Today, we’re diving into the captivating world of acrylic adhesion. Ever wondered if acrylic can be glued?

Acrylic is a fantastic material that’s used in everything from construction to artwork.

But when it comes to bonding acrylic pieces together, choosing the right adhesive is key. That’s where we come in.

In this post, we’ll explore the realm of acrylic glue – its properties, applications, and all the amazing benefits it brings. Whether you’re a DIY enthusiast, a skilled craftsman, or just someone curious about the wonders of acrylic adhesion, we’ve got your back.

So, grab your goggles and join us as we uncover the art and science of gluing acrylic.

What is Acrylic?

Contents

- 1 What is Acrylic?

- 2 What Type of Adhesive Should be Used for Gluing Acrylic?

- 3 Preparing the Surfaces Before Gluing Acrylic

- 4 Applying Acrylic Cement to Bond Acrylic Pieces

- 5 Other Types of Adhesives for Bonding Acrylic

- 6 Considerations When Selecting an Appropriate Adhesive

- 7 Alternative Joining Methods for Applications Requiring Higher Strength

- 8 Conclusion

Acrylic, also known as polymethyl methacrylate (PMMA), is a captivating material that has captivated various industries and applications. Its transparency, durability, and weather resistance make it a standout choice for a plethora of uses. But what about gluing acrylic? Can it be done effectively? In this blog post, we will unveil the enchanting world of acrylic and delve into the art of bonding this versatile material.

The Strength and Brilliance of Acrylic:

Acrylic is a type of plastic derived from acrylic acid or related compounds. It possesses exceptional optical properties, allowing light to pass through with minimal distortion. This remarkable feature makes it the go-to material for windows, display cases, and even skylights. Furthermore, its impact resistance surpasses that of glass, making it ideal for protective barriers, outdoor signage, and automotive components.

Weather Resistance and Outdoor Applications:

One stellar characteristic of acrylic is its unrivaled weather resistance. Unlike other materials that may yellow or deteriorate when exposed to the harsh sun or extreme conditions, acrylic remains strong and vibrant. This makes it the perfect choice for architectural glazing, outdoor furniture, and signage that can withstand the elements.

The Art of Acrylic Bonding:

Yes, acrylic can be successfully bonded. However, it requires special adhesives and proper techniques to achieve a strong and durable bond. Acrylic cement or solvent cement is one of the most commonly used adhesives for joining acrylic pieces. It chemically melts the surfaces of the acrylic, allowing them to fuse together as they dry. Other options include epoxy glue and cyanoacrylate (super glue), but it is crucial to select adhesives suitable for acrylic to avoid damage or discoloration.

Surface Preparation and Technique:

To attain a successful glue bond with acrylic, proper surface preparation is imperative. Thoroughly clean the edges to be glued, eliminating any dust, dirt, or grease. Gently sand the surfaces with fine-grit sandpaper to create a rough texture that enhances adhesive adherence. After sanding, cleanse any residue with a mild soap and water solution. Apply a thin layer of adhesive along one edge, align the second piece, and firmly press them together. Holding the pieces in place until the adhesive sets is pivotal for a sturdy bond.

Considerations and Consultations:

While gluing acrylic can be effective, it may not provide the same strength as other joining methods like welding or mechanical fasteners. Factors such as load-bearing capacity, temperature resistance, and exposure to moisture or chemicals should be considered when selecting the appropriate adhesive. If uncertain, seeking advice from professionals will ensure the best results for your project.

What Type of Adhesive Should be Used for Gluing Acrylic?

When it comes to gluing acrylic, selecting the right adhesive is paramount. The wrong adhesive can compromise the strength and durability of the bond, potentially leading to disappointment and frustration. So, let’s dive into the world of adhesives and explore the best options for gluing acrylic.

First up is solvent cement, a tried and true adhesive specifically formulated for acrylic. This magical adhesive chemically melts and fuses the acrylic pieces together, creating a bond that is as strong as it is reliable.

If you’re looking for strength and durability, epoxy resin is an excellent choice. However, not all epoxy resins are created equal, so make sure to choose one designed specifically for bonding plastics. With proper surface preparation and curing time, epoxy resin can create a bond that can withstand the test of time.

For those who want an adhesive made exclusively for acrylic, acrylic adhesives are the way to go. These little gems are resistant to yellowing over time and provide exceptional adhesion. Typically consisting of a liquid adhesive and an activator or catalyst, acrylic adhesives create a chemical reaction when mixed together, resulting in a bond that is both strong and long-lasting.

But what about good old super glue? Fear not. You can still use cyanoacrylate adhesives on acrylic surfaces. Just make sure to choose one specifically formulated for plastics. This ensures that you won’t accidentally damage your beautiful acrylic masterpiece.

However, not all adhesives are created equal. Steer clear of hot glue or general-purpose craft glue when working with acrylic. They simply won’t deliver the strong bond you need.

Preparing the Surfaces Before Gluing Acrylic

Think of it as laying a solid foundation for your masterpiece. In this blog post, we’ll delve into the importance of properly preparing surfaces before gluing acrylic, so grab your goggles and let’s dive in.

Cleaning the Surfaces:

Just like preparing a canvas before painting, cleaning the surfaces is essential. Dust, dirt, and grease can sabotage your bonding efforts, so give your acrylic pieces a spa day by gently cleaning them with a mild detergent and a lint-free cloth. Let them shine like stars on the red carpet.

Sanding for Success:

To amp up the adhesion game, sanding is your secret weapon. Using fine-grit sandpaper, give both surfaces a gentle sanding to create a rough texture. This roughness provides more surface area for the adhesive to grip onto, resulting in a stronger hold. It’s like sprinkling some magic dust that makes your bond unbreakable.

Banishing Greasy Foes:

Grease and oils are the villains of the bonding world. They create a barrier between the acrylic and adhesive, preventing them from forming a strong connection. So grab some isopropyl alcohol or an acrylic degreaser and banish those greasy foes. Your bond will thank you later.

Acrylic Primer: The Superhero You Need

For an extra boost of strength, meet the acrylic primer – your trusty sidekick in achieving an unbeatable bond. Applying an acrylic primer before gluing creates a smoother and more uniform surface, sealing any imperfections or microfractures that could weaken your bond. It’s like armor for your acrylic pieces, ensuring they’re ready to face any challenge.

Masking Tape: The Unsung Hero

To ensure a neat finish and prevent any adhesive mishaps, don’t forget the masking tape. By applying it around the edges of your acrylic pieces, you create a barrier that keeps excess glue from seeping out. This way, your bond stays strong, and you maintain that professional touch.

Applying Acrylic Cement to Bond Acrylic Pieces

Creating strong and seamless bonds between acrylic pieces requires the skillful application of acrylic cement. In this guide, we will explore the art of applying acrylic cement to bond acrylic pieces, ensuring a professional and long-lasting result. Whether you’re an experienced craftsman or new to the world of gluing, this step-by-step process will help you achieve flawless results.

Preparing the Surfaces:

To begin, ensure that the surfaces to be bonded are pristine. Clean them thoroughly, removing any dust, dirt, or grease with a mild soap and water solution. Once clean, dry the surfaces completely. Additionally, lightly sand the surfaces with fine-grit sandpaper to create a rougher texture that enhances the adhesion of the acrylic cement.

Choosing the Right Tools:

For precision application, select a small brush or applicator with a fine tip. This will allow for accurate placement and reduce the risk of excess cement spreading onto unwanted areas.

Applying Acrylic Cement:

Apply the acrylic cement sparingly and evenly along the edges or surfaces to be bonded. Remember, less is more when it comes to acrylic cement; over-application can result in unsightly marks or smudges.

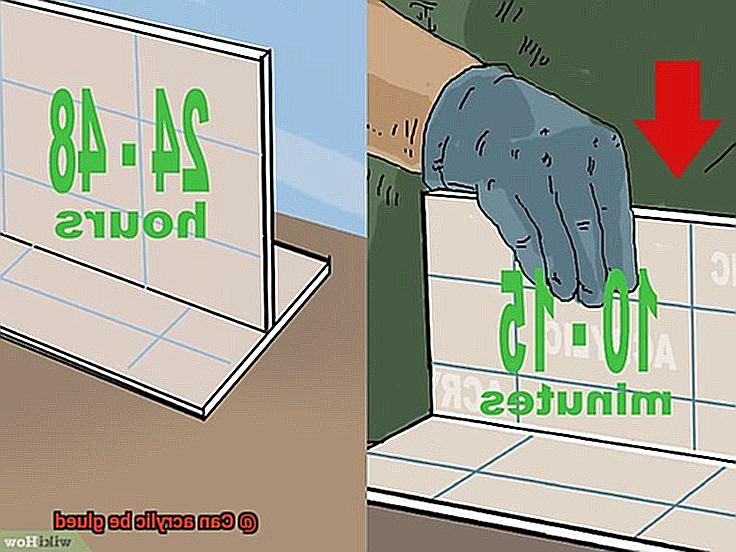

Pressing and Bonding:

After applying the cement, firmly press the two pieces together. For larger or complex projects, use clamps or weights to hold the pieces in place while the adhesive dries. This ensures a strong bond and prevents any movement during the curing process.

Drying and Curing:

Follow the manufacturer’s instructions regarding drying time and curing process. Although acrylic cement dries quickly, it may take several hours or even a day for the bond to fully cure and reach maximum strength. Patience is key.

Removing Excess Cement:

After bonding, remove any excess acrylic cement using a scraper or razor blade. Be cautious not to scratch or damage the acrylic surfaces during this step.

Compatibility and Testing:

Always remember that acrylic cement is specifically designed for bonding acrylic materials. Before applying it to the entire surface, test the adhesive on a small, inconspicuous area to ensure compatibility and prevent any potential damage or adverse reactions.

Other Types of Adhesives for Bonding Acrylic

Acrylic is a versatile material that is commonly used in various applications, from art and crafts to construction and manufacturing. When working with acrylic, it is essential to choose the right adhesive to ensure a strong and durable bond. In this article, we will explore five different types of adhesives specifically designed for bonding acrylic. Each adhesive has its own unique properties and strengths, making them suitable for different applications. Let’s dive in.

Epoxy Adhesive: The Mighty Bonding Strength

Epoxy adhesives are known for their exceptional bonding strength and durability. They consist of two components – a resin and a hardener – that need to be mixed before application. Epoxy adhesives provide a strong bond that can withstand moisture, chemicals, and temperature fluctuations. They are ideal for bonding large surfaces or areas that require a robust bond. Whether you’re working on an art project or constructing a structure, epoxy adhesives will ensure a long-lasting bond.

Cyanoacrylate Adhesive: The Speedy Super Glue

If you’re looking for an adhesive that bonds quickly, cyanoacrylate adhesives are your best bet. Commonly known as super glue, these adhesives create an instant bond when applied to acrylic surfaces. They are perfect for small projects or situations where a fast bond is required. However, keep in mind that cyanoacrylate adhesives may not be as durable as epoxy adhesives in certain circumstances. It is important to choose a cyanoacrylate adhesive specifically formulated for bonding acrylic to ensure optimal results.

UV-Curing Adhesive: The Transparent Wonder

UV-curing adhesives offer a unique way to bond acrylic. These adhesives cure under ultraviolet light, creating a strong bond while leaving no visible residue. They are especially useful in applications where transparency and precision bonding are essential, such as in electronics or optics. UV-curing adhesives provide fast curing times, high bond strength, and excellent transparency, making them the go-to choice for bonding acrylic without compromising aesthetics.

Solvent-Based Adhesive: The Quick and Strong Buddy

For quick and strong bonding, solvent-based adhesives are a reliable option. These adhesives contain solvents that dissolve the surface of the acrylic, creating a robust bond when the solvents evaporate. While they may not be as resistant to moisture or temperature fluctuations as other types of adhesives, solvent-based adhesives offer good initial tack and bond strength. They are suitable for various applications where a quick and strong bond is required.

Considerations When Selecting an Appropriate Adhesive

When it comes to selecting an appropriate adhesive for bonding acrylic, there are several crucial considerations to keep in mind. Let’s dive into these factors and explore how they can impact the success of your project.

- Compatibility: Acrylic materials have unique properties that require a specific type of adhesive. It’s essential to choose an adhesive that is specifically designed for bonding acrylic. Using the wrong adhesive can result in weak bonds or even damage to your precious acrylic surfaces.

- Strength and Durability: Acrylic materials often need to withstand various forces like tension, compression, or shear. To ensure a long-lasting bond, opt for an adhesive that offers high strength and durability. You don’t want your beautiful project falling apart, right?

- Transparency: Acrylic is known for its clarity and transparency, so it’s crucial to choose an adhesive that dries clear and leaves no visible residue or marks on the surface. After all, you want your project to look flawless.

- Chemical Resistance: Acrylic materials can be sensitive to certain chemicals. Therefore, select an adhesive that is resistant to chemicals that may come into contact with the bonded surface. Nobody wants their project ruined by corrosive substances.

- Application Method: Different adhesives may have specific requirements like curing time, temperature, or mixing ratios. Choose an adhesive that can be easily applied and fits within your desired application process. No one likes a complicated glue situation.

- Environmental Considerations: Depending on where your bonded acrylic will be used, environmental factors like temperature extremes, humidity, UV exposure, or outdoor exposure can impact adhesive performance. Make sure you choose an adhesive that can handle the environmental conditions it will be exposed to.

Alternative Joining Methods for Applications Requiring Higher Strength

When it comes to applications requiring higher strength, weak and flimsy joints just won’t cut it. If you’re a DIY enthusiast or crafter looking to elevate your projects with stronger and more durable connections, then I’ve got some alternative joining methods for you when working with acrylic materials.

First on the list is solvent welding. This method utilizes a solvent that chemically bonds the acrylic pieces together. As the solvent softens the surfaces of the acrylic, they can be pressed firmly to fuse seamlessly. The result? A strong bond that is perfect for applications where both aesthetics and strength are crucial.

But let’s not forget about mechanical fastening. By using screws, bolts, or other mechanical fasteners in conjunction with adhesive bonding, you can achieve a reliable and robust connection. These fasteners distribute the load and provide additional strength to the joint, ensuring its longevity.

Adhesive bonding, on its own, is another option to consider. There are specialized adhesives designed specifically for acrylic bonding that can deliver excellent strength and durability. Through chemical bonding, these adhesives create a permanent bond between acrylic surfaces. Just be sure to select an adhesive compatible with acrylic and follow the manufacturer’s instructions for optimal results.

Thermal bonding also presents itself as an alternative joining method for acrylic materials. By heating the acrylic pieces to their melting point and pressing them together as they cool down, a strong and seamless connection is formed. This technique is especially useful in applications where aesthetics play a vital role.

Last but certainly not least is ultrasonic welding. This cutting-edge technique harnesses high-frequency vibrations to generate heat at the joint interface, melting the material and creating a strong bond. Ultrasonic welding is ideal for larger or more complex acrylic assemblies, providing a reliable connection that withstands the test of time.

hT6Ow_cBTps” >

Also Read: How To Glue Acrylic Together? – Glue Things

Conclusion

In conclusion, the answer is a resounding yes – acrylic can most certainly be glued. This incredibly versatile material boasts an array of impressive qualities, including exceptional optical properties, durability that can withstand the test of time, and remarkable resistance to various weather conditions. When it comes to bonding acrylic pieces together, the key lies in selecting the right adhesive that will ensure a strong and long-lasting bond.

Fortunately, there are numerous adhesive options available for gluing acrylic. One popular choice is acrylic cement or solvent cement, which works by chemically melting the surfaces of the acrylic and allowing them to fuse together as they dry. If you’re looking for strength and durability, epoxy glue is an excellent option. And don’t forget about cyanoacrylate, also known as super glue – just make sure it’s specifically formulated for plastics.

However, it’s not just about choosing the right adhesive; proper surface preparation plays a crucial role in achieving successful acrylic bonding. To enhance adhesive adherence, be sure to thoroughly clean the surfaces, create a rough texture by sanding them down, and eliminate any traces of grease or oils. For an extra boost of strength, consider applying an acrylic primer before diving into your gluing adventure.

Keep in mind that different projects have different requirements. Factors such as load-bearing capacity, temperature resistance, and exposure to moisture or chemicals should all be taken into consideration when selecting the appropriate adhesive. If you find yourself unsure about which adhesive to use or how to proceed with your project, seeking advice from professionals will ensure that you achieve flawless results.

While there may be alternative joining methods available for applications requiring higher strength levels, adhesive bonding remains a reliable option when working with acrylic materials.

By following proper techniques and utilizing suitable adhesives tailored specifically for your needs, you’ll unlock endless possibilities in creating stunning creations with acrylic.