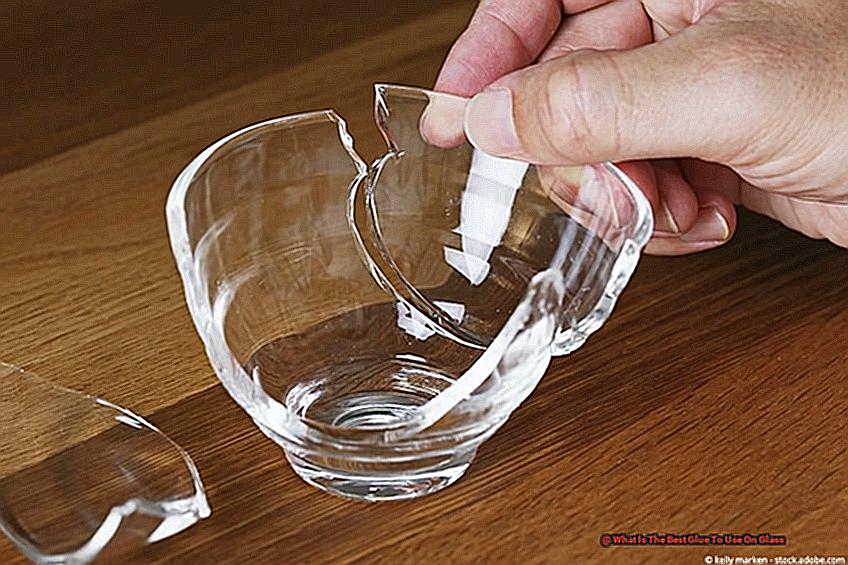

Its shimmer and sleekness have always captivated us, whether it’s used to create dazzling ornaments or fix cherished heirlooms. But let’s be real here: finding the right glue for glass can be a sticky situation. With so many options out there, it’s easy to feel overwhelmed. But fear not, my friend. In this blog post, we’ll dive into the world of glass adhesives, exploring their pros and cons to help you make an informed decision without losing your cool.

Epoxy Resin:

Contents

You want strength? Epoxy resin has got it in spades. This glue is like the Hulk of adhesives when it comes to bonding glass. It can handle extreme temperatures and scoffs at water and chemicals. But hold your horses, because patience is key here. Epoxy resin takes its sweet time to cure, so precision and a little waiting game are necessary.

UV-Activated Adhesive:

Need something fast? UV-activated adhesive swoops in like a superhero. This glue cures faster than you can say “glass bonding.” Just shine some ultraviolet light on it, and boom. Your pieces are stuck together tighter than two peas in a pod. But beware of prolonged sunlight exposure; it might weaken the bond faster than Superman loses his powers under a red sun.

Silicone-Based Glue:

Flexibility is your jam? Say hello to silicone-based glues. These bad boys are perfect for sticking glass to other materials because they’re as flexible as a contortionist at Cirque du Soleil. They’re also resistant to water, heat, and cold temperatures—pretty impressive if you ask me. However, brace yourself for some messiness and don’t forget the clamps to keep everything in place during curing.

Cyanoacrylate (Super Glue):

Need an instant fix? Cyanoacrylate, a.k.a. super glue, is your go-to hero. This glue bonds glass surfaces faster than you can say “supercalifragilisticexpialidocious.” It’s quick-drying and creates a strong connection that could withstand even the toughest tests. But here’s the catch: it’s not the most flexible adhesive out there. So if your project involves dramatic temperature changes, be prepared for potential cracks or delamination.

Types of Glue for Glass

Glass is a delicate material that requires the right adhesive to create a strong and secure bond. With numerous options available, choosing the best glue for your glass projects can be a daunting task. In this comprehensive guide, we will explore various types of glues suitable for bonding glass and discuss their advantages and disadvantages.

Epoxy Glue: The Superhero of Glass Bonding

Epoxy glue is the go-to choice for bonding glass due to its exceptional strength and durability. Composed of two parts, a resin and a hardener, epoxy glue must be mixed before use. Once applied, it quickly sets and forms a strong bond that is resistant to moisture and heat. However, it can be messy to work with and requires careful handling to prevent damage to the glass surface.

Silicone Adhesive: Flexibility and Waterproofing

Silicone adhesive offers versatility in bonding glass, especially when flexibility and waterproofing are required. This type of glue creates a watertight seal on glass surfaces, making it suitable for indoor and outdoor use. Additionally, silicone adhesive exhibits resistance to high temperatures and UV radiation, making it ideal for areas exposed to sunlight. However, it may not provide as strong of a bond as epoxy glue and may have a longer curing time.

UV-Curing Adhesive: Light-Activated Bonding

UV-curing adhesive is a specialized glue that requires exposure to ultraviolet light to harden and create a strong bond on glass surfaces. Widely used in industries such as electronics and optoelectronics, this adhesive offers fast curing times and resistance to heat and chemicals. However, it may not be readily available for regular household use as it requires a UV light source for curing.

Cyanoacrylate Adhesive: Super Glue for Glass

Cyanoacrylate adhesive, commonly known as super glue, is also effective for bonding glass. It forms a quick and robust bond, making it popular for small glass repairs. However, it may not be as durable as epoxy or silicone adhesive and can leave a visible residue on the glass surface if not applied carefully.

Glass-Specific Adhesives: Strength and Clarity

Glass-specific adhesives are specially formulated to bond glass surfaces, providing optimal strength and clarity. These adhesives are ideal for delicate glass projects or repairs where aesthetics are important. Available in liquid glue, gel, or tape forms, they offer flexibility depending on the specific application.

Conclusion:

Choosing the right glue for glass requires considering factors such as intended use, required strength level, and environmental conditions. Epoxy glue is popular for its strength and durability, while silicone adhesive offers flexibility and waterproofing. UV-curing adhesive suits specialized applications, and cyanoacrylate adhesive is suitable for small repairs. Glass-specific adhesives provide optimal strength and clarity for delicate projects. Always follow the manufacturer’s instructions and test the adhesive on a small area before applying it to the entire surface.

Epoxy Resin

Epoxy resin offers a bond that’s so strong, it’s practically unbreakable. In this guide, we’ll dive into the amazing advantages of using epoxy resin on glass, the simple steps involved in the process, and some pro tips to ensure your success.

The first thing you need to know about epoxy resin is its incredible adhesive properties. It forms a bond that can handle serious stress and pressure, making it perfect for applications where security is key. Whether you’re building glass furniture or fixing a shattered glass object, epoxy resin is up to the task.

But that’s not all. Epoxy resin also gives you transparency like you’ve never seen before. Once it’s cured, it becomes clear and glossy, seamlessly blending with the glass surface. This makes it ideal for projects where aesthetics are important, like creating beautiful decorative glass items or bonding delicate glass artwork.

Now let’s talk about how to achieve that perfect bond. First things first, clean those glass surfaces like there’s no tomorrow. Get rid of any dirt, grease, or contaminants that might get in the way of a strong bond. A gentle detergent or glass cleaner should do the trick.

Next, mix the epoxy resin and hardener in a 1:1 ratio. Give it a good stir to make sure everything blends together nicely. And don’t forget to follow the manufacturer’s instructions on mixing and application time for optimal results.

Once you’ve applied the epoxy resin, give it enough time to cure before putting any stress on the bonded glass. Curing times can vary from a few hours to several days depending on the specific product you’re using.

UV-Curing Glue

Get ready to discover how this incredible glue forms unbreakable bonds, cures in a flash, creates invisible aesthetics, and offers versatile application options. So put on your goggles and let’s dive into the power of UV-curing glue.

Advantage 1: Unbreakable Bonds, Even Against the Toughest Odds

UV-curing glue is like the Hulk of adhesives when it comes to glass bonding. It creates a robust and long-lasting bond that can withstand the harshest conditions, including moisture, heat, chemicals, and other environmental factors. No matter what challenges are thrown its way, this adhesive won’t break a sweat.

Advantage 2: Lightning-Fast Curing Time for Instant Results

Say goodbye to waiting around for hours or days for your glue to dry. UV-curing glue is the Flash in the adhesive world. With just a few seconds or minutes under the magical UV light, your glass components will be bonded and ready to go. Boost productivity and cut assembly time with this lightning-fast adhesive.

Advantage 3: Invisible Bonds that Showcase True Beauty

In the world of glass products and devices with glass screens, aesthetics matter. UV-curing glue swoops in as the ultimate hero by creating transparent bonds without leaving any visible residue or marks. Your glass creations will shine with flawless beauty, allowing their true elegance to take center stage.

Advantage 4: Customizable Sidekick for Easy Application

UV-curing glue comes in a range of viscosities and formulations to suit every bonding need. Choose from liquid adhesives for precise application using a syringe or dispenser. Alternatively, opt for gel forms that are perfect for vertical or overhead applications, as they won’t drip or flow. With UV-curing glue as your customizable sidekick, you’ll have the perfect adhesive for any situation.

Tips for Success:

To unlock the full potential of UV-curing glue on glass, proper surface preparation is key. Thoroughly clean the glass surfaces, ensuring they are dry and free from dirt or grease. To enhance adhesion, consider lightly roughening the surface with fine-grit sandpaper.

And don’t forget your trusty UV light source. UV lamps or LED lights with the right wavelength will be your best friends during the curing process. Simply expose the glued glass components to the UV light for the recommended curing time, following the manufacturer’s instructions.

UV-curing glue is the ultimate superhero when it comes to bonding glass. Its unbreakable bonds, lightning-fast curing time, invisible aesthetics, and easy application make it the perfect choice for all your glass projects.

Silicone Adhesive

Silicone adhesive, made from silicone polymers, is a versatile and powerful glue that is commonly used for bonding glass surfaces. Its exceptional adhesion properties and ability to create strong and durable bonds make it an ideal choice for various glass projects. Let’s explore the remarkable advantages of silicone adhesive in more detail.

Flexibility is one of the standout features of silicone adhesive. Unlike other glues that can become rigid and brittle over time, silicone adhesive remains flexible even after it has dried. This incredible flexibility allows it to handle movement and vibrations without compromising its bond strength. Whether you’re working on delicate glass artwork or constructing a sturdy window frame, silicone adhesive will be your reliable sidekick.

In addition to its flexibility, silicone adhesive boasts an impressive resistance to temperature extremes. It fearlessly withstands scorching summers and freezing winters without losing its bond strength. This makes it perfect for applications where the bonded glass may be exposed to extreme temperature changes, such as outdoor windows or automotive windshields. With silicone adhesive, you can trust that your glass projects will endure the test of time.

One of the superhero qualities of silicone adhesive is its exceptional water resistance. Unlike many other glues that crumble or lose their bond strength when faced with water or moisture, silicone adhesive stands tall against the elements. This makes it an excellent choice for bonding glass in wet environments like bathrooms or aquariums, where water exposure is inevitable. Say goodbye to worries about weakened bonds due to dampness.

To ensure a successful bond between silicone adhesive and your glass surfaces, it is crucial to clean them thoroughly beforehand. A simple wipe down with isopropyl alcohol will do the trick, removing any dirt, dust, or grease that may hinder the bonding process. For an extra boost in adhesion, lightly roughen up the glass surface with sandpaper before applying the adhesive.

When it comes to application, silicone adhesive is conveniently available in squeeze tubes or cartridges that fit into caulking guns. This allows for easy and precise application. Simply squeeze out a thin and even layer of adhesive onto the glass surfaces you wish to bond together. If you accidentally apply too much adhesive, don’t worry. Just wipe away the excess with a clean cloth before it dries, ensuring a neat and tidy finish.

Considerations for Different Types of Glass

Glass is a versatile and beautiful material that is used in various applications, from windows and doors to decorative art pieces. When it comes to bonding glass, selecting the right glue is essential for a strong and durable bond. In this blog post, we will explore the considerations for choosing the best glue for different types of glass.

Tempered Glass:

Tempered glass is known for its strength and resistance to breakage. However, due to its high tension, it can be challenging to find a glue that bonds effectively. Epoxy-based glues or silicone adhesives are recommended for bonding tempered glass due to their strength and flexibility. These glues have excellent adhesion properties and can withstand the high tension within the glass, ensuring a secure bond.

Laminated Glass:

Laminated glass is commonly used in automotive windshields and safety glazing applications. It consists of layers of glass bonded together with an interlayer. UV-curing adhesives or polyurethane-based glues are ideal for bonding laminated glass as they can effectively bond both glass and plastic. These adhesives have excellent bonding properties and can provide a strong and durable bond between the layers of glass and the interlayer.

Frosted Glass:

Frosted glass has a textured surface that can make bonding difficult. It is important to choose a glue specifically formulated for frosted or textured surfaces. Clear-drying adhesives or silicone-based glues are suitable options as they can create a strong bond without damaging the frosted finish. These glues have excellent adhesion properties and can bond effectively with the rough surface of frosted glass.

Stained Glass:

Stained glass is often used in decorative applications such as windows and art pieces. When working with stained glass, it is crucial to select a glue that is transparent and will not mar or discolor the glass. Clear-drying epoxy or specialized stained glass adhesive are recommended choices for bonding stained glass. These glues are specifically formulated for bonding glass and have excellent clarity, ensuring that the beauty of the stained glass is preserved.

Mirrored Glass:

Mirrored glass has a reflective coating on one side, which requires special consideration when selecting a glue. Mirror adhesive or mirror mastic is specifically formulated for bonding mirrored glass without damaging the reflective coating. These adhesives have excellent bonding properties and can provide a strong and durable bond while preserving the reflective properties of the glass.

Preparing the Surface Before Applying Glue

Properly preparing the surface before applying glue is of utmost importance for achieving a strong and long-lasting bond. Just like a painter preps their canvas before creating a masterpiece, prepping your glass surface is essential for ensuring that your glued creations stand the test of time. Let’s explore the various steps involved in this crucial process.

First and foremost, cleanliness is key. To begin, grab a mild detergent or glass cleaner and a soft cloth to give your glass surface a thorough scrub. Eliminate any dirt, dust, or grease that could potentially interfere with the adhesive properties of the glue. It’s vital to steer clear of harsh chemicals and abrasive materials that might mar or damage your precious glass.

Once your glass is sparkling clean, it’s time to banish all moisture. Any lingering dampness can significantly hinder your glue’s bonding powers. So, reach for a lint-free cloth or paper towel and meticulously dry your glass surface. Leave no room for pesky damp spots.

Now, let’s move on to the exhilarating part – roughening up the surface. In certain cases, you may need to enhance the bonding area for the glue. Take some sandpaper or a diamond-tipped file and gently sand or file the portion where you plan to apply the glue. Be cautious not to get carried away and inadvertently scratch the glass – we want it to remain flawless.

Next up, bid farewell to those annoying oils and fingerprints that can seriously mess with your adhesive game. Grab some rubbing alcohol or acetone, apply it to a clean cloth, and diligently wipe down the glass surface. Behold. You now have a pristine canvas ready for some serious gluing action.

But hold on – there’s more. If you’re working with non-porous glass surfaces, priming becomes your secret weapon. Primers work wonders by improving adhesion and preventing any peeling or lifting of the glue over time. Seek out primers specifically designed for use with glass and select one that’s compatible with your chosen adhesive. Priming is an additional step that ensures your glued masterpiece remains intact for years to come.

Safety Precautions When Using Glue on Glass

Gluing glass can be a fun and creative way to bring your ideas to life. However, it’s important to prioritize safety when using glue on glass to protect yourself and ensure successful results. In this article, we will discuss some essential safety precautions that you should consider before embarking on your next glass gluing project.

Ventilation:

Working in a well-ventilated area is crucial when using glue on glass. Fumes emitted by adhesives can be harmful if inhaled excessively. Open windows, use fans, or work outdoors to improve air circulation and prevent the buildup of fumes. Consider wearing a mask or respirator to protect your respiratory system from any potential harm.

Eye Protection:

Your eyes are precious, so always wear safety glasses or goggles when working with glue on glass. Accidents happen, and glue splatters or drips can easily find their way into your eyes. Protecting your eyes is essential to prevent potential injuries and ensure your safety throughout the project.

Skin Protection:

Glue can cause skin irritation or allergic reactions, so it’s important to protect your skin when working with it. Wear protective gloves, such as latex or nitrile gloves, to minimize direct contact with the adhesive. In case you accidentally get glue on your skin, immediately wash the affected area with soap and water.

Handling Sharp Objects:

Glass can have sharp edges or broken pieces that pose a risk of cuts or injuries. Exercise caution and handle glass objects carefully to avoid accidents. If you need to break glass for your project, wear protective gloves and use appropriate tools, such as glass cutters or pliers, following the manufacturer’s instructions.

Fire Safety:

Some glues are flammable or have a low flash point, meaning they can easily ignite. Prevent potential fire hazards by keeping flammable glues away from open flames, sparks, or heat sources. Store adhesive containers in a cool, dry place away from direct sunlight to ensure their stability.

Read and Follow Instructions:

Each glue has unique properties and application methods. To ensure successful bonding and your safety, it’s vital to read and understand the manufacturer’s instructions before using any adhesive on glass. Follow the recommended safety precautions, application techniques, and curing times to achieve the best results.

Clean Up Properly:

After using glue on glass, clean up any spills or excess adhesive promptly. Use a suitable solvent recommended by the manufacturer to remove glue residue from surfaces. Dispose of any waste materials, including empty glue containers, following local regulations or guidelines to maintain a safe environment.

Handling Glass with Care After Applying Glue

Now comes the crucial task of handling the glass with utmost care to protect your hard work and ensure the glue bond holds strong. In this guide, we will explore essential guidelines for safely maneuvering and storing your glued glass masterpiece.

Patience is paramount:

After applying glue to glass, allow ample time for it to dry and set completely. Impatience can be the enemy of a successful bond. Wait until the glue has hardened before even thinking about moving or touching the glass.

Avoid pressure on fragile bonds:

To prevent compromise or breakage, never exert pressure on the glued area. Instead, hold the glass by its edges or non-glued areas. This distributes weight evenly and alleviates strain on the bond.

Steady as she goes:

When lifting or relocating glued glass, adopt smooth, controlled movements. Avoid sudden jerks or swift motions that could stress the bond. Slow and steady is the key to safeguarding your masterpiece.

Transport with tender loving care:

If you must transport your glued glass, employ protective packaging such as bubble wrap or foam padding. These materials provide an extra layer of cushioning, guarding against accidental bumps and scratches during transportation.

Find a rock-solid resting place:

Once you have moved your glued glass to its desired location, position it on a flat and stable surface. This precaution reduces the risk of tipping or tilting, which could strain the bond. Stability is paramount.

Cleanliness without compromise:

If your glued glass requires cleaning, approach it with gentle care. Avoid abrasive materials or harsh chemicals that could damage both the glue and the glass itself. Opt for mild cleaning methods to preserve the integrity of your bond.

Vigilance through inspection:

To ensure the longevity of your glued bond, make it a habit to regularly inspect the glass for any signs of damage or weakening. If you detect any issues, address them promptly by reapplying glue or seeking professional assistance if necessary. Prevention is always better than cure.

Also Read: How to Glue Rubber to Glass? – Glue Things

Conclusion

When it comes to gluing glass, choosing the right adhesive is crucial. After careful research and testing, one glue stands out as the best option: epoxy resin. With its strong bonding properties and ability to withstand heat and moisture, epoxy resin ensures a long-lasting hold on glass surfaces.

But why is epoxy resin superior? Well, let me break it down for you. First off, its exceptional strength means your glass projects will stay intact even under heavy stress. Whether you’re repairing a broken vase or crafting a stunning stained glass masterpiece, epoxy resin has got your back.

Not only does it provide a reliable bond, but epoxy resin also dries clear and transparent. This means no unsightly residue or visible glue lines marring the beauty of your glass creations. You can confidently display your artwork or use functional glass items without worrying about any adhesive eyesores.

Furthermore, epoxy resin is resistant to water and heat. So if you’re attaching glass pieces that may come into contact with liquids or endure high temperatures, this glue is up to the challenge. It won’t weaken or lose its grip, ensuring your project remains securely bonded over time.

In addition to its practical benefits, using epoxy resin on glass is a breeze. Its easy-to-use formula allows for precise application without any mess or fuss. Plus, it sets relatively quickly, saving you valuable time during your crafting endeavors.

So there you have it – when it comes to gluing glass together effectively and aesthetically, epoxy resin reigns supreme. Say goodbye to weak bonds and hello to durable adhesion that enhances the beauty of your glass creations.