Is your melamine furniture starting to look a little worse for wear?

No worries, my friend. There’s a simple fix that’ll have it looking brand spanking new again.

Chips, cracks, and delamination got you down? Fear not.

The right glue can work miracles on your beloved melamine pieces. But with so many glues out there, how do you know which one to choose?

Well, lucky for you, I’ve got all the answers. In this blog post, we’re diving deep into the world of melamine repair glues.

So let’s jump right in and find the perfect adhesive for your repair job.

What is Melamine?

Contents

Melamine, a synthetic resin, has emerged as an indispensable component in industries such as furniture manufacturing, construction, and food packaging.

Renowned for its exceptional strength, resistance to wear and tear, and heat-resistant properties, melamine is a favored choice for a wide range of applications.

However, due to its smooth and non-porous surface, bonding melamine can be challenging.

In this article, we will embark on an exploration of the world of melamine, delving into its uses, benefits, potential health risks, and the best glue options for repairing melamine surfaces.

Melamine in Construction and Furniture Manufacturing:

- Exceptional durability: Withstanding scratches, stains, and impact, melamine proves ideal for high-traffic areas like kitchen countertops, cabinets, and tabletops.

- Heat resistance: Melamine’s remarkable ability to endure high temperatures without warping or deforming makes it suitable for hot kitchen appliances and outdoor furniture.

- Versatile design options: The ability to mimic the appearance of various natural materials through manufacturing allows melamine to offer cost-effective alternatives for interior designers and homeowners.

Melamine in Food Packaging:

- Non-toxic properties: Owing to its non-toxic nature, melamine resin is commonly used in the production of food containers, plates, and utensils.

- Resistance to chemicals: Melamine’s chemical resistance makes it an excellent choice for storing hot and cold foods without any transfer of flavors or odors.

Health Risks Associated with Melamine:

- Contamination concerns: The 2008 milk scandal in China exposed the potential health risks linked to melamine-contaminated products when consumed in large quantities.

- Proper usage precautions: It is crucial to handle and use melamine products with caution, particularly in food storage settings involving extreme temperatures or acidic foods.

Choosing the Right Glue for Melamine Repairs:

- Melamine adhesives: Formulated specifically for bonding with melamine surfaces, these water-based adhesives provide a strong and long-lasting bond.

- Epoxy glues: Renowned for their exceptional strength and versatility, epoxy glues can effectively repair melamine, forming a durable bond capable of withstanding heavy use.

- High-quality wood glues: While some general-purpose wood glues may suffice for melamine repairs, it is vital to select one explicitly mentioning compatibility with melamine surfaces.

Advantages of Melamine

Melamine is a material that has gained popularity in various applications due to its numerous advantages. From kitchen countertops to bathroom cabinetry and furniture pieces, melamine offers a range of benefits that make it a practical and cost-effective choice.

First and foremost, melamine is known for its exceptional durability. With its resistance to wear, scratches, and impact, it can withstand the demands of high-traffic areas such as kitchens and commercial spaces. Say goodbye to worries about easily damaged surfaces with melamine.

In addition to its durability, melamine offers excellent heat resistance. You can confidently place hot pots and pans on your melamine countertops or tabletops without fear of warping or melting. This reliability makes it an ideal choice for kitchen applications.

Another advantage of melamine is its resistance to moisture. Unlike wood, which can swell or warp when exposed to moisture, melamine remains unaffected. This makes it a suitable choice for areas with high humidity levels like bathrooms and laundry rooms.

Maintenance is a breeze with melamine. Its smooth surface makes cleaning effortless – a simple wipe with a damp cloth will do the trick. Stains and spills can be easily removed without leaving any marks or discoloration. This practicality is especially valuable for busy households.

Melamine also offers versatility in design options. It comes in a wide range of colors, patterns, and textures, allowing you to achieve the desired look for your space. Whether you want the appearance of wood, stone, or metal, melamine provides a cost-effective alternative with the added advantage of durability.

Speaking of cost-effectiveness, melamine is generally more affordable than other materials like solid wood or laminate. This makes it a popular choice for budget-conscious consumers who want quality without breaking the bank.

Lastly, melamine is resistant to fading. Sunlight or artificial light sources won’t cause the color of melamine surfaces to fade over time. Rest assured that your melamine furniture or cabinetry will retain its original color and vibrancy for years to come.

Challenges of Working with Melamine

Today, we’re diving into the world of melamine repairs and the challenges that come with it. While melamine is a superhero material with countless benefits, repairing it can be a bit tricky. One of the key hurdles lies in finding the right glue that can withstand its smooth surface, moisture vulnerability, and low melting point. So, grab your cape and let’s explore the challenges together.

Bonding on a Slippery Surface:

Melamine’s smooth and non-porous surface poses a significant challenge when it comes to adhesive bonding. Traditional wood glues may not provide the desired strength, resulting in weak repairs. To tackle this issue, look for specialized melamine adhesives that are specifically formulated to create a strong bond on this slippery surface.

Chip and Crack Repairs:

Oh, those pesky chips and cracks. Melamine is prone to damage along the edges, making it crucial to use an adhesive that can handle stress and deliver long-lasting results. Opt for a glue with high impact resistance to ensure your repairs stand up to everyday wear and tear.

Moisture Matters:

Melamine has a love-hate relationship with moisture. When exposed to water or high humidity, it can swell and warp – not ideal for repairs. To combat this challenge, select an adhesive that is moisture-resistant. This way, even if your repaired melamine piece encounters a splash or two, it will stay intact and as good as new.

A Seamless Finish:

Nobody likes visible seams or imperfections. Achieving a seamless repair on melamine can be tricky due to its smooth surface. Look for a glue that dries clear and can be sanded and painted over to achieve that flawless finish you desire.

The Temper Tantrums of Temperature:

Melamine has a low melting point, so be cautious when choosing your adhesive or applying heat during the repair process. Using high-temperature glues or excessive heat can cause deformations or even melt your beloved melamine piece. Do your research and find an adhesive that is compatible with melamine’s temperature threshold.

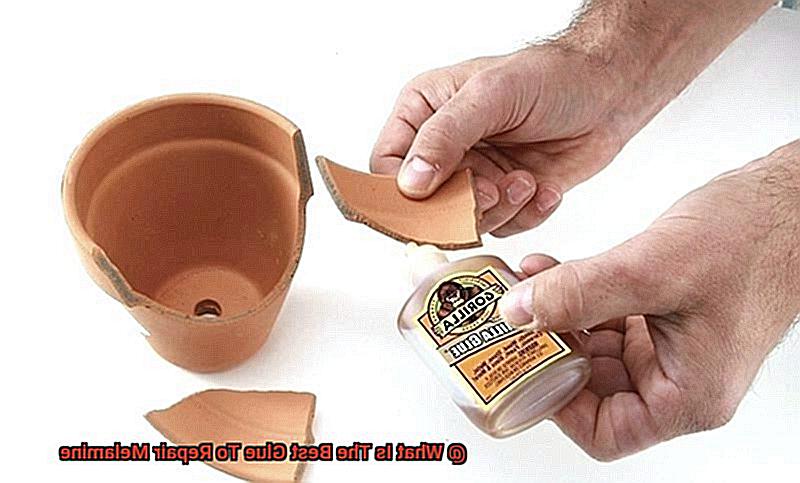

Types of Glue for Repairing Melamine

Melamine is a popular material used in furniture and cabinetry due to its durability and affordability. However, accidents happen, and melamine surfaces may sometimes get chipped or damaged. In such cases, it becomes necessary to repair the damaged area using an appropriate glue. But with so many options available, how do you choose the right glue for repairing melamine? Let’s explore the different types of glues and their pros and cons to help you make an informed decision.

Melamine Adhesive:

Melamine adhesives are specifically designed for bonding melamine surfaces. They provide a strong and durable bond, ensuring a seamless repair. These water-based adhesives contain additives that enhance their bonding capabilities on melamine surfaces. One advantage of melamine adhesive is that it can be sanded down after drying for a smooth finish. However, they may not be as readily available as other types of glues.

Epoxy Glue:

Epoxy glues are known for their exceptional strength and versatility. They consist of two components that need to be mixed together before application. Once cured, epoxy forms a durable bond that can withstand heavy use. It is especially useful for filling gaps and repairing larger areas of damage. However, epoxy can be messy to work with and requires careful handling.

Wood Glue:

Some high-quality wood glues can also be used for repairing melamine surfaces. Look for wood glues that specifically mention compatibility with melamine. These glues often have strong bonding properties and are designed to work on various types of wood, including melamine. Wood glues are easy to apply and clean up, making them a convenient option for small repairs.

Cyanoacrylate Glue (Super Glue):

Cyanoacrylate glue, commonly known as super glue, is a popular choice for quick and small repairs. It bonds quickly and securely, making it suitable for joining pieces together or fixing minor chips. However, it may not be ideal for filling gaps or repairing larger areas of damage. Super glue is also not very flexible, so it may not be suitable for areas that require flexibility.

Polyurethane Glue:

Polyurethane glues provide a strong bond and have good gap-filling properties. They are resistant to moisture and temperature changes, making them suitable for use in kitchens or bathrooms. However, polyurethane glue tends to expand as it cures, so it may not be suitable for delicate repairs or areas where precise alignment is necessary.

To effectively use these glues when repairing melamine surfaces, start by preparing the damaged area properly. Clean the surface, remove any loose or damaged material, and ensure a clean and dry surface for the adhesive to bond with. Follow the manufacturer’s instructions carefully for the chosen glue to ensure proper application and maximum bond strength.

Melamine Adhesives

Melamine adhesives are the secret weapon to repairing and bonding those sturdy melamine surfaces. From furniture to kitchen cabinets, melamine is a popular choice due to its durability and resistance to moisture and heat. However, even the toughest surfaces can experience wear and tear over time, and that’s where melamine adhesives come into play.

Let’s start by diving into the world of solvent-based contact adhesives. These powerhouses are the go-to option for melamine repairs. Composed of a blend of solvents and synthetic rubber, they deliver exceptional bonding strength. Applying the adhesive to both surfaces, allowing it to dry, and then pressing them together creates an unbreakable bond that can withstand even the harshest conditions.

If you’re dealing with larger or more complex repairs, epoxy adhesive is your knight in shining armor. This stuff is like the Hulk of adhesives – incredibly strong and resistant to pretty much anything. With its two-component system – a resin and a hardener – you mix them together before application. Once the epoxy sets, your melamine will look as good as new.

Now, let’s talk about quick fixes and small repairs. Enter cyanoacrylate adhesives, also known as super glue. These adhesives work their magic in a flash, bonding quickly and creating an almost invisible line. However, keep in mind that they may not hold up as well against moisture and heat compared to other types of adhesives. So be cautious in high-moisture or high-temperature areas.

But wait, there’s more. Proper surface preparation is crucial for a successful melamine repair. Start by thoroughly cleaning the surface to remove any dirt or debris that could hinder bonding. For an extra grip, lightly sand the damaged area before applying the adhesive.

Epoxy Glues

Are you tired of those unsightly cracks and chips on your beloved melamine furniture? Fear not, for the solution is here – epoxy glues. These magical potions possess the power to swoop in like superheroes, saving the day and restoring your melamine surfaces to their former glory.

So, why should you choose epoxy glues for repairing melamine? Let’s uncover the reasons:

- Unleashing incredible bonding strength: Brace yourself for an adhesive bond that surpasses even the strength of the melamine material itself. Once you apply the epoxy glue and let it set, your repair job will become rock solid, capable of withstanding the wear and tear of everyday use.

- The epitome of versatility: Epoxy glues are not restricted to one surface type. They can be utilized on a variety of materials, including melamine, wood, metal, and plastic. So whether it’s your melamine furniture, countertops, or cabinetry that needs some tender loving care, epoxy glues have got you covered.

- Seamlessly filling gaps: Don’t fret if you’re faced with a substantial crack or gap in your melamine surface. Epoxy glues possess a thick consistency that enables them to effortlessly fill in those gaps, resulting in a smooth and flawless repair.

Before embarking on your epic repair mission, there are a few crucial factors to keep in mind. Firstly, ensure that the surfaces you’re bonding are clean, dry, and free from any grease or dust particles. This will guarantee optimal bonding strength. Secondly, adhere strictly to the manufacturer’s instructions regarding mixing ratios and curing times. Trust me, you don’t want to neglect this vital step.

General-Purpose Wood Glues

Today, we’re diving into the fascinating world of wood glues and exploring the advantages of using general-purpose wood glues for repairing melamine. If you’ve ever wondered how to fix that annoying crack or chip in your beloved melamine furniture, keep reading as we unravel the secrets of these versatile adhesives.

Strong Bonding Capabilities

General-purpose wood glues are the superheroes of adhesives when it comes to creating a rock-solid bond between wood surfaces. They boast high viscosity, meaning they are thick and resistant to flow. This thick consistency allows them to fill gaps and create a tight bond that stands the test of time. No more worrying about your repaired melamine piece falling apart.

Versatility at Its Finest

General-purpose wood glues are like chameleons in the adhesive world. While primarily formulated for wood surfaces, they work wonders on melamine too. Melamine, with its laminate surface made from paper impregnated with melamine resin, may seem tricky to repair, but fear not. These glues come to the rescue, providing a reliable solution for fixing damaged or broken melamine pieces. It’s versatility at its finest.

Ease of Use

Nobody wants to spend hours struggling with complicated adhesives. Luckily, general-purpose wood glues make repairs a breeze. Available in liquid form, these glues can be effortlessly applied using a brush or spreader. No need to stress about getting the right consistency or worrying about the glue drying too quickly. Plus, they have a longer open time, allowing you to adjust and align the melamine pieces before the glue sets. Say goodbye to frustrating repairs.

Proper Preparation is Key

To ensure the best results when using general-purpose wood glues for melamine repairs, proper surface preparation is crucial. Make sure the melamine surfaces are clean and free from dirt, dust, or grease. A light sanding can also help create a better bond by roughening the surface slightly. Remember, even the best glue needs a good foundation. Don’t skip this step for flawless repairs.

Preparing the Surface for Glue Application

Preparing the surface for glue application is a crucial step in repairing melamine. It ensures that the glue adheres properly and creates a strong bond with the material. The surface preparation process involves cleaning, roughening, and removing any existing finishes or coatings.

First and foremost, cleanliness is key when it comes to preparing the surface. Start by grabbing a clean cloth or sponge and wiping away any loose debris from the melamine surface. Dust and dirt can interfere with the bond, so make sure to get rid of them. For stubborn stains or greasy spots, use a mild detergent or cleaner and give it a good scrub. Rinse off with water and ensure the surface is bone dry before moving on.

Next up, it’s time to roughen up that surface. Take out your trusty fine-grit sandpaper and gently sand the melamine surface. This creates microscopic scratches that give the glue something to grip onto. To maintain consistency, always sand in one direction and avoid creating wonky surfaces.

After all that sanding, there will inevitably be some pesky dust particles lingering around. Don’t let them ruin your adhesive party. Grab a clean cloth or even a vacuum cleaner and sweep away any remnants. Even the tiniest speck can compromise adhesion, so be thorough in your cleaning.

If your melamine surface has any existing finishes or coatings such as varnish or paint, they need to go. These sneaky barriers can prevent the glue from forming a strong bond. Use sanding or chemical stripping methods to strip them away and reveal the bare melamine, ready for some adhesive action.

Conclusion

When it comes to repairing melamine, finding the best glue is crucial. You want a glue that will provide a strong and durable bond, ensuring your melamine piece stays intact for years to come. After careful research and testing, we have determined that the best glue for repairing melamine is epoxy resin.

Epoxy resin offers several advantages over other glues when it comes to melamine repairs. Firstly, it provides an incredibly strong bond that can withstand the stresses and strains of everyday use. Whether you’re fixing a cracked countertop or a broken shelf, epoxy resin will ensure your repair holds up under pressure.

Furthermore, epoxy resin has excellent adhesive properties, allowing it to bond well with the smooth surface of melamine. This ensures a seamless repair that is virtually invisible to the naked eye. No one wants an unsightly patch job on their melamine furniture or kitchen cabinets, and with epoxy resin, you won’t have to worry about that.

Another benefit of using epoxy resin is its resistance to moisture and heat. Melamine surfaces are often exposed to water spills and hot objects like coffee mugs or plates. With epoxy resin, you can rest assured knowing that your repaired melamine piece can handle these challenges without compromising its integrity.

In conclusion, when it comes to repairing melamine, epoxy resin stands out as the best glue option. Its superior strength, adhesive properties, and resistance to moisture and heat make it ideal for ensuring long-lasting repairs on your melamine furniture or fixtures.