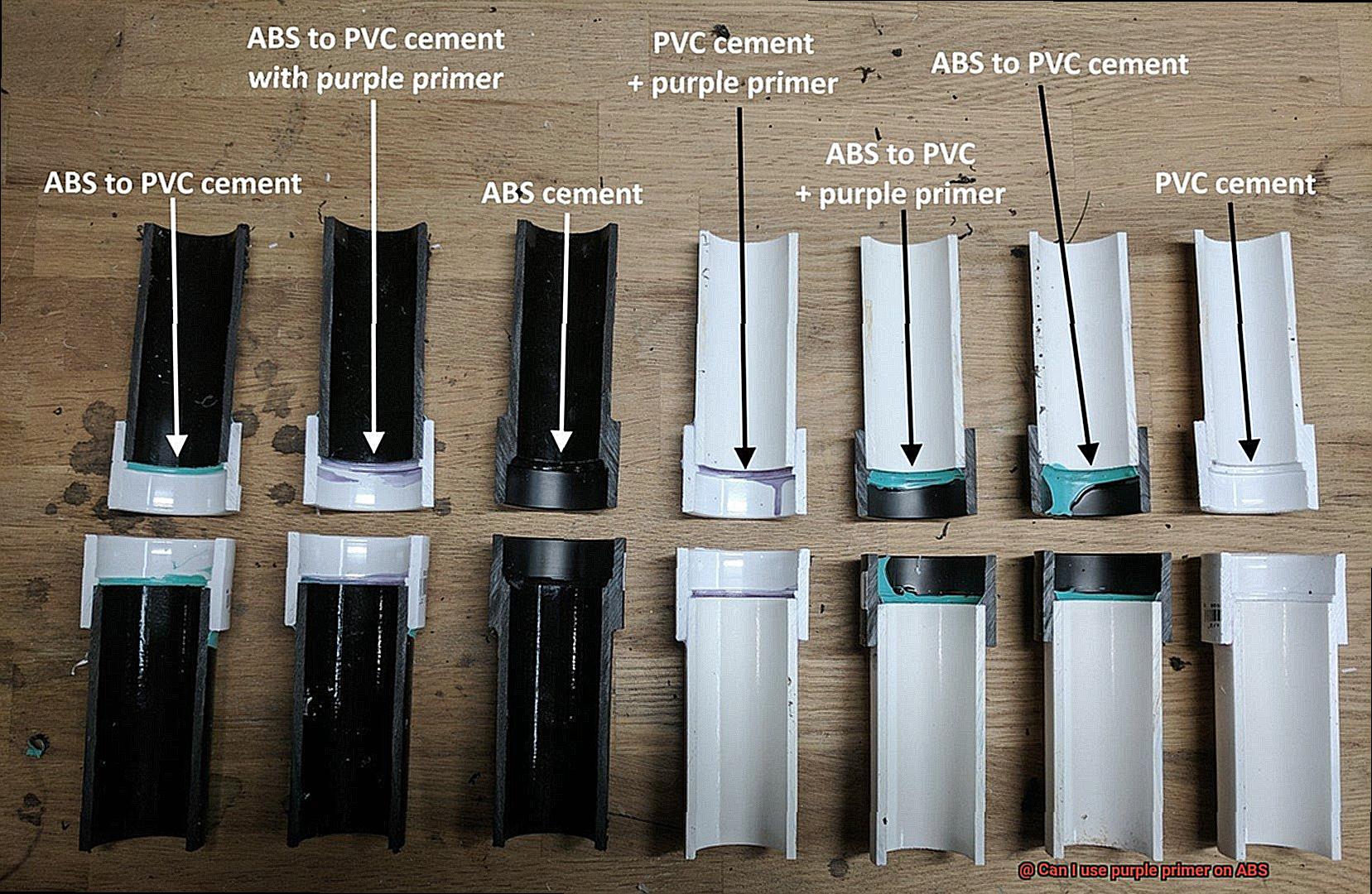

Well, the short answer is yes – you can use purple primer on ABS. But if you want your bond to last and be super strong, you need to understand the properties of both the purple primer and ABS. Purple primer (also known as PVC primer) is typically used with PVC pipes and fittings, but it can also work with ABS pipes and fittings – as long as it has the right solvents.

ABS is a thermoplastic polymer that’s known for being tough, durable, and resistant to chemicals and heat. To work with ABS successfully, it’s important to use a primer specifically designed for this material. While purple primer can work on ABS, make sure you pair it with an approved cement for the best results.

So if you’re keen to use purple primer on your next ABS project, be sure to choose a product with the proper solvents – and follow those manufacturer’s instructions carefully. With the right technique, you’ll achieve a solid bond between your ABS pipes and fittings that’ll stand up over time.

Advantages of ABS

Contents

ABS or Acrylonitrile Butadiene Styrene is a thermoplastic polymer renowned for its exceptional properties and versatility, which has made it a popular choice among manufacturers in various industries. In this blog post, we will explore the advantages of ABS and why it has become a favorite material for many.

Advantage 1: Exceptional Impact Resistance

ABS offers outstanding impact resistance, making it ideal for products that require durability and can withstand heavy shocks and vibrations without cracking or breaking. This property makes ABS a top choice for manufacturing automotive parts, electronic housings, and toys.

Advantage 2: Chemical Resistance

Another advantage of ABS is its excellent chemical resistance. It is resistant to corrosion and degradation from exposure to oils, acids, and other chemicals, making it a reliable material for products that may come into contact with harsh chemicals or environments.

Advantage 3: Processing Versatility

ABS is incredibly versatile in processing; it can be easily molded into complex shapes using injection molding or extrusion techniques. It can also be effortlessly machined or fabricated using various cutting tools and techniques. This versatility makes ABS a popular choice for manufacturers who need to produce high-quality parts quickly and efficiently.

Advantage 4: Electrical Insulation Properties

ABS provides good electrical insulation properties, making it an ideal material for use in electrical enclosures and housings. This property ensures that products made from ABS are safe and reliable even in high-voltage environments.

Advantage 5: Aesthetic Appeal

ABS can be easily painted or coated with other materials, enhancing its aesthetic appeal and improving its durability. This advantage makes ABS an excellent choice for products that require an attractive appearance.

What is Purple Primer?

This unique type of solvent-based primer is making waves in the plumbing industry, and it’s not hard to see why.

So, what exactly is Purple Primer? As the name suggests, it’s a purple-colored primer that is used to prepare the surface of PVC materials for bonding with an adhesive. Unlike other types of primers that are typically clear or yellow in color, Purple Primer stands out with its distinctive hue.

What makes Purple Primer so effective? Well, it’s specially designed to work with PVC materials. It contains a powerful combination of solvents and chemicals that break down the surface of the material and create an incredibly strong bond with the adhesive. The exact composition can vary depending on the manufacturer, but it usually includes a mixture of acetone, methyl ethyl ketone, and tetrahydrofuran.

One important thing to note is that while Purple Primer may be possible to use on other types of materials like ABS, it may not provide the same level of adhesion and bonding strength as it does with PVC. So if you’re working with PVC pipes or fittings, make sure to use Purple Primer for optimal results.

Is Purple Primer Suitable for ABS?

Well, hold on tight because we’re going to dive deep into the world of primers and find out.

First off, let’s get to know ABS a bit better. It’s a tough thermoplastic material that’s commonly used in automotive parts, toys, and electronics due to its high durability and impact resistance. However, bonding ABS can be a challenge because of its low surface energy.

Enter primers – they’re meant to help soften and clean the surface of materials, making it easier for adhesives to penetrate and bond. Purple primer is a popular choice for PVC pipes and fittings, but using it on ABS can lead to trouble.

While purple primer can work on ABS, it’s not specifically formulated for it. This means it might not be as effective as a primer that’s designed for bonding ABS. Additionally, using purple primer on ABS can result in discoloration or even damage to the material due to a chemical reaction between the primer and the ABS surface.

So what should you use instead? It’s recommended to go for primers that are specifically formulated for bonding ABS. Acetone, MEK (methyl ethyl ketone), or a combination of both are great examples of ABS primers that contain chemicals compatible with ABS and effectively prepare its surface for bonding.

In summary, although purple primer can technically work on ABS, it may not be the best option due to potential discoloration or damage to the material. Therefore, it’s crucial to use a primer that’s formulated specifically for bonding ABS. Making the right choice will save you time and effort while ensuring a successful bond.

Factors to Consider When Choosing a Primer for ABS

Fear not, because choosing the right primer for ABS is crucial for achieving a successful bond that won’t damage or discolor your material. With so many options available, it can be overwhelming to choose the best one. However, by considering several factors, you can make an informed decision.

Firstly, consider the type of material you will be bonding to ABS. Different primers are designed to work with specific materials, so it’s crucial to choose one that is compatible with the material being used. For example, if bonding ABS to PVC, a primer designed for use on both materials would be necessary.

Secondly, determine the type of bond you desire. Some primers are ideal for solvent-based adhesives, while others work best with water-based adhesives. The type of bond needed will depend on your application and the materials being bonded.

In addition to compatibility and bonding type, it’s important to consider the application method when choosing a primer for ABS. Some primers are suitable for use with spray guns, while others are better applied with a brush or roller. Choosing a primer that is compatible with your chosen application method can ensure proper coverage and adhesion.

Moreover, cost and availability are also essential considerations when choosing a primer for ABS. While it’s necessary to choose a high-quality primer that will provide optimal bonding, it’s equally important to stay within budget and select a readily available product.

Different Types of Primers for ABS

ABS is a popular thermoplastic polymer that is used in various applications. To ensure strong bonding between ABS and other materials, a primer is often used. There are different types of primers available for ABS, each with its specific properties and applications. Let’s explore some of the most common types of primers for ABS.

Solvent-based Primers

Solvent-based primers are the most widely used type of primer for ABS. They contain solvents that help the primer penetrate the surface of the ABS, creating a strong bond. Solvent-based primers are often used in industrial applications where durability and resistance to chemicals and abrasion are essential. However, they can be quite harsh on the environment and may pose health risks to users.

Water-based Primers

Water-based primers use water as a carrier instead of solvents, making them a more environmentally friendly option. They also provide good adhesion properties, but they may not be as durable as solvent-based primers. Water-based primers are an excellent choice for those looking for an eco-friendly option without sacrificing adhesion.

Epoxy-based Primers

Epoxy-based primers are a type of two-part primer that provides excellent adhesion properties and resistance to chemicals and abrasion. They require mixing before application and have a shorter pot life than other types of primers. However, they offer excellent bonding strength, making them ideal for high-stress applications.

Adhesion Promoter Primers

Adhesion promoter primers contain chemicals that help to improve the adhesion of the adhesive or paint to the surface of the ABS. They are ideal for use on hard plastics like ABS as they can bond well with such surfaces. Adhesion promoter primers can improve the strength of your bond while ensuring excellent adhesion.

Plastic Primers

Plastic primers are specifically designed to bond with plastic surfaces and can be used on a wide range of plastics, including ABS. They can provide excellent adhesion and help to improve the durability of the bond. Plastic primers are an excellent choice for those looking for a primer that can bond with multiple types of plastics.

Benefits of Using the Right Primer on ABS

As someone who takes pride in their ABS plastic projects, you want to make sure that your bonds are both strong and long-lasting. That’s where the right primer comes in. A primer is a type of adhesive solution that prepares the surface of ABS for bonding with other materials, and using the right one can make all the difference.

Firstly, the benefits of using the right primer on ABS include increased adhesion. The correct primer will not only bond the surfaces together but also improve their overall strength and durability. This is especially important for applications that will be subject to stress or pressure, as a stronger bond means a more reliable end result.

But that’s not all – using the right primer on ABS can also protect against environmental factors. ABS plastics are prone to degradation from UV light and moisture, which can shorten their lifespan. However, the right primer can help to shield the surface from these factors and keep it looking great for longer.

In addition to its protective qualities, a good quality primer will provide a smooth and even surface for painting or finishing. This means that your finished product will look more professional and polished, with a consistent appearance that is sure to impress.

To achieve these benefits, it’s essential to choose a primer that is specifically designed for use with ABS plastics and follow the manufacturer’s instructions carefully. By taking these steps, you’ll be able to create bonds that are strong, durable, and resistant to environmental factors – all while achieving an impressive finish.

Tips for Applying Primer on ABS

Applying primer on ABS requires attention to detail and careful execution. Here are five sub-sections that detail important tips for applying primer on ABS:

Clean the Surface Thoroughly

Before applying the primer, the surface of the ABS should be thoroughly cleaned. Any dirt or oil left on the surface can prevent the primer from adhering well. To clean the surface, use a mild soap and water, followed by a rinse with clean water and drying with a soft cloth. If necessary, use a degreaser to remove any stubborn grease or oil.

Use a Primer Specifically Designed for ABS

Choosing a primer that is specifically designed for use on ABS is crucial. The wrong primer can result in poor adhesion or even damage to the material. It’s best to choose a high-quality primer that is specifically formulated for use on ABS.

Apply Thin, Even Coats

When applying the primer, it’s best to use thin, even coats. Thick layers of primer can take longer to dry and may result in an uneven finish. Additionally, it’s important to allow each layer of primer to dry completely before applying another coat or moving on to the next step in the process.

Work in a Well-Ventilated Area

When applying the primer, make sure to work in a well-ventilated area. Fumes from the primer can be harmful if inhaled, so it’s crucial to have proper ventilation. Protective equipment such as gloves and a respirator may also be necessary.

Follow Manufacturer’s Instructions

To ensure optimal results, always follow the manufacturer’s instructions when applying primer on ABS. This includes recommendations for temperature and humidity conditions and application techniques such as spraying or brushing. It’s also important to follow any instructions for subsequent steps in the process, such as painting or gluing.

Conclusion

In summary, the answer to whether you can use purple primer on ABS pipes and fittings is a resounding yes. However, it’s essential to have a thorough understanding of both the purple primer and ABS properties to guarantee a secure and long-lasting bond.

ABS boasts remarkable qualities such as exceptional impact resistance, chemical resistance, processing versatility, electrical insulation properties, and aesthetic appeal. To achieve successful bonding between ABS and other materials, selecting the appropriate primer is critical.

When choosing a primer for ABS, compatibility with the material being used, bonding type needed, application method, cost and availability should be considered. There are various types of primers available for ABS such as solvent-based primers, water-based primers, epoxy-based primers, adhesion promoter primers and plastic primers.

Applying primer on ABS requires meticulous attention to detail and careful execution. It’s vital to clean the surface thoroughly before applying thin and even coats of a primer specifically designed for ABS in a well-ventilated area while following manufacturer’s instructions.