Ready to dive into the exciting world of bonding metal to granite? Whether you’re a DIY daredevil or a seasoned pro, mastering this art is an invaluable skill that opens up endless possibilities for your projects. Say goodbye to flimsy connections and hello to rock-solid bonds that will stand the test of time.

At first glance, metal and granite may seem like an odd couple. But don’t be fooled. There are countless options available to create a powerful bond between these two unlikely materials. In this comprehensive guide, we’ll take you on an exhilarating journey through various methods, equipping you with detailed instructions on the essential materials, tools, and techniques needed.

From tried-and-true adhesives that can save the day in a pinch, to mighty epoxy solutions that defy gravity itself, we’ve got you covered. No matter what kind of project you’re tackling – big or small, simple or intricate – we’ll explore a range of options tailored just for you. So grab your safety glasses, roll up those sleeves, and prepare yourself for the adventure of gluing metal to granite. With our expert guidance, there’s no challenge too tough for you.

So let’s get started. Together, we’ll unlock the secrets behind creating unbreakable bonds between metal and granite. Get ready to unleash your inner glue guru and conquer any metal-granite bonding challenge that comes your way.

Types of Adhesives for Bonding Metal to Granite

Contents

- 1 Types of Adhesives for Bonding Metal to Granite

- 2 Preparing Surfaces for Adhesive Application

- 3 Applying the Adhesive: Tips and Tricks

- 4 Pressure Application to Secure Bond

- 5 Curing Time for Different Adhesives

- 6 Removing Excess Adhesive After Curing

- 7 Factors That Affect Bond Strength

- 8 Testing the Adhesive Before Use

- 9 Conclusion

When it comes to bonding metal to granite, the right adhesive can make all the difference. In this blog post, we will explore five distinct types of adhesives that are commonly used for this purpose. From rock-solid epoxies to flexible polyurethanes, these adhesives offer unique properties that ensure a strong and durable bond. So, let’s dive in and discover the adhesive superheroes that keep metal and granite together.

Epoxy Adhesive:

Epoxy adhesives are like the superheroes of bonding metal to granite. These two-part adhesives consist of resin and hardener that are mixed together before application. Once applied, epoxy forms an incredibly strong bond that can withstand heavy loads and temperature changes.

It’s the rock-solid glue that keeps metal and granite fused together. Whether you’re installing countertops or securing metal fixtures, epoxy adhesives offer unmatched durability and reliability.

Polyurethane Adhesive:

If you need a flexible bond that can handle movement and moisture, polyurethane adhesive is your go-to hero. Like a gymnast, it bends and stretches to accommodate vibrations or changes in your metal-to-granite connection.

Polyurethane adhesives offer excellent flexibility and resistance to water and chemicals. They can withstand the test of time while maintaining their adhesive strength. Whether it’s outdoor furniture or metal trim on granite surfaces, polyurethane adhesives provide a bond that can weather any storm.

Silicone Adhesive:

When it comes to high temperatures and outdoor applications, silicone adhesive takes the spotlight as the brave knight protecting your bond from extreme heat. Silicone adhesives designed for metal bonding provide excellent adhesion and can withstand scorching temperatures without losing their grip.

They are like a shield against thermal expansion and contraction, ensuring a strong bond between metal and granite in environments where other adhesives might fail. From kitchen appliances to outdoor sculptures, silicone adhesives are the reliable armor that keeps your metal and granite united.

Construction Adhesive:

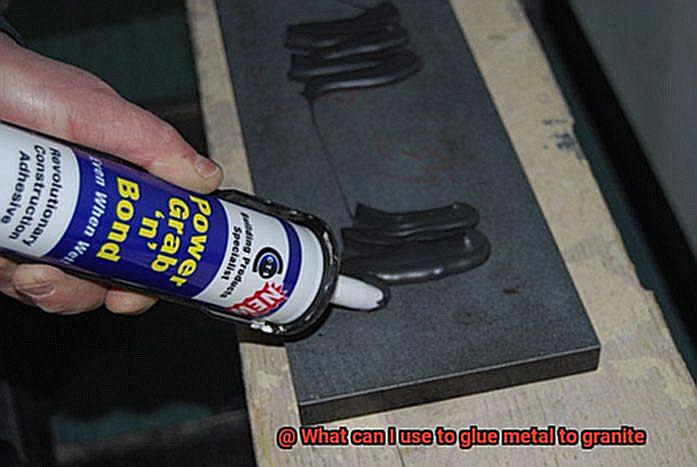

For heavy-duty projects, construction adhesives are the true champions. These tough adhesives, available in polyurethane or epoxy formulations, provide exceptional strength for permanent bonds. They are like the superheroes of the adhesive world, saving the day in construction projects.

Whether you’re bonding metal brackets to granite walls or securing metal handrails, construction adhesives offer a reliable and long-lasting bond that can withstand the test of time.

Structural Adhesive:

For those looking for an adhesive that can bond different materials together, structural adhesives are here to save the day. These high-strength adhesives, available in different types like acrylic-based or methacrylate-based, can bond metals to granite with ease. They bring harmony to different materials, just like peacekeepers resolving conflicts.

Preparing Surfaces for Adhesive Application

To ensure a strong and lasting bond when gluing metal to granite, proper surface preparation is crucial. By following these steps, you can unleash the power of adhesive bonding and create a rock-solid connection.

- Cleanliness: Start by removing any dirt, dust, grease, or contaminants from both the metal and granite surfaces. Use a suitable degreaser or solvent for the metal and a gentle stone cleaner for the granite. A soft cloth or sponge will help you achieve a clean and pristine surface.

- Roughening: To enhance bonding strength, lightly roughen both surfaces. Gently sand the metal using sandpaper or a wire brush to create a textured surface that allows the adhesive to grip effectively. Be careful not to damage the metal. For the granite, use sandpaper or a diamond pad to create a slightly roughened texture without causing any harm.

- Priming: Consider using primers to boost adhesion. Metal primers and granite primers are available to enhance bonding strength. Follow the manufacturer’s instructions and allow sufficient drying time before proceeding.

- Compatibility: Select an adhesive that is compatible with both metal and stone surfaces. Epoxy adhesives are often the go-to choice due to their excellent bonding strength and compatibility with different materials.

- Application: Apply the adhesive according to the manufacturer’s instructions, as each adhesive has its unique application method and curing time. Ensure even distribution of the adhesive and avoid excess glue leakage. Bring the metal and granite surfaces together firmly, ensuring proper alignment. If necessary, use clamps or weights to hold them in place while the adhesive sets.

Applying the Adhesive: Tips and Tricks

The process may seem daunting, but fear not. With expert tips and tricks, you can become a master of adhesive application, ensuring a durable and long-lasting connection between these two materials. In this informative guide, we will delve into the secrets of applying adhesive correctly, providing you with invaluable advice to make your project a resounding success.

Prepare for Success

Before embarking on the adhesive application process, meticulous surface preparation is paramount. Take the time to cleanse both the metal and granite surfaces thoroughly, using a gentle detergent or solvent. Rid them of any stubborn dirt, grease, or debris that could hinder optimal adhesion. For an added boost in bond strength, gently sand the surfaces to create a tactile texture that amplifies the adhesive’s grip.

Choose the Perfect Adhesive

Selecting the ideal adhesive is key to achieving a seamless bond between metal and granite. Enter epoxy adhesives – renowned for their exceptional strength and durability. Opt for an epoxy specifically formulated for bonding metal and stone surfaces, ensuring it possesses the resilience to withstand temperature fluctuations.

Mix It Right

When working with epoxy adhesives, precision is paramount. Diligently adhere to the manufacturer’s instructions regarding the mixing ratio. Typically, equal parts of resin and hardener are required. Vigorously blend them until they unite seamlessly, forming a uniform consistency. Pay heed to the recommended mixing time, leaving no trace of unmixed portions behind.

Apply with Precision

Ensure a flawless bond by meticulously applying the adhesive across both the metal and granite surfaces. Employ a brush or spatula to distribute the adhesive evenly, guaranteeing comprehensive coverage. To prevent premature drying, work in small sections, allowing for meticulous control and optimal adhesive spread.

Secure for Success

Once the adhesive is artfully applied, the time has come to align the metal piece with the granite surface. Exercise caution and precision, applying measured pressure using clamps or weights. This ensures that the surfaces remain in intimate contact throughout the curing process. Adhere strictly to the manufacturer’s guidelines concerning curing time and temperature to achieve an unwavering bond.

A Finishing Touch

During the clamping process, it is not uncommon for a surplus of adhesive to escape from the bond line. Fear not – simply utilize a clean cloth or paper towel soaked in a suitable solvent (refer to adhesive instructions) to delicately eliminate any excess adhesive before it sets. Exercise caution, ensuring that the alignment of the metal and granite remains undisturbed.

Pressure Application to Secure Bond

Pressure application is a vital step in securing a bond between metal and granite using adhesive. By exerting pressure, the adhesive is driven into the microscopic surface irregularities of both materials, creating a robust and long-lasting bond. There are several methods available for applying pressure during the bonding process, each with its own advantages and considerations.

One popular method is the use of clamps or weights to directly apply pressure to the joint. Clamps are ideal for smaller or delicate metal pieces, offering precise control over pressure distribution. By strategically placing clamps along the joint line, you can avoid uneven pressure that could compromise the bond. We want our bond to be as smooth as butter, so even pressure is key.

When dealing with larger or heavier metal pieces, it’s time to bring out the heavy artillery – weights. Think bricks or sandbags strategically positioned on top of the joint to press it together. The secret here lies in distributing the weight evenly across the joint, eliminating any localized pressure points. We want our bond to be strong and durable, not lopsided and wonky.

But that’s not all. Enter the mechanical press, perfect for bonding metal brackets or fixtures to granite surfaces. With controlled and consistent pressure, a mechanical press ensures a uniform bond along the entire joint line. Just remember to adjust the settings according to the adhesive being used and follow the manufacturer’s instructions like a boss.

Let’s not forget about specialized tools, like vacuum presses. These magical contraptions create a suction effect that pulls the materials together, providing consistent pressure along the entire joint. They’re particularly handy when working with curved or irregular surfaces where clamps or weights may not suffice. Sometimes, we need a little extra help from our tool friends.

No matter which method you choose, always remember to apply pressure for the recommended duration specified by the adhesive manufacturer. This allows the adhesive to fully cure and develop its maximum strength. We don’t want a weak bond, but we also don’t want adhesive oozing out everywhere like a melting ice cream cone.

Curing Time for Different Adhesives

Look no further. In this article, we will delve into the captivating realm of adhesives and their curing times, specifically when it comes to bonding metal to granite. From epoxy to cyanoacrylate and polyurethane, knowing the right adhesive and its curing time is essential for achieving a robust and long-lasting bond.

Epoxy Adhesives:

When it comes to bonding metal to granite, epoxy adhesives are a popular choice due to their exceptional strength and durability. However, they do require a longer curing time compared to other adhesives. The curing process of epoxy involves a chemical reaction between the resin and hardener components. While factors like temperature and humidity can influence curing time, epoxy adhesives typically require a minimum of 24 hours to fully cure and achieve maximum strength.

Cyanoacrylate (Super Glue):

For quick fixes, cyanoacrylate adhesives, also known as super glue, are your go-to option. These adhesives boast an incredibly fast curing time, often drying within seconds or a few minutes. While they offer instant bonding, it’s important to note that cyanoacrylates may not provide the same level of strength and durability as epoxy adhesives.

Polyurethane Adhesives:

If you’re seeking a balance between curing time and strength, consider polyurethane adhesives. They typically have a moderate curing time, ranging from a few hours to overnight. Known for their flexibility and resistance to moisture and temperature changes, polyurethane adhesives are suitable for outdoor applications or areas with high humidity.

Specialized Adhesives:

In addition to general-purpose adhesives, specialized adhesives are available for bonding metal to stone surfaces like granite. These adhesives often have shorter curing times and are formulated to provide excellent bond strength and durability on porous materials like granite.

Removing Excess Adhesive After Curing

So, you’ve successfully bonded your metal to granite and achieved a strong connection. But now you’re faced with a pesky problem – excess adhesive that needs to be eliminated. Not to worry, we’ve got your back. In this informative guide, we’ll take you through the necessary steps to remove that stubborn adhesive after it has fully cured.

The first step is crucial – ensure the adhesive has completely cured. Removing excess adhesive before it reaches its full strength can jeopardize the bond between the metal and granite. So exercise patience and allow the adhesive to reach its maximum potential.

Once the adhesive has cured, it can become hard and resistant to removal. One effective method is carefully scraping off the excess adhesive using a plastic scraper or putty knife. The key here is to use these tools made of plastic to avoid any scratches or damage to the granite surface.

If scraping alone doesn’t suffice, you can turn to solvents or adhesive removers. However, it’s important to choose a solvent that is safe for both the metal and granite surfaces. Acetone is commonly used for removing adhesive residue, but it can potentially harm certain types of granite. To be on the safe side, test the solvent on a small inconspicuous area before proceeding.

When using a solvent, apply it to a clean cloth or sponge and gently rub the adhesive residue. Avoid excessive rubbing as this may damage the surface. Repeat the process as needed until all excess adhesive has been successfully eliminated.

In some cases, heat can come to your rescue. Applying controlled amounts of heat can soften the adhesive and make it easier to remove. However, exercise caution as excessive heat can damage both the metal and granite surfaces. Heat should only be used as a last resort.

After successfully removing all excess adhesive, it’s important to give the area a thorough cleaning. Use a mild detergent and water solution to remove any remaining residue or solvent from the surface.

Lastly, take a moment to inspect the bond between the metal and granite. Ensure it is secure and free from any remaining adhesive. If you have any concerns, it may be necessary to reapply adhesive and repeat the bonding process.

Factors That Affect Bond Strength

When it comes to gluing metal to granite, achieving a strong bond is crucial. The bond strength refers to the adhesive’s ability to firmly hold the metal and granite together. Several factors can affect the bond strength, and understanding these factors is essential when selecting the right adhesive for the job.

- Surface Preparation: Properly preparing the surfaces is vital for a strong bond. Both the metal and granite surfaces should be clean, dry, and free from contaminants like dust, grease, or oil. Any residue on either surface can interfere with the adhesive’s ability to create a strong bond. It is recommended to use a mild detergent or solvent to thoroughly clean the surfaces before applying the adhesive.

- Adhesive Selection: Choosing the right adhesive is critical for a strong bond between metal and granite. Epoxy-based adhesives are commonly used because they have excellent bonding properties and high strength. However, it is important to select an epoxy adhesive specifically designed for bonding metal and stone surfaces. Using just any glue won’t cut it.

- Adhesive Application: How you apply the adhesive matters. It should be applied evenly and consistently on both the metal and granite surfaces. Follow the manufacturer’s instructions regarding application temperature, mixing ratio, and curing time. Applying too much or too little adhesive can compromise the bond strength.

- Curing Time: Patience is key when it comes to curing time. The adhesive needs sufficient time to reach its full strength after application. Rushing the curing process can result in a weaker bond. It is important to allow the recommended curing time before subjecting the bonded metal and granite to any stress or load.

- Temperature and Humidity: Temperature and humidity levels can impact bond strength. Check the adhesive manufacturer’s recommendations for optimal temperature and humidity ranges during application and curing. Extreme temperatures or high humidity levels can weaken the bond or affect the curing process. Working in a controlled environment that meets these recommendations is essential.

- Joint Design: The design of the joint between the metal and granite surfaces also affects bond strength. A well-designed joint with the right surface area and geometry allows for better adhesive distribution and contact between the two materials, resulting in a stronger bond. Consider factors like joint width, depth, and shape when planning the gluing process.

Testing the Adhesive Before Use

Creating a bond between metal and granite may seem like a daunting task, but with the right adhesive and thorough testing, you can achieve a connection that is as unyielding as steel. In this blog post, we will delve into the significance of testing the adhesive before use and explore the steps involved in ensuring a durable and long-lasting bond between these two materials.

Step 1: Clean and Dry

Before applying any adhesive, it is crucial to meticulously clean both the metal and granite surfaces, leaving no room for dirt, dust, or debris that could compromise adhesion. A pristine surface is essential for optimal results. Once cleaned, allow the surfaces to dry completely, ensuring no moisture interferes with the bonding process.

Step 2: Test on Sample Pieces

To determine the adhesive’s suitability for bonding metal to granite, apply a small amount on sample pieces of both materials. These samples serve as a reference point for observation and testing purposes. Follow the manufacturer’s instructions regarding curing time, allowing sufficient time for the adhesive to reach its maximum strength and form an unyielding bond.

Step 3: Visual Inspection

During the curing period, carefully observe how effectively the adhesive bonds the metal and granite together. Keep an eye out for any signs of weak adhesion or peeling. These issues may indicate that the adhesive is not suitable for this specific application, prompting you to explore alternative options.

Step 4: Consider Environmental Factors

Temperature and moisture levels play a significant role in an adhesive’s performance. To ensure longevity and durability, test the adhesive under conditions similar to where it will be used. By subjecting it to environmental factors akin to its intended application, you can rest assured that it will maintain its strength over time.

Step 5: Strength Testing

Conducting a strength test on the sample pieces provides valuable insights into the adhesive’s performance. Apply force or pressure on the bonded area and scrutinize for any separation or damage. A robust bond that withstands this test confirms that the adhesive is suitable for gluing metal to granite, ensuring a connection that will endure.

YMDZKL-hqeI” >

Also Read: How To Glue Metal To Granite?

Conclusion

When it comes to bonding metal to granite, you need a reliable adhesive that can withstand the test of time. Fortunately, there are several options available that can do the job effectively.

One popular choice is epoxy adhesive. Epoxy is known for its strong bond and durability, making it an excellent option for attaching metal to granite. It forms a tight seal and provides a long-lasting connection that won’t easily break or weaken over time.

Another option is construction adhesive, which is specifically designed for heavy-duty applications. This type of adhesive is incredibly strong and can securely bond metal to granite surfaces. Just make sure to choose a construction adhesive that is suitable for both materials.

If you’re looking for a quick and easy solution, consider using a cyanoacrylate adhesive, commonly known as super glue. While not as strong as epoxy or construction adhesive, super glue can still provide a solid bond between metal and granite. However, keep in mind that it may not be as durable in high-stress situations.

No matter which adhesive you choose, it’s important to properly prepare the surfaces before applying the glue. Clean both the metal and granite thoroughly, ensuring they are free from any dirt, grease, or debris. This will help create a stronger bond and ensure the longevity of your attachment.

In conclusion, when it comes to gluing metal to granite, epoxy adhesive, construction adhesive, and cyanoacrylate adhesive are all viable options. Consider your specific needs and requirements before selecting the best adhesive for your project.