Sticking rubber to steel may sound like a sticky situation, but fear not. With the right glue in your toolbox, you can achieve a bond that’s stronger than superglue’s hold on a broken vase. Whether you’re a DIY enthusiast or an industrial wizard, knowing which adhesive will do the trick is essential.

When it comes to rubber and steel, they couldn’t be more different. Rubber is all about flexibility and bounce-back, while steel demands toughness and resistance. But don’t worry, there are glues out there that can bridge this material gap with ease.

So let’s dive into two glue options that will make rubber and steel stick together like lifelong friends – cyanoacrylate (super glue) and industrial-grade epoxies.

Cyanoacrylate glue, also known as super glue, is the superhero of adhesives. It forms an instant bond between rubber and steel, penetrating the rubber’s surface and creating an unbreakable grip. This glue can handle temperature changes like a champ and has impressive tensile strength. It’s perfect for those smaller projects where you need a quick fix.

But if you’re tackling something bigger or tougher, enter industrial-grade epoxies. These bad boys consist of two parts – resin and hardener – that combine forces to create a chemical bond of epic proportions. Industrial-grade epoxies laugh in the face of heat, moisture, and chemicals. They’re built for heavy-duty applications where rubber components face constant stress or harsh environments.

In conclusion, finding the right glue for sticking rubber to steel is crucial for success. Cyanoacrylate glue works wonders for smaller projects with its fast adhesion and reliability. Meanwhile, industrial-grade epoxies bring unmatched strength and resilience to larger endeavors. So consider the unique properties of your materials and project requirements before making your adhesive choice. With the right glue in hand, you’ll be sticking rubber to steel like a pro in no time.

What is Rubber and Steel?

Contents

- 1 What is Rubber and Steel?

- 2 Different Types of Glue for Bonding Rubber to Steel

- 3 Advantages and Disadvantages of Epoxy Adhesive

- 4 Advantages and Disadvantages of Cyanoacrylate (Super Glue)

- 5 Specialized Adhesives for Bonding Rubber to Steel

- 6 Environmental Considerations When Bonding Rubber to Steel

- 7 How to Prepare Surfaces for Bonding Rubber to Steel

- 8 Conclusion

Rubber and steel, two materials with distinct properties, have found their way into various industries and applications. From tires to construction, they play a crucial role in our everyday lives. But have you ever wondered how these two materials can be effectively bonded together? In this blog post, we will dive into the world of rubber and steel, exploring their unique characteristics and the secrets behind successful bonding.

Rubber: Elasticity meets versatility

Rubber, derived from tree sap or synthetically produced, boasts impressive properties like elasticity, resilience, and electrical insulation. Natural rubber offers flexibility and low-temperature resistance, making it perfect for tires, seals, gaskets, and conveyor belts. Synthetic rubbers are engineered to possess specialized properties such as oil or heat resistance.

Steel: The epitome of strength and durability

Steel, widely recognized for its strength, durability, and corrosion resistance, is an alloy primarily composed of iron mixed with carbon and other elements. Its high tensile strength enables it to withstand heavy loads, making it a popular choice in construction, automotive manufacturing, and aerospace industries.

The challenge of bonding rubber to steel

Bonding rubber to steel presents a unique challenge due to their inherent differences in composition and surface characteristics. Rubber surfaces have low surface energy and are generally non-porous, making it difficult for adhesives to form strong bonds. On the other hand, steel surfaces can be rough or smooth depending on the manufacturing process.

The glue that holds them together

To achieve a reliable bond between rubber and steel, selecting the right adhesive is crucial. Epoxy adhesives are known for their strong bond strength and versatility. They require proper surface preparation to ensure effective bonding. Cyanoacrylates, popularly known as super glue, offer instant bonding but require specific formulations designed for rubber-to-steel applications.

Specialized adhesives for specialized needs

In addition to epoxy and cyanoacrylate, specialized adhesives formulated specifically for rubber-to-steel bonding are available. These adhesives contain ingredients that enhance bond strength and flexibility between the two materials, ensuring long-lasting results.

Consider the environment

When selecting an adhesive, it is important to consider the environmental conditions the bond will be exposed to. Temperature, moisture, and chemicals can affect adhesive performance. Choose an adhesive suitable for the specific application and environment.

Different Types of Glue for Bonding Rubber to Steel

It may seem like an impossible task, but with the right glue, it’s as easy as piecing together a puzzle. In this blog post, we will explore five different types of glue that can be used to bond rubber to steel. Each type has its own unique properties and strengths, so let’s dive in and find out which one is the best fit for your project.

Epoxy Adhesive:

Imagine a superhero with super strength – that’s epoxy adhesive. This glue is known for its incredible bonding capabilities. It works by mixing two special ingredients together – a resin and a hardener. When these two substances combine, they create a chemical reaction that forms a super strong adhesive. Epoxy adhesive is resistant to moisture and chemicals, making it perfect for all sorts of projects.

Cyanoacrylate Adhesive:

If you need a quick fix, look no further than cyanoacrylate adhesive, also known as super glue. Just like its name suggests, this glue works super fast. When it comes into contact with moisture in the air, it hardens and creates an instant bond. However, be careful not to use too much of this glue as it can become brittle over time.

Rubber Cement:

Rubber cement is like the rubber’s best friend – they go together like peanut butter and jelly. This special adhesive is designed specifically for bonding rubber materials. It works by using a process called solvent evaporation. When you apply rubber cement to the surfaces, the solvent evaporates, leaving behind a strong bond between the rubber and steel. Keep in mind that rubber cement may not be as strong as other adhesives, so choose wisely depending on your project.

Polyurethane Adhesive:

If your project involves lots of movement or vibrations, then polyurethane adhesive is your go-to glue. It’s like a gymnast, flexible and resistant to impact. This adhesive chemically reacts and cures to create a strong bond between rubber and steel. It can withstand a wide range of temperatures and environmental conditions, making it perfect for outdoor or high-stress applications.

Silicone Adhesive:

Last but not least, we have silicone adhesive – the heat-resistant hero. This glue is known for its flexibility and resistance to chemicals. It creates a strong bond by curing over time. Silicone adhesive can handle high temperatures and tough environmental conditions. However, keep in mind that it may not be as strong as other adhesives when it comes to sheer strength.

Advantages and Disadvantages of Epoxy Adhesive

Epoxy adhesive is a commonly used option for bonding rubber to steel surfaces due to its exceptional bonding strength. However, it’s important to consider the advantages and disadvantages before choosing this adhesive. This post explores the pros and cons of using epoxy adhesive for this specific application.

Advantages:

- Strong Bonding: Epoxy adhesive forms a robust and long-lasting bond between rubber and steel surfaces, making it suitable for demanding applications that require resistance to stress.

- Versatility: Epoxy adhesive can be used on a wide range of materials, including rubber and steel, offering flexibility in bonding different surfaces together.

- Chemical Resistance: Epoxy adhesive exhibits excellent resistance to chemicals, oils, and solvents, ensuring the bond remains intact even in harsh environments with exposure to such substances.

- Temperature Resistance: Epoxy adhesive remains stable under extreme temperatures, making it suitable for applications in diverse temperature conditions without compromising its bonding properties.

- Gap Filling Abilities: Epoxy adhesive has the remarkable ability to fill gaps and create a strong bond on irregular or uneven surfaces, making it invaluable for joining rubber and steel components that may not have a perfect fit.

Disadvantages:

- Mixing Required: Epoxy adhesives typically come in two parts—a resin and a hardener—that need to be mixed before application. This additional step can be time-consuming and requires careful measurements to achieve the proper ratio for optimal performance.

- Curing Time: Compared to other types of adhesives, epoxy adhesive takes longer to cure. It can take several hours or even days for the adhesive to fully set and achieve its maximum strength. Patience is required when using epoxy adhesive.

- Limited Flexibility: Once cured, epoxy adhesive becomes relatively rigid. This lack of flexibility may not be suitable for applications where rubber and steel components require some degree of movement or flexibility.

- Health and Safety Considerations: Epoxy adhesives contain chemicals that can be harmful if not handled properly. It is crucial to follow safety guidelines, such as wearing protective gloves and working in a well-ventilated area, to avoid any adverse health effects.

- Difficult Removal: Once epoxy adhesive has fully cured, it can be challenging to remove or reposition the bonded components. This lack of reversibility can make repairs or modifications more difficult and time-consuming.

Advantages and Disadvantages of Cyanoacrylate (Super Glue)

Cyanoacrylate, more commonly known as super glue, has both advantages and disadvantages when it comes to bonding rubber to steel. Let’s explore these factors in more detail.

Advantages:

- Incredible bonding strength: Super glue forms a tight seal between rubber and steel surfaces, ensuring a secure connection. This strength provides peace of mind, knowing that your project will stay intact.

- Lightning-fast drying time: In just a matter of seconds, super glue sets and forms a strong bond. This quick drying time is perfect for projects that require immediate adhesion, saving you time and effort.

- Versatility: Super glue can bond a wide range of materials, including plastic, wood, ceramics, and metals. Whether you’re working on an arts and crafts project or fixing something around the house, super glue has got you covered.

- Water resistance: Once cured, super glue creates a waterproof seal that can withstand moisture and humidity. This makes it suitable for both indoor and outdoor use.

Disadvantages:

- Lack of flexibility: Super glue is not very flexible, which can be problematic when bonding materials that need to bend or stretch, such as rubber components.

- Limited gap-filling ability: Super glue works best on smooth and flat surfaces that fit together tightly. If there are gaps or uneven surfaces between the rubber and steel, super glue may not be the most effective choice.

- Sensitivity to temperature and moisture: Extreme heat or humidity can weaken the bond or cause it to fail completely. If you’re working in extreme conditions, you may need to explore other adhesive options.

- Potential health hazards: Super glue emits fumes during the curing process that can irritate your eyes, nose, and throat. It’s important to use it in a well-ventilated area and take proper precautions to minimize exposure.

Specialized Adhesives for Bonding Rubber to Steel

Rubber and steel, an unlikely duo that sometimes needs to join forces in perfect harmony. Whether it’s automotive components, industrial equipment, or household appliances, the challenge of bonding rubber to steel is a common one. Luckily, there are specialized adhesives that can handle this task with ease.

One popular choice for bonding rubber to steel is neoprene-based adhesive. Neoprene adhesives offer excellent adhesion to both rubber and steel surfaces. They are resistant to water, oils, and chemicals, making them suitable for a wide range of applications. These adhesives also provide flexibility, allowing for movement between the bonded surfaces without compromising the strength of the bond.

Epoxy adhesives are another go-to option. They offer exceptional bonding strength, high shear strength, and excellent resistance to impact and vibration. With good chemical resistance properties, they can handle applications where exposure to harsh chemicals is expected.

For extreme temperatures and excellent flexibility, look no further than polyurethane adhesives. These adhesives offer a strong bond between rubber and steel surfaces and have outstanding resistance to impact, vibration, and aging. That’s why they are often found in automotive applications, bonding rubber components to steel frames.

Now that we’ve covered the different types of specialized adhesives, let’s talk about surface preparation. Before applying any adhesive, it’s crucial to properly clean and degrease both the rubber and steel surfaces. This ensures there are no contaminants that could interfere with the bonding process.

In addition to cleaning, roughening the surfaces can greatly improve the adhesive bond. Sandpaper or chemical etching techniques can be used to create a roughened texture on both the rubber and steel surfaces. This rough surface allows the adhesive to grip onto the materials more effectively, resulting in a stronger bond.

When choosing the right adhesive for your rubber to steel bonding needs, consider factors such as temperature resistance, chemical compatibility, flexibility, and curing time. Consulting with adhesive manufacturers or experts can provide valuable guidance if you’re unsure which adhesive is best for your project.

Environmental Considerations When Bonding Rubber to Steel

When bonding rubber to steel, it is crucial to consider the environmental factors that can impact the durability of the bond. These factors include temperature, moisture, exposure to chemicals, and UV radiation.

Temperature is a key player in the bonding process. Extreme heat or cold can wreak havoc on both the adhesive and the materials being bonded. Adhesives not designed for high temperatures may soften or degrade, weakening the bond. On the flip side, low temperatures can make adhesives brittle and less effective. To ensure a durable bond, it is essential to choose an adhesive specifically formulated for the expected operating temperatures.

Moisture is another environmental consideration that cannot be ignored. Water or excessive humidity can wreak havoc on adhesives, causing them to swell, soften, or lose their bonding properties. In some cases, moisture can even lead to corrosion of the steel substrate. Opting for adhesives with excellent water resistance properties is crucial when exposure to moisture is expected.

Chemical exposure is yet another factor to take into account. Oils, solvents, acids, or alkalis present in the environment can weaken or degrade the adhesive over time. It is important to choose an adhesive that is resistant to the specific chemicals present in the operating environment to ensure a long-lasting bond.

UV radiation from sunlight poses a challenge in outdoor applications. Adhesives and rubber materials can degrade and lose their strength and elasticity when exposed to UV rays. Choosing adhesives with UV resistance properties is necessary for applications exposed to direct sunlight or other sources of UV radiation.

In addition to these environmental considerations, it is important to be aware of any regulatory requirements or industry standards that may apply. Different industries may have specific bonding requirements for safety or performance reasons. Adhering to these standards ensures compliance and optimal performance.

How to Prepare Surfaces for Bonding Rubber to Steel

Well, you’ve come to the right place. In this comprehensive guide, we will walk you through the steps to prepare surfaces for a successful bonding process. Whether you’re a DIY enthusiast or a professional in the industry, these tips will help you achieve a strong and durable bond between rubber and steel.

Cleanliness is Key:

Before applying any adhesive, it’s crucial to ensure that both the rubber and steel surfaces are squeaky clean. Take a moment to remove any dirt, dust, grease, or oil from the surfaces. You can use a degreaser or isopropyl alcohol to clean the steel surface thoroughly. For the rubber surface, a simple soap and water solution will do the trick. Remember, cleanliness is the foundation for a successful bond.

Roughen Up for Better Adhesion:

To enhance adhesion, you can lightly sand the steel surface with fine-grit sandpaper. This will create a roughened texture that provides more surface area for the adhesive to grip onto. For smooth rubber surfaces, gently sanding them with sandpaper can also improve adhesion. However, be careful not to oversand and damage the rubber.

Dryness Matters:

Moisture is the enemy of a strong bond. After cleaning the surfaces, make sure they are completely dry before applying any adhesive. Allow them to air dry for at least 24 hours. Moisture can interfere with the bonding process and weaken the adhesive’s effectiveness. So, be patient and let them dry naturally.

Choosing the Right Glue:

Selecting the appropriate adhesive is crucial for bonding rubber to steel successfully. Epoxy adhesives are known for their strength and versatility, making them a popular choice. Cyanoacrylate, or super glue, can also work well, but make sure to use a formulation specifically designed for rubber and steel. There are also specialized rubber-to-steel adhesives available on the market that offer enhanced bond strength and flexibility.

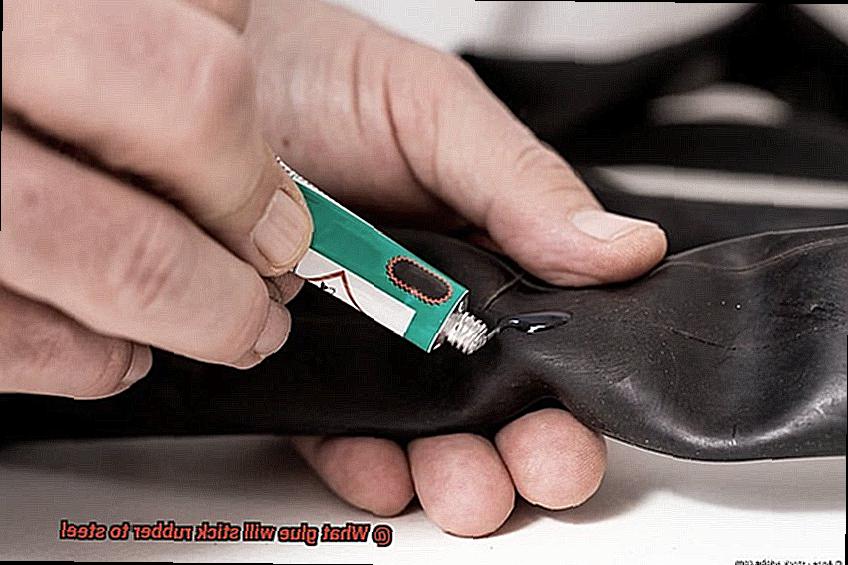

Applying the Adhesive:

Follow the manufacturer’s instructions carefully when applying the adhesive. Apply a thin, even layer of adhesive to both the steel and rubber surfaces. Remember, a little goes a long way. Avoid applying too much adhesive as it can lead to excess buildup and weaken the bond. After applying the adhesive, align the rubber and steel surfaces together and apply even pressure to ensure good contact.

Patience is a Virtue:

Allow the adhesive to cure according to the manufacturer’s instructions. This may involve leaving the bonded surfaces undisturbed for a specific period or subjecting them to specific temperature or humidity conditions. Be patient and give the adhesive ample time to reach its maximum strength before subjecting it to any stress or load.

jzhXmioKTa4″ >

Also Read: How to Glue Rubber to Painted Metal?

Conclusion

When it comes to bonding rubber to steel, finding the right glue is crucial.

Luckily, there are several options available that can create a strong and durable bond between these two materials. One popular choice is epoxy adhesive, known for its exceptional strength and versatility.

Another reliable option is cyanoacrylate adhesive, commonly referred to as super glue, which forms an instant bond and works well on both rubber and steel surfaces. For more specific applications, such as automotive or industrial use, polyurethane adhesive is often recommended due to its resistance to heat, chemicals, and water.

Whichever glue you choose, make sure to thoroughly clean and prepare the surfaces before applying it for optimal adhesion.