Have you ever found yourself lost in the mesmerizing reflection of a mirror, pondering the invisible wizardry that holds it all together? Well, my friend, this blog post is your backstage pass into the captivating world of mirror glass adhesion. Mirrors are not just mere reflections; they are masterpieces demanding utmost precision and care when it comes to repairs or DIY projects. And at the heart of their flawless hold lies the unsung hero – glue.

So, what’s the secret sauce for bonding mirror glass? Brace yourself as we dive deep into the realm of adhesive wonders that safeguard these shimmering beauties.

But before we reveal our top contenders in this gluing game, let’s address your primary concerns when dealing with mirror glass adhesive. We’re talking stability, durability, and transparency – all crucial elements to ensure a rock-solid bond without compromising that oh-so-precious reflective surface.

Throughout our exploration, we’ll scrutinize various adhesive formulations and assess their suitability for different types of mirrors and application methods. From flexible silicone adhesives renowned for their weather resistance to lightning-fast UV-cured glues with unmatched bonding strength – we’ve got you covered. Our mission is simple: to equip you with a comprehensive guide that empowers you to make an informed choice for all your mirror-related endeavors.

Whether you’re planning to rescue a cracked mirror from its shattered fate or embarking on an awe-inspiring DIY project involving mirrored furniture, our journey will arm you with all the knowledge you need. Prepare yourself for an enlightening adventure through the art and science of perfect bonding.

Stay tuned for more articles as we unravel the complexities of mirror glass adhesives. Get ready to unveil the best glue for mirror glass and discover what truly makes those reflections shine.

What is Mirror Glass?

Contents

- 1 What is Mirror Glass?

- 2 Types of Adhesives for Mirror Glass

- 3 The Benefits of Silicone-Based Adhesives

- 4 The Benefits of Epoxy Resin Adhesives

- 5 Choosing the Right Adhesive for Mirror Glass

- 6 Preparing the Surface Before Applying Adhesive

- 7 Applying the Adhesive to Mirror Glass

- 8 Curing and Testing the Bonded Surface

- 9 Conclusion

Step into the mesmerizing world of mirror glass, where artistry and scientific ingenuity combine to create surfaces that reflect beauty and serve a practical purpose. In this captivating blog post, we will dive deep into the composition, manufacturing process, and versatile applications of mirror glass. Prepare to be enchanted by the magic of reflection.

Composition of Mirror Glass:

At its core, mirror glass is a masterpiece of craftsmanship. It begins with a base layer of glass, onto which a thin coating of highly reflective metal, such as silver or aluminum, is applied. This delicate metal layer, measuring just a few micrometers in thickness, ensures both translucency and exceptional reflectivity.

Manufacturing Process:

The creation of mirror glass involves a dance between science and art. Through techniques like vacuum deposition, chemical deposition, or electroplating, the metal layer is meticulously deposited onto the glass surface. These methods allow for precise control over the thickness and uniformity of the reflective coating. Vacuum deposition vaporizes the metal before depositing it onto the glass in a controlled environment. Chemical deposition employs chemical reactions to create the metal layer, while electroplating uses an electric current to transfer the metal ions onto the glass.

Reflective Properties:

Prepare to be captivated by the enchanting reflection brought to life by mirror glass. When light strikes its surface, it dances off the metallic coating, forming a vivid image. The quality of this reflection depends on factors such as the smoothness and uniformity of the metal layer, as well as the glass’s exceptional quality. High-quality mirror glass offers clear, distortion-free reflections that faithfully represent the objects before them.

Practical Applications:

Mirror glass finds its way into every corner of our lives, enriching both residential and commercial spaces with its charm and practicality. From mirrors in our homes to grand wall-mounted mirrors in dressing rooms, bathrooms, and gyms, mirror glass allows us to gaze upon our reflections with clarity and grace. Embracing smaller handheld mirrors, we take on the world with confidence and poise.

Types of Adhesives for Mirror Glass

Mirror glass is a beautiful addition to any space, but it needs the right adhesive to keep it securely in place. In this guide, we’ll delve into the world of mirror adhesives and unveil five remarkable options that ensure a strong and long-lasting bond. From the superhero-like strength of silicone adhesive to the time-saving convenience of double-sided tape, let’s discover the magic behind these adhesive marvels.

Silicone Adhesive – The Versatile Hero:

Silicone adhesive emerges as a true hero when it comes to bonding mirror glass. Its exceptional versatility and flexibility make it an ideal choice for attaching mirrors to various surfaces. With its robust bonding capabilities, silicone adhesive ensures that your mirror stays firmly in place. It even triumphs over moisture and temperature changes, safeguarding the bond for years to come. So, if you want your mirror to conquer any challenge, silicone adhesive is the reliable sidekick you need.

Epoxy Adhesive – The Unyielding Champion:

When it comes to durability and strength, epoxy adhesive takes the crown. This adhesive consists of two components – resin and hardener – that combine to form an unbreakable bond. Once cured, epoxy creates a rigid connection that can withstand heavy loads and extreme conditions. However, handling epoxy requires precision, as proper mixing ratios and quick application are crucial due to its relatively short working time. But fear not, for with epoxy adhesive as your ally, your mirror will stand tall against any adversity.

Liquid Nails Mirror Adhesive – The Swift Enchanter:

When time is of the essence, Liquid Nails Mirror Adhesive comes to the rescue. This specialized solvent-based adhesive works its magic quickly, ensuring a secure bond in no time. With its easy tube application, there’s no need for mixing or curing time. Simply squeeze it onto your mirror and the desired surface, and watch as the bond forms effortlessly. Liquid Nails Mirror Adhesive is the enchantment you need for swift and hassle-free mirror installations.

Construction Adhesive – The Mighty Supporter:

For heavy-duty applications and mirrors in high-traffic areas, construction adhesive is the mighty supporter you can rely on. These robust polyurethane-based adhesives provide exceptional strength and durability, ensuring that your mirror stays firmly affixed. While they may require a longer curing time compared to other adhesives, their unyielding nature makes them perfect for any weighty mirror installation. So, if you seek unwavering support for your mirror, construction adhesive is the unshakeable ally you’ve been searching for.

The Benefits of Silicone-Based Adhesives

When it comes to mirror installations, there’s one adhesive that stands out from the rest – silicone-based adhesives. With their exceptional properties, these adhesives have become the superheroes in the world of mirror bonding. Let’s explore the extraordinary benefits of silicone-based adhesives and understand why they are the ultimate choice for any mirror installation project.

Unmatched Adhesion:

Silicone-based adhesives possess a remarkable ability to adhere to glass surfaces with unrivaled strength and durability. Once applied, they create a bond that can effortlessly withstand the weight and stress of your mirror. Rest easy knowing that your mirror will stay firmly in place.

Temperature Resistance:

From scorching summers to freezing winters, silicone-based adhesives are built to conquer extreme temperature variations. They exhibit excellent resistance, ensuring that they maintain their adhesive properties even in the harshest climates. No matter where you install your mirror, these adhesives will keep it securely attached.

Flexibility for Extra Protection:

One of the standout features of silicone-based adhesives is their flexibility. They possess a unique elasticity that allows them to absorb vibrations and movement. This flexibility acts as a shield, protecting your mirror from cracks or damage caused by everyday use or unexpected impact.

Defying Water’s Power:

In environments prone to moisture, like bathrooms or humid areas, silicone-based adhesives shine. Their superior water resistance prevents any unwanted seepage through the bond, ensuring that your mirror remains securely attached and protected from potential damage or detachment.

Safety Without Sacrifice:

Unlike some other adhesives, silicone-based options prioritize safety without sacrificing effectiveness. They do not emit strong odors or release harmful chemicals during the curing process, making them safe for use in enclosed spaces like bathrooms or bedrooms. Breathe easy knowing that your mirror installation is free from any harmful substances.

Resilience Under the Sun:

The sun’s rays can be harsh and relentless, but silicone-based adhesives can handle the challenge. With their excellent UV resistance, these adhesives can withstand prolonged exposure to sunlight without degrading or yellowing. Your mirror will remain securely attached and maintain its aesthetic appeal for years to come.

The Benefits of Epoxy Resin Adhesives

Mirror installations require an adhesive with superpowers – one that can withstand heavy loads, resist moisture, and seamlessly bond with various surfaces. Enter epoxy resin adhesives, the unsung heroes of mirror glass bonding. In this article, we will delve into the remarkable benefits of using epoxy resin adhesives for mirror glass. From their unmatched strength to their versatility and user-friendly application, these adhesives are the ultimate choice for securing mirrors.

Unmatched Bonding Properties:

Epoxy resin adhesives are renowned for their exceptional bonding capabilities. When applied properly, they create a durable and permanent bond between the mirror and the surface it is attached to. This ensures that your mirrors stay securely in place, even in high-traffic areas or when subjected to vibrations and movements.

Herculean Strength:

Strength is paramount when it comes to securing mirror glass, and epoxy resin adhesives deliver in spades. With excellent tensile and shear strength, these adhesives can shoulder heavy loads without failing. Hang your mirrors with confidence, knowing that accidents and breakage are a thing of the past.

Defying Moisture and Chemicals:

Mirror glass often encounters water and cleaning agents, making resistance to moisture and chemicals crucial. Epoxy resin adhesives create a watertight barrier that prevents moisture from seeping into the bond line. This reduces the risk of damage or deterioration over time, ensuring your mirrors retain their lustrous shine.

Versatile Bonding Solutions:

Regardless of the material your mirror glass is made from – be it glass, metal, wood, or plastic – epoxy resin adhesives have got you covered. Their versatility allows for seamless bonding on different surfaces, ensuring a strong and reliable attachment. Whether you have framed or frameless mirrors, epoxy resin adhesives rise to the challenge.

Flexibility for Dynamic Environments:

Mirrors mounted in vehicles or on movable surfaces face vibrations and slight movements. Epoxy resin adhesives offer the flexibility needed to absorb these forces without compromising the bond. Your mirrors will stay securely in place, even on the bumpiest of rides.

Choosing the Right Adhesive for Mirror Glass

Mirror installations demand an adhesive with superpowers, one that can handle heavy loads, resist moisture, and seamlessly bond with various surfaces. So, how do you choose the perfect adhesive for your mirror glass? Let’s explore the factors to consider when selecting the right adhesive for your mirror project.

- Silicone adhesive: This popular choice boasts a strong bond and remarkable flexibility. It effortlessly bonds mirror glass to different surfaces, enduring temperature changes and moisture like a pro. Its ability to flex ensures your mirror stays securely in place, no matter the conditions.

- Mirror adhesive: Designed specifically for bonding mirrors, this adhesive provides a robust and durable bond, guaranteeing your mirror stays put. Conveniently packaged in tubes or cartridges, it can be easily applied using a caulking gun. Strength and convenience combined.

- Epoxy adhesive: Known for its impressive strength and durability, epoxy adhesive forms a bond that can withstand heavy loads and vibrations. It’s perfect for larger mirrors or those subject to movement or stress. If you want a bond that can handle anything thrown its way, epoxy adhesive is the choice for you.

When selecting an adhesive, compatibility is crucial. Ensure the adhesive is compatible with both your mirror glass and the surface it will be bonded to. Some adhesives may not adhere well to certain types of glass or surfaces, so carefully read the product instructions and specifications.

Prior to application, cleanliness is paramount. Thoroughly clean both the mirror glass and the surface to remove any dust, dirt, or residue. Even the tiniest particle can affect the bonding process, so take your time and ensure a clean and dry surface.

When it’s time to apply the adhesive, follow the manufacturer’s instructions precisely. Some adhesives may require mixing, while others can be applied directly from the tube or cartridge. Apply the adhesive evenly, avoiding excessive application that could seep out from the mirror’s edges, resulting in a messy finish.

Patience is key during the adhesive bonding process. Allow the adhesive to dry and cure according to the manufacturer’s instructions. This may take several hours or even days, depending on the adhesive used. During this time, avoid disturbing or putting pressure on the mirror to ensure a strong and secure bond.

Preparing the Surface Before Applying Adhesive

Well, before you dive headfirst into the adhesive application, let’s talk about the crucial step of preparing the surface. Trust me, this is the secret sauce to a successful mirror installation that will stand the test of time.

First things first, we need to get that mirror glass sparkling clean. No one wants a smudged and streaky reflection, right? Grab a mild detergent or glass cleaner and a soft cloth or sponge. Gently wipe down the entire surface of the mirror, paying extra attention to any pesky fingerprints or smudges. And remember, no abrasive materials or harsh chemicals here – we want to treat that mirror glass like the delicate beauty it is.

Now that your mirror is looking squeaky clean, it’s time to kick it up a notch. Give that surface another wipe down with specialized glass cleaner or rubbing alcohol. This step is crucial for removing any remaining residue or oils that could interfere with the adhesive’s magical bonding powers. Apply your chosen cleaner onto a clean cloth and give the mirror a gentle once-over. Trust me, this extra step will pay off in the long run.

Next up, it’s time to give that mirror glass some texture to grip onto. Take some fine-grit sandpaper and gently sand the surface using light strokes. We’re not trying to create a masterpiece here, just a rougher texture that will help the adhesive stick like glue (pun intended). Keep that sandpaper flat against the glass and take it easy – we don’t want any scratches or damage.

Now that we’ve roughed up the surface a bit, let’s tidy up. Grab a soft brush or a clean, lint-free cloth and gently sweep away any dust or debris that may have been generated during our sanding session. We want that surface nice and clean, so our adhesive can work its magic without any interference.

Last but certainly not least, we need to make sure that mirror glass is bone dry. Yeah, I know, it’s tempting to rush through this step, but trust me, patience is key. Even the tiniest bit of moisture can mess with the performance of the adhesive and compromise its bond. So, give that mirror some time to air dry naturally or grab a clean, dry cloth and gently pat it dry. No shortcuts here – we want that surface as dry as a desert.

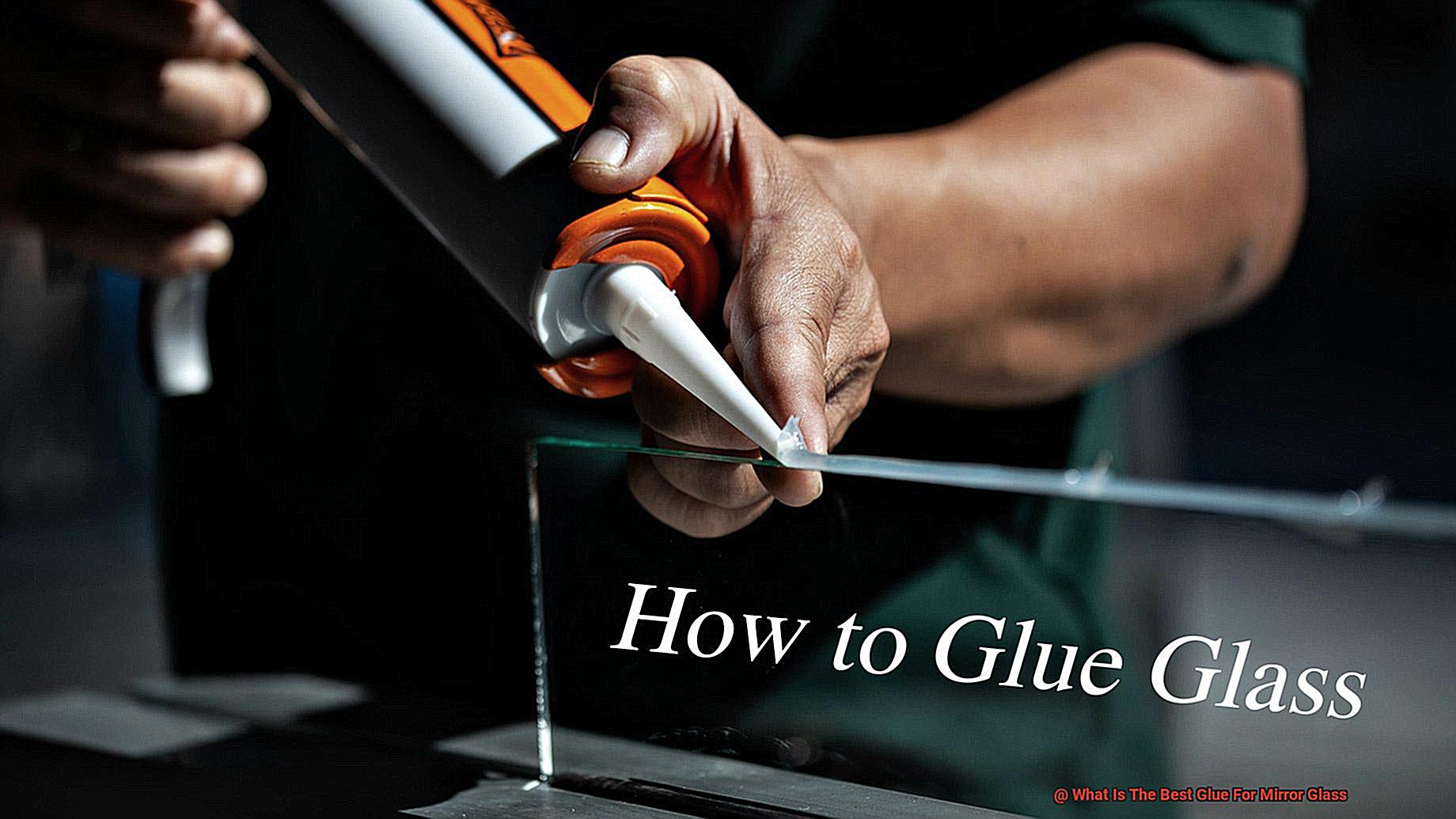

Applying the Adhesive to Mirror Glass

Transforming a simple mirror into a stunning focal point requires more than just hanging it up. To ensure a secure and long-lasting bond between mirror glass and its mounting surface, mastering the art of applying adhesive is essential. In this article, we will delve into the step-by-step process of achieving a strong and reliable attachment for your mirror glass.

Step 1: Cleanliness is Key

The first secret to a successful installation lies in the cleanliness of the mirror surface. Dust and debris can weaken the bond, so start by wiping the mirror with a clean cloth and a mild detergent solution. For an extra level of perfection, use specialized glass cleaner or rubbing alcohol to eliminate any residue. Remember, a pristine surface is the foundation for a secure bond.

Step 2: Prime Time

To elevate your mirror bonding game, consider adding a primer to the equation. Applying a primer before the adhesive helps create an even stronger connection between the mirror and the adhesive itself. Think of it as the secret sauce that adds an extra layer of security to your installation. Don’t overlook this step if you want your mirror to remain steadfast for years to come.

Step 3: Choosing the Right Adhesive

Not all adhesives are created equal when it comes to bonding mirror glass. Selecting the appropriate adhesive is crucial for a successful installation. You have options like silicone-based adhesives, epoxy adhesives, and mirror mastic. Each type possesses unique qualities. Silicone-based adhesives offer flexibility and moisture resistance but may require additional support for larger mirrors. Epoxy adhesives are renowned for their strength and durability but have a longer curing time. Mirror mastic, specifically designed for attaching mirrors, provides a shorter curing time. Assess your project’s needs and choose accordingly.

Step 4: Smooth Operator

With the right adhesive in hand, it’s time to apply it smoothly and evenly across the mirror’s surface. Following the manufacturer’s instructions is vital, as each adhesive may have specific application guidelines. Take your time and ensure that the adhesive is distributed evenly to achieve a secure bond.

Curing and Testing the Bonded Surface

You may think that gluing a mirror to the wall is as simple as applying adhesive and sticking it on. However, the true secret to a bond that lasts lies in the careful curing and testing of the bonded surface. In this captivating journey, we will explore the significance of properly curing and testing when using glue for mirror glass. Prepare to be enthralled.

Curing: Unleashing the Power of Patience

Curing is like allowing a superhero to charge up before taking on the world. Following the manufacturer’s instructions, it is crucial to give the adhesive enough time to reach its maximum strength. Rushing this process may result in a feeble bond that could crumble over time.

Embrace Stillness: Protecting the Precious Bond

During the curing period, any movement or stress can disrupt the bonding process. Imagine handling a fragile piece of art – avoid touching, moving, or exerting pressure on the mirror until the glue has fully cured. Let it bask in tranquility and solidify its grip.

The Dance of Perfect Conditions: Temperature and Humidity Harmony

Creating an optimal environment for curing is akin to orchestrating a symphony. Follow the manufacturer’s recommendations regarding temperature and humidity to ensure a harmonious bond formation. Remember, extremes in these factors can throw off the delicate balance required for successful curing.

Proving Strength and Stability

Once the adhesive has completed its transformation, it’s time to put its strength to the test. Start by gently tapping or applying light pressure on different areas of the mirror, observing for any signs of movement or detachment. If all seems well, prepare for further challenges.

Challenge #1: Everyday Handling Mastery

Like a warrior preparing for battle, your mirror must be able to withstand the rigors of everyday usage. Take a soft cloth or material and apply moderate pressure to different areas of the mirror surface. This test evaluates the adhesive’s resilience under normal handling conditions. Exercise caution, for a delicate touch is key – we seek to test, not obliterate.

4ElbQ18bkXU” >

Conclusion

When it comes to finding the best glue for mirror glass, there are a few options that stand out.

One of the top contenders is a high-quality adhesive specifically designed for glass surfaces. This type of glue provides a strong bond that can withstand the weight and pressure of a mirror.

Another popular choice is a clear silicone adhesive, which not only securely holds the mirror in place but also provides a seamless finish. It’s important to choose a glue that is specifically formulated for glass to ensure optimal results.

Additionally, make sure to thoroughly clean and prepare the surface before applying the glue to ensure maximum adhesion.