Imagine this: You’ve just finished a stunning epoxy resin project and are itching to coat it with another layer of epoxy for added protection. But, can you actually add multiple layers of epoxy? The answer is simple – yes, you can. In fact, adding multiple layers of epoxy is a popular practice among resin artists and DIY enthusiasts.

Multiple layers of epoxy not only provide extra protection but also give your project a glossy finish and a more vibrant color depth. However, it’s crucial to understand the do’s and don’ts of adding multiple layers to avoid any mistakes that could ruin your masterpiece.

In this blog post, we’ll delve into the details of adding multiple layers of epoxy – when is the best time to add another coat, how many coats are safe, and how to achieve that perfect finish. We’ll also discuss some common mistakes to avoid such as overpouring or not waiting long enough between coats.

Ready to elevate your epoxy resin projects with multiple layers? Keep reading.

We’ll take you through the process step-by-step so that you can achieve an impeccable finish.

What is Epoxy?

Contents

Epoxy – a wonder adhesive that has revolutionized construction, woodworking, and manufacturing industries, owes its popularity to its remarkable strength and durability. It is a two-part adhesive that comprises a resin and a hardener. When mixed together, the resin and hardener interact chemically to create a strong bond.

The resin component of epoxy is made from bisphenol A (BPA) or bisphenol F (BPF), which are combined with epichlorohydrin to form a viscous liquid that can be easily applied to surfaces. The hardener component is usually made from amines or polyamines, which initiates the chemical reaction that causes the mixture to cure and harden.

Epoxy’s versatility lies in its ability to bond materials together, coat surfaces, and fill gaps or cracks. It can also be used to repair damaged surfaces or create a protective layer over new surfaces. Epoxy can be applied in a single layer or multiple layers depending on the desired thickness and durability.

One of the most significant advantages of epoxy is its ability to form multiple layers, which can create a strong, durable bond. However, it’s essential to limit the number of layers applied to prevent weakening of the bond. Applying too many layers adds thickness and weight to the surface, causing stress and strain on the underlying materials.

To ensure optimal adhesion, experts recommend applying no more than three or four layers of epoxy and sanding down the surface between each layer. This technique helps reduce thickness and improve bonding.

Benefits of Using Multiple Layers of Epoxy

As an expert in the field, I can tell you that there are numerous benefits to using multiple layers of epoxy.

One of the most significant advantages is increased durability. By adding layers of epoxy, you are essentially building up a thicker and stronger coating that can withstand more wear and tear. This is especially important if you are using epoxy on a high-traffic surface or in an area that will be exposed to harsh conditions.

But it’s not just about durability. Multiple layers of epoxy can also improve the aesthetics of your project. Adding layers can create a smooth and glossy finish that is both visually appealing and easy to clean. This is particularly useful in areas such as garages, workshops, and commercial spaces where a clean and professional appearance is essential.

In addition to durability and aesthetics, multiple layers of epoxy can also provide added protection against moisture and other environmental factors. By creating a barrier between the surface and the outside world, epoxy can prevent damage from water, chemicals, and other harmful substances.

Moreover, multiple layers of epoxy can help to fill in any imperfections or irregularities in the surface. This is particularly useful when working with concrete floors or other uneven surfaces. By building up layers of epoxy, you can create a smooth and even surface that looks great and is easy to maintain.

How Does Epoxy Work?

Epoxy is a two-part adhesive that consists of resin and hardener. When these two components are mixed together, they undergo a chemical reaction, resulting in a hard and durable substance.

The secret behind the strength of epoxy lies in its ability to create a powerful chemical bond between two surfaces. As the resin and hardener cross-link, they form a formidable bond that can withstand exposure to water and chemicals. This unique property makes epoxy an ideal choice for a wide range of applications, whether you need to seal off gaps or repair broken items.

One of the most intriguing characteristics of epoxy is its ability to cure over time. This curing process allows the epoxy to solidify and create a strong bond between the surfaces it is applied to. However, it’s crucial to ensure that each layer has fully cured before applying the next layer. Failing to do so could lead to poor adhesion between layers and compromise the overall strength of the bond.

Another important factor when using epoxy is avoiding the application of too much at once. This can cause the epoxy to heat up and cure too quickly, which can also compromise the strength of the bond. By following best practices for application, users can achieve strong and long-lasting bonds for their projects.

In addition to its impressive bonding properties, epoxy can also resist exposure to water and chemicals with ease. This makes it beneficial for projects that require a durable adhesive that can withstand harsh conditions.

Curing Time for Each Layer of Epoxy

If you’re planning on using multiple layers of epoxy for your next project, it’s essential to understand the importance of curing time for each layer. Curing time refers to the duration needed for the epoxy to harden and fully cure. It’s crucial to adhere to the recommended curing time for each layer to ensure the best results.

Different types of epoxy have varying curing times, which can be affected by the thickness of the layer applied. For instance, some epoxies require at least 12-24 hours to cure before applying another layer. However, some epoxies may need longer curing times depending on the manufacturer’s instructions.

Temperature and humidity can also affect the curing time of epoxy. Higher temperatures can speed up the curing process while cooler temperatures can slow it down. High humidity can prolong curing time, while low humidity can accelerate it.

To guarantee proper adhesion between layers, it’s crucial to wait for each layer to fully cure before applying another one. Rushing this process can result in poor adhesion and a weaker bond, leading to an unsatisfactory outcome.

Too Many Layers May Weaken the Bond

While it’s tempting to add more layers for increased strength, too many layers may actually lead to a weakened bond between two surfaces.

Why is this the case? Each layer of epoxy adds thickness to the joint, which can create stress and strain on the bond. This means that if you apply too many layers, the bond may not be able to withstand the added pressure, eventually leading to failure.

But that’s not all. If you don’t allow each layer of epoxy to fully cure before adding another layer, they may not bond properly. This results in a weaker overall bond than intended, putting your project at risk for potential damage or failure.

So how can you determine when it’s safe to apply multiple layers of epoxy? It depends on several factors such as the type of surface being bonded, the type of epoxy being used, and the intended use of the finished product. For instance, if you’re repairing a minor crack in a plastic surface, multiple layers may be necessary to fill and reinforce the crack. However, if you’re using epoxy as a coating for a wooden surface, multiple layers may not be necessary or even recommended.

To ensure a sturdy and long-lasting bond when applying multiple layers of epoxy, follow proper application techniques. This includes allowing each layer to fully cure before adding another layer, ensuring that the surface is clean and dry before applying each layer and using an appropriate amount of epoxy on each layer to avoid thickness-related curing issues.

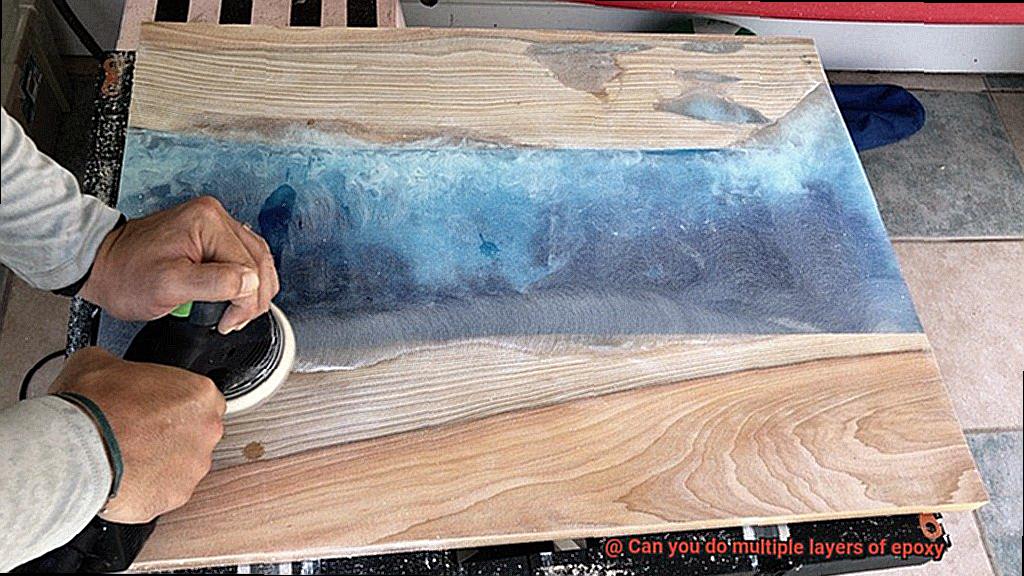

Sanding Down Between Layers

Sanding down between layers is the ultimate key to success. This step helps to remove any imperfections, bubbles, or bumps in the previous layer and provides a clean surface for the next layer to adhere to.

The first rule of sanding is patience. You must allow the previous layer to dry completely before sanding. Waiting for at least 24 hours is recommended, but the waiting time may differ depending on the type of epoxy used. Rushing this step can lead to rough patches and damage the previous layer, resulting in an unprofessional-looking finish.

Once you’re ready to sand, use a fine-grit sandpaper (around 220-320 grit) and work in circular motions. Applying too much pressure can cause uneven sanding and leave scratches on the surface. To ensure an even sanding, it’s recommended to use a sanding block or sponge and be gentle.

After sanding, it’s crucial to clean the surface thoroughly with a tack cloth or damp cloth to remove any dust or debris. Any residue left on the surface can interfere with the adhesion of the next layer, which could ruin all your hard work.

In summary, here are some essential tips for sanding down between layers of epoxy:

- Wait for each layer to dry completely before sanding.

- Use a fine-grit sandpaper (around 220-320 grit) and work in circular motions.

- Be gentle and avoid applying too much pressure.

- Use a sanding block or sponge for an even sanding.

- Clean the surface thoroughly with a tack cloth or damp cloth after sanding.

Proper Application Techniques

Epoxy is an amazing material that can provide a sleek and long-lasting finish to your project. However, to achieve the best results, it’s important to know the proper application techniques.

The first step in applying multiple layers of epoxy is to clean the surface thoroughly. Ensure that the surface is dry and free of debris as dust or particles left on the surface can cause bubbles or imperfections in the epoxy coating. So, grab a cleaning cloth and give the surface a good wipe down.

Next, it’s time to mix the epoxy. It’s essential to follow the manufacturer’s instructions carefully and only mix the amount needed for one layer at a time. The mixture will begin to harden within a certain timeframe, so avoid mixing more than you need.

When applying each layer, use a brush or roller to spread the epoxy evenly over the surface. Avoid over-brushing, as this can cause bubbles and unevenness in the coating. Work quickly, but don’t rush. Timing is crucial when applying each layer, with each layer best applied within 24 hours of the previous layer.

Between each layer, lightly sand the surface with fine-grit sandpaper. This creates a rough texture that helps the next layer adhere correctly. Be patient and wait for each layer to fully cure before applying the next layer; this prevents cracking and other issues.

In summary, here are some key takeaways for proper application techniques when using multiple layers of epoxy:

- Clean the surface thoroughly before applying any layers

- Mix only what you need for one layer at a time

- Spread each layer evenly with a brush or roller

- Avoid over-brushing

- Apply each layer within 24 hours of the previous layer

- Lightly sand between each layer

- Wait for each layer to fully cure before applying the next

Limiting the Number of Layers

The thickness of each layer is crucial in determining the strength and durability of the final product. Ideally, each layer should be no thicker than 1/8 inch. Anything thicker can lead to cracking and other issues with the epoxy. Therefore, building up the coating over several thin layers is preferable to one thick layer.

Another critical factor is the curing time between layers. Patience is key here as it’s essential to wait until each layer is completely cured before adding another layer. Rushing this process can lead to complications and potentially ruin your project. While this wait time may vary depending on the type of epoxy used, a general rule of thumb is to wait at least 24 hours between layers.

Temperature and humidity also play a significant role in the success of multiple layers of epoxy. If the temperature is too high or the humidity is too low, it can affect the curing process and lead to issues with the epoxy. Therefore, it’s essential to check the weather forecast before starting your project and ensure that you’re working in optimal conditions.

To summarize, it’s vital to limit the number of layers and ensure that each layer is correctly cured before adding another layer. Following these guidelines will increase your chances of achieving that perfect finish. Remember, slow and steady wins the race when it comes to working with epoxy.

In conclusion, keep these points in mind when working with epoxy:

- Limit each layer’s thickness to 1/8 inch

- Wait at least 24 hours between each layer for proper curing

- Check temperature and humidity levels before starting your project

RDtosWhm5lw” >

Conclusion

In summary, the art of layering epoxy is a widely practiced technique among resin artists and DIY enthusiasts alike. It not only offers an extra layer of protection but also enhances the color depth and provides a glossy finish to your project.

However, it’s crucial to adhere to proper application techniques to avoid any potential blunders that could ruin your masterpiece.

To achieve a flawless finish when working with multiple layers of epoxy, it’s essential to follow specific guidelines. Start by meticulously cleaning the surface before applying any layers, mixing only enough for one layer at a time, spreading each layer evenly with either a brush or roller, avoiding over-brushing, applying each layer within 24 hours of the previous one, lightly sanding between each layer, and waiting for each layer to fully cure before adding another.

It’s also important to limit the number of layers you apply and ensure that each one is adequately cured before moving on. Following these steps will increase your chances of achieving that perfect finish you’re after.