Glass, with its unrivaled beauty and timeless allure, has captivated our hearts and homes. Whether you’re a craft enthusiast, a glassware collector, or simply someone who appreciates the delicate artistry of this material, there’s one challenge that unites us all: finding the best glue to stick glass to glass.

But fear not. In this all-encompassing guide, we’ll embark on a journey through the realm of glues, uncovering the secrets behind achieving an unbreakable bond between glass surfaces. Our quest for the ideal adhesive will lead us down countless paths as we search for reliability and simplicity.

As we delve into the art of bonding glass, we’ll explore the unique characteristics of different glues, their compatibility with various types of glass, and the level of expertise required for successful application. Whether you’re a seasoned crafter or just starting out on your creative exploration, this guide is tailored to meet your needs.

Prepare yourself for expert advice as we unveil the glue that will make your glass creations shine. Together, let’s dive into discovering an adhesive that will fuse your glass-to-glass projects with unwavering precision and strength, ensuring they withstand the test of time.

Join us on this captivating journey as we unlock secrets and reveal the best glue for sticking glass to glass—empowering you to bring your visions in glass to life.

What Factors to Consider When Choosing the Right Adhesive

Contents

- 1 What Factors to Consider When Choosing the Right Adhesive

- 2 Epoxy Resin: A Strong and Transparent Bonding Option

- 3 UV-Curing Adhesive: High Precision and Minimal Mess

- 4 Silicone Adhesive: Flexible Strength for Construction and Automotive Applications

- 5 Specialized Glues for Specific Projects

- 6 Testing the Adhesive Before a Large-Scale Project

- 7 Proper Application and Curing Time

- 8 Conclusion

When choosing the right adhesive for sticking glass to glass, there are several factors to consider. These factors include compatibility, strength, transparency, curing time, temperature resistance, flexibility, application method, and safety.

Firstly, compatibility is crucial. Not all adhesives are suitable for bonding glass, so it’s important to choose one specifically formulated for this purpose or one that has a strong bond with glass mentioned in its product description. This ensures a reliable and long-lasting bond.

Secondly, strength is essential. Glass objects can be heavy and fragile, so selecting an adhesive with sufficient strength is necessary. Consider the weight and size of the glass objects being bonded and choose an adhesive that can handle the load.

Transparency is another factor to consider. If you want the adhesive to be invisible when bonding glass to glass, opt for transparent or clear adhesives. This maintains the aesthetic appeal of the glass objects by leaving no visible traces of glue.

Curing time is also important. Different adhesives have varying curing times, which refers to how quickly they dry and reach their maximum strength. Consider the urgency of your project and select an adhesive with a curing time that aligns with your requirements.

Temperature resistance is crucial as glass objects may experience varying temperature conditions. Choose an adhesive that can withstand these fluctuations to ensure a long-lasting bond.

Flexibility may be necessary depending on the intended use of the bonded glass objects. Consider if any flexibility is required and choose an adhesive accordingly.

Furthermore, consider the ease of application and any specific requirements of your project when choosing an adhesive. Some adhesives may require specific tools or techniques for proper application.

Lastly, always prioritize safety. Check product labels for any harmful chemicals or fumes emitted during curing, especially if working in enclosed spaces or handling the adhesive for an extended period.

Epoxy Resin: A Strong and Transparent Bonding Option

When it comes to bonding glass to glass, epoxy resin emerges as the superhero of adhesives. This two-part adhesive, consisting of a resin and a hardener, undergoes a chemical reaction when mixed together, resulting in a bond that is as tough as nails.

So, why is epoxy resin the go-to choice for glass bonding? Let’s break it down:

- Strength: Epoxy resin creates a bond that can withstand the test of time. It can handle significant stress and force, making it perfect for applications where strength is crucial.

- Transparency: Once cured, epoxy resin becomes transparent, creating an almost invisible bond between glass surfaces. Say goodbye to unsightly glue lines and hello to seamless beauty.

- Resistance: Moisture, chemicals, and temperature fluctuations are no match for epoxy resin. It acts like a shield, protecting your bond from environmental factors that could weaken it.

Now that you understand why epoxy resin is the chosen one, let’s discuss the application process:

Preparation: Before applying epoxy resin, clean and roughen the glass surfaces to improve adhesion.

- Mixing: Follow the manufacturer’s instructions to mix the resin and hardener in the correct ratio. This ensures optimal performance.

- Application: Apply the mixture evenly onto one of the glass surfaces. Carefully press the second piece of glass onto the adhesive, aligning everything perfectly.

- Curing: Give your bond time to cure. The curing time varies depending on the product you use, so follow the instructions provided by the manufacturer for optimal results.

While working with epoxy resin, keep in mind that it can be sticky and messy. Therefore, don’t forget your gloves and opt for a well-ventilated workspace.

UV-Curing Adhesive: High Precision and Minimal Mess

UV-curing adhesive is revolutionizing the world of glass-to-glass bonding with its exceptional precision and clean application process. Let’s delve into the captivating advantages of this adhesive:

- Lightning-Fast Curing Time: Say goodbye to waiting hours or even days for traditional glues to cure. UV-curing adhesive hardens almost instantly when exposed to UV light, making the bonding process quick and efficient. This remarkable feature reduces production time, boosting productivity to new heights.

- Exquisite Precision: Like a liquid marvel, UV-curing adhesive effortlessly flows into the tiniest gaps, embracing intricate patterns and contours on glass surfaces. Its ability to fill these minute crevices ensures precise adhesion, making it ideal for delicate glass applications like optical lenses or electronic displays.

- A Mess-Free Masterpiece: The conventional methods of clamping or holding pieces together during the curing process are rendered obsolete by UV-curing adhesive. Its rapid curing under UV light eliminates the risk of shifting or misalignment, resulting in a pristine and seamless bond between glass surfaces. Moreover, this adhesive doesn’t leave behind any residue or unsightly marks after curing, preserving the aesthetic allure of the bonded glass surfaces.

- Unyielding Strength and Durability: Once cured, UV-curing adhesive forms an unwavering bond between glass surfaces that withstands even the harshest conditions. From fluctuating temperatures to exposure to moisture, this adhesive ensures long-lasting adhesion. Industries requiring reliable and robust bonding solutions, such as automotive or aerospace, find solace in the steadfastness provided by UV-curing adhesive.

- Purposeful Formulations for Glass-to-Glass Bonding: It is crucial to select a UV-curing adhesive specifically formulated for bonding glass to glass. Not all adhesives possess the necessary properties for optimal adhesion between glass surfaces. These purposeful formulations often boast high transparency, minimal shrinkage, and exceptional resistance to UV light.

Silicone Adhesive: Flexible Strength for Construction and Automotive Applications

Silicone adhesive is the superhero of bonding when it comes to construction and automotive applications. With its flexible strength, it fearlessly tackles the stress and movements that these industries throw its way.

First and foremost, silicone adhesive has the power to create a mighty bond on various surfaces, including glass. It fearlessly adheres to both smooth and rough surfaces, ensuring a secure connection between glass panels. This is crucial in environments where safety and durability reign supreme.

But there’s more to silicone adhesive than just raw strength. It also boasts incredible resistance to temperature extremes and weathering. It can withstand scorching temperatures without breaking a sweat, making it perfect for environments where heat runs rampant. Plus, it’s impervious to the harsh forces of UV radiation, moisture, and chemicals, ensuring that it stands strong against the elements.

In the realm of construction, silicone adhesive is a trusted ally for bonding glass panels in structures such as curtain walls, windows, and skylights. Its flexibility allows for the natural expansion and contraction of glass due to temperature changes, preventing pesky stress cracks and leaks. And let’s not forget its fantastic insulation properties, which help improve energy efficiency by keeping heat loss or gain through the glass at bay.

In the automotive kingdom, silicone adhesive reigns supreme in bonding windshields and windows. It offers unparalleled impact resistance, safeguarding vehicle occupants in the event of a collision. Its flexibility absorbs vibrations and shocks like a champ, reducing the risk of glass shattering under pressure. And with its ability to endure extreme temperature variations without flinching, it’s the perfect sidekick for automotive applications exposed to relentless sunlight and ever-changing weather conditions.

Of course, even superheroes have rules to follow. When using silicone adhesive to bond glass to glass, proper surface preparation is key for achieving optimal results. The surfaces need to be squeaky clean, bone-dry, and free from any contaminants or residues that could undermine the adhesive’s strength. Uniform application and adherence to recommended curing times and temperatures are also crucial for unlocking the adhesive’s full potential.

Specialized Glues for Specific Projects

Specialized glues for specific projects refer to the various types of adhesives that are designed for bonding glass surfaces in different applications. These glues offer unique benefits and properties that make them suitable for specific projects.

One type of specialized glue is UV-curing adhesive, which hardens and forms a strong bond between glass surfaces when exposed to ultraviolet light. This type of adhesive is commonly used in applications where clarity and transparency are important, such as in the construction of glass display cases or aquariums.

Epoxy adhesive is another reliable choice for bonding glass surfaces. Known for its high strength and resistance to chemicals and moisture, epoxy adhesives are ideal for projects where the bonded glass will be exposed to harsh conditions. These adhesives consist of two components – a resin and a hardener – that are mixed together prior to use and cure over time to create a strong bond.

Silicone adhesive is suitable for outdoor applications or situations where the bonded glass surfaces may expand or contract. These adhesives are flexible and have good resistance to temperature extremes, water, and UV radiation. They are commonly used for sealing windows or bonding glass panels in outdoor structures.

For small or delicate glass items, cyanoacrylate adhesive, also known as super glue, can be used. This adhesive forms an instant bond when it comes into contact with moisture and is perfect for quick repairs or bonding small pieces of glass together. However, it is not suitable for large or load-bearing applications as it tends to be brittle and may not provide enough strength.

Testing the Adhesive Before a Large-Scale Project

Testing the adhesive before a large-scale project that involves sticking glass to glass is crucial. It ensures the longevity and durability of the bond between the glass surfaces. Here are a few reasons why testing the adhesive before embarking on your project is so important:

- Bonding Strength: Different adhesives have varying levels of bonding strength. Testing the adhesive allows you to determine its ability to withstand stressors such as pulling or twisting. You need an adhesive that can hold up against these demands.

- Compatibility with Glass: Not all adhesives adhere well to every type of glass. Some may react negatively with the surface, leading to a weak bond or even damage to the glass itself. By conducting compatibility tests, you can ensure that the adhesive is suitable for the type of glass you intend to use.

- Resistance to Environmental Conditions: Temperature fluctuations, moisture levels, and exposure to UV radiation can impact the performance of an adhesive over time. Subjecting bonded glass samples to accelerated aging tests helps you evaluate how well the adhesive withstands these conditions. This information is essential in determining if it is suitable for your project’s specific requirements.

- Ease of Use and Curing Time: Testing the adhesive allows you to assess its ease of use and curing time. Some adhesives may require specific application techniques or longer cure times, which can affect the efficiency and timeline of your project. By familiarizing yourself with the adhesive’s application process beforehand, you can ensure a smoother workflow during your large-scale project.

Proper Application and Curing Time

Proper application and curing time are crucial when it comes to sticking glass to glass using glue. To achieve a strong and durable bond, it is important to follow a step-by-step process and consider various factors.

Firstly, prepare the surfaces by thoroughly cleaning both glass surfaces. Use a mild detergent or glass cleaner and wipe away any dirt, dust, or grease with a lint-free cloth. This step is not to be underestimated as it ensures that the glue adheres properly to the glass.

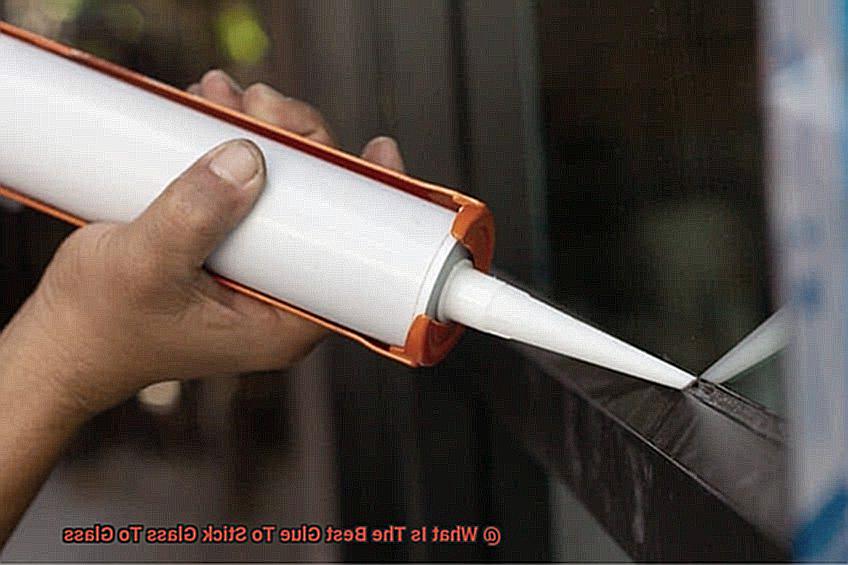

Next, apply the glue following the manufacturer’s instructions. Different glues may have different application methods, so it is essential to read and follow the instructions carefully. Apply the glue evenly on one of the glass surfaces using a brush, spatula, or nozzle, depending on the type of glue.

Once the glue is applied, press the two glass surfaces firmly together. To ensure a strong bond, use clamps or other tools to hold the pieces in place while the glue sets. Applying even pressure across the entire surface will help achieve a secure attachment.

Now comes the crucial step of allowing for curing time. Curing time refers to the time it takes for the glue to fully dry and form a strong bond. This can vary depending on the type of glue used and environmental factors such as temperature and humidity. It is essential to follow the manufacturer’s instructions regarding curing time for optimal bonding.

During the curing process, it is vital not to disturb or move the glued pieces. Any movement can weaken the bond and lead to a less secure attachment between the glass surfaces. Allow sufficient time for the glue to cure undisturbed.

After the recommended curing time has passed, gently test the bond by applying slight pressure or tapping on the glued area. If the bond feels weak or the glass pieces separate easily, it may be necessary to reapply the glue and allow for additional curing time.

Conclusion

In conclusion, the quest for the perfect glue to stick glass to glass demands careful consideration of multiple factors. Compatibility, strength, transparency, curing time, temperature resistance, flexibility, application method, and safety all play pivotal roles in selecting the ideal adhesive.

One standout contender in the realm of glass bonding is epoxy resin. Its formidable strength and remarkable transparency make it a top choice. Once cured, it creates an almost invisible bond that can endure the test of time. For those seeking lightning-fast results and precision beyond compare, UV-curing adhesive steals the show. Its rapid curing time and exquisite precision offer minimal mess and maximum efficiency. When it comes to construction and automotive applications, silicone adhesive reigns supreme with its flexible strength and resistance to extreme temperatures.

Remember: different projects call for specialized glues that offer unique benefits tailored to their specific purposes. Before embarking on a large-scale endeavor, it’s crucial to test the adhesive thoroughly. This ensures optimal bonding strength, compatibility with glass surfaces, resistance to environmental conditions, and ease of use.

Achieving a successful bond involves meticulous preparation of the surface, precise application of glue, firm pressure during bonding, and adherence to recommended curing times. It is vital not to disturb or jostle the glued pieces while they undergo the curing process.

By considering these essential factors and selecting an appropriate adhesive that meets your specific needs, you can forge a robust and enduring bond between glass surfaces.