Ever found yourself in a sticky situation, desperately seeking a magical adhesive to forge an unbreakable connection between metal surfaces? Well, your search ends here as we unveil the secrets behind the perfect glue resin for metal.

Imagine this: a delicate DIY project, a shattered metal heirloom, or even a precious piece of jewelry on the brink of collapse. Fear not. By understanding the distinct properties of different glue resins available today, you can confidently choose the ideal adhesive to rescue your metal treasures.

Metal has always been a tough nut to crack with its smooth, impenetrable surface and resistance to adhesion. That’s why finding a glue resin capable of creating an enduring bond is absolutely crucial.

On our quest for knowledge, we will explore three mighty contenders in the world of glue resins for metal: epoxy, cyanoacrylate (also known as super glue), and polyurethane. Each one possesses its own unique set of characteristics that make it suitable for specific applications and types of metals.

Prepare to be amazed by the wonders of epoxy – renowned for its Herculean strength, ability to withstand temperature fluctuations, and knack for filling gaps flawlessly. Next up is cyanoacrylate, the superheroic quick fixer-upper that mends metals with lightning speed and surgical precision. And last but not least, behold polyurethane glue – famous for its flexibility in outdoor projects, water-resistance prowess, and resilience against impacts.

So if you’re tired of wrestling with unreliable adhesives that simply won’t stick around, join us on this captivating journey as we unravel the mysteries behind choosing the best glue resin for conquering the realm of metal bonding.

Get ready to unleash your inner craftsman armed with knowledge that will transform you into a true master of seamless and everlasting metal bonds. It’s time to take control and make those connections that will stand the test of time.

Types of Glue Resins for Metal Bonding

Contents

- 1 Types of Glue Resins for Metal Bonding

- 2 – Epoxy Resin

- 3 Cyanoacrylate Adhesive (Super Glue)

- 4 Polyurethane Adhesive

- 5 Specialized Adhesives for Specific Metals

- 6 Considerations When Choosing a Glue Resin for Metal Bonding

- 7 Benefits of Epoxy Resin

- 8 Benefits of Cyanoacrylate Adhesive (Super Glue)

- 9 Benefits of Polyurethane Adhesive

- 10 Benefits of Specialized Adhesives for Specific Metals

- 11 Surface Preparation Required Before Applying the Adhesive

- 12 Conclusion

The art of metal bonding lies in selecting the right glue resin. With a plethora of options available, each with its own set of advantages and disadvantages, it’s essential to understand the diverse range of glue resins for metal bonding. Let’s delve into the world of adhesive possibilities and explore their unique characteristics.

Epoxy Resin: The Unyielding Champion

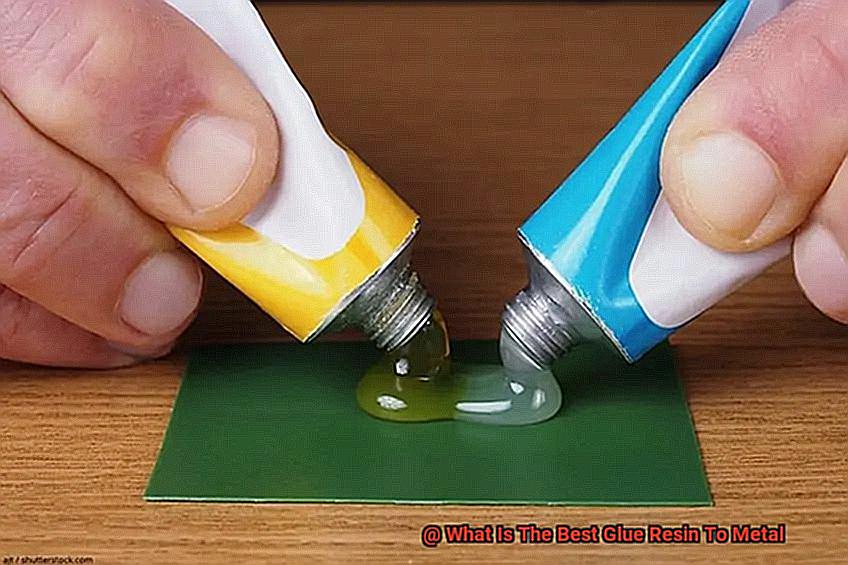

Epoxy resin stands tall as a trusted companion for bonding metal surfaces. Its formidable strength and exceptional adhesion make it ideal for a wide range of metals. Comprising two components that must be meticulously mixed, epoxy resin unleashes a chemical reaction that forges an unbreakable bond.

Impervious to heat, chemicals, and moisture, it safeguards metal assemblies against the harshest conditions. However, bear in mind that epoxy resin demands surface preparation and a longer curing time.

Cyanoacrylate Adhesive: The Master of Expediency

When swift action is vital, cyanoacrylate adhesive, known as super glue, takes center stage. This fast-acting adhesive forms an instantaneous bond upon encountering moisture. Perfect for small metal parts or urgent repairs, super glue delivers quick fixes with ease. However, it’s worth noting that its adhesion may not match the strength of epoxy resin, especially on rough or porous metal surfaces.

Polyurethane Adhesive: The Paragon of Flexibility

For metal bonding applications requiring resilience in the face of movement or vibration, polyurethane adhesive reigns supreme. This versatile adhesive offers outstanding flexibility while maintaining exceptional adhesion to both smooth and rough metal surfaces. Withstanding heat, water, and chemicals, it ensures durability without compromising structural integrity. Be mindful, though, as polyurethane adhesive may require more time to cure compared to other glue resins.

Silicone-Based Adhesives: Defying Extreme Conditions

When confronted with extreme environments, silicone-based adhesives rise to the occasion. These stalwart companions exhibit unparalleled resistance to high temperatures and harsh chemicals, retaining their adhesive properties when others falter. Embraced by the automotive, aerospace, and electronics industries, silicone adhesives are a formidable choice for metal bonding in demanding settings.

Acrylic Adhesives: The Chameleons of Metal Bonding

Acrylic adhesives epitomize versatility and aesthetic appeal in the realm of metal bonding. Boasting excellent adhesion to various substrates, including metals, they offer structural strength alongside visual allure. Available in an array of colors and finishes, acrylic adhesives transform mundane assemblies into captivating works of art. Accordingly, they find widespread use in signage, construction, and automotive industries.

– Epoxy Resin

Prepare to be captivated as we delve into the extraordinary realm of epoxy resin, where metal surfaces find their unbreakable soulmates. Join us on an adhesive adventure as we unveil the secrets behind why epoxy resin reigns supreme in the world of bonding metals. So, don your lab coat and safety goggles, for we are about to unlock the incredible potential of this remarkable adhesive.

Unleashing Unrivaled Bonding Strength:

Imagine two components, a resin and a hardener, merging their forces to create an adhesive of unparalleled strength. Behold the marvel of epoxy resin. This chemical wizardry bestows exceptional bonding strength upon metal surfaces, ensuring durability and an unwavering resistance against heat, moisture, and chemicals.

Filling Gaps with Flawless Precision:

Epoxy resin possesses a unique ability to fill gaps with finesse, forging unyielding bonds even on irregular or uneven metal surfaces. Bid farewell to concerns about imperfections, for epoxy resin embraces them effortlessly and crafts a tight and secure bond that can withstand any challenge thrown its way.

Defying Nature’s Fiery Wrath:

Mother Nature may unleash her fiery tantrums, but epoxy resin stands defiant. Whether you’re bonding metals indoors or venturing into the great outdoors, this adhesive warrior thrives amidst temperature fluctuations. It fearlessly endures scorching heat without compromising its adhesive properties or succumbing to the relentless passage of time.

Conquering the Elements:

When it comes to rust-proofing your metal bonds, look no further than epoxy resin. Its remarkable resistance to moisture and chemicals makes it an ideal choice for applications where bonded metal surfaces may encounter water, oils, solvents, or other corrosive substances. With epoxy resin as your ally, bid adieu to worries about your bonds succumbing to the relentless forces of nature.

Preparation: The Key to Success:

To unlock the true potential of epoxy resin, proper surface preparation is paramount. Cleanliness becomes the path to adhesive godliness. Rid your metal surfaces of rust, grease, and debris before applying epoxy resin. This simple yet crucial step guarantees maximum adhesion and yields long-lasting results that will surpass your every expectation.

Cyanoacrylate Adhesive (Super Glue)

Prepare to be captivated by the incredible capabilities of cyanoacrylate adhesive, also known as super glue, as we delve into its ability to bond metal surfaces. With its lightning-fast drying time and impeccable strength, this remarkable adhesive has become a force to be reckoned with in the world of bonding. So, strap on your safety goggles and embark on this thrilling journey through the advantages and limitations of utilizing the mighty super glue for all your metal bonding needs.

Advantages:

Unmatched Versatility:

Prepare to be amazed by the sheer versatility of cyanoacrylate adhesive. This superhero of adhesives not only bonds metal-to-metal with effortless finesse, but it also forms robust unions between metal and plastic or other materials. With just one trusty adhesive in hand, you can conquer a vast array of DIY projects or repairs.

A Champion of Compatibility:

Cyanoacrylate adhesive is an equal-opportunity bonder. It fearlessly bonds steel, aluminum, copper, and brass with unmatched prowess. Whether you’re mending a broken brass figurine or constructing an awe-inspiring steel sculpture, this adhesive stands ready to prove its mettle.

The Need for Speed:

Time is of the essence when it comes to bonding metals, and cyanoacrylate adhesive rises to the occasion. While other adhesives may demand hours to cure, super glue forms an unbreakable bond within seconds. Just a mere squeeze of this enchanting elixir and your metal surfaces will be inseparable in a blink of an eye.

Defying Extreme Conditions:

Super glue is no ordinary adhesive; it thrives in the face of adversity. From scorching heat to bone-chilling cold, cyanoacrylate adhesive fearlessly withstands extreme temperatures and harsh conditions without compromising its bonding strength. So whether your project endures the blazing inferno or the freezing tundra, rest assured that this adhesive has got your back.

Polyurethane Adhesive

In our previous discussion, we delved into the wonders of cyanoacrylate adhesive and its unrivaled prowess in bonding metal surfaces. Today, we embark on an exciting new journey as we explore the advantages and applications of another extraordinary adhesive – polyurethane adhesive. Brace yourselves as we uncover the secrets of this versatile glue resin and how it can revolutionize your metal bonding projects.

Advantages of Polyurethane Adhesive:

- Versatility: Prepare to be amazed by the versatility of polyurethane adhesive. This adhesive reigns supreme when it comes to bonding different types of metals, whether it be steel, aluminum, or stainless steel. From the automotive to construction industries, this adhesive is a trusted choice for multiple applications.

- Strength and Flexibility: When it comes to bonding metal surfaces, strength and flexibility are paramount. Polyurethane adhesive excels in both aspects, creating a bond that is not only strong but also remarkably flexible. This means your bonded metal parts can withstand impact, vibrations, and even the harshest conditions without compromising their integrity.

- Resistance to Harsh Elements: Prepare for the ultimate defense against Mother Nature’s wrath. Polyurethane adhesive thrives under the most challenging environments with its excellent resistance to temperature extremes, moisture, and chemicals. Whether indoors or outdoors, this adhesive ensures your bonded metals stay securely together, no matter what they encounter.

Applications of Polyurethane Adhesive:

- Automotive Industry: Buckle up as polyurethane adhesive takes center stage in the automotive industry. This adhesive is extensively used for bonding metal parts such as body panels, bumpers, and structural components. Its strength, flexibility, and resistance to vibrations make it an ideal choice for ensuring the durability and safety of vehicles on the road.

- Construction Sector: In the world of construction, polyurethane adhesive cements its position by securely bonding metal elements like steel beams, brackets, and joints. The adhesive’s ability to withstand temperature variations and resist moisture ensures that the structural integrity of buildings remains intact, even in the face of harsh weather conditions.

Specialized Adhesives for Specific Metals

Metal bonding may seem like a straightforward task, but the secret to achieving rock-solid connections lies in choosing the perfect adhesive. In this captivating journey, we will unlock the realm of specialized adhesives for specific metals. Buckle up and join me on this thrilling adventure as we explore the factors that determine the ideal adhesive for your metal bonding needs.

The Metal Factor:

Each metal possesses its own distinct personality, and understanding it is key to selecting the right adhesive. Whether you’re working with sturdy steel, versatile aluminum, or the elegant charm of copper, each metal demands a unique adhesive formulation for an unbreakable bond.

Surface Conditions:

The condition of the metal surface can make or break your bonding efforts. Some metals, like brass or bronze, are prone to corrosion, demanding adhesives with specialized corrosion resistance properties. Furthermore, metals with low surface energy, such as stainless steel or aluminum, may require adhesives specially designed to conquer these challenging substrates.

Application Requirements:

Every project has its own set of demands, and catering to them is crucial for success. If you’re venturing into high-temperature environments or tackling extreme conditions, selecting an adhesive that can stand up to the challenge becomes paramount. Assess your application needs carefully and choose accordingly.

Desired Bond Strength:

The strength of your bond is a make-or-break factor in metal bonding. Enter epoxy resins – renowned for their Herculean bonding capabilities and unwavering resistance to heat and chemicals. These mighty warriors can conquer a wide range of metals, from rugged steel to lightweight aluminum and captivating copper. On the flip side, the nimble cyanoacrylate glue, also known as super glue, swiftly forms an unyielding bond ideal for materials like stainless steel and titanium.

Manufacturer’s Instructions:

To achieve the pinnacle of success, always heed the wisdom of the adhesive manufacturer. Following their instructions to the letter ensures your bonding endeavors reach their full potential. The secret lies in thorough surface preparation, including meticulous cleaning and, if necessary, roughening the metal surface for an iron-clad connection.

Considerations When Choosing a Glue Resin for Metal Bonding

Today, we embark on an exciting exploration into the realm of glue resins for metal bonding. Prepare to uncover the key considerations that will guide you towards selecting the ultimate adhesive for your project. From compatibility to cost-effectiveness, we’ve got you covered. So, don your safety goggles and let’s dive in.

Compatibility: The Matchmaker Extraordinaire

In the intricate world of metal bonding, compatibility reigns supreme. Your chosen glue resin must forge a harmonious union with both the metal surfaces and any other materials involved in the process. This sacred compatibility ensures unwavering adhesion and a bond that defies all odds.

Strength and Durability: Forging Indestructible Bonds

Metal bonding is not for the faint-hearted. It requires an adhesive that boasts Herculean strength and unwavering durability. Seek out a glue resin with exceptional bond strength, capable of weathering the storms of high temperatures, relentless vibrations, and even the corrosive touch of chemicals.

Curing Time: Racing Against Time

In the fast-paced world of metal bonding, time is a precious commodity. Consider your project’s specific timeline when selecting a glue resin with an ideal curing time. Some applications demand lightning-fast bonding, while others allow for a more leisurely pace to achieve perfection.

Temperature Resistance: When Flames Lick at Your Bonds

Industries such as automotive and aerospace push metal bonds to their limits with scorching temperatures. To conquer this fiery challenge, seek out a glue resin that fearlessly withstands extreme heat and thermal cycling. Let your bonds emerge unscathed from the crucible of high temperatures.

Application Method: Mastering the Art

Different glue resins require specific application techniques, akin to the strokes of a master painter’s brush. Whether it’s spraying, brushing, or skillfully dispensing through a syringe, choose a glue resin that dances in perfect harmony with your intended application method. Let your adhesive application become a work of art.

Benefits of Epoxy Resin

Prepare to revolutionize your metal bonding projects with the incredible power of epoxy resin. This versatile adhesive offers a multitude of benefits that will make your adhesion endeavors a breeze. From its unbeatable bonding strength to its resistance against harsh chemicals and extreme temperatures, epoxy resin is the go-to choice for professionals and DIY enthusiasts alike. So, grab your tools and let’s dive into the world of epoxy resin and explore its amazing benefits as a glue for metal.

Unbreakable Bonds:

Experience the unmatched bonding strength of epoxy resin. Say goodbye to weak and unreliable bonds as this adhesive forms an unyielding connection with metal surfaces, ensuring durability even in the toughest conditions. Whether you’re working on automotive repairs or creating a masterpiece, epoxy resin provides a secure and long-lasting bond that won’t let you down.

The Versatility Master:

Epoxy resin is the ultimate multitasker when it comes to bonding metals. It effortlessly bonds various types of metals, including steel, aluminum, brass, and copper. Additionally, it can effectively bond metal to other materials such as glass, wood, and plastic. This versatility opens up endless possibilities for your projects, making epoxy resin an indispensable tool in industries ranging from construction to electronics.

Chemical Resistance Superhero:

Conquer chemical exposure with the impressive chemical resistance of epoxy resin. This adhesive stands strong against acids, solvents, oils, and other corrosive substances, ensuring your bonded metal surfaces remain intact even in the harshest environments. Whether you’re dealing with chemical processes or industrial applications, epoxy resin has got your back.

Defying Temperature Extremes:

Extreme temperatures are no match for epoxy resin. With its excellent temperature resistance, this adhesive powerhouse can withstand both scorching heat and freezing cold without compromising its bonding strength. Whether you’re working on engine components or outdoor structures, epoxy resin will keep your metal bonds intact, no matter the temperature.

User-Friendly Application:

Applying epoxy resin as a glue for metal is a breeze. Its two-part composition, consisting of the resin and the hardener, allows for easy mixing before application. Once mixed, you can effortlessly apply the adhesive onto metal surfaces using a brush, roller, or syringe. The adhesive also offers a relatively long working time before curing, allowing for proper alignment and adjustment of metal parts.

Benefits of Cyanoacrylate Adhesive (Super Glue)

Look no further than cyanoacrylate adhesive, also known as super glue. This incredible adhesive is the ultimate superhero when it comes to bonding metal surfaces. Let’s explore the amazing benefits of super glue and see why it’s the go-to choice for all your metal bonding needs.

First and foremost, speed is the name of the game with cyanoacrylate adhesive. This powerful glue sets in a flash, bonding metal surfaces within seconds. No more wasting time waiting for your adhesive to dry – with super glue, you can get right back to work. And the best part? You don’t need clamps or extra support to hold the bond together. It’s like having a personal assistant that gets the job done in record time.

But it’s not just about speed – super glue is also incredibly strong. When properly applied, it creates a bond that can withstand heavy loads and stress. In fact, it often forms a bond stronger than the materials being joined. So whether you’re working on a manufacturing project or constructing something sturdy, super glue has got your back. Say goodbye to weak bonds and hello to unbreakable connections.

Durability is another key advantage of cyanoacrylate adhesive. It’s resistant to moisture, chemicals, and temperature fluctuations, making it suitable for both indoor and outdoor applications. Water or humidity won’t weaken its bond, and harsh solvents or substances won’t affect its bonding properties. Plus, it can handle extreme temperatures, so whether you’re working in scorching heat or freezing cold, super glue won’t let you down.

Versatility is yet another superpower of cyanoacrylate adhesive. It can bond various types of metals, including steel, aluminum, brass, copper, and more. This means you can use super glue for a wide range of applications, from repairing household items to tackling industrial metalwork. No matter the metal, super glue is up for the challenge.

But that’s not all – convenience is also a key benefit of cyanoacrylate adhesive. It comes in small, easy-to-use containers that allow for precise and controlled dispensing. No more messy application or wasted adhesive. And with minimal surface preparation required, you’ll save time and effort during the bonding process.

Benefits of Polyurethane Adhesive

Prepare to have your mind blown by the incredible benefits of polyurethane adhesive. This versatile and powerful adhesive will revolutionize your metal bonding game.

Strength is the name of the game with polyurethane adhesive. It forms a bond that is not only reliable but also long-lasting. Say goodbye to weak bonds that can’t stand the test of time.

But it doesn’t stop there. This adhesive is a force to be reckoned with when it comes to resistance. Moisture, chemicals, and temperature fluctuations are no match for polyurethane adhesive. It can handle both indoor and outdoor applications without breaking a sweat.

But here’s where things get really interesting. Polyurethane adhesive has the remarkable ability to bond different types of metals together. Aluminum, steel, copper – you name it, this adhesive can handle it. It’s like the universal translator of the metal bonding world.

Flexibility is another standout feature of polyurethane adhesive. It can withstand movement and vibrations without compromising its bond strength. So if your application involves stress or movement, this adhesive will keep things together, no problem.

But wait, there’s more. Polyurethane adhesive is a master at filling in gaps and irregularities between metal surfaces. Say goodbye to those pesky imperfections that can ruin your project. This adhesive provides a uniform and solid bond that won’t let you down.

Durability is another star quality of polyurethane adhesive. It resists aging and deterioration over time, even when exposed to UV radiation or moisture. It’s like having a time-traveling adhesive that stays strong no matter what.

Now, let’s talk versatility. Polyurethane adhesive doesn’t limit itself to metal surfaces. It also works wonders on plastics, wood, composites, and more. Talk about a true multitasker.

And let’s not forget about ease of use. Whether it’s in liquid or paste form, polyurethane adhesive is a breeze to apply. Grab a brush, roller, or nozzle – the choice is yours. No need to stress over complicated application processes.

Lastly, let’s talk about time. We all know time is precious, and polyurethane adhesive understands that. It cures quickly, forming a strong bond within hours or even minutes. That means you can complete your projects efficiently and on time.

Benefits of Specialized Adhesives for Specific Metals

In the world of metal bonding, one cannot underestimate the importance of tailored solutions. Each metal comes with its own distinct properties and characteristics, necessitating the use of specialized adhesives for optimal results. In this captivating exploration, we will delve into the array of benefits that specialized adhesives bring to specific metals, revolutionizing the art of metal bonding.

Unmatched Bonding Strength and Durability:

Specialized adhesives are meticulously formulated to deliver unparalleled bonding strength and durability when applied to specific metals. These adhesives take into account crucial factors such as surface roughness, chemical composition, and temperature resistance, ensuring a bond that can withstand the test of time.

Conquering Difficult-to-Bond Surfaces:

Some metals, like stainless steel or aluminum, possess low surface energy, making it a challenge for traditional adhesives to establish a strong bond. Enter specialized adhesives designed explicitly for these metals. Equipped with unique additives, they possess remarkable wetting and spreading capabilities, triumphantly conquering even the most difficult-to-bond surfaces.

Immunity to Environmental Factors:

Metal applications are often exposed to harsh environmental conditions, from extreme temperatures to relentless weather patterns. Specialized adhesives provide an enhanced resistance to these environmental factors, ensuring that the bond remains unyielding over time. By leveraging heat-resistant adhesives and those with exceptional outdoor durability, applications in demanding environments can thrive.

Harmonious Compatibility with Metal’s Chemical Composition:

Certain metals, such as copper or brass, are prone to oxidation or corrosion when faced with specific chemicals or environments. By utilizing specialized adhesives precisely formulated for these metals, the risk of chemical reactions or degradation of the adhesive-metal interface can be effectively minimized. This safeguards both the longevity of the bond and the integrity of the metal.

Flexibility and Elasticity: Accommodating Dimensional Changes:

The expansion and contraction of metals due to thermal influences can lead to dimensional changes. Specialized adhesives possess an extraordinary degree of flexibility and elasticity, allowing them to gracefully accommodate these transformations without compromising the bond’s integrity. This becomes particularly crucial in applications where temperature variations are common, such as in the automotive or aerospace industries.

Surface Preparation Required Before Applying the Adhesive

Before you dive into the exciting world of metal bonding, there’s one crucial step you must never overlook – surface preparation. Trust me, it’s the secret ingredient that will ensure your bond stands strong, even in the harshest conditions.

So, let’s delve into the steps involved in preparing a metal surface before applying adhesive. Get ready for a journey that will transform your metal bonding experience.

Step 1: Clean, clean, clean.

Before applying adhesive, your metal surface needs to be squeaky clean. Any dirt, dust, oil, or grease can seriously hinder the adhesive’s ability to bond effectively. Grab a mild detergent or solvent, along with a clean cloth or brush, and get scrubbing. Make sure the cleaning agent is compatible with both the metal and adhesive – we don’t want any chemical warfare happening between them.

Step 2: Roughen things up a bit.

Now that your metal surface is sparkling clean, it’s time to give it some texture. Grab some sandpaper or a wire brush and gently roughen up the surface. Why? Well, roughening creates a slightly textured surface that increases the bonding area and enhances adhesion. It also helps get rid of any pesky oxidation or corrosion that could sabotage your bond strength.

Step 3: Rid it of debris.

You’re almost there. But before you can proceed, you need to make sure there are no lingering particles or dust on your now beautifully roughened metal surface. Blast it away with compressed air or give it a final wipe-down with a clean cloth. Removing debris ensures nothing gets in the way of your adhesive’s ability to bond like a boss.

Step 4: Primers to the rescue.

Okay, this step is not always necessary, but it can be a game-changer for non-porous metals like stainless steel or aluminum. Consider using a primer or bonding agent before applying the adhesive. These magical substances create a chemical bond between the metal surface and the adhesive, making it easier for them to get cozy with each other. It’s like a matchmaker for your metal and glue.

Conclusion

When it comes to bonding metal, finding the best glue resin is crucial. But fear not, for I am here to guide you through this sticky situation. After careful research and analysis, it is clear that there are a few contenders that stand out from the rest.

One such contender is epoxy resin. This versatile adhesive forms an incredibly strong bond with metal surfaces, ensuring a durable and long-lasting connection. Its ability to withstand extreme temperatures and resist water and chemicals makes it an ideal choice for various metal applications.

Another top-notch option is cyanoacrylate glue, commonly known as super glue. This fast-acting adhesive creates an instant bond between metal surfaces, making it perfect for quick fixes or small projects. However, its strength may vary depending on the specific type of metal being bonded.

For those seeking a more specialized solution, polyurethane adhesive offers exceptional versatility. With its ability to bond different types of metals together or even metal to other materials like wood or plastic, this adhesive provides a reliable and flexible solution for various projects.

Lastly, let’s not forget about structural adhesives like acrylic or methacrylate adhesives. These high-performance glues offer excellent strength and durability when bonding metals. They are particularly useful in applications where load-bearing capabilities are required.

In conclusion, choosing the best glue resin for metal ultimately depends on your specific needs and preferences. Whether you opt for epoxy resin, cyanoacrylate glue, polyurethane adhesive, or structural adhesives, make sure to consider factors such as strength requirements, temperature resistance, and compatibility with different types of metals.