Hey there shoe lovers.

Contents

- 1 Advantages of Using Gorilla Glue for Shoe Repair

- 2 Disadvantages of Using Gorilla Glue for Shoe Repair

- 3 Types of Adhesives Suitable for Different Types of Shoes

- 4 Steps to Take When Repairing Shoes with Gorilla Glue

- 5 Tips on How to Maximize the Strength of the Bond Created by Gorilla Glue

- 6 Common Mistakes to Avoid When Using Gorilla Glue for Shoe Repair

- 7 Alternatives to Gorilla Glue For Shoe Repair

- 8 Conclusion

Are your trusty kicks starting to look a little worse for wear? Don’t fret, because I’ve got some exciting news for you.

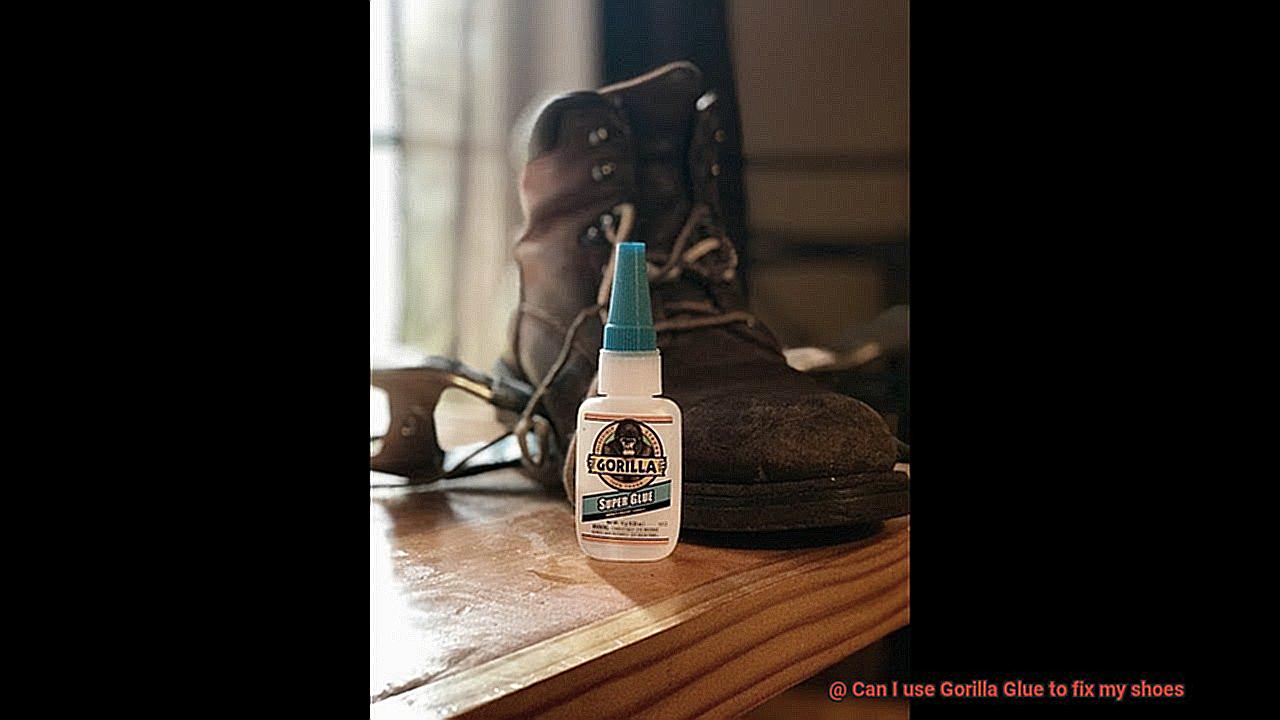

Guess what? Gorilla Glue might just be the secret sauce you need to bring those shoes back to life.

Yeah, I know it sounds crazy, but this stuff is seriously strong and durable. In this blog post, we’re going to dive into the nitty-gritty of using Gorilla Glue to fix your beloved footwear.

So, grab your favorite pair of shoes and let’s get busy restoring them to their former glory.

Advantages of Using Gorilla Glue for Shoe Repair

When it comes to shoe repair, finding the right adhesive is crucial to ensure a lasting and effective fix. Among the various options available, Gorilla Glue stands out as a versatile and reliable choice. With its strong adhesive properties and unique features, Gorilla Glue offers several advantages that make it an excellent option for shoe repair.

Waterproof Bond:

Gorilla Glue’s standout advantage for shoe repair is its remarkable waterproof nature. Unlike many other adhesives, Gorilla Glue creates a bond that can withstand exposure to water and moisture. This feature is particularly beneficial for repairing shoes that are often exposed to wet conditions, such as rain boots or hiking shoes. With Gorilla Glue, you can confidently wear your favorite shoes in any weather without worrying about the glue deteriorating.

Gap-Filling Capability:

Gorilla Glue’s ability to expand as it cures is another exceptional feature that makes it perfect for shoe repair. It fills in gaps and creates a tight bond between the surfaces being glued together. This unique property reinforces weak areas or areas where the sole may be detaching from the upper part of the shoe, ensuring a strong and durable bond that can withstand daily wear and tear. Say goodbye to loose soles and detached parts with Gorilla Glue’s gap-filling capability.

Versatility:

Gorilla Glue is highly versatile and suitable for fixing a wide range of shoe-related issues. Whether you need to repair loose soles, reattach detached parts, fix tears or rips in the fabric or leather, or even fill in holes or gaps in the shoe, Gorilla Glue can handle it all. Its ability to bond various materials, including leather, rubber, fabric, and certain plastics, makes it an ideal choice for different types of shoes. With Gorilla Glue, you have the ultimate solution for all your shoe repair needs.

Durability:

Once properly cured, Gorilla Glue forms a long-lasting and durable bond. This means that repaired shoes can withstand repeated use and stress without the need for frequent repairs. By using Gorilla Glue, you can extend the lifespan of your shoes, saving you money in the long run and reducing unnecessary waste. With its exceptional durability, Gorilla Glue ensures that your repaired shoes stay intact and reliable for an extended period.

Aesthetically Pleasing:

Gorilla Glue dries clear, ensuring that the repaired area does not stand out conspicuously. This transparent finish maintains the overall aesthetics of the shoe, making it suitable for use on shoes of various colors and materials. You don’t have to worry about a visible repair job compromising the appearance of your favorite footwear. With Gorilla Glue, your repaired shoes will look as good as new.

Disadvantages of Using Gorilla Glue for Shoe Repair

When it comes to shoe repair, using Gorilla Glue may seem like a convenient solution, but it comes with its fair share of drawbacks. It’s important to be aware of these disadvantages before embarking on a shoe repair project. Let’s dive into the disadvantages of using Gorilla Glue for shoe repair.

- Expansion: One major drawback of Gorilla Glue is that it tends to expand as it cures. While this may be beneficial in certain applications, it can wreak havoc on shoe repairs. Imagine meticulously fixing a loose sole, only to have the glue expand and distort the shoe material. This can result in an uneven and unattractive repair that affects both the comfort and fit of your beloved shoes.

- Lack of Flexibility: Flexibility is crucial when it comes to shoe repairs. Unfortunately, Gorilla Glue falls short in this department. Once it dries, it becomes rigid and inflexible. Shoes constantly endure bending and flexing during normal wear, and if the glue used for repair is not flexible, it can lead to cracks or breaks in the bond. Nobody wants their hard work to come undone and their shoes to revert back to their original damaged state.

- Foaming Action: Moisture can pose a problem when using Gorilla Glue for shoe repair. When this adhesive comes into contact with moisture, it foams up. This can be a real headache when repairing shoes, especially if they are made from materials that easily absorb moisture like leather or fabric. The foaming action of the glue can create a messy and uneven bond that may not hold up well over time.

- Not Specifically Designed for Shoe Repair: While Gorilla Glue is a powerful adhesive, it is not specifically designed for shoe repair. There are other adhesives on the market that are formulated specifically for this purpose, offering better results. These specialized shoe adhesives are designed to be flexible, durable, and resistant to moisture – all qualities that are crucial for successful shoe repairs.

- Difficulty in Removal: If you choose to use Gorilla Glue for a shoe repair, be prepared to face the consequences if you need to undo or modify the repair. Gorilla Glue forms such a strong bond that separating the bonded surfaces can be challenging and may result in damage to the shoe material. This limits your options for future repairs or alterations.

- Strong Odor: Let’s not forget about the smell. Gorilla Glue has a strong odor that can linger even after it has dried. If you are sensitive to strong smells or prefer your shoes to be odor-free, this can be a major drawback.

Types of Adhesives Suitable for Different Types of Shoes

We’ve got the inside scoop on the absolute best adhesives to revive your beloved shoes. Whether you’re dealing with leather, rubber, canvas, or suede, we’ve got you covered. Get ready to strut your stuff with confidence once again.

Heading 1: Shoe Goo – The All-Purpose Miracle Worker

If you’re on the hunt for a true shoe savior, look no further than Shoe Goo. This enchanting adhesive works wonders on a multitude of shoe materials, including rubber, leather, vinyl, canvas, and fabric. It’s like having a superhero at your disposal – forming an exceptionally strong and flexible bond that protects your soles from water, heat, and even frigid temperatures. From repairing soles to reattaching loose parts or sealing pesky cracks and holes, Shoe Goo is here to save the day.

Heading 2: E6000 – The Heavy-Duty Hero

When it comes to heavy-duty repairs, E6000 is the glue that means business. This tough adhesive is perfect for leather, rubber, fabric, and vinyl shoes. With its exceptional strength and durability, it can handle anything life throws at your feet. Repair soles, attach embellishments, or fix those stubborn problems with unwavering confidence. E6000 forms a permanent bond that won’t be phased by water, chemicals, or impacts. Talk about giving your shoes a well-deserved makeover.

Heading 3: Super Glue – The Swift Fixer

Need a quick fix? Super Glue to the rescue. This fast-setting adhesive is perfect for plastics, rubber, leather, and metal shoes. It instantly creates an unbreakable bond within seconds – providing a strong and long-lasting hold. However, keep in mind that it may not be suitable for flexible materials or areas that require flexibility over time. So, if you have a small repair or need to stick something in a jiffy, Super Glue is your go-to.

Heading 4: Contact Cement – The Versatile Wonder

When it comes to bonding large surfaces or repairing seams, Contact Cement is the adhesive you need. It works like magic on leather, rubber, fabric, and vinyl shoes. Apply it to both surfaces, allow it to dry, and then press them together for an ultra-strong bond. This versatile adhesive is perfect for attaching soles to uppers or fixing those pesky seams that just won’t stay put. Get ready to walk with confidence.

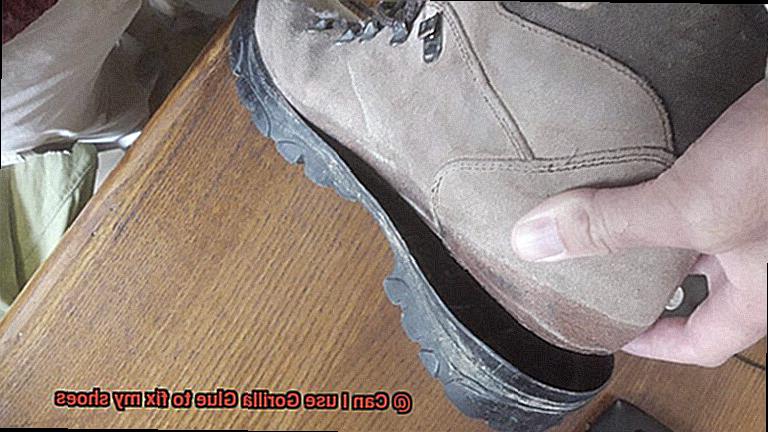

Steps to Take When Repairing Shoes with Gorilla Glue

When it comes to shoe repairs, Gorilla Glue is a reliable and strong adhesive that can work wonders. Whether you’re dealing with a loose sole, a cracked heel, or a torn seam, Gorilla Glue can help bring your shoes back to life. To ensure a successful repair, follow these steps:

- Clean the area: Before applying any glue, make sure to clean the area that needs to be repaired. Use a mild soap and water solution to remove any dirt, dust, or debris. This step is crucial for ensuring that the glue adheres properly to the surface.

- Roughen up the surface: Next, roughen up the surface of the shoe where the glue will be applied. You can do this by using sandpaper or a nail file. The goal is to create a slightly textured surface that will provide better adhesion for the glue.

- Apply the glue: Now it’s time to apply the Gorilla Glue. Start by applying a small amount of glue to one of the surfaces that need to be bonded. Be careful not to use too much glue, as it can expand and create a mess. A thin layer is usually sufficient.

- Press and hold: Press the two surfaces together firmly, ensuring that they are aligned properly. Hold them in place for at least a few minutes to allow the glue to start bonding. This step is crucial for creating a strong bond between the two surfaces.

- Apply pressure if needed: If necessary, you can use clamps or heavy objects to apply additional pressure while the glue dries. This will help ensure an even stronger bond between the two surfaces.

- Allow time to dry: Patience is key. Allow the glue to dry completely. While Gorilla Glue typically takes about 24 hours to fully cure, it’s always best to check the product instructions for specific drying times. Avoid using the repaired shoes during this time to allow the glue to set properly.

- Inspect and touch up: Once the glue has dried, inspect the repair and make any necessary touch-ups. If there are any excess glue residue, carefully remove it using a razor blade or sandpaper. This step will help give your repair a polished finish.

- Test the repair: Finally, test the repaired area by gently flexing or bending it. If it feels secure and holds up well, then congratulations. Your shoe repair should be successful.

It’s important to note that while Gorilla Glue is a versatile adhesive, it may not be suitable for all types of shoe repairs. It works best on materials such as leather, rubber, and fabric. However, it may not adhere well to certain plastics or delicate materials. Additionally, Gorilla Glue expands as it dries, so it’s important to use it sparingly and avoid applying too much pressure during the bonding process.

Tips on How to Maximize the Strength of the Bond Created by Gorilla Glue

When it comes to fixing shoes, Gorilla Glue is renowned for its super-strong bond. However, there are several tips and techniques that can be employed to maximize the strength of this adhesive. In this comprehensive guide, we will explore how to ensure a robust and long-lasting bond when using Gorilla Glue for shoe repairs.

Clean and Prepare:

Before applying Gorilla Glue, it is crucial to thoroughly clean the surfaces you intend to bond. Remove any dirt, oil, or debris by using a clean cloth or a mild detergent if necessary. By ensuring a clean surface, you provide the glue with an optimal grip and enhance its bonding strength.

Roughen Up:

To further enhance the adhesive’s hold, roughen up the surfaces being bonded. Gently sand or score them using sandpaper or a utility knife. This creates tiny grooves and scratches, increasing the surface area for the glue to adhere to. These micro-imperfections strengthen the bond and prevent any potential weak points.

Apply Sparingly:

Contrary to popular belief, less is more when it comes to Gorilla Glue. Applying a thick layer can actually weaken the bond. Since the adhesive expands as it cures, apply a thin and even layer of glue on both surfaces being bonded. This ensures full coverage without excess glue interfering with the bond’s strength.

Clamp Firmly:

After applying Gorilla Glue, firmly clamp or hold the glued parts together. Applying consistent pressure ensures that the glue makes full contact with both surfaces, creating a strong bond. Depending on the shoe material, you may use clips or clamps for leather shoes or tightly hold fabric shoes together with your hands.

Moderate Environment:

Temperature and humidity play a significant role in maximizing the bonding strength of Gorilla Glue. It is crucial to work in a moderate environment, as extreme heat or cold can hinder the adhesive’s performance. Avoid applying Gorilla Glue in excessively hot or freezing conditions to ensure optimal bonding strength.

Allow Proper Curing Time:

Patience is key when using Gorilla Glue. Give the adhesive enough time to fully bond and cure. While Gorilla Glue typically takes 24 hours to cure completely, factors such as temperature and humidity can affect the drying time. To achieve the strongest bond possible, follow the manufacturer’s instructions regarding curing time.

Common Mistakes to Avoid When Using Gorilla Glue for Shoe Repair

When it comes to shoe repair, Gorilla Glue is a popular choice due to its strong adhesive properties. However, there are common mistakes that can compromise the effectiveness of the repair. This guide will explore these mistakes and provide valuable tips to ensure successful and long-lasting shoe repairs with Gorilla Glue.

Applying Too Much Glue:

One of the most frequent mistakes is applying an excessive amount of glue. While it may seem logical that more glue equals a stronger bond, this is not the case with Gorilla Glue. As the glue dries, it expands, leading to messy and uneven application when too much is used. To avoid this, apply a thin layer of glue evenly on the shoe’s surface.

Improper Shoe Preparation:

Another mistake to avoid is failing to properly prepare the shoe before applying the glue. Thoroughly clean the surface, removing dirt, dust, and old adhesive residue. A damp cloth or mild detergent can be used for cleaning. Inadequate preparation prevents the glue from adhering effectively and may result in a weak bond over time.

Using Gorilla Glue on Incompatible Materials:

While Gorilla Glue boasts strong adhesive properties, it may not work well on all shoe materials. For instance, rubber or vinyl shoes may not bond effectively with this glue. It is crucial to check the manufacturer’s instructions or perform a small test patch to ensure compatibility with the specific material.

Premature Pressure or Weight on the Glued Area:

Applying pressure or wearing the shoes too soon after gluing can compromise the bond and weaken the repair. Proper curing time is necessary for Gorilla Glue to reach maximum strength, which typically takes at least 24 hours. Adhere to the recommended curing time provided by the manufacturer for a durable and long-lasting repair.

Neglecting Clamps or Securing Methods:

A common mistake is not using clamps or other securing methods while the glue dries. This can result in an uneven or ineffective bond. Select clamps suitable for the size and shape of the shoe to avoid any damage during the drying process.

Alternatives to Gorilla Glue For Shoe Repair

While Gorilla Glue is a popular choice, there are other options that may be better suited for your shoe repair needs. Let’s explore some alternative adhesives that can bring your shoes back to life.

First on the list is Shoe Goo, a specially designed adhesive that provides a strong and flexible bond. Say goodbye to loose soles and hello to sturdy repairs. This clear adhesive is perfect for fixing soles, reinforcing seams, and tackling other areas of your shoes that need some extra love.

For those seeking a professional-grade adhesive, Barge All Purpose Cement is the way to go. Widely used in the shoe industry, it offers exceptional bonding strength and durability. Repairing leather and rubber soles? Barge Cement has got you covered, ensuring your shoes can handle whatever comes their way.

Looking for versatility? E6000 Craft Adhesive may be the answer. Although not specifically designed for shoe repair, it can be used on various materials like leather, fabric, and rubber. Its strong bond and flexibility make it suitable for fixing shoes in a pinch.

If natural alternatives are more your style, consider natural rubber contact cement. This non-toxic adhesive provides a strong bond and can be used on materials like leather and rubber.

Sometimes, minor repairs only require temporary solutions. Fabric glue or even super glue can come to the rescue for small tears in fabric or loose stitching. Just remember, they may not offer the same level of strength and durability as specialized shoe adhesives.

6irO_IN27rU” >

Also Read: Best Glue for Ugg Boots

Conclusion

Yes, Gorilla Glue can be used to fix your shoes.

Its strong adhesive properties make it a suitable choice for repairing various shoe materials, including leather, rubber, and fabric. By applying a small amount of Gorilla Glue to the damaged area and holding it in place until it dries, you can restore your shoes to their former glory.

However, it is important to note that Gorilla Glue expands as it cures, so be cautious not to use too much glue or apply excessive pressure during the drying process. Additionally, ensure that you follow the manufacturer’s instructions and allow sufficient time for the glue to fully set before wearing your repaired shoes.

With Gorilla Glue in your toolkit, you can confidently tackle shoe repairs and extend the lifespan of your favorite footwear.