Prepare to be captivated by the adhesive wonder that is hot melt glue. This versatile bonding agent has taken industries by storm, revolutionizing construction, packaging, woodworking, and even the world of DIY. With a plethora of options available today, hot melt glue offers a solution for every application.

In this blog post, we embark on an exciting adventure into the enchanting realm of hot melt glue. Brace yourself as we unravel the unique characteristics and specialized uses of each type. Whether you’re looking to bond paper, fabric, or even metal – fear not. Armed with this knowledge, you’ll be equipped to select the perfect adhesive for your project.

Join us on this thrilling journey as we delve into the benefits and distinctive properties of hot melt glues like EVA (Ethylene Vinyl Acetate), polyamide (Nylon), polyolefin, and more. Prepare to witness how these magical adhesives can transform your creative endeavors and practical undertakings into seamless triumphs. Say goodbye to weak connections and hello to stronger bonds that are faster and more efficient than ever before. It’s time to unleash your adhesive creativity with the extraordinary power of hot melt glue.

What is Hot Melt Glue?

Contents

Hot melt glue, also known as hot glue, is a remarkable adhesive that has found its way into countless industries and applications. Whether you’re a craft enthusiast, a packaging professional, or a woodworking aficionado, hot melt glue is likely a familiar name.

So, what exactly is hot melt glue? Well, it’s a thermoplastic adhesive that starts out as a solid and transforms into a liquid when heated. This unique characteristic allows for easy application and quick drying. Once applied, the glue solidifies upon cooling, creating a strong bond between surfaces.

Hot melt glue is made up of three main components: a polymer base, a tackifier, and various additives. The polymer base, which can be ethylene-vinyl acetate (EVA), polyurethane (PUR), or polyamide (PA), determines the overall characteristics of the glue. It’s the backbone of the adhesive.

The tackifier is responsible for giving hot melt glue its stickiness or tackiness. It enhances the adhesive properties and ensures effective bonding to different materials. The choice of tackifier depends on the specific application and the materials being bonded.

In addition to the polymer base and tackifier, hot melt glue may contain additives such as stabilizers, antioxidants, and fillers. Stabilizers prolong the shelf life of the glue by preventing degradation over time. Antioxidants protect the glue from oxidation, which can weaken its adhesive properties. Fillers are added to modify the viscosity or texture of the hot melt glue.

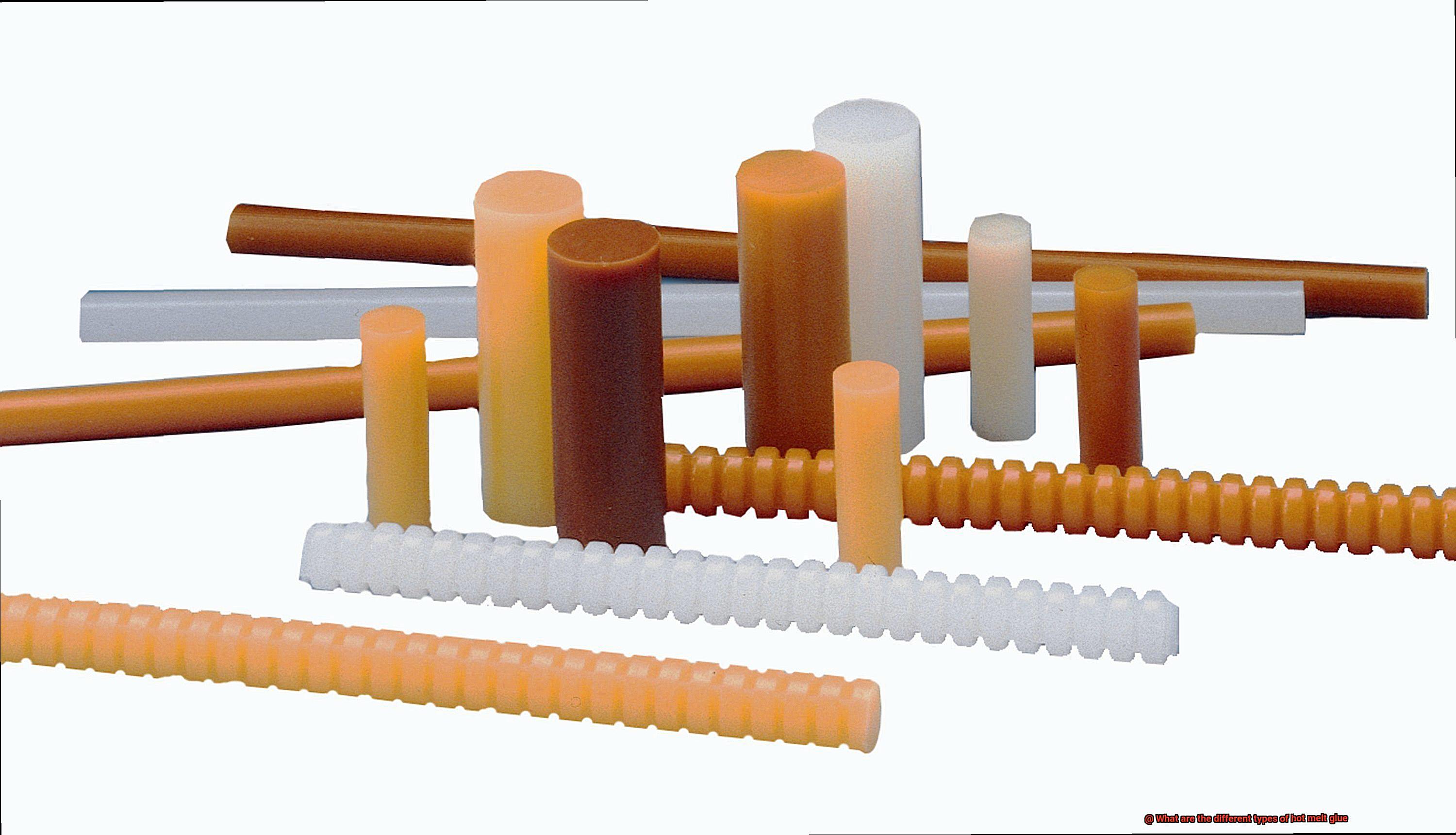

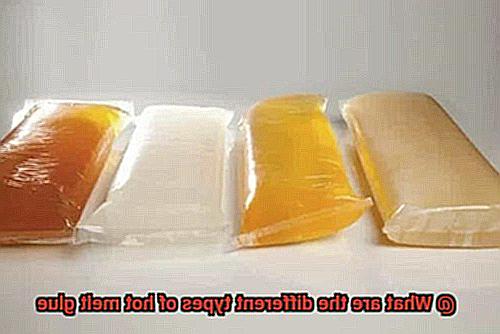

Hot melt glue comes in two primary forms: sticks and pellets. Hot glue sticks are solid cylindrical rods that are inserted into a hot glue gun for melting. They offer convenience and precision in application. On the other hand, hot glue pellets are small beads or granules that are melted in specialized hot melt equipment before being dispensed.

Applying hot melt glue is a breeze. All you need is a hot glue gun or other heating devices to heat the glue to its melting point. Once melted, you can dispense the hot glue onto the desired surface using the gun’s nozzle or a dispensing system. As the glue cools and solidifies, it forms a strong bond between the surfaces.

Hot melt glue offers several advantages over other adhesives. Its fast setting time allows for efficient assembly and production processes. It provides good adhesion to a wide range of materials, from wood and plastic to fabric and metal. Additionally, hot melt glue exhibits excellent heat resistance, making it suitable for applications that involve high temperatures.

Types of Hot Melt Glue

Step into the captivating world of hot melt glue, where each type possesses its own extraordinary abilities. Whether you’re an imaginative artist, a master of woodworking, or a packaging guru, there’s a hot melt glue that perfectly suits your needs. Join us on this thrilling journey as we delve into the fascinating universe of hot melt glues and uncover their superpowers.

Super Strong EVA Glue:

Imagine wielding a glue with the power to bond paper, cardboard, fabric, and wood in an instant. Enter EVA glue, a true force to be reckoned with. With its exceptional bonding strength and rapid drying time, EVA glue is your go-to superhero for crafting exquisite paper creations or repairing cherished wooden treasures.

Mighty PA Glue:

PA glue is like a superhero capable of withstanding intense heat, chemicals, and moisture. It’s the perfect companion for challenging tasks in the automotive, aerospace, and electrical industries. With its extended drying time, PA glue provides valuable extra moments to create robust and long-lasting bonds.

Flexible PO Glue:

PO glue possesses the flexibility of a seasoned yoga master, effortlessly bending and flexing as needed. This low-temperature adhesive is ideal for bonding plastic materials like polyethylene and polypropylene. Whether you’re fashioning a plastic masterpiece or mending a beloved toy, count on PO glue to deliver remarkable results.

Powerful PUR Glue:

When you need a bond as strong as steel, look no further than PUR glue. This remarkable superhero has the ability to bond nearly any material – wood, metal, plastic, ceramics – you name it. Furthermore, PUR glue boasts resistance against temperature fluctuations and moisture. So whether you’re constructing furniture or fixing a shattered mug, trust in PUR glue as your loyal sidekick.

Versatile SBC Glue:

SBC glue is akin to a chameleon, effortlessly adapting to bond almost any surface. Whether it’s paper, cardboard, plastic, or metal, SBC glue has got you covered. Its remarkable bonding strength makes it ideal for packaging, woodworking, and even car repairs. SBC glue is the ultimate all-in-one adhesive superhero.

Sticky PSA Glue:

PSA glue possesses the enchanting qualities of a magical sticker that adheres and releases with ease. This sticky superpower enables instant bonding upon contact while allowing for effortless removal without leaving any residue behind. So whether you’re creating labels, tapes, or stickers, PSA glue is your secret weapon.

General-Purpose Hot Melt Glue

Today, we embark on an exhilarating journey through the enchanting realm of general-purpose hot melt glue. This adhesive dynamo is a true chameleon, boasting a remarkable range of applications and a myriad of benefits. So, grab your trusty glue guns and let’s delve into the captivating world of this versatile adhesive.

Versatility at its Finest:

General-purpose hot melt glue, a thermoplastic adhesive, works wonders on an array of materials. From paper and cardboard to fabric, wood, plastic, and metal, this glue is the ultimate Jack-of-all-trades. Whether you’re diving into arts and crafts, tackling DIY projects, packaging goods, or venturing into woodworking endeavors, this adhesive powerhouse has got you covered. Its ability to bond different surfaces with strong adhesion makes it an indispensable tool in every handyman’s arsenal.

Quick and Easy Application:

Prepare to be amazed by the lightning-fast application process of general-purpose hot melt glue. With a relatively low melting point, this adhesive marvel melts rapidly when exposed to heat. Picture this: effortlessly applying the glue using a hot glue gun or other dispensing equipment. And just like that, your projects spring to life within seconds to minutes.

Strength and Durability:

When it comes to keeping your creations intact, general-purpose hot melt glue is second to none. It offers excellent initial bond strength that ensures your masterpieces stay put. However, it’s important to note that its durability and resistance to heat and moisture may not match specialized hot melt adhesives designed for specific purposes. So keep this in mind when selecting the perfect glue for your project.

Colorful Possibilities:

Let your creativity run wild with the vast array of color options available in general-purpose hot melt glues. Choose from a palette of clear, white, black, or even colored glues to bring your vision to life. And for those invisible bonds that need to remain discreet, transparent glue is your go-to, leaving your masterpiece seamless and flawless.

Safety First:

As you embark on your glue-filled adventures, safety should always be your number one priority. Protect your precious skin from potential burns by donning a pair of trusty gloves. Additionally, ensure proper ventilation when working with hot glue to avoid inhaling any fumes released during the melting process.

Storage and Availability:

To preserve the quality of your general-purpose hot melt glue, store it in a cool, dry sanctuary. This will prevent the glue from becoming brittle or losing its adhesive properties.

Fear not, for this versatile glue is easily attainable at craft stores, hardware stores, and online retailers. Choose from a variety of forms such as sticks, pellets, or cartridges that cater to your unique application methods.

High-Temperature Hot Melt Glue

Enter high-temperature hot melt glue – the unsung hero of adhesives that withstands extreme heat without breaking a sweat. In this blog post, we will delve into the fascinating features and applications of this remarkable glue that remains steadfast while others simply melt away.

First and foremost, high-temperature hot melt glue is specifically engineered to tackle intense heat. With a melting point above 200 degrees Celsius (392 degrees Fahrenheit), it is the adhesive of choice for industries such as automotive, aerospace, and electronics. Imagine bonding engine parts or securing wiring harnesses that face the blistering heat generated by engines – high-temperature hot melt glue has got you covered.

What sets high-temperature hot melt glue apart from its counterparts is its composition. It contains additives and thermally stable polymers like polyamides or polyimides. These ingredients make it a formidable adhesive that maintains its strength and durability even in extreme temperature conditions.

Versatility is yet another feather in this adhesive’s cap. It can bond different materials together, including metals, plastics, ceramics, and even heat-sensitive substrates. Whether you are working on an intricate electronic circuit or assembling an aerospace component, high-temperature hot melt glue proves its mettle across various industries.

When it comes to application methods, fear not. High-temperature hot melt glue can be used with traditional hot melt glue guns or specialized equipment tailored for high-temperature adhesives. The solid form of the glue, such as pellets or sticks, is melted in the applicator and then skillfully applied to surfaces. Within moments, it cools and solidifies into a robust bond.

While high-temperature hot melt glue reigns supreme in extreme heat, it may not exhibit the same bond strength in normal or low-temperature conditions compared to regular hot melt glues. Therefore, it is crucial to consider your project’s specific requirements and select the appropriate adhesive accordingly.

Low-Temperature Hot Melt Glue

Low-temperature hot melt glue is a game-changer when it comes to adhesive technology. No more painful burns or damaged materials – this glue is specifically designed to be used at lower temperatures, making it perfect for delicate projects and sensitive materials.

What sets low-temperature hot melt glue apart from its traditional counterpart? Let’s explore its unique characteristics and wide range of uses.

First and foremost, this glue has a lower melting point than regular hot melt glues. Typically ranging from 250 to 325 degrees Fahrenheit (121 to 163 degrees Celsius), it heats up in a flash, saving you precious time and effort. Convenience at its finest.

Don’t be fooled by its lower melting point though – low-temperature hot melt glue still packs a powerful punch when it comes to bonding. Once it solidifies, it forms a strong and reliable bond that will keep your projects intact, no matter the challenge.

Arts and crafts enthusiasts, rejoice. Low-temperature hot melt glue is an absolute favorite in the creative world. Whether you’re working with delicate fabric, foam, or paper, this gentle adhesive will securely bond these materials without causing any damage. Say goodbye to ruined masterpieces.

But wait, there’s more. Low-temperature hot melt glue sticks come in various sizes and shapes, catering to your specific needs. Need a thin line for intricate designs? They’ve got you covered. Want a pop of color in your project? Some low-temperature hot melt glues even come in vibrant shades, adding an extra touch of creativity to your crafts.

However, it’s important to note that low-temperature hot melt glue might not be the best choice for heavy-duty projects or materials that require high strength adhesion. Always consult the manufacturer’s instructions to ensure you’re using the right glue for the job.

Specialty Hot Melt Glues

In the world of adhesives, hot melt glues have revolutionized the way we bond materials. But did you know that there’s an entire realm of specialty hot melt glues waiting to be discovered? These extraordinary adhesives are specially formulated to meet the unique demands of various applications, unlocking a whole new level of adhesive power. From high-strength bonding to heat resistance and flexibility, specialty hot melt glues are the heroes we need for our most challenging projects.

Unyielding Strength:

When faced with heavy-duty materials like metal or extreme stress, high-strength hot melt glue is the trusty sidekick you need. Its superior bonding capabilities ensure an unbreakable and enduring connection that won’t let you down.

Flexibility Unleashed:

Bending, stretching, and movement are no match for flexible hot melt adhesive. This superhero glue maintains its flexibility even after curing, making it perfect for materials that need to withstand constant motion without compromising strength.

Heat Defying:

When things get hot, heat-resistant hot melt glue remains cool under pressure. Designed to withstand high temperatures without losing its adhesive properties, this glue is your go-to for applications exposed to heat or extreme temperatures.

Gentle Touch:

Delicate fabrics, foam, and paper rejoice. Low-temperature hot melt adhesive comes to the rescue with its lower melting point. No more worrying about burns or damage, as this gentle adhesive ensures a flawless bond without harming sensitive materials.

Tailored Solutions for Every Industry:

Certain industries demand specialized adhesive solutions, and specialty hot melt glues rise to the occasion. Whether you’re in packaging, automotive, electronics, or medical fields, there’s a glue crafted to meet your specific needs. These remarkable adhesives offer unique properties like UV resistance, water resistance, chemical resistance, or rapid curing times, ensuring optimal performance in your industry of choice.

Removable/Repositionable Hot Melt Glues

In this blog post, we’ll delve into the realm of removable/repositionable hot melt glues and discover their unique advantages and considerations. Whether you’re a crafting enthusiast or a manufacturing professional, these glues are sure to become your new secret weapon for tackling projects with ease.

Advantages:

Temporary Bonding Magic:

Imagine having the power to experiment with different layouts and designs without the fear of damaging your materials or leaving behind residue. Removable/repositionable hot melt glues offer this magical ability. Crafters and scrapbookers can now confidently hold paper, fabric, or other materials in place before applying permanent bonding methods like sewing or traditional gluing.

Precision Assembly:

In the world of manufacturing, especially electronic component assembly, precision is key. Removable/repositionable hot melt glues come to the rescue by temporarily holding delicate parts in place during the soldering process. This ensures perfect alignment before permanent bonding occurs. And once the soldering is complete, these glues can be easily removed without leaving any trace behind.

Quick Setting Time:

Time is of the essence in production processes, and removable/repositionable hot melt glues excel in this aspect. Their quick setting time ensures efficient workflow, allowing you to move swiftly from one task to another without compromising quality.

Wide Material Compatibility:

When it comes to versatility, these glues are true superheroes. They exhibit excellent adhesion to a wide range of materials including plastics, metals, and fabrics. No matter what your project entails, you can rely on removable/repositionable hot melt glues to bond effectively.

Varying Adhesive Strength:

Not all hot melt glues labeled as “removable” or “repositionable” are created equal. Some may have stronger adhesive properties than others, so it’s important to choose the right glue for your specific needs. Testing on a small, inconspicuous area is always recommended before using them on a larger scale or valuable materials.

Surface Sensitivity:

While these glues are designed to be gentle on most surfaces, some delicate materials may still require extra caution. Always check the compatibility of the glue with your specific surface before application.

Choosing the Right Type of Hot Melt Glue for Your Application

Prepare yourself for an exhilarating journey into the realm of adhesive perfection. Just like finding the ideal match on a dating app, choosing the right type of hot melt glue for your application requires a delicate balance and a touch of chemistry. So, let’s delve into the intricacies and explore the factors to consider when selecting the perfect hot melt glue for your needs.

First and foremost, let’s talk about temperature resistance. Much like our own tolerance on a scorching summer day, hot melt glues have their limits. Some applications call for glues that can withstand high temperatures, while others require only moderate resistance. It is crucial to select a glue that can handle the heat, quite literally.

Next up, we have bonding strength. Are you constructing a mammoth skyscraper or simply piecing together some delightful art projects? The strength of the bond becomes paramount. Heavy loads or stress necessitate a robust adhesive, while lighter endeavors can get by with a more delicate bond.

Open time is another vital aspect to consider. No, it’s not about leaving your glue bottle exposed – it’s about the window of opportunity you have to work with the adhesive before it sets. Do you require flexibility in positioning and adjusting? Then opt for a longer open time. Urgently seeking quick bonding? Choose a shorter open time.

Now, let’s turn our attention to substrates. Different glues possess varying adhesion properties, so you must select one that harmonizes with the materials you’ll be working with. The last thing you want is any adhesive-related drama unfolding in your project.

And let us not forget about application methods. Are you a spray enthusiast, do you prefer rolling it on, or are you more inclined towards bead application? Different glues perform better with different application techniques, so choose one that aligns with your personal style.

Last but definitely not least, check if there are any specific requirements or regulations for your application. Certain industries have stringent standards that must be met, so ensure your chosen glue passes the test.

6MXs393c67A” >

Also Read: How Much Weight Can Hot Glue Hold?

Conclusion

Hot melt glue is a versatile adhesive that comes in various types, each with its own unique properties and applications. Understanding these different types can help you choose the right hot melt glue for your specific needs.

One type of hot melt glue is the general-purpose adhesive. As the name suggests, this type of glue is suitable for a wide range of materials and surfaces. It offers excellent bonding strength and quick drying time, making it ideal for everyday projects and repairs.

Another type is the high-temperature hot melt glue. This adhesive can withstand extreme heat, making it perfect for applications where heat resistance is crucial. It is commonly used in industries such as automotive, electronics, and aerospace.

For more specialized applications, there are specific types of hot melt glues available. For example, there are low-temperature hot melt adhesives that are designed to bond heat-sensitive materials without causing damage. These are often used in the packaging industry or for delicate crafts.

If you need a strong bond that can withstand moisture or outdoor conditions, then waterproof or weather-resistant hot melt glues are the way to go. These adhesives have enhanced durability and can withstand exposure to water, humidity, and even UV rays.

Additionally, there are hot melt glues specifically formulated for specific materials like wood or fabric. These adhesives provide excellent adhesion to their respective substrates and ensure long-lasting bonds.

In conclusion, the world of hot melt glues offers a variety of options to suit different needs. From general-purpose adhesives to high-temperature resistant glues, there’s a type of hot melt glue for every project.