Are you tired of constantly replacing your water-damaged possessions? Are you in need of a quick fix for a leaky roof or pipe? Well, have no fear – your trusty bottle of glue may just be the solution you’ve been searching for.

But before you start slathering glue on everything in sight, it’s important to understand which types of glue are suitable for waterproofing and what precautions to take. Not all glues are created equal, and some may only provide temporary waterproofing.

In this article, we’ll explore the fascinating world of glue and waterproofing, delving into the different types of adhesives and their unique properties. We’ll examine how glue works to create a watertight seal and highlight both the benefits and limitations of using glue for waterproofing.

Whether you’re an avid DIY enthusiast or simply seeking a quick and easy fix, this article will equip you with the knowledge necessary to confidently use glue for waterproofing. So grab your favorite adhesive and let’s dive in.

Types of Glue Suitable for Waterproofing

Contents

When it comes to waterproofing, not all glues are created equal. To ensure the success of your project, it is essential to choose the correct type of glue. In this section, we’ll take a closer look at some of the most common types of glue that are suitable for waterproofing.

Epoxy glue is an ideal choice for waterproofing applications due to its exceptional strength and durability. This two-part adhesive creates a robust bond that can withstand exposure to water and moisture over time. It works well on various surfaces, including metal, plastic, and wood.

Polyurethane glue is another popular choice for waterproofing. This type of glue creates a strong, flexible bond that can also withstand exposure to water and moisture without losing its hold. It works well on various surfaces and is perfect for applications that require flexibility.

Silicone adhesive is a specialized type of glue designed specifically for use in wet environments, such as plumbing applications. It creates a robust, watertight seal that can withstand exposure to water and moisture over time without breaking down. It’s perfect for plumbing work or any other application where water resistance is a must.

Contact cement is an incredibly versatile adhesive that is often used in construction and woodworking projects. It creates a rock-solid bond between two surfaces and is also resistant to water and moisture. This makes it an excellent choice for bonding materials that will be exposed to water.

Marine-grade adhesive is a specialized type of glue designed specifically for use in marine environments. This adhesive is highly resistant to water, saltwater, and other corrosive substances found in the marine environment. It’s perfect for boat building or any other application where exposure to saltwater and moisture is a concern.

When working with waterproofing glues always ensure that the surface is clean and dry before applying the glue. Sometimes multiple coats may be necessary to ensure complete coverage and waterproofing. Also, consider temperature and humidity conditions when applying glue as these factors can affect its effectiveness.

Preparing the Surface for Glue Application

If so, don’t forget that preparing the surface for glue application is just as critical as choosing the right adhesive. Without proper preparation, your glue may not adhere correctly, compromising the waterproofing abilities of your project.

To ensure that your surface is ready for glue application, follow these simple steps:

Step 1: Clean the Surface

The first step is to clean the surface thoroughly using a mild detergent and water. This will remove any dirt, grime, or other substances that could prevent the glue from adhering properly. After cleaning, rinse the surface thoroughly with water and allow it to dry completely.

Step 2: Repair Any Damage

Inspect the surface for any cracks, holes, or damage that may need repair before applying the glue. If there are any cracks or holes present, fill them with an appropriate filler or patching compound and let them dry completely.

Step 3: Roughen Up the Surface

After repairing any damage, roughen up the surface using sandpaper or a wire brush. This creates a more porous surface for the glue to adhere to. Be sure to remove any dust or debris created by roughening up the surface before applying the glue.

Step 4: Ensure the Surface is Dry

Before applying the glue, make sure that the surface is completely dry. Any moisture present on the surface can prevent the glue from adhering properly and compromise its waterproofing abilities. Use a fan or wait for natural air-drying to ensure that the surface is dry before applying the glue.

By following these steps, you can prepare your surface properly for glue application and ensure that your waterproofing project is a success. Remember always to read and follow the instructions on your specific glue product for best results.

Applying the Glue for Waterproofing

When it comes to waterproofing, choosing the right glue is as important as properly preparing the surface. Not all adhesives are created equal, and using the wrong one can result in a failed project. So, let’s dive into applying glue for waterproofing.

One popular choice for waterproofing is silicone sealant. This type of glue is water-resistant and perfect for sealing around sinks, bathtubs, and toilets. It can also be used on windows and doors to prevent water from seeping through. Its versatility makes it a go-to option for many DIYers.

Epoxy resin, on the other hand, is incredibly strong and durable. It’s ideal for outdoor applications where water exposure is a concern. Use it to seal cracks in concrete or repair leaks in pipes. While it may be a bit trickier to apply than silicone sealant, its strength and durability make it worth the extra effort.

When applying glue for waterproofing, take heed of the manufacturer’s instructions. This may involve cleaning and preparing the surface to be sealed, applying the glue evenly using a brush or applicator, and allowing sufficient time for it to dry and cure. Skipping any of these steps may result in an ineffective seal.

It’s important to remember that glue may not provide a permanent solution. Over time, it may break down or wear away, leaving the surface vulnerable to water damage once again. As such, you may need to reapply the glue periodically to maintain its effectiveness. Generally, you should expect to reapply every few years.

Factors Affecting the Effectiveness of Glue for Waterproofing

To ensure a strong and long-lasting bond, it’s essential to consider these factors before starting any project that requires waterproofing.

One of the most critical factors to consider is the type of glue being used. Different adhesives have different properties, and some are better suited for waterproofing than others. For example, polyurethane-based glues are well-known for their water-resistant properties and are often used in marine applications. Conversely, superglue isn’t recommended for waterproofing as it tends to break down when exposed to water. Therefore, selecting the right type of glue for your project is crucial to ensure a water-resistant bond.

Another important factor to consider is the surface materials being bonded. Some materials, like metal or glass, are naturally more resistant to water and may not need specialized glue for waterproofing. However, porous materials like wood or fabric may require a more water-resistant adhesive to prevent moisture from seeping through. It’s essential to consider the properties of the surface materials before selecting an adhesive for your project.

Lastly, the environment in which the bond is made can also affect the effectiveness of glue for waterproofing. High humidity or extreme temperature changes can weaken the bond over time, making it more susceptible to water damage. Exposure to UV rays can also cause some adhesives to break down and lose their water-resistant properties. Therefore, it’s crucial to consider the environment in which the bond is made and select an adhesive that can withstand those conditions.

Applying Multiple Coats of Glue

If you want to waterproof a surface with glue, applying multiple coats can be a critical step in achieving maximum effectiveness. The number of coats required will vary depending on the type of glue and the material it is being applied to.

However, one thing that always remains constant is the importance of allowing each layer to dry completely before applying the next. Not only does this ensure proper adhesion, but it also prevents moisture from being trapped between layers, which could compromise the waterproofing ability.

It’s also crucial to ensure that each coat is applied evenly, leaving no gaps or missed spots. Any inconsistency can lead to leaks and render the entire waterproofing process ineffective. So, take your time and apply each coat with precision.

Choosing a high-quality waterproof adhesive designed for long-term use is equally important. Some types of glue may break down over time when exposed to water or other elements, compromising their effectiveness. So, do your research and choose a glue that is up to the task.

Temperature and Humidity Considerations

Extreme temperatures can spell disaster for your glue, whether it’s hot enough to melt it or cold enough to make it brittle and crack. To avoid this, you should always check the recommended temperature range from the manufacturer before starting your project.

But temperature isn’t the only factor to consider. Humidity can also play a big role in determining how effective your glue will be. High levels of moisture can cause the glue to take longer to dry, which could compromise its ability to create a strong bond. In some cases, excessive moisture can even cause the glue to break down entirely.

To get the best results from your waterproofing glue, you should work in a controlled environment with moderate temperatures and humidity levels. This will ensure that your adhesive cures properly, creating a strong and long-lasting seal that won’t let water penetrate.

It’s also essential to choose the right type of adhesive for your project. There are many specialized waterproof glues available on the market today, designed specifically for different applications and environmental conditions. Using one of these products will give you peace of mind knowing that your waterproofing solution is up to the task.

When applying your glue, remember to apply multiple coats evenly and allow each layer to dry completely before adding another. This will guarantee maximum effectiveness in waterproofing your surface with glue.

w48KkdKbXNI” >

Conclusion

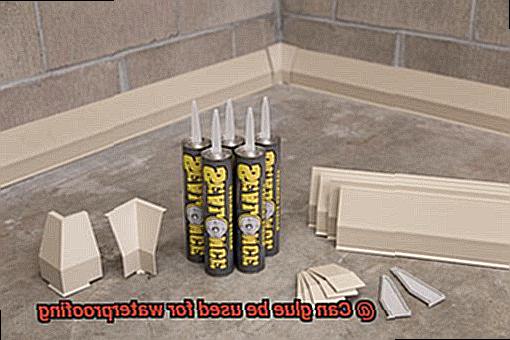

In summary, glue can be a great option for waterproofing, but it’s important to use the right type of adhesive and take necessary precautions. Epoxy, polyurethane, silicone, contact cement, and marine-grade adhesives are all excellent choices for waterproofing applications. However, before applying any glue, make sure to properly prepare the surface by cleaning it thoroughly, repairing any damage, roughening it up and ensuring it’s dry.

When applying the glue, be sure to follow the manufacturer’s instructions closely and consider factors such as temperature and humidity levels that can impact its effectiveness. Applying multiple coats of glue evenly is crucial in achieving maximum effectiveness in waterproofing your surface with glue. It’s also worth noting that not all glues provide a permanent solution; reapplication may be necessary every few years.

Selecting a high-quality waterproof adhesive designed for long-term use is equally vital. Extreme temperatures and humidity levels can compromise the effectiveness of your adhesive; hence working in a controlled environment with moderate temperatures and humidity levels will guarantee maximum effectiveness in waterproofing your surface with glue.