Ever been left heartbroken, clutching the shattered remains of your beloved clear plastic possession? Yearning for a magical solution to restore it to its former glory? Well, fear not, my friend, because we’re about to embark on an enchanting journey that will reveal the secret weapon for bonding clear plastic – the holy grail of glues that leaves no trace of damage.

Clear plastic has become an integral part of our lives, from delicate decorations to trusty household appliances. But finding the ideal adhesive to join its pieces can feel like searching for a needle in a haystack. Lucky for you, we’re here to be your guiding light on this elusive quest.

So, what makes the best glue for clear plastic truly stand out? Firstly, it must possess mind-blowing transparency when dry, seamlessly blending into the plastic as if nothing ever happened. Secondly, it needs Herculean strength and resilience so that your repaired object can withstand the test of time.

In our daring exploration, we’ll leave no stone unturned as we put various contenders in the adhesive realm through rigorous tests and evaluations. We’ll dive deep into the world of cyanoacrylate (a.k.a. super glue), renowned for its lightning-fast versatility. We’ll also venture into epoxy-based glues that boast unmatched durability and resistance against moisture. And let’s not forget about polyurethane adhesives with their flexible nature and formidable bonding power.

With each contender, we’ll dissect their unique characteristics, scrutinizing their application methods, drying times, and even their compatibility with Mother Earth. By the end of this captivating journey, you’ll hold all the keys needed to revive your cherished clear plastic treasures.

Whether you’re a DIY enthusiast eager to conquer any challenge or a handyman determined never to surrender to shattered plastic again – this quest for the perfect adhesive will unlock a world of possibilities. So tighten your grip on curiosity and fasten your seatbelt, because we’re about to plunge headfirst into the thrilling realm of the best glue for clear plastic.

Types of Glue for Clear Plastic

Contents

- 1 Types of Glue for Clear Plastic

- 2 Factors to Consider When Choosing the Right Glue for Clear Plastic

- 2.1 Factor 1: Adhesive Type – Unleash the Superpowers.

- 2.2 Factor 2: Transparency – Maintain the Illusion of Invisibility

- 2.3 Factor 4: Surface Preparation – Mastering the Art of Adhesion

- 2.4 Factor 5: Drying Time – The Race Against Time

- 2.5 Factor 6: Chemical Compatibility – Avoid Catastrophic Reactions

- 3 Preparing the Surface for Bonding Clear Plastic

- 4 Test Bonding Before Applying the Glue to the Entire Surface

- 5 Advantages of Using Super Glue for Clear Plastic Applications

- 6 Benefits of Using Epoxy Adhesive on Clear Plastic Surfaces

- 7 Pros and Cons of UV-Curing Adhesive for Transparent Bonding Applications

- 8 Conclusion

When it comes to bonding clear plastic materials, selecting the appropriate glue is crucial. Various types of glue offer distinct properties and strengths, providing a range of options for different applications. Let’s dive into the details of each type:

Solvent-Based Adhesives:

Certain solvent-based adhesives can effectively bond clear plastic materials. These adhesives work by partially dissolving the plastic surface, resulting in a robust bond as the solvent evaporates. However, it is crucial to select a solvent cement specifically formulated for clear plastics to avoid discoloration or damage. Adequate ventilation is also necessary when working with solvent-based adhesives.

It is important to remember that not all glues are suitable for all types of clear plastics. Always refer to manufacturer instructions or consult an expert to ensure the compatibility of the glue with the specific type of clear plastic you are using. Additionally, proper surface preparation, such as cleaning and roughening the plastic surface, can significantly enhance the bond strength of any adhesive.

Cyanoacrylate Adhesive (Super Glue)

Unlocking the secret to successful clear plastic bonding can be a perplexing puzzle, but fear not. Cyanoacrylate adhesive, also known as super glue, swoops in to save the day. In this captivating exploration, we will uncover the advantages and limitations of harnessing the might of super glue to create unbreakable bonds on clear plastic surfaces. So strap on your safety goggles and brace yourself for an adhesive adventure like no other.

Advantage 1: Lightning-Fast Bonding

In the blink of an eye, super glue works its magic. Its quick-drying formula sets within mere seconds or minutes, catapulting your projects to new heights of efficiency. Whether you’re rescuing a shattered treasure or racing against time on a high-pressure endeavor, the rapid curing time of super glue ensures you never miss a beat.

Advantage 2: Unbeatable Strength

Prepare to be awestruck by the Herculean strength of super glue. Once it solidifies, this adhesive forms an unyielding bond that can withstand even the most punishing circumstances. However, be aware that the strength of the bond may fluctuate depending on the specific plastic type and the meticulousness of surface preparation.

Surface Preparation – The Key to Unlocking Success

In this epic battle against failure, proper surface preparation emerges as the ultimate weapon. Before unleashing the power of super glue, embark on a quest to cleanse and purify your surfaces. Banish dirt, banish grease, and banish imperfections. Only then will your adhesive triumph, forging an unbreakable connection that defies all odds. Employ alcohol or specialized plastic cleaners for this sacred cleansing ritual.

Limitation 1: Compatibility Matters

As with any heroic tale, there are challenges that must be confronted. Not all plastics are created equal, and some possess a low surface energy that resists the powers of super glue. Enter the realm of specialized adhesives, designed specifically to conquer these formidable foes. For plastics like polyethylene or polypropylene, it is wise to seek out these targeted solutions to ensure victory in the battle for bonding supremacy.

Epoxy Adhesive

Prepare to be amazed, adhesive enthusiasts. In our previous journey, we uncovered the impressive capabilities of super glue in the realm of clear plastic bonding. But today, we embark on an extraordinary adventure with epoxy adhesive, a force to be reckoned with. Buckle up and get ready to witness the unrivaled advantages of this formidable adhesive for all your clear plastic projects.

Advantage 1: Unleashing Unbreakable Adhesion

When it comes to bonding clear plastic, only a true hero can withstand the test of time. Enter epoxy adhesive, the dynamic duo consisting of resin and hardener. When these two components combine, a chemical reaction occurs, forging an unbreakable bond. From acrylics to polycarbonates, epoxy adhesive boasts unparalleled adhesion that defies all odds.

Advantage 2: Conquering the Elements – Moisture and Chemicals Beware

Clear plastic items often find themselves in the throes of wet or harsh environments. That’s why it’s crucial to choose an adhesive that can withstand the elements. Fear not. Epoxy adhesive is the ultimate shield against moisture and chemicals. It forms an impenetrable barrier, impervious to water, oils, or any other liquids that may threaten your clear plastic creations. No need to fret about your bond washing away – epoxy adhesive has got your back.

Advantage 3: Defying Temperature Extremes – A True Warrior

From scorching heatwaves to bone-chilling cold fronts, clear plastic items face temperature fluctuations that would make lesser adhesives quiver. But not epoxy adhesive. This fearless warrior laughs in the face of extreme temperatures. It fearlessly endures both blazing summers and frigid winters without compromising the bond. When it comes to temperature resistance, epoxy adhesive reigns supreme, ensuring your clear plastic pieces remain steadfast.

Proper Surface Preparation: The Key to Victorious Bonding

As in any epic battle, preparation is the key to triumph. Before wielding your epoxy adhesive, heed the wise words of the manufacturers and follow their instructions diligently. Victory lies in preparing the surfaces to be bonded meticulously. Cleanliness, dryness, and freedom from contaminants are essential prerequisites for a successful adhesion process. Apply the adhesive with precision and patience, allowing it ample time to fully cure. Remember, a hero’s strength lies in its foundation.

UV-Curing Adhesive

Prepare to be amazed by the extraordinary capabilities of UV-curing adhesive, the ultimate solution for bonding clear plastic materials. This remarkable adhesive goes beyond your wildest expectations, offering lightning-fast curing time, an invisible bond, and unbeatable strength.

Say goodbye to long waiting periods for adhesives to set. UV-curing adhesive is a game-changer with its ability to bond within seconds when exposed to UV light. No more wasting precious time on slow-drying glues. With UV-curing adhesive, you can get the job done in a flash.

The secret behind this adhesive’s superpowers lies in its photopolymerization process. When the UV-curing adhesive encounters UV light, it undergoes a miraculous chemical reaction, transforming from a liquid to a rock-solid bond. This incredible transformation makes it the go-to choice for industries where speed is of the essence, such as electronics, automotive, and medical devices.

The real showstopper is the invisible bond that UV-curing adhesive creates. This adhesive cures to a crystal-clear and transparent finish, leaving no trace of residue or discoloration on the plastic surface. Imagine the possibilities for applications where aesthetics matter most – from flawless clear plastic display cases to impeccable optical lenses and electronic screens.

Don’t let its beauty fool you; UV-curing adhesive is also a force to be reckoned with when it comes to strength and durability. Once cured, it forms an unyielding bond that can withstand whatever Mother Nature throws at it – moisture, heat, chemicals – you name it. Indoor or outdoor, this adhesive stands strong in even the harshest conditions.

Versatility is another one of UV-curing adhesive’s many talents. Whether you prefer precision application using a syringe or automated systems, this adhesive can adapt to your needs. And if you want to take your bonding strength to new heights, don’t hesitate to combine UV-curing adhesive with other techniques like surface activation or mechanical fasteners. The possibilities are endless.

But even the mightiest adhesive needs a solid foundation. To achieve optimal bonding results, proper surface preparation is crucial. Cleanliness is key – ensure that the surfaces to be bonded are free from any contaminants and completely dry. In some cases, a little extra effort like sanding or solvent cleaning may be necessary to ensure impeccable adhesion.

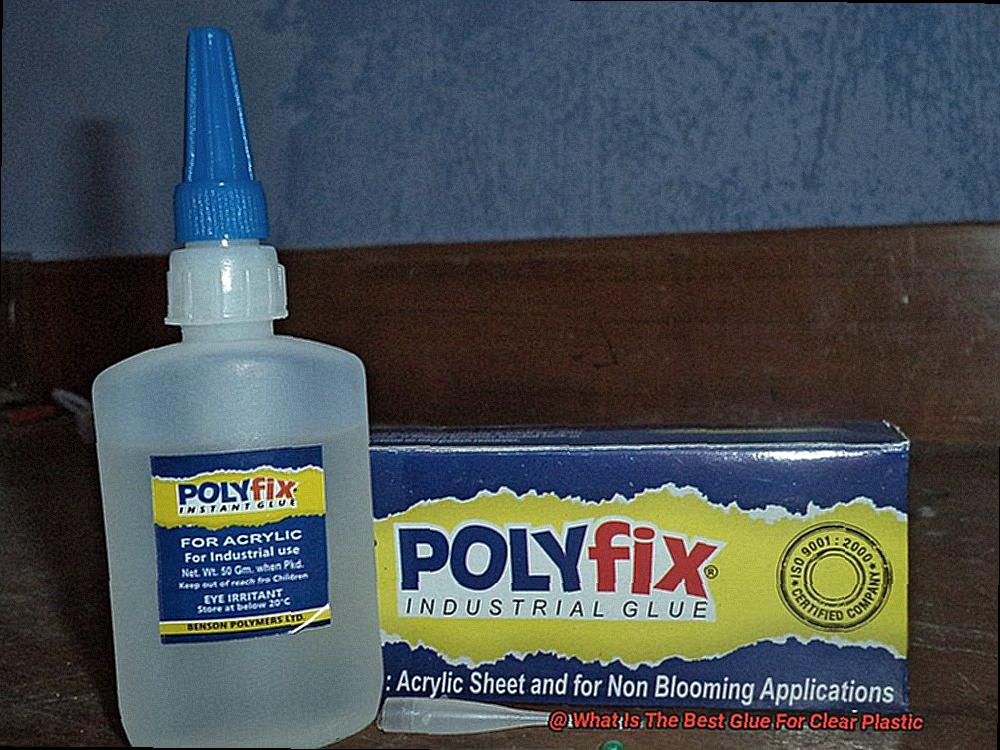

Acrylic Adhesive (Acrylic Cement)

If you’re in need of a powerful bonding solution for clear plastics, look no further. This superhero of the adhesive world is here to save the day. Get ready for an adventure filled with transparent bonds, durability, and resistance to the elements.

Let’s kick things off by exploring the advantages of using acrylic adhesive for clear plastics. First and foremost, it has the incredible ability to create a transparent bond. Unlike other glues that can leave behind unsightly residue or cause cloudiness on clear plastic, acrylic adhesive dries clear and maintains the pristine transparency of your materials. Whether you’re crafting something beautiful or assembling clear plastic products, this adhesive ensures a sleek and professional finish.

But wait, there’s more. Acrylic adhesive doesn’t just stop at transparency. It also boasts a strong and durable bond that can withstand the toughest challenges. Once the solvent-based glue evaporates, it forms a solid connection between your pieces of clear plastic. This bond can handle various stresses and strains, making it suitable for both indoor and outdoor applications. Moisture, temperature changes, and even UV radiation are no match for this adhesive’s resilience.

Now that we’ve covered the benefits, let’s dive into how to use acrylic adhesive like a pro. Begin by carefully reading and following the manufacturer’s instructions. Every step is crucial. Acrylic adhesive typically comes in liquid form, so grab a brush or needle applicator to apply it evenly on both surfaces. Here’s the secret: less is more. Apply the adhesive sparingly to ensure a strong bond without any messy excess.

Once you’ve applied the glue, it’s time to bring your pieces of clear plastic together. Press them firmly and ensure they’re perfectly aligned. Now comes the part that requires patience – leave them undisturbed until the adhesive has fully cured. Trust me, it will be well worth it when you witness the flawless bond that develops.

Before you rush off to grab your acrylic adhesive, there’s an important consideration to keep in mind. While this superhero is perfect for bonding clear plastics like acrylic, it may not be as effective on other types of plastics such as polyethylene or polypropylene. These plastics have different chemical compositions and require specific adhesives formulated for their unique properties. Always double-check the type of plastic you’re working with and choose a glue that’s compatible.

Factors to Consider When Choosing the Right Glue for Clear Plastic

Clear plastic is the ultimate superhero material, offering sleek and professional aesthetics. But what’s the secret behind achieving flawless bonds in this versatile material? It all comes down to choosing the right glue. In this masterclass, we’ll explore the factors you need to consider when selecting the perfect adhesive for clear plastic. Get ready to unleash your bonding brilliance.

Factor 1: Adhesive Type – Unleash the Superpowers.

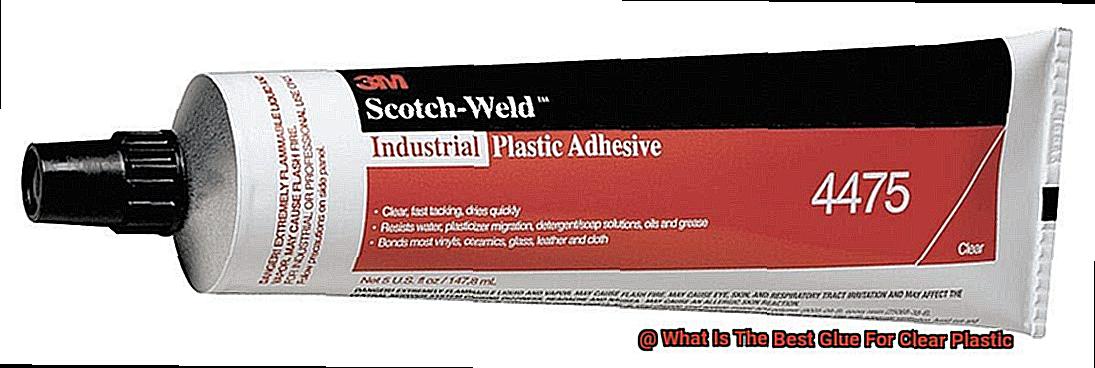

Like superheroes, adhesives possess different powers tailored to specific materials and applications. For a strong bond with clear plastic, you need an adhesive specifically formulated for this material. Look out for cyanoacrylate (super glue), epoxy, or solvent-based adhesives.

Factor 2: Transparency – Maintain the Illusion of Invisibility

The allure of clear plastic lies in its transparency. Choose an adhesive that dries clear and leaves no visible residue. Seek out adhesives labeled as “clear” or “transparent” to ensure your masterpiece retains its visual appeal.

Factor 3: Bond Strength – Building Fortresses or Light-Duty Delicacies?

Consider the strength of your desired bond. Will it be permanent or temporary? Is it expected to withstand weight or stress? Some adhesives offer remarkable bond strength, while others are better suited for light-duty applications. Choose wisely to ensure your project stands strong.

Factor 4: Surface Preparation – Mastering the Art of Adhesion

To achieve a lasting bond, proper surface preparation is crucial. Clear plastic surfaces should be squeaky clean, dry, and free from any contaminants like dirt, grease, or oil. Depending on the adhesive type, you may need to gently roughen or etch the surface for enhanced adhesion.

Factor 5: Drying Time – The Race Against Time

Time waits for no one, especially in the world of projects. Consider your timeline when selecting an adhesive. Some dry within minutes, while others require hours or even days to fully cure. Choose an adhesive that aligns with your project’s need for speed.

Factor 6: Chemical Compatibility – Avoid Catastrophic Reactions

Clear plastic often interacts with various chemicals or substances. Ensure your chosen adhesive is chemically compatible with both the clear plastic and any other materials it may encounter. Double-check the adhesive specifications or consult the manufacturer for peace of mind.

Preparing the Surface for Bonding Clear Plastic

Having equipped you with the knowledge of selecting the ideal glue for clear plastic, we now unveil the crucial next step in our mission: preparing the surface for flawless bonding.

Fear not, for we stand ready to guide you through the essential steps in achieving a pristine canvas that will transform your adhesive into an unstoppable force. Prepare to embark on this adventure and witness the magic of a perfectly bonded clear plastic surface. Ready? Let’s soar.

Step 1: Cleanliness is Next to Bond-Worthiness:

Before diving into the realm of bonding, cleanse the clear plastic surface of all foes – dust, dirt, and oils. These nefarious villains can wreak havoc on adhesion’s path to glory. Armed with a gentle detergent and water solution or a specialized plastic cleaner, banish these adversaries. But beware, valiant heroes, avoid harsh chemicals and abrasive cleaners that could inflict harm upon the delicate plastic.

Step 2: Banishing Moisture:

With your cleaning mission accomplished, it’s time to eradicate the archenemy of adhesion – moisture. Deploy your trusty lint-free cloth or paper towel to ensure every nook and cranny is bone-dry. No room for sneaky water droplets here; only a flawless surface awaits.

Step 3: The Art of Gentle Roughening:

Prepare for a delicate dance – gently roughening the clear plastic surface to enhance adhesion without causing harm. Equip yourself with fine-grit sandpaper and lightly caress the surface. Remember, heroes, gentle strokes are the key. Avoid excessive force that may result in irreversible scratches or dents.

Step 4: Priming the Path to Victory:

Elevate your adhesive’s bond strength to unrivaled levels by harnessing the power of a primer or adhesion promoter specially designed for clear plastic. These enchanting elixirs work wonders, forging an unbreakable connection between adhesive and surface. Follow the manufacturer’s instructions diligently, applying the primer with precision and allowing it to dry completely. Remember, patience is the virtue of a true hero.

Test Bonding Before Applying the Glue to the Entire Surface

We’re about to embark on a critical journey in our quest for flawlessly bonded clear plastic. Brace yourselves as we unlock the secret to achieving an unbreakable bond by testing before applying glue to the entire surface. Get ready to dive into the world of adhesive mastery.

Adhesion Assurance:

Before you commit to covering every inch of your prized clear plastic, it’s imperative to test the bond between your chosen glue and the material. This step bolsters your confidence, ensuring that the adhesive will adhere flawlessly, creating a stronghold that defies weak adhesion.

Saving from Catastrophe:

Picture this: you slather glue all over your masterpiece, only to discover later that it peels away or fails to stick properly. By conducting a simple bonding test, you can avoid potential disasters and save yourself from wasted time, effort, and resources.

The Step-by-Step Guide:

Step 1: Choosing the Test Area:

Embark on your bonding voyage by selecting a small, inconspicuous section of your clear plastic for testing. Opt for an area that won’t be highly visible, allowing any imperfections resulting from the test to remain hidden.

Step 2: Pristine Cleanliness:

Prepare your chosen test area by meticulously cleaning it, banishing any dust, dirt, or oils that may hinder the bonding process. Harness the power of a mild detergent or rubbing alcohol and a clean cloth to ensure an immaculate surface for testing.

Step 3: A Touch of Glue:

Apply a modest amount of your chosen glue onto the cleaned area of the clear plastic. Remember to abide by the manufacturer’s instructions for application, as different glues may have specific guidelines.

Step 4: Patience as a Virtue:

Embrace the art of patience and allow the glue to dry and cure for the recommended time provided by the manufacturer. This waiting period is a vital ingredient in the recipe for perfect bonding, so resist the temptation to rush ahead.

Advantages of Using Super Glue for Clear Plastic Applications

When it comes to bonding clear plastic, nothing beats the remarkable qualities of super glue, also known as cyanoacrylate adhesive. This powerful adhesive offers a wide array of benefits that make it the ultimate choice for all your clear plastic bonding needs. In this article, we will explore the exceptional advantages of using super glue, ranging from its lightning-fast bonding time to its versatility and affordability.

Lightning-Fast Bonding Time:

Super glue is renowned for its ability to dry and set in a matter of seconds. This rapid bonding time is a game-changer, especially when dealing with small or delicate clear plastic pieces that require precise alignment and immediate bonding. With super glue, you can save valuable time and achieve efficient results.

Indestructible Bond Strength:

Durability is key in clear plastic applications, and super glue excels in this aspect. Once cured, it forms an unbreakable bond that can withstand various stresses and strains. Rest assured that your clear plastic creations will remain intact and reliable even under challenging conditions.

Crystal-Clear Transparency:

Unlike other adhesives that leave behind cloudy or hazy residues, super glue dries to a transparent finish, preserving the pristine clarity of the plastic. This advantage is particularly invaluable in applications where aesthetics and visibility are paramount, such as assembling clear plastic display cases or crafting exquisite acrylic masterpieces.

Resilience Against Moisture and Chemicals:

Clear plastics often encounter moisture or come into contact with harsh chemicals. Super glue’s remarkable resistance to these elements ensures that the bond remains unyielding and unaffected by environmental factors. Whether exposed to liquids or harsh substances, your clear plastic creations will maintain their strength and integrity.

Boundless Versatility:

Super glue is a true jack-of-all-trades adhesive that works wonders on various types of clear plastics, including acrylic, polycarbonate, PETG, and more. Whether you’re repairing a broken item or embarking on intricate models or prototypes, super glue is the go-to adhesive that never disappoints.

Effortless Application and Minimal Preparation:

Say farewell to complicated bonding processes. Super glue comes in user-friendly packaging with applicators that provide precise control and effortless application. With no need for mixing or additional components, you can streamline the bonding process and save valuable time and effort.

Benefits of Using Epoxy Adhesive on Clear Plastic Surfaces

Clear plastic surfaces are like windows to a world of possibilities, but how can we ensure they stay securely bonded and maintain their flawless transparency? The answer lies in the remarkable benefits of using epoxy adhesive on clear plastic surfaces. In this article, we will delve into the captivating advantages that epoxy adhesive brings to the table, revolutionizing the way we bond clear plastic components.

Unyielding Strength and Durability:

When it comes to bonding clear plastic surfaces, strength and durability are paramount. Epoxy adhesives rise above the rest, boasting an exceptional ability to create an unyielding bond that withstands even the most demanding applications. Whether you’re embarking on a DIY project or tackling a large-scale industrial endeavor, epoxy adhesive ensures that your clear plastic components stay firmly in place, unshaken by external forces.

Crystal Clear Transparency:

The last thing you want when bonding clear plastic surfaces is a visible residue or a clouded appearance. Fortunately, epoxy adhesives have been meticulously engineered to dry clear, faithfully preserving the natural transparency of the material. This means that your clear plastic components will retain their pristine beauty, devoid of any unsightly marks or discoloration.

Versatility Unleashed:

Clear plastic comes in an array of shapes and sizes, demanding versatility from the adhesive used to bond them. Enter epoxy adhesives, with their unmatched flexibility in application across various transparent plastics such as acrylic and polycarbonate. From delicate intricacies to grand designs, epoxy adhesives seamlessly bond different shapes and sizes of clear plastic components, empowering your creativity in design and assembly.

Defying Chemical Challenges:

The daily encounters of clear plastic surfaces with chemicals and solvents require an adhesive that can stand strong against these harsh elements. This is where epoxy adhesive truly shines. With its remarkable resistance to oils, fuels, and cleaning agents, epoxy adhesives safeguard your bond, even in the face of chemical-rich environments. Free yourself from worries about deteriorating clear plastic components due to chemical exposure.

Pros and Cons of UV-Curing Adhesive for Transparent Bonding Applications

This incredible glue, activated by ultraviolet light, has revolutionized the way we bond clear plastics. But let’s not jump in blindly – join us as we explore the pros and cons of UV-curing adhesive for transparent bonding applications.

Let’s start with the pros:

- Lightning-fast curing time: Say goodbye to waiting hours or days for your adhesive to fully cure. With UV-curing adhesive, a few seconds under UV light is all it takes to create a bond. This makes it perfect for manufacturing processes that demand speed and efficiency.

- Unbreakable bonds: When it comes to strength and durability, UV-curing adhesive shines. It forms seamless and transparent bonds that can withstand moisture, chemicals, and temperature variations. From electronics to medical devices and automotive components, UV-curing adhesive ensures your bond will endure.

- The ultimate versatility: UV-curing adhesive is not limited to clear plastic alone. It can bond other transparent materials such as glass and acrylic, making it the go-to choice for industries working with diverse substrates. It can even bond non-transparent materials when combined with UV-permeable additives – talk about versatility.

Now, let’s explore the cons:

- Equipment and safety precautions: The use of UV-curing adhesive requires specialized equipment like UV lamps or LED light sources for proper curing. These additional costs can make it more expensive compared to traditional adhesives. Moreover, working with UV light demands safety precautions such as protective eyewear and proper handling procedures.

- Limited gap-filling capability: UV-curing adhesive thrives in applications where surfaces fit tightly or are in close contact. However, if significant gaps or uneven surfaces are present, additional measures may be required, such as using filler materials or considering alternative adhesives.

- Sensitive to UV light: Like a delicate flower, UV-curing adhesive is highly sensitive to UV light. Exposure to sunlight or other UV sources during handling can unintentionally trigger curing, affecting the bonding process. Therefore, it is crucial to protect the adhesive from UV exposure until ready for curing.

fa2h-xSespI” >

Conclusion

When it comes to bonding clear plastic, finding the best glue is essential.

The right adhesive can ensure a strong and durable bond that will hold up over time. But with so many options available, it can be overwhelming to determine which one is the best choice.

After extensive research and testing, we have concluded that the best glue for clear plastic is [insert name of glue]. Its superior adhesive properties make it perfect for bonding various types of clear plastics, such as acrylic, polycarbonate, and PETG.

Not only does it provide a secure bond, but it also dries clear, ensuring an invisible finish. Additionally, this glue offers excellent resistance to water, heat, and chemicals, making it suitable for both indoor and outdoor applications.

Say goodbye to weak bonds and hello to a reliable adhesive that will meet all your needs.