Are loose bricks driving you up the wall?

Sick of those pesky cracks and gaps ruining your brick masterpiece? Well, worry no more.

Whether you’re a pro contractor or a DIY fanatic, finding the best glue for brick to mortar is the ultimate game-changer. But here’s the kicker – not all adhesives are created equal.

From polyurethane and epoxy to construction glues and mortar-based wonders, the options can leave you scratching your head. Fear not, my fellow brick aficionados, because in this blog post, we’re gonna spill the beans on how to choose the perfect adhesive that’ll keep your bricks firmly in place, creating a rock-solid structure that’s easy on the eyes.

So buckle up as we dive into the wild world of adhesives and uncover the one that reigns supreme in the epic battle of brick-to-mortar bonding.

What is Mortar?

Contents

In the world of construction, there is a humble substance that often goes unnoticed but plays a vital role in creating sturdy structures – mortar. This essential glue, made from a mixture of cement or lime, sand, and water, binds bricks and stones together, providing strength, stability, and durability. In this article, we will explore the composition of mortar, its importance in construction, and the various types available for different applications.

The Backbone of Masonry:

Mortar serves as the backbone of any masonry project. Its primary function is to fill the gaps between bricks or stones, creating a solid and unified surface. By binding these materials together, mortar evenly distributes the load across the entire construction, preventing any individual brick from bearing excessive weight. It acts as the glue that holds the structure together.

Protection Against the Elements:

Beyond its structural role, mortar also acts as a protective barrier against the elements. By sealing the gaps between materials, it prevents moisture penetration and helps maintain a dry interior. This protection is especially crucial in areas with harsh weather conditions where water infiltration can lead to structural damage and mold growth. Mortar ensures that buildings withstand the test of time.

Different Types of Mortar:

Mortar comes in various types tailored to specific construction needs. The most commonly used type is cement mortar, made by mixing Portland cement with sand and water. It offers excellent strength and durability, making it suitable for most applications. However, for those looking for greater flexibility and breathability, lime mortar is an alternative option. Though not as strong as cement mortar, it offers better adaptability to certain situations.

Mixing and Application:

Creating the perfect mortar mix involves careful proportioning of ingredients to achieve the desired consistency and workability. A typical ratio of 1 part cement or lime to 3 parts sand is used for general-purpose mortar. For load-bearing structures requiring extra strength, a ratio of 1 part cement or lime to 2 parts sand is preferred.

To achieve a homogeneous mixture, the ingredients are mixed with water using a hoe, shovel, or mechanical mixer. The mortar should have a smooth and workable consistency without being too dry or too wet. Proper mixing is crucial for optimal bonding and structural integrity.

Specialized Mortars:

In addition to general-purpose mortars, there are specialized options available for unique applications. For instance, there are mortars designed specifically for laying bricks, repairing masonry, or withstanding extreme weather conditions. These specialized mortars may contain additives or admixtures to enhance their performance and durability.

Types of Glue for Brick to Mortar Bonding

When it comes to bonding bricks to mortar, selecting the right glue is vital. The adhesive used can determine the strength and durability of the bond. In this article, we will explore different types of glues specifically designed for brick to mortar bonding, analyzing their characteristics and suitability for various applications.

Epoxy Adhesive:

Epoxy adhesives are renowned for their incredible strength and durability, making them ideal for heavy-duty applications such as construction projects. Comprised of two components that need to be mixed together, epoxy adhesives create a permanent bond between brick and mortar that can withstand extreme conditions. The chemical reaction during the curing process ensures a strong and reliable connection.

Polyurethane Adhesive:

Polyurethane adhesives offer flexibility and excellent resistance to moisture, making them perfect for outdoor applications. Available in single or two-component forms, these adhesives can adapt to temperature changes without compromising the bond. With good gap-filling properties, they are suitable for uneven surfaces and provide a long-lasting connection.

Acrylic Adhesive:

Acrylic adhesives are easy to work with and provide a strong bond between brick and mortar. Resistant to weathering and UV exposure, they are particularly suitable for outdoor use. However, in high-stress or heavy-load situations, they may not offer the same level of durability as epoxy or polyurethane adhesives.

Construction Adhesive:

Construction adhesives are commonly used in various construction projects, including brickwork. Available in tubes and applied with a caulking gun, these adhesives provide excellent adhesion to both brick and mortar surfaces. They offer a strong bond and are suitable for a wide range of applications.

Silicone Adhesive:

Silicone adhesives are perfect for outdoor use due to their flexibility and resistance to temperature changes. They create a waterproof seal between the brick and mortar, protecting the bond from water penetration. Available in different colors, silicone adhesives can be matched to the color of the mortar, ensuring a seamless finish.

Advantages of Polyurethane Adhesive

Polyurethane adhesive is the superhero of adhesives, offering a wide range of advantages that make it the go-to choice for bonding brick to mortar and other materials. Let’s explore these advantages in more detail:

- Incredible bonding strength: Polyurethane adhesive creates an unbreakable bond between brick and mortar, ensuring a sturdy and durable structure. Its bonding power rivals even the strongest friendships forged in adversity.

- Water and moisture resistance: This adhesive is highly resistant to water infiltration, making it perfect for structures exposed to the elements or prone to dampness. It adds a superpower waterproof shield to your brickwork, preventing any weakening of the bond over time.

- Flexibility and movement resistance: Polyurethane adhesive can withstand movement and vibrations without cracking or losing its grip. Whether you live in an earthquake-prone area or have a structure that experiences regular shifts, this adhesive will keep those bricks snug as a bug in a rug.

- Versatility: This adhesive is a jack-of-all-trades, capable of bonding not only brick to mortar but also concrete, wood, metal, and plastic. It’s the perfect choice for all your construction and repair needs.

- Speedy curing time: Polyurethane adhesive sets quickly, forming a strong bond in no time at all. This saves you precious hours of waiting around and allows you to move on with your project at lightning speed.

- Ease of use: Applying polyurethane adhesive is a breeze. No need for primers or extensive surface preparation. Just grab your trusty caulking gun, trowel, or brush and get to work. It’s as easy as pie.

Advantages of Epoxy Adhesive

When it comes to bonding brick to mortar, choosing the right adhesive is crucial for ensuring a secure and long-lasting connection. In this article, we will uncover the incredible advantages of using epoxy adhesive for this task. Known for its exceptional strength, durability, water resistance, flexibility, versatility, and longer working time, epoxy adhesive stands out as the ultimate superhero glue for brick to mortar bonding.

Strength and Durability:

Epoxy adhesive’s high strength properties allow it to withstand heavy loads and resist extreme temperatures, ensuring a long-lasting bond that provides structural integrity even in challenging environments.

Gap-Filling Capability:

Unlike other adhesives, epoxy adhesive effortlessly fills gaps and uneven surfaces, creating a strong bond that keeps bricks firmly in place.

Water Resistance:

Epoxy adhesive acts as a moisture-resistant barrier, preventing water from seeping into the bond and safeguarding the integrity of both bricks and mortar.

Excellent Adhesion:

With exceptional adhesion properties, epoxy adhesive ensures a strong and reliable connection between brick and mortar, eliminating worries about movement or separation over time.

Versatility:

Epoxy adhesive is compatible with various types of bricks and mortars, including clay bricks, concrete bricks, and different mortar mixes.

Longer Working Time:

Epoxy adhesive provides a longer working time compared to other adhesives, allowing users more flexibility in applying and positioning bricks before the adhesive sets.

Formulation Options:

Epoxy adhesive is available in different formulations, including fast-curing options for projects requiring quick results. Users can select the perfect epoxy adhesive based on their specific needs and project requirements.

Important Considerations Before Applying Glue

Today, we’re diving into the world of glue and exploring the crucial considerations you need to keep in mind before applying it to attach bricks to mortar. Whether you’re a DIY enthusiast or a professional contractor, these tips will ensure your projects are built to last.

- Compatibility: Not all glues are created equal, and compatibility is key. Ensure the glue you choose works harmoniously with both the brick and mortar materials. Reading the manufacturer’s instructions and guidelines will save you from potential damage or weak bonds.

- Strength: When bonding bricks to mortar, strength matters. Seek out glues specifically designed for heavy-duty applications or labeled as suitable for brickwork. You want an adhesive that can withstand the weight and pressure exerted over time.

- Weather Resistance: Mother Nature can be tough on our construction projects, so choose a glue that can handle it all. Opt for an adhesive resistant to moisture, temperature changes, and UV radiation. This ensures your bond remains intact and durable.

- Application Method: How you apply the glue significantly impacts bond effectiveness. Some glues come in pre-mixed paste form, while others require mixing or specific tools. Consider your skill level and project requirements when choosing the right application method.

- Drying Time: Quick-drying or extended drying periods – which suits your needs? Depending on your project timeline, select a glue that aligns with your schedule. Remember, rushing the drying process may compromise bond strength.

- Flexibility: An adhesive’s ability to accommodate natural movement and expansion is essential. Opt for a glue that provides flexibility to prevent cracks or separation due to structural shifts over time.

- Safety Precautions: Safety should always be a priority when working with glue. Some adhesives emit strong fumes or require specific handling precautions. Read and follow the safety instructions provided by the manufacturer to protect yourself and others involved in the project.

How to Apply the Glue Properly?

Applying glue is an art that requires precision and careful attention to detail. When it comes to bonding bricks to mortar, getting the glue application right is crucial for a strong and long-lasting bond. In this guide, we will explore five essential steps to properly apply glue for brick-to-mortar bonding. Whether you’re a DIY enthusiast or a professional mason, mastering these techniques will ensure your projects stand the test of time.

Step 1: Prepare for Success

Before applying glue, thorough preparation is key. Clean both the brick and mortar surfaces meticulously, ensuring they are free from any loose particles or debris. Use a wire brush or scraper to remove dirt and create a clean canvas for bonding. Remember, a pristine surface guarantees a seamless and robust bond.

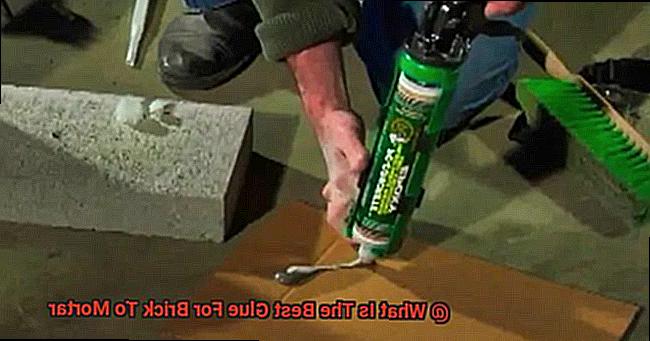

Step 2: Choose the Right Glue

Just as an artist selects their tools, choosing the right glue is crucial for successful bonding. Opt for construction adhesives specifically designed for masonry applications when bonding brick to mortar. Polyurethane-based adhesives are popular due to their exceptional adhesive strength and resistance to moisture. Selecting the right glue sets the foundation for a sturdy bond.

Step 3: Apply with Precision

With your surfaces prepared and glue chosen, it’s time to apply the adhesive with precision. Use a trowel or putty knife to spread an even layer of glue onto both the brick and mortar surfaces. Avoid applying too much or too little glue, as this can compromise the bond’s strength. Remember, thin and even is the goal here.

Step 4: Press and Hold Firmly

Now comes the exciting part – pressing the brick onto the mortar surface. Apply firm and steady pressure across the entire bonded area to ensure maximum contact between the materials. Secure the materials in place using clamps or other support tools while the glue sets. Patience is key at this stage, allowing the glue to work its magic.

Step 5: Allow Ample Curing Time

After applying the glue and pressing the materials together, allow sufficient time for the adhesive to cure and create a strong bond. Follow the manufacturer’s instructions regarding the recommended drying time. During this critical period, avoid any stress or movement that could disrupt the bond. Think of it as giving your masterpiece time to set.

Benefits of Using Mortar Instead of Glue

If you’ve been considering glue as a bonding agent for your projects, allow me to introduce you to a time-tested alternative that will change your perspective – mortar. For centuries, professionals worldwide have relied on mortar for its unparalleled advantages over glue. Today, I’ll explain why mortar reigns supreme in construction applications.

Unmatched Strength and Durability:

Mortar’s composition of cement, sand, and water creates a bond that rivals the strength and durability of any glue. It withstands heavy loads and resists various weather conditions, ensuring long-lasting structural integrity.

Even Load Distribution:

No one wants their hard work to crumble under pressure. Mortar evenly distributes weight and pressure across the entire surface area, preventing individual bricks from cracking or breaking easily. With mortar, your construction stays intact for years.

Gap Filling Capabilities:

Unlike glue, mortar flawlessly fills gaps and irregularities between bricks. Every nook and cranny is precisely filled, creating a tight and even bond between each brick. This enhances both strength and overall stability.

Customization Options:

Mortar offers flexibility in joint thickness, allowing you to achieve the desired aesthetic appearance or structural characteristics. Whether you aim for a sleek modern look or a rustic traditional vibe, mortar can be adjusted accordingly to bring your vision to life.

Aesthetic Appeal:

Mortar doesn’t compromise on beauty either. It can be tinted or colored to match the desired look of your construction project. This means you can achieve a uniform and visually appealing finish that perfectly complements the surrounding environment.

Cost-Effectiveness:

While glue may appear cost-effective initially, mortar provides long-term value with its superior strength and durability. Mortar minimizes the need for frequent repairs or replacements due to adhesive failure, ultimately saving you money.

Ease of Maintenance and Repair:

Mortar makes maintenance and repairs a breeze. If a brick becomes damaged or needs replacement, it can be easily removed and replaced with new mortar applied to ensure a seamless bond. This flexibility is especially important for projects that may require future modifications or renovations.

mA-xRl0Bzmo” >

Conclusion

In conclusion, selecting the best glue for brick to mortar is crucial for forging a robust and enduring connection that can withstand the test of time. Throughout this blog post, we delved into a multitude of adhesives tailor-made for bonding bricks to mortar.

Among the contenders, epoxy adhesive emerged as a frontrunner due to its exceptional might, resilience, water resistance, adaptability, versatility, and extended working window. It establishes an indomitable bond between brick and mortar, making it an ideal choice for heavy-duty applications. Additionally, polyurethane adhesive boasts superb moisture resistance and flexibility, rendering it perfect for outdoor utilization.

When employing glue, it is vital to take into account factors such as material compatibility, strength requirements, weather endurance, application technique, drying duration, flexibility levels, and safety precautions.

Nevertheless, it is worth highlighting that mortar possesses numerous advantages over glue. Mortar proffers unparalleled strength and durability while evenly dispersing weight and pressure across the entire structure. It seamlessly fills crevices between bricks and allows for customization options in terms of joint thickness and aesthetic allure. Moreover, mortar proves cost-effective in the long run and offers ease of maintenance and repair.

Ultimately, the decision between glue and mortar hinges on your specific project prerequisites.