Ever wondered if that trusty adhesive glue in your toolbox has a hidden talent for conducting electricity? Well, prepare to be electrified by the answers. In this blog post, we’ll dive into the captivating world where sticky substances and electrical currents collide.

Understanding the electrical properties of adhesive glue isn’t just some nerdy science stuff – it’s actually super important in our tech-driven world. As technology zooms ahead at warp speed, we need materials that can seamlessly integrate with all those fancy electronic gizmos. Think circuit boards, wearable tech, and renewable energy systems – they all rely on adhesive glues that conduct electricity like rockstars.

So here’s the plan: we’re going to unpack the basics of electrical conductivity (don’t worry, it won’t be as shocking as it sounds), explore what factors affect how well adhesive glue conducts electricity, and even dive into its potential applications and limitations.

Whether you’re a science geek or just someone who loves sticking things together (no judgment here), get ready to have your mind blown by the electrifying properties of adhesive glue.

Are you amped up yet? Good. Let’s zap into action and discover the fascinating world where science gets sticky. Get ready to become an expert on whether adhesive glue can conduct electricity or not. It’s time to get your “glue-on”.

What Is Adhesive Glue?

Contents

- 1 What Is Adhesive Glue?

- 2 What Is Conductivity?

- 3 Does Traditional Adhesive Glue Conduct Electricity?

- 4 What Are Specialized Conductive Glues?

- 5 How Do Specialized Conductive Glues Work?

- 6 Factors That Affect The Conductivity Of A Conductive Glue

- 7 Applications Of Specialized Conductive Glues

- 8 Conclusion

Adhesive glue, the unsung hero of countless DIY projects and industrial applications, is a remarkable substance with the power to bond materials together. From everyday repairs to complex construction projects, adhesive glue is an essential tool in achieving strong and durable connections. But what exactly is adhesive glue and how does it work its magic?

The Composition of Adhesive Glue:

Adhesive glue can be made from a variety of materials, including natural substances like animal hide or synthetic compounds such as polymers. These materials are carefully formulated to create a substance that can adhere to different surfaces and form a reliable bond. Whether it’s a liquid, gel, or solid form, adhesive glue is designed to be applied to one or both surfaces being joined and left to dry or cure.

Chemical and Mechanical Adhesion:

The bonding power of adhesive glue comes from its ability to chemically or mechanically adhere to surfaces. Chemical adhesion occurs when the molecules of the glue form bonds with the molecules on the surface of the materials being bonded. This type of adhesion relies on intermolecular forces like hydrogen bonding or van der Waals forces. In contrast, mechanical adhesion involves the physical interlocking of the glue with the surface irregularities of the materials.

Versatility and Applications:

The versatility of adhesive glue makes it indispensable in various industries and everyday use. It can bond materials such as wood, metal, plastic, fabric, and ceramics, among others. Whether you’re fixing a broken chair leg, creating a piece of artwork, or constructing a building, adhesive glue provides a strong and durable connection that withstands the test of time.

Electrical Conductivity:

In general, adhesive glues are not conductive materials. They are formulated to have high resistance and low conductivity, making them insulators when it comes to electrical flow. However, there are specialized conductive glues available for specific applications that require electrical conductivity. These glues are formulated with additives like silver particles or carbon nanotubes, creating pathways within the adhesive matrix for the flow of electric current. They find their place in electronics, where bonding components and creating conductive traces on circuit boards are necessary.

What Is Conductivity?

Conductivity is the ability of a material to conduct electricity, allowing for the flow of electric charges. It is a fundamental property that determines whether a substance can act as an insulator, inhibiting the movement of charges, or facilitate the flow of electric currents. The conductivity of a material is measured in units called siemens per meter (S/m) or mho per meter (Ω⁻¹·m⁻¹).

Several factors influence the conductivity of a material. One of the primary factors is the presence of free electrons. Conductive materials, such as metals, have a high density of free electrons that can move freely within the material, creating pathways for electric charges to flow. In contrast, insulating materials lack free electrons and do not allow easy movement of charges.

The structure of a material also affects its conductivity. Crystalline structures, with their organized arrangement of atoms, tend to have higher conductivity than amorphous structures. The ordered structure allows for better electron mobility and more efficient transmission of electric charges.

Conductivity plays a significant role in various applications, including adhesive glue. Most glues used in everyday applications are not conductive and are designed to create strong bonds between materials without interfering with electrical currents. However, specialized glues containing silver particles or carbon nanotubes can be conductive.

Silver is an excellent conductor due to its atomic structure and high density of free electrons. When silver particles are added to glue, they create pathways for electric charges to flow through the adhesive. This makes conductive glue valuable in electronics, where it can be used to bond components and ensure electrical connectivity.

Carbon nanotubes, which are cylindrical structures made of carbon atoms, can also enhance conductivity when added to glue. The unique properties of carbon nanotubes allow them to act as efficient conductors of electricity, making them suitable for specialized adhesive applications.

Does Traditional Adhesive Glue Conduct Electricity?

Prepare to have your curiosity satisfied as we delve into the science behind this electrifying question.

Let’s start with the basics. Traditional adhesive glues, like the trusty white glue and dependable wood glue, are comprised of polymers and solvents. These remarkable glues work their magic by forging robust physical connections between materials. But here’s the secret: they possess a superpower – they’re insulators.

Now, what exactly does that mean? Insulators are materials that impede the flow of electric current through them. Imagine them as formidable “no entry” signs for electric charges. And guess what? The polymers found in traditional adhesive glues embody this very essence – they are insulators.

Polymers are colossal molecules composed of recurring units that relish resisting the flow of electrons, making it arduous for electric charges to traverse. Visualize attempting to infiltrate a jam-packed concert without a ticket – an impossible task.

But that’s not all. The solvents utilized in traditional adhesive glues also contribute to this non-conductive affair. These solvents lack ions or free electrons that could facilitate the movement of electric charges. So even if they yearned to partake in the dance, they simply cannot.

As these glues dry and solidify, they form an impervious barrier between the bonded materials, impeding electrical conductivity. It’s akin to erecting an impenetrable fortress against electric currents. This property renders traditional adhesive glues ideal for scenarios where electrical conductivity is strictly prohibited.

Imagine yourself engrossed in a woodworking project, diligently joining pieces together using glue. The last thing you desire is for your adhesive to interfere with any electrical components or circuits nestled within the wooden structure, right? Fear not. Traditional adhesive glues come to the rescue, providing the much-needed insulation for such situations.

What Are Specialized Conductive Glues?

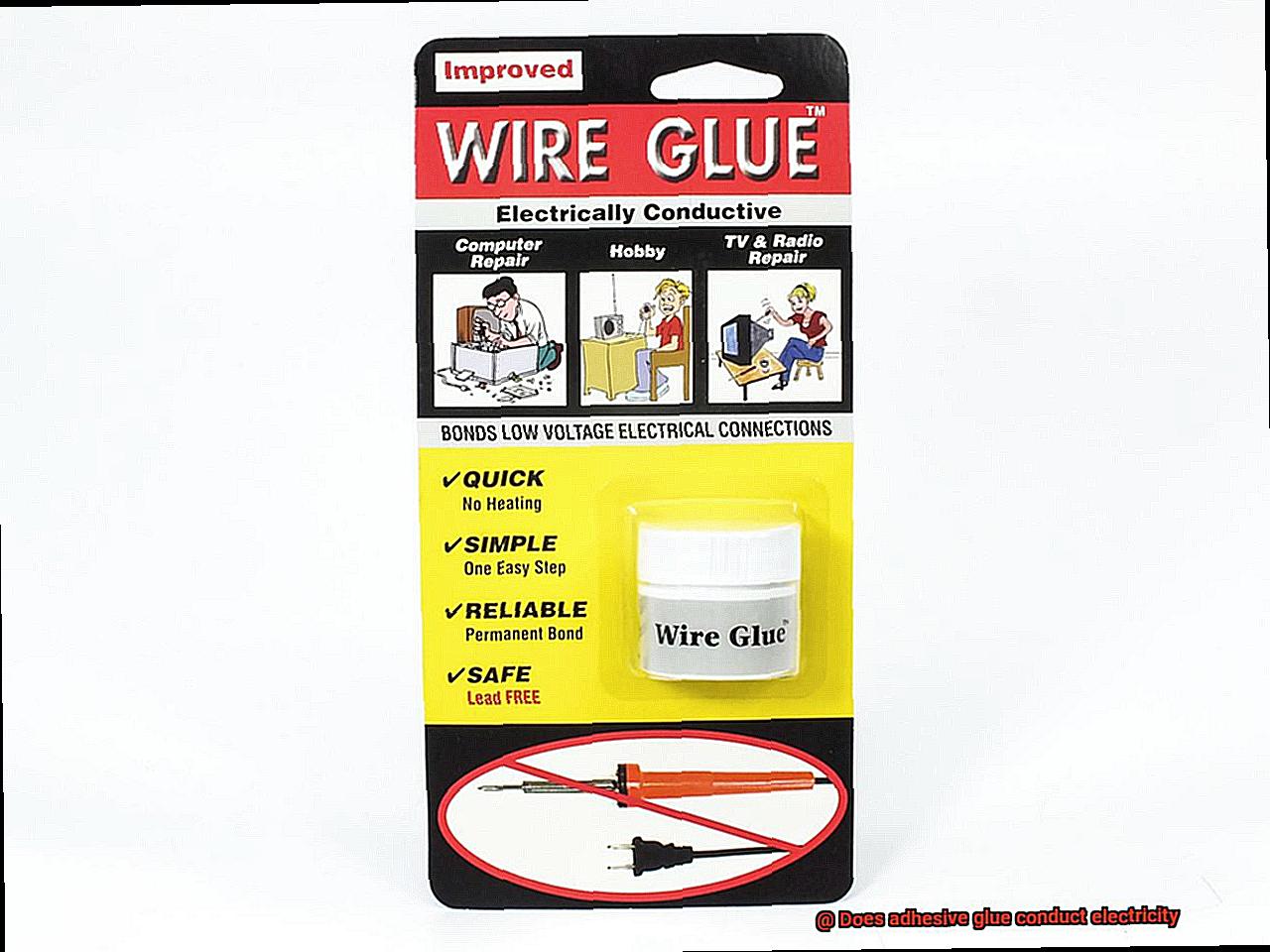

Specialized conductive glues, also known as electrically conductive adhesives, are a remarkable type of adhesive with a unique ability – they can conduct electricity. These glues are specifically designed for applications where electrical conductivity is required, making them invaluable in various industries.

One of the key components of specialized conductive glues is silver particles. Silver is an exceptional conductor of electricity and is commonly used in electronic applications. By incorporating silver particles into the glue, a conductive network is formed, allowing electrical current to flow through.

In addition to silver, other conductive fillers like copper, nickel, carbon, or graphite can also be used in these glues. Each filler offers different levels of conductivity and cost considerations, providing flexibility for different applications.

Specialized conductive glues come in various forms – paste, liquid, or film. The choice of form depends on the specific requirements of the application. Paste or liquid forms are commonly used for bonding components or creating electrical connections on circuit boards. They can be applied using dispensing methods like screen printing or syringe dispensing. Conductive glue films, on the other hand, are pre-cut sheets that can be easily applied to specific areas requiring conductivity.

There are several advantages to using specialized conductive glues over traditional soldering methods. Firstly, they eliminate the need for high-temperature soldering processes, which can be time-consuming and require specialized equipment. Conductive glues can be applied at room temperature or with mild heating, reducing the risk of damaging sensitive electronic components.

Furthermore, these glues offer flexibility and compatibility with a wide range of materials, including plastics, glass, ceramics, and metals. This versatility opens up a world of possibilities for design and application.

Specialized conductive glues find applications in various industries like electronics, automotive, aerospace, and medical devices. They are used for bonding or sealing electrical components, creating connections on flexible circuits or touchscreens, repairing circuit traces, or encapsulating electronic assemblies.

How Do Specialized Conductive Glues Work?

Specialized conductive glues are the superheroes of the adhesive world, armed with conductive fillers like silver particles or carbon nanotubes. They have revolutionized industries such as electronics, automotive, aerospace, and medical devices. In this article, we will dive into the fascinating world of specialized conductive glues and uncover the secrets behind their magical abilities.

The Conductive Network:

At the heart of specialized conductive glues lies a secret weapon – conductive fillers. These fillers create a network throughout the adhesive, forming a pathway for electrical current to flow. Metallic particles like silver or copper are commonly used due to their high conductivity. They establish contact with each other, ensuring an efficient transfer of electricity from one point to another. Carbon nanotubes (CNTs) also play a superhero role in these glues, thanks to their exceptional electrical conductivity.

Enhancements for Optimal Performance:

To boost electrical conductivity and adhesive properties, specialized conductive glues may contain additional additives. These additives improve the contact between the conductive fillers and enhance their dispersion within the adhesive matrix. The result is reliable electrical connections and stronger bonds between components – a true win-win situation.

Curing Process:

The curing process is crucial in achieving optimal electrical conductivity. Most specialized conductive glues cure at low temperatures, allowing them to be used on temperature-sensitive components or substrates. During curing, solvents evaporate or polymer chains cross-link, resulting in a strong and conductive adhesive bond.

The Dual Functionality:

One of the most impressive aspects of specialized conductive glues is their dual functionality. Not only do they provide an electrical pathway for current flow, but they also possess adhesive properties. This means that these glues can bond components together while simultaneously ensuring an uninterrupted electrical connection. It’s like having a superhero with two superpowers.

Factors That Affect The Conductivity Of A Conductive Glue

Have you ever wondered what makes conductive glue so conductive? Well, in this article, we’ll explore the five key factors that affect the conductivity of a conductive glue. So, let’s dive in and uncover the secrets behind this amazing adhesive.

Composition of the Glue:

The composition of a conductive glue plays a vital role in determining its conductivity. Conductive glues typically consist of a polymer matrix filled with conductive particles such as silver, copper, or carbon. The type and concentration of these particles greatly influence the conductivity of the glue.

Silver particles, known for their high electrical conductivity, are commonly used and higher concentrations result in better conductivity. Copper particles offer good conductivity as well but tend to oxidize easily. Carbon particles, while less conductive, are more resistant to oxidation and suitable for specific applications.

Particle Size and Distribution:

The size and distribution of conductive particles within the glue matrix are crucial factors affecting conductivity. Smaller particle sizes generally result in better conductivity as they provide more contact points for electron transfer.

Additionally, an even distribution of particles throughout the glue matrix ensures consistent conductivity across the adhesive joint. Uneven distribution or agglomeration of particles can create areas with poor electrical connectivity, negatively impacting overall conductivity.

Adhesive Matrix Properties:

In addition to the conductive particles, the properties of the adhesive matrix also contribute to conductivity. The polymer matrix should possess good electrical insulation properties to prevent short circuits between adjacent conductive traces.

It should also exhibit good mechanical stability and adhesion to ensure reliable electrical connections. Any degradation or detachment of the adhesive matrix can lead to increased resistance and reduced conductivity.

Temperature and Environmental Factors:

Conductivity can vary with temperature and environmental conditions. Some conductive glues exhibit changes in conductivity with temperature due to thermal expansion and contraction of conductive particles or changes in the adhesive matrix.

Environmental factors such as humidity or exposure to moisture can also affect conductivity. Moisture can cause corrosion or oxidation of conductive particles, leading to increased resistance.

Application Method and Process:

The application method and process used for applying conductive glue can influence conductivity. Factors such as pressure, curing time, and temperature during the application process can impact bond strength and electrical connectivity between conductive particles.

Proper application techniques and adherence to recommended curing conditions are essential for achieving optimal conductivity in conductive glue joints.

Understanding these factors is crucial for selecting the appropriate adhesive for specific applications. By considering the composition, particle size and distribution, adhesive matrix properties, temperature and environmental factors, as well as the application method and process, one can make informed decisions to ensure optimal conductivity in their adhesive joints.

Applications Of Specialized Conductive Glues

Specialized conductive glues are not your ordinary adhesive materials. These remarkable substances have been formulated to possess electrical conductivity, making them indispensable in a wide range of applications. Let’s explore the fascinating world of specialized conductive glues and discover their diverse uses.

In the field of electronics, these glues are the unsung heroes behind the intricate web of connections inside your smartphone or laptop. They bond circuit boards, connectors, and other electrical parts together, ensuring the reliable flow of electrical current between them. Without these glues, your electronic devices would be nothing more than a jumble of disconnected components.

The manufacturing of electronic devices such as smartphones, tablets, and laptops also heavily relies on specialized conductive glues. These glues play a crucial role in bonding various internal components together, ensuring proper electrical connections and functionality. They are the invisible glue that holds your favorite gadgets together.

The automotive industry is another sector that benefits from the magic of specialized conductive glues. In vehicles, these glues are used to bond electrical sensors, connectors, and circuits. By ensuring efficient transmission of electrical signals, they prevent disruptions or failures that could jeopardize your safety on the road.

Now let’s dive into the world of medicine. Specialized conductive glues are key players in the manufacturing of life-saving devices like pacemakers and defibrillators. They bond delicate electrical components inside these devices, ensuring their proper functioning and reliability. Without these glues, these medical marvels would not be able to deliver life-saving shocks or regulate your heartbeat.

Even in the aerospace industry, specialized conductive glues have found their place. They are used to bond electrical circuits and connections in aircraft and spacecraft. The conductivity provided by these glues helps maintain the integrity of electrical systems even under extreme conditions, ensuring smooth operations in the sky or beyond.

And let’s not forget about renewable energy. Specialized conductive glues are vital in the production of solar panels.

They bond solar cells together, allowing for efficient electricity generation from sunlight. These glues are the invisible force that makes solar energy a viable and sustainable source of power.

hFK0CIpTqsE” >

Conclusion

In conclusion, traditional adhesive glue does not possess the ability to conduct electricity. The presence of polymers and solvents within these glues creates a formidable barrier that obstructs the flow of electric current, effectively rendering them insulators. This characteristic proves invaluable in situations where electrical conductivity is strictly forbidden, such as woodworking projects or repairs involving delicate electrical components.

However, the ever-innovative world of materials science has given rise to specialized conductive glues that cater to the demand for electrical conductivity in specific applications. These extraordinary glues incorporate conductive fillers like silver particles or carbon nanotubes, which establish pathways for electric charges to traverse through the adhesive matrix. Industries ranging from electronics and automotive to aerospace, medical devices, and renewable energy have all found immense value in these groundbreaking adhesives.

The conductivity of a conductive glue hinges upon various factors, including its composition, particle size and distribution, properties of the adhesive matrix, temperature and environmental conditions, as well as the application method and process employed. A comprehensive understanding of these factors becomes paramount when selecting an adhesive that will deliver optimal conductivity for a particular application.

Let us not forget that specialized conductive glues are the unsung heroes behind our electronic devices, automotive systems, medical devices, aerospace technologies, and renewable energy solutions. They not only forge reliable electrical connections but also bond components together seamlessly.

Without these remarkable adhesives at our disposal, many of today’s modern technologies would simply cease to exist.