Welcome, epoxy enthusiasts. Today, we’re diving deep into the fascinating world of epoxy and its reaction to heat. Have you ever wondered if heat can soften this adhesive wonder? Well, get ready for some mind-blowing discoveries because we’re about to unlock the secrets of manipulating epoxy with the power of heat.

Picture this: it’s a scorching summer day and your favorite chocolate bar is melting in your hand. Or imagine sinking your teeth into a slice of freshly baked pizza, where the cheese stretches and oozes with delicious gooeyness. Heat has this incredible ability to transform materials, making them more pliable and malleable. But what about epoxy? Can it be molded and shaped like these tasty treats?

Well, my friends, you’re about to find out. Join us on this captivating journey as we explore the intriguing relationship between heat and epoxy. Grab a cup of your favorite beverage, buckle up, and let’s embark on this adventure together.

What is Epoxy?

Contents

This thermosetting polymer has become a staple in a wide range of industries and applications. In this comprehensive guide, we will embark on a journey into the world of epoxy, uncovering its remarkable characteristics, diverse applications, and even the secrets behind softening or removing cured epoxy.

Exceptional Bonding Strength and Durability:

Prepare to be astonished by the extraordinary bonding strength of epoxy. It forms an unbreakable connection with various materials including metals, wood, concrete, and plastics. This versatility makes it the go-to choice for construction, automotive, aerospace, electronics, and even artistic endeavors. Rain or shine, epoxy bonds endure the harshest conditions, resisting heat, chemicals, moisture, and mechanical stress.

Electrical Insulation Properties:

But wait, there’s more. Epoxy isn’t just about unyielding adhesion. It also excels in electrical insulation. This makes it the perfect companion for electrical and electronic applications where protection is paramount. By sealing and safeguarding electronic components from moisture and other environmental factors, epoxy ensures their longevity and optimal performance.

Customization and Application Methods:

Unlock the potential of epoxy through customization. With the addition of various additives like fiberglass or carbon fibers, its properties can be enhanced to reach new heights of strength and stiffness. Need a splash of color? No problem.

Epoxy can be pigmented as well. Furthermore, epoxy is available in different forms such as liquid resins, putty or paste, coatings, and even adhesives like double-sided tapes or films. Each form offers unique advantages and requires specific application methods.

Softening or Removing Cured Epoxy:

Sometimes, even the most powerful bonds need to be softened or removed. Enter heat, the secret weapon against cured epoxy. With temperatures ranging from 150 to 200 degrees Fahrenheit (65 to 93 degrees Celsius), epoxy can be rendered malleable for manipulation or removal. However, caution is paramount. Proper ventilation and protective gear are essential when working with heated epoxy.

How Heat Softens Epoxy

Epoxy, that mighty adhesive we all know and love, can be softened by harnessing the power of heat. Picture this: two components, resin and hardener, combining forces to create a bond so strong it could withstand the test of time. But what if you need to soften or remove cured epoxy? That’s where heat swoops in like a superhero.

Let’s start with the basics. Epoxy has a softening point, usually between 50 to 90 degrees Celsius (122 to 194 degrees Fahrenheit). Below this range, it remains solid and stable. However, crank up the temperature, and the molecular structure of epoxy starts to break down, causing it to soften.

Now let’s explore some methods of heating things up with epoxy. One popular approach is using a heat gun or a hairdryer. By directing hot air onto the epoxy surface, you can effectively soften it, making it more pliable and easier to manipulate or remove. But remember, too much heat can cause the epoxy to degrade or even burn, so tread carefully.

Another option is the good ol’ hot water bath. By immersing the bonded object in hot water, you allow the heat to gradually transfer to the epoxy, softening it over time. While this method may take longer than using direct heat sources, it can be useful for certain situations.

For those epic epoxy structures that demand precision, professionals turn to specialized ovens or heat chambers. These controlled environments provide accurate temperature regulation for consistent results.

But hold on. There’s a catch. While heat can soften epoxy, it won’t reverse the chemical reaction that occurred during curing. Once epoxy has fully hardened and cured, no amount of heat can turn back time and transform it back into its original liquid state.

So remember, my glue enthusiasts, always consult the manufacturer’s instructions and temperature limits when working with epoxy. Applying excessive heat or subjecting it to temperatures beyond its softening point can jeopardize its integrity and adhesion properties.

Methods of Applying Heat to Epoxy

Epoxy, that versatile adhesive we all know and love, can be softened and manipulated through various methods of applying heat. These methods offer flexibility and control, ensuring that your epoxy projects are a success. So let’s dive into the fascinating world of epoxy and explore the different ways to apply heat to this magical substance.

First up, we have the trusty heat gun and hairdryer. These powerful tools emit a stream of hot air that can be directed onto the epoxy surface. Perfect for smaller projects or when you need to remove cured epoxy without causing too much damage. But remember, keep a safe distance and avoid overheating.

Next on our list is the oven or heat chamber method. This one’s a favorite in industrial settings, where larger epoxy components need softening for molding or shaping purposes. Just pop your epoxy creation into the oven, gradually increase the temperature, and watch it become more malleable before your very eyes. It’s like giving your epoxy a rejuvenating spa day.

If you prefer a gentler approach, consider a hot water bath. Submerge your epoxy object or material in hot water and let the magic happen. This method is perfect for delicate projects or when you don’t want to risk overheating your epoxy. Plus, it gives you an excuse to relax with a cup of tea while waiting for your epoxy to soften.

For those who crave precise temperature control, heat blankets or heating pads are your go-to option. These flexible heating elements wrap around or sit on top of your epoxy surface, providing consistent warmth for an even softening experience. Industrial artists rejoice.

Last but not least, we have infrared lamps. These bad boys emit heat through a specific wavelength of light that gets absorbed by materials like epoxy. Simply direct the infrared lamp towards your epoxy surface, let it work its magic, and voila. Softened epoxy at your fingertips.

But before you embark on your epic epoxy adventures, remember to play it safe. Different types of epoxy have different temperature limits, so always refer to the manufacturer’s guidelines. And don’t forget proper ventilation when using heat guns or ovens – no one wants to inhale those fumes.

So there you have it, my glue-loving friends. The methods of applying heat to epoxy are as diverse as the projects you can create with this incredible adhesive. Whether you’re using a heat gun, oven, hot water bath, heat blankets, or infrared lamps, just ensure you follow safety precautions and temperature limits for a successful and safe softening experience.

Benefits of Using Heat to Soften Epoxy

Working with epoxy can be both rewarding and challenging, but there is a secret weapon that can make your epoxy adventures a breeze – heat. Using heat to soften epoxy is a game-changer, offering numerous benefits that will enhance your epoxy projects.

First and foremost, one of the biggest advantages of using heat to soften epoxy is the ease of removal or repositioning. When epoxy is heated, it becomes more pliable and less resistant, allowing you to effortlessly manipulate or separate bonded materials. No more struggling and straining to pry things apart. The application of heat makes the job easier and saves precious time.

Speaking of time, using heat to soften epoxy speeds up the process. By applying heat to the epoxy, the chemical reaction is accelerated, resulting in quicker results compared to other methods like solvents or mechanical force. Time is money, after all. So why spend unnecessary hours waiting for epoxy to soften when you can expedite the process with heat?

Precision is key in epoxy work, and that’s where heat truly shines. By adjusting the temperature, you have complete control over how much the epoxy softens. This means you can fine-tune your technique and achieve the perfect level of pliability for your specific project. Whether you need just a slight softening for delicate tasks or a more significant softening for larger projects, heat allows you to customize your approach.

But here’s something else that will put your mind at ease – using heat to soften epoxy is a non-destructive method. Unlike other techniques that may damage or alter the bonded materials, heat poses minimal risk when applied correctly. So whether you’re working with delicate surfaces or valuable equipment, you can rest easy knowing that your precious items are in safe hands.

But wait, there’s more. Heat isn’t just for removing or repositioning epoxy – it can also be used to remove cured epoxy from tools or equipment. Simply apply heat to the affected area and watch as the epoxy softens and can be easily scraped off without causing any harm to the underlying surface. This versatility adds another layer of convenience and efficiency to your epoxy projects.

Furthermore, heat is practical. In certain environments where solvents may not be suitable or readily available, heat can be a lifesaver. It’s a cost-effective solution that doesn’t require any fancy equipment – a heat gun or hairdryer will do the trick. So whether you’re in your workshop or out in the field, you’ll always have a reliable option at your fingertips.

Safety Measures When Applying Heat to Epoxy

Epoxy, renowned for its strength and durability, is a powerful adhesive widely used across industries. However, when heat comes into play, potential safety hazards arise. This comprehensive article explores essential safety measures to follow when working with heat and epoxy. By adhering to these guidelines, you can ensure your well-being and the success of your projects.

Ensure Proper Ventilation:

Shield yourself from harmful fumes by working in a well-ventilated area or employing exhaust fans to swiftly remove any fumes from the workspace. For an added layer of protection against inhaling noxious fumes, don a respirator.

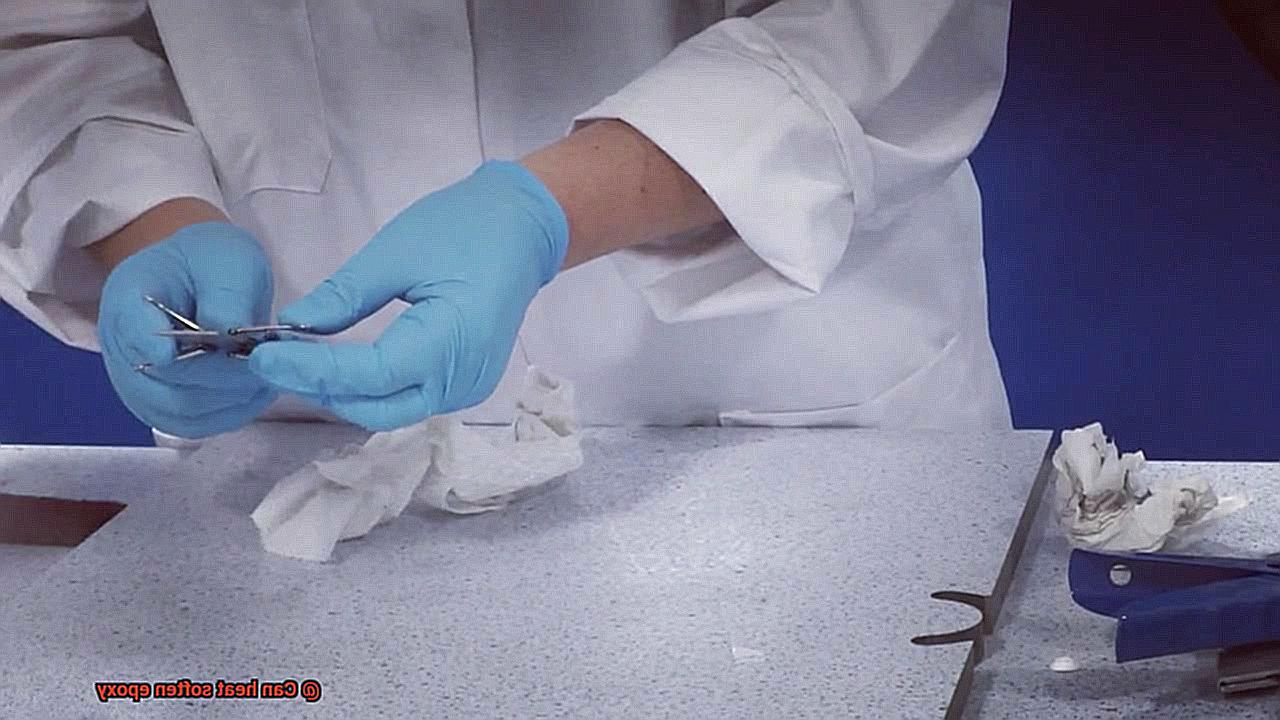

Wear Appropriate Protective Gear:

Prevent burns and injuries by equipping yourself with heat-resistant gloves, safety goggles, and long sleeves/pants. These protective measures minimize direct contact with hot surfaces or splashes of scorching epoxy.

Prepare the Work Area Properly:

Prior to applying heat, eliminate any flammable materials that could ignite due to the heat source. Remove clutter or debris that may pose safety hazards during the process. Keep a fire extinguisher nearby as a precautionary measure.

Use the Correct Temperature and Technique:

Different epoxy types have distinct temperature thresholds. Consult the manufacturer’s guidelines for the specific epoxy being used. Avoid excessive heat as it can damage the epoxy and increase accident risks. Begin with a low temperature and gradually increase if necessary.

Monitor Closely:

Never leave a heat source unattended while working with epoxy. Continuously observe the temperature and the epoxy’s reaction. If smoke or unusual behavior appears, promptly remove the heat source and allow the epoxy to cool down before proceeding.

Cool Down Completely:

After applying heat, ensure the epoxy cools down entirely before further handling or manipulation. Direct contact with hot epoxy can cause severe burns. Employ tools or utensils to interact with the epoxy, avoiding bare-handed contact.

Proper Disposal:

Dispose of excess epoxy and waste materials in compliance with local regulations and guidelines. Act swiftly to clean up spills or drips, as epoxy hardens when cooled, making removal challenging.

Limitations of Heat-Based Removal Methods

When it comes to removing epoxy, heat-based methods can be a viable solution. However, it’s important to understand their limitations to avoid potential mishaps and ensure successful removal. In this article, we’ll explore the challenges associated with heat-based removal methods for epoxy and discuss alternative solutions that may be more effective. So, let’s dive into the hot truth.

Epoxy Variability:

Different types of epoxy may respond differently to heat. Some epoxies are more resistant and require higher temperatures for softening, making heat-based removal methods less effective in certain cases. It’s crucial to consider the specific epoxy’s composition and characteristics before attempting a heat-based removal method.

Potential Surface Damage:

Excessive heat can cause damage to delicate or sensitive surfaces. Materials like plastics or electronics may suffer from warping or even permanent damage when exposed to high temperatures. Such limitations make heat-based removal methods unsuitable for these applications.

Uneven Softening and Incomplete Removal:

Heat may not distribute evenly throughout the epoxy, resulting in uneven softening or incomplete removal. This can lead to frustrating experiences where complete epoxy removal becomes a challenge or residue is left behind.

Health Risks:

Working with high temperatures for extended periods can release toxic fumes or odors, posing health risks to individuals handling the epoxy. Proper ventilation and personal protective equipment should be used to minimize exposure.

Impracticality for Large or Complex Applications:

Heat-based removal methods may not be practical or safe for larger or complex epoxy applications. These situations often require excessive heat and prolonged exposure, making alternative removal methods like chemical solvents or mechanical scraping more efficient and suitable.

Alternatives to Heating for Removing Cured Epoxy

Epoxy, a versatile and durable adhesive, is widely used in various industries. However, removing cured epoxy can be a daunting task when heat-based methods are not feasible or available. In this article, we will explore alternative methods that can help you remove cured epoxy with precision and finesse.

Solvents:

Solvents provide an effective solution for softening and dissolving cured epoxy. Acetone, commonly found in nail polish removers, is favored for its ability to break down epoxy’s chemical bonds. Methyl ethyl ketone (MEK) and denatured alcohol are also effective solvents. Remember to test a small area before proceeding as different types of epoxy may respond differently to solvents.

Mechanical Removal:

Sometimes, stubborn cured epoxy requires a little elbow grease. Mechanical removal involves using physical force to chip away at the epoxy and remove it from the surface. A scraper or chisel can be employed for this purpose. Apply pressure and angle the tool correctly to avoid damaging the underlying material.

Sanding:

Sanding is another alternative method suitable for smaller areas or thin layers of epoxy. By using sandpaper or a sanding block, you can gradually sand away the epoxy until it is completely removed. Exercise patience and precision to avoid damaging the surrounding area.

R3q5opTXKm8″ >

Conclusion

In conclusion, the application of heat can indeed soften epoxy, rendering it more malleable and easier to manipulate or extract. Epoxy possesses a softening point that falls within the range of 50 to 90 degrees Celsius (122 to 194 degrees Fahrenheit). Once subjected to temperatures beyond this threshold, its molecular structure begins to disintegrate, resulting in a softening effect.

There exist several techniques for employing heat in the manipulation of epoxy. One popular approach involves utilizing a heat gun or hairdryer to direct streams of hot air onto the epoxy surface. Alternatively, immersing the bonded object in hot water facilitates gradual softening.

Specialized ovens or heat chambers offer precise temperature control for consistent outcomes. Heat blankets or heating pads provide flexibility and regulation, while infrared lamps emit heat through a specific wavelength of light that is absorbed by epoxy.

The utilization of heat in softening epoxy boasts an array of advantages. It enables effortless removal or repositioning of bonded materials, expedites the process when compared to alternative methods, ensures precision in achieving desired levels of pliability, and serves as a non-destructive technique that poses minimal risk when executed correctly.

Nevertheless, adherence to safety measures is crucial when working with both heat and epoxy. These precautions encompass ensuring proper ventilation, donning suitable protective gear, adequately preparing the work area, employing appropriate temperature settings and techniques, closely monitoring the process throughout its duration, allowing sufficient time for complete cooling before further handling, and disposing waste materials appropriately.

While heat-based removal methods possess certain limitations concerning epoxy variations, potential surface damage, uneven softening or incomplete removals, health risks associated with exposure to toxic fumes, as well as impracticality for extensive or intricate applications; alternative approaches such as solvents (acetone), mechanical removal (scraper or chisel), and sanding prove effective solutions for eliminating cured epoxy when heat-based methods are unfeasible or unavailable.

In conclusion, comprehending the intricate relationship between heat and epoxy opens up a realm of possibilities for manipulating this adhesive marvel across various industries and applications.