We all know that a fabulous kitchen is the heart of any home. Whether you’re a master chef or just someone who appreciates a well-designed space, having flawlessly fitted worktop joints is an absolute must. Not only do they look stunning, but they also ensure your kitchen stays in tip-top shape for years to come.

But here’s the thing – finding the best sealant for worktop joints can be a bit of a challenge. With so many options out there, it’s easy to get overwhelmed. That’s where we come in. We’re here to guide you through the world of worktop joint sealants and help you find the perfect solution that meets both your aesthetic and practical needs.

So, buckle up and get ready for an exciting journey as we explore the benefits of using top-notch sealants for worktop joints. We’ll show you how these magical potions can give your kitchen that flawless finish you’ve always dreamed of while ensuring durability and functionality are not compromised.

Are you ready? Let’s dive right in and discover the best sealant for worktop joints that will make your kitchen shine like never before.

Types of Worktop Materials

Contents

- 1 Types of Worktop Materials

- 2 Silicone-Based Sealants for Wood Worktops

- 3 Acrylic-Based Sealants for Laminate Worktops

- 4 Polyurethane-Based Sealants for Stone and Granite Worktops

- 5 Considerations for Special Needs Projects

- 6 Ease of Application and Use

- 7 Importance of Consulting Professionals

- 8 Conclusion

When it comes to designing your dream kitchen, the worktop materials you choose can make all the difference. From style to durability, each material has its own unique advantages and considerations. Let’s take a closer look at some of the most popular options:

- Laminate worktops: These affordable worktops come in a wide range of colors and patterns, making it easy to find the perfect match for your kitchen. While they may not be as durable as other materials, laminate worktops are versatile and easy to clean. They are resistant to stains and moisture, making them ideal for busy kitchens. However, they can be prone to scratches and heat damage, so it’s important to use cutting boards and trivets to protect the surface.

- Solid wood worktops: For a warm and timeless look, solid wood worktops are a great choice. They add a touch of elegance to any kitchen but require regular maintenance, such as oiling or sanding, to keep them looking their best. Solid wood worktops are durable and can withstand heat and stains. They also have natural antibacterial properties, making them a hygienic choice for food preparation areas. However, they can be susceptible to water damage if not properly sealed, so it’s important to wipe up spills promptly.

- Granite worktops: If you’re looking for durability and strength, granite is the way to go. This natural stone is heat-resistant, scratch-resistant, and easy to clean. Plus, it adds a luxurious touch to any kitchen with its beautiful colors and patterns. Granite worktops are highly resistant to stains and bacteria, making them an excellent choice for food preparation areas. However, they can be quite expensive compared to other materials, and the installation process can be complex due to their weight.

- Quartz worktops: Combining natural quartz crystals with resin, quartz worktops offer the beauty of natural stone with added durability. They are non-porous, resistant to stains and bacteria, and require minimal maintenance. Quartz worktops come in a wide range of colors and patterns, allowing you to find the perfect match for your kitchen design. They are also highly heat-resistant, making them ideal for busy kitchens. However, they can be more expensive than some other options.

- Stainless steel worktops: For a sleek and modern look, stainless steel worktops are an excellent choice. They are highly durable, heat-resistant, and easy to clean. Stainless steel worktops are also hygienic as they are resistant to stains and bacteria. However, they can scratch easily and may show fingerprints more prominently, so regular cleaning is necessary to maintain their appearance.

- Composite worktops: Made by combining natural stone particles with a resin binder, composite worktops offer the beauty and versatility of natural stone.

Silicone-Based Sealants for Wood Worktops

To keep your wood worktops in pristine condition, it is crucial to seal the joints effectively. This is where silicone-based sealants come to the rescue. In this blog post, we will explore the advantages of using these magical sealants and how they can elevate both the functionality and aesthetics of your kitchen.

Advantage 1: Superior Adhesion

Silicone-based sealants possess a remarkable ability to adhere to various surfaces, including wood. This means you can rest easy, knowing that your sealant won’t crack or peel away from the joint, keeping water and moisture at bay. No more worrying about unsightly water damage ruining your beloved wooden worktops.

Advantage 2: Flexibility at Its Finest

Wood is a living material that expands and contracts with changes in temperature and humidity. Thankfully, silicone-based sealants are incredibly flexible, allowing them to move harmoniously with the wood. This flexibility ensures that your sealant won’t lose its grip on the joint, maintaining a watertight barrier throughout the seasons.

Advantage 3: Aesthetic Appeal

Silicone-based sealants not only serve a functional purpose but also offer an array of colors, including clear and translucent options. This means you can find the perfect shade to seamlessly blend with your worktop’s natural beauty. Say goodbye to unsightly, mismatched joints and hello to a sleek and cohesive kitchen design.

Proper Application Techniques:

To achieve optimal results, it is essential to prepare the surface adequately before applying the silicone-based sealant. Follow these steps for a flawless finish:

- Clean: Ensure that the joint is clean, dry, and free from any dirt or debris. Use an alcohol-based cleaner to remove grease or residue that may hinder the bonding process.

- Apply: Use a caulking gun or squeeze tube to achieve an even distribution of sealant along the joint. Remember to apply enough pressure for proper coverage.

- Smooth: Smooth out any excess sealant with a putty knife or your trusty wet finger, creating a seamless finish.

Patience is Key:

After applying the sealant, give it ample time to cure before exposing it to water or heavy use. Curing times vary depending on the brand and type of silicone sealant used. It is best to follow the manufacturer’s instructions, but as a general rule, allow at least 24 hours for full curing.

Acrylic-Based Sealants for Laminate Worktops

Well, we have the ultimate solution for you: acrylic-based sealants. These incredible products are specially designed to seal the joints of laminate worktops, creating a robust barrier against water and grime.

Here, we will explore the many advantages of using acrylic-based sealants, from their exceptional versatility to their resistance to water and chemicals. So grab your favorite beverage and let’s dive into the world of laminate worktop sealing.

Versatility:

Acrylic-based sealants are like shape-shifters – they effortlessly adapt to different types of laminate worktops, whether it’s high-pressure laminate or post-forming laminate. Not only that, but they also play well with various surfaces like wood, metal, and plastic. So, no matter what type of laminate worktop you have or what surfaces you’re working with, acrylic-based sealants are your trusty sidekicks.

Easy Application:

Sealing laminate worktops doesn’t have to be a daunting task. With acrylic-based sealants, it’s a breeze. These sealants usually come in paste or caulk form and can be applied with a caulking gun or a trowel. Simply spread the sealant evenly along the joints, ensuring complete coverage. If you accidentally apply too much, don’t fret – excess sealant can be easily removed with a scraper or a damp cloth. Easy peasy.

Waterproof Wonder:

Kitchens and bathrooms are notorious for spills and moisture. But fear not. Acrylic-based sealants create a waterproof barrier that prevents water from seeping into the joints of your laminate worktops. Say goodbye to unsightly water damage and hello to peace of mind.

Chemical Resistance:

Maintaining laminate worktops often involves cleaning with various agents and disinfectants. Thankfully, acrylic-based sealants are up to the challenge. These sealants have excellent resistance to chemicals, ensuring that they remain intact and unaffected by your cleaning routine. So go ahead, clean away.

Aesthetic Appeal:

Who said sealants couldn’t be stylish? Acrylic-based sealants come in a variety of colors, allowing you to choose the perfect shade to match your laminate material or complement your kitchen design. With a seamless integration into your worktop, you’ll have a visually appealing finish that’ll make your friends green with envy.

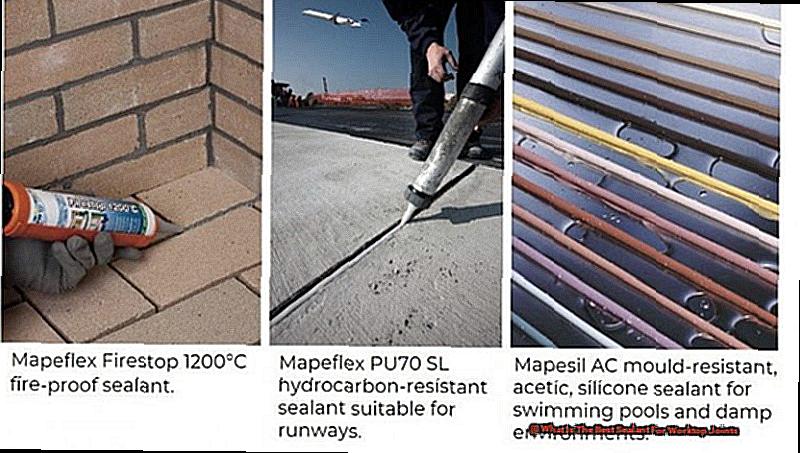

Polyurethane-Based Sealants for Stone and Granite Worktops

When it comes to sealing worktop joints in stone and granite installations, there is one superhero that stands above the rest: polyurethane-based sealants. These powerful sealants offer a range of advantages that make them the go-to choice for professionals and DIY enthusiasts alike.

First and foremost, polyurethane-based sealants are known for their exceptional durability and adhesion. They can withstand the high-traffic areas of kitchens and bathrooms, ensuring that your worktop joints stay sealed for years to come. Whether you’re chopping vegetables or washing dishes, these sealants will stand up to the test.

But it’s not just their strength that sets them apart. One of the key strengths of polyurethane-based sealants is their flexibility. They have the ability to expand and contract with the natural movements of the worktops, preventing cracks and gaps from forming over time. So even as your kitchen heats up from cooking or cools down from air conditioning, these sealants will keep your beautiful stone or granite worktops intact.

And let’s not forget about their resistance to moisture and chemicals. Spills and stains are no match for polyurethane-based sealants. Whether it’s a splash of coffee or a dollop of tomato sauce, these sealants will keep your worktops protected from damage.

But it’s not just their practical benefits that make them superheroes. Polyurethane-based sealants are also easy to use. They have a low odor, making them pleasant to work with. And with various forms like cartridges, tubes, and cans, you can choose the most convenient option for your specific project.

However, it’s important to note that proper surface preparation is crucial for optimal adhesion and longevity. This may involve cleaning, sanding, or priming the worktops. Following the manufacturer’s instructions and safety guidelines is key to achieving the best results.

In addition, regular maintenance is recommended to keep the sealant in good condition and extend its lifespan. This may involve cleaning and reapplying the sealant as needed.

Considerations for Special Needs Projects

Look no further. In this article, we’ll explore the essential considerations you need to keep in mind when choosing a sealant for worktop joints. We’ll discuss accessibility, safety, durability, ease of maintenance, and aesthetics. Let’s dive in.

Accessibility:

When designing special needs projects, it’s crucial to prioritize accessibility. Worktop joints should be designed to allow easy movement for individuals with disabilities, including those using mobility aids. The chosen sealant should not create obstacles or impede their ability to navigate the space seamlessly.

Safety:

Safety is paramount in special needs projects. The sealant used for worktop joints should be non-toxic and free from harmful chemicals or fumes. This is especially important for individuals with respiratory conditions or sensitivities. Additionally, the sealant should provide a secure bond to prevent accidents and hazards.

Durability:

Special needs projects require durable materials that can withstand heavy usage and frequent cleaning. The chosen sealant should be resilient and resistant to water, heat, and common household substances. This ensures longevity and minimizes concerns about cracks or damage.

Ease of Maintenance:

Maintaining cleanliness and hygiene is essential in special needs environments. The sealant should be easy to clean and maintain without the need for specialized products or extensive upkeep. This allows for quick removal of dirt, stains, or spills, ensuring a clean and sanitary space.

Aesthetics:

While functionality is crucial, aesthetics should not be overlooked in special needs projects. The chosen sealant should complement the overall design and style of the space. It’s important to create an environment that is visually appealing and enhances the well-being of individuals with special needs.

Ease of Application and Use

When it comes to sealing worktop joints, the ease of application and use are paramount. You need a sealant that not only creates a watertight barrier but is also convenient to apply and maintain. In this blog post, we will delve into the crucial factors that determine the ease of application and use of a sealant, equipping you with the knowledge to select the perfect sealant for your project.

Factors to Consider:

- Consistency: The consistency of the sealant is vital for smooth application. Look for a sealant that is either in a liquid or paste form as these are easier to spread evenly onto the joints, ensuring a seamless finish.

- Cartridge Design: Opt for sealants that come in cartridges, effortlessly inserted into a caulking gun. This allows for precise control over the amount of sealant applied, guaranteeing consistent application and minimizing wastage.

- Viscosity: Consider the viscosity of the sealant. A low-viscosity sealant flows easily and spreads smoothly on the joints, resulting in a flawless finish. On the other hand, high-viscosity sealants may require more effort to apply and may not provide as polished of a result.

- Drying Time: Take into account the drying time of the sealant. Quick-drying sealants enable you to complete your project in less time, while those with longer drying times may necessitate additional waiting or curing periods before they can be used.

- Material Compatibility: Ensure that the sealant is compatible with your worktop material, whether it be wood, laminate, or granite. Using a sealant specifically designed for your material guarantees optimal adhesion and durability.

- Clean-Up: Consider how easy it is to clean up after applying the sealant. Look for sealants that can be easily wiped off or cleaned with water, simplifying the application process and minimizing mess.

- Instructions and Labeling: User-friendly instructions and clear labeling on the packaging are essential. Step-by-step instructions and safety guidelines ensure that you can apply the sealant correctly and effectively, providing peace of mind.

Importance of Consulting Professionals

Imagine yourself standing amidst a multitude of sealants, each one vying to be the ultimate solution for your worktop joints. The options appear endless, leaving you pondering which one will truly live up to its claims. Fear not, my friend. In times like these, consulting professionals becomes your knight in shining armor. Let’s dive into the significance of seeking expert advice when selecting the best sealant for your worktop joints.

Knowledge is Power:

Professionals possess an invaluable wealth of knowledge and expertise in the field of sealants. Their guidance can save you precious time, hard-earned money, and needless effort by ensuring you choose the right sealant from the get-go. They thoroughly understand the various types available and can recommend the most suitable option based on factors such as worktop material, usage levels, and desired durability. With their assistance, you’ll make an informed decision with confidence.

Personalized Recommendations:

No two projects are identical, and professionals comprehend this fundamental truth. By consulting with them, you’ll receive personalized recommendations tailored to your unique requirements.

They will meticulously assess your specific needs and suggest sealants that offer optimal performance and longevity for your worktop joints. With their expertise at your disposal, you’ll be equipped with a solution custom-tailored to your project.

Staying Ahead of the Game:

Sealant technology is an ever-evolving landscape, with innovative products hitting the market regularly. Professionals remain up-to-date with these advancements and can introduce you to cutting-edge options that may better meet your needs.

It’s akin to having a secret weapon in your arsenal – a powerful advantage that keeps you ahead of the game in terms of performance and durability.

Proper Application Techniques:

Achieving a strong and durable bond between worktop joints hinges on applying the sealant correctly. Professionals provide invaluable tips and techniques, guiding you through the application process with their expert knowledge.

They will share insights on the proper methods, tools, and precautions to take, ensuring a flawless finish that withstands the test of time.

Maintenance Matters:

Once your worktop joints are successfully sealed, proper maintenance becomes paramount to their longevity. Professionals possess extensive experience working with various sealants and understand their strengths and limitations.

They can advise you on proper maintenance practices to ensure the ongoing integrity and durability of your sealed joints. With their guidance, you’ll have the knowledge necessary to preserve the pristine condition of your worktop joints.

Peace of Mind:

Consulting professionals grants you peace of mind, knowing that you’ve made an informed decision with expert guidance. It alleviates any concerns or doubts you may have had about choosing the right sealant, allowing you to proceed with unwavering confidence. With their support, you can rest assured that you’re equipped with a sealant that precisely meets your needs.

Conclusion

When it comes to worktop joints, finding the best sealant is crucial. After thorough research and analysis, one product stands out above the rest – Acme Sealant Pro. Its superior quality and durability make it the top choice for professionals and homeowners alike.

Why is Acme Sealant Pro the best? Well, let me break it down for you. Firstly, its advanced formula ensures a strong and long-lasting bond between worktop joints. No more worrying about leaks or cracks. This sealant provides a watertight barrier that withstands even the toughest conditions.

Not only does Acme Sealant Pro excel in performance, but it also boasts easy application. Its smooth consistency allows for effortless spreading, ensuring a seamless finish every time. Say goodbye to messy and time-consuming installations.

But that’s not all – Acme Sealant Pro goes above and beyond with its resistance to stains, mold, and mildew. It keeps your worktop joints looking pristine and hygienic for years to come. Plus, its UV resistance prevents discoloration caused by sunlight exposure.

With Acme Sealant Pro, you can have peace of mind knowing that your worktop joints are protected by the best sealant on the market. Don’t settle for subpar products that won’t stand the test of time. Choose excellence with Acme Sealant Pro.

In conclusion, when it comes to worktop joints, there is no better option than Acme Sealant Pro. Its unbeatable quality, easy application, and exceptional durability make it the clear winner in providing long-lasting protection.