Picture this – your cherished ceramic teapot, a beloved family heirloom, slips from your grasp and shatters into countless delicate fragments. Your heart sinks as you survey the wreckage, realizing the daunting task ahead. But fear not, fellow ceramic enthusiasts. I bring you tidings of hope and an adhesive so powerful, it might just work miracles.

When it comes to restoring broken ceramics, choosing the right glue is absolutely crucial. Whether it’s a dainty figurine, a chipped plate, or a cracked vase, using the best adhesive ensures a flawless repair that not only brings back the piece itself but also revives the memories intertwined with it.

But what exactly is the best glue for ceramic repairs? Join me on this captivating journey as we plunge into the world of adhesives that possess unparalleled bonding power for ceramic restoration. We’ll explore key factors to consider during the selection process and delve into top contenders celebrated for their reliability and durability.

In this enlightening article, we’ll uncover the secrets behind epoxy resins, cyanoacrylates, and silicon adhesives – each boasting unique attributes and applications. Discover how these glues can defy temperature fluctuations, repel moisture, and provide exceptional strength to ensure your beloved ceramic treasures remain intact for years to come.

Furthermore, we’ll venture into expert tips and tricks that reveal techniques for precise application and maximizing bond strength when utilizing these extraordinary adhesives.

So come along on this adhesive adventure where we unravel the mysteries of ceramic repairs and assist you in selecting the perfect glue to resurrect your broken masterpieces. Prepare to be captivated by the boundless potential of these remarkable adhesives.

Types of Glue for Ceramic Repairs

Contents

- 1 Types of Glue for Ceramic Repairs

- 2 Advantages and Disadvantages of Different Glues

- 3 Epoxy Glue for Ceramic Repairs

- 4 Super Glue for Ceramic Repairs

- 4.1 Step 1: Clean and Dry Surfaces – The Foundation of Success

- 4.2 Step 2: Lightly Sand the Surfaces – Building a Stronger Bond

- 4.3 Step 3: Apply Super Glue Sparingly – Less is More

- 4.4 Step 4: Hold Firmly and Let It Set – Patience is Key

- 4.5 Step 5: Enjoy the Unbreakable Bond – Marvel at Your Achievement

- 5 Silicone Adhesive for Ceramic Repairs

- 6 Ceramic-Specific Adhesives for Ceramic Repairs

- 7 Factors to Consider When Choosing a Glue for Ceramic Repairs

- 8 Manufacturer Instructions for Applying Glues to Ceramics

- 9 Conclusion

Repairing ceramics requires a delicate touch and the right glue to ensure a seamless bond. With a plethora of options available, it’s crucial to select the perfect adhesive for your specific repair needs. In this comprehensive guide, we will delve into the world of ceramic glues, uncovering their unique advantages and limitations.

Epoxy Glue: A Fortress of Strength and Durability

For ceramic repairs demanding unparalleled resilience, epoxy glue is the knight in shining armor. Renowned for its robust bond, epoxy glue consists of two parts – a resin and a hardener – which must be meticulously mixed before application.

Once blended, this adhesive forms an unyielding connection capable of withstanding scorching temperatures and water exposure. Ideal for resurrecting shattered pottery or mending delicate ceramic figurines, epoxy glue is a stalwart companion. However, its viscosity may render it less suitable for minute or fragile repairs.

Super Glue: The Speedy Savior

When time is of the essence, super glue, also known as cyanoacrylate adhesive, swoops in to save the day with its lightning-fast bonding properties. This adhesive establishes an instant bond upon contact with the ceramic surface, drying transparently to conceal any evidence of repair.

Super glue excels at fixing chips or cracks in ceramic objects, yet it may not possess the same durability as epoxy glue. Extreme temperatures or continuous water exposure could potentially undermine its effectiveness.

Silicone Adhesive: Flexibility in Rugged Terrain

In the realm of flexibility and water resistance, silicone adhesive reigns supreme. This adaptable adhesive forges a pliable bond that accommodates movement and expansion within the ceramic surface. Perfectly suited for repairing outdoor ceramics or items frequently exposed to moisture, such as bathroom tiles or kitchenware, silicone adhesive demonstrates remarkable resilience against the elements.

Ceramic-Specific Adhesives: The Majestic Masters of Bonding

For those seeking professional-grade results, ceramic-specific adhesives stand majestically above the rest. Tailored exclusively for bonding ceramics, these exceptional adhesives boast unparalleled strength and durability.

Often employed within industrial or heavy-duty ceramic repairs, they can withstand blistering temperatures and harsh conditions.

While they may command a higher price tag than other options, their regal performance justifies the investment.

Selecting the Ideal Glue: A Mosaic of Considerations

To ensure a successful repair, several factors must be considered when selecting the ideal glue for ceramic repairs. The type of ceramic material, the size and weight of the repair, and the intended use of the restored item all play vital roles in choosing the right adhesive.

Each glue possesses its own unique advantages and limitations, so it is imperative to match the glue to your specific requirements.

Advantages and Disadvantages of Different Glues

In this enlightening article, we will explore the advantages and disadvantages of various glues, bringing you closer to finding the perfect solution for your ceramic repair needs.

So, grab a cup of tea and prepare to be amazed.

Epoxy Glue: The Indisputable Champion of Durability

Advantages:

- A bond like no other: Epoxy glue is celebrated for its exceptional strength and durability, creating an unbreakable connection between ceramic surfaces.

- Defying the elements: Resistant to water, heat, and chemicals, epoxy glue fearlessly protects your ceramic repairs from any threats that nature may throw its way.

- A seamless finish: Drying clear, epoxy glue ensures that your ceramic repairs blend seamlessly into their surroundings, leaving no traces of its mending magic.

Disadvantages:

- Time is of the essence: Epoxy glue demands patience as it takes its time to cure completely, with curing times ranging from several hours to overnight.

- A touch of messiness: Its thick consistency can occasionally lead to a bit of a messy application process, requiring some extra care and precision.

- Tools at the ready: To unlock the full potential of epoxy glue, be prepared to have mixing cups and applicators on hand for smooth and precise application.

Super Glue: The Swift Savior with a Few Caveats

Advantages:

- Instant satisfaction: Super glue lives up to its name by forming a powerful bond in an instant, allowing you to use your repaired ceramic item right away.

- Invisible strength: When dry, super glue becomes transparent, leaving your repaired area nearly invisible and preserving the beauty of your ceramic piece.

Disadvantages:

- Fragile beauty: While super glue delivers quick results, it may not be the most durable option for ceramic repairs, as it can be brittle and susceptible to damage from frequent handling or stress.

- Ventilation is key: Beware of the potent fumes emitted during the application process, ensuring proper ventilation to protect your senses.

Silicone Adhesive: The Flexible Guardian of Moisture-Exposed Repairs

Epoxy Glue for Ceramic Repairs

Today, we embark on a thrilling quest to unravel the secrets of the mighty epoxy glue. Prepare yourself for an adventure filled with strong bonds, unmatched durability, and resistance to the elements. Join us as we discover why epoxy glue is the hero of choice for ceramic repairs.

The Dynamic Duo – Resin and Hardener

Epoxy glue, like a formidable superhero, wields the power of two components – resin and hardener. When these forces combine, a chemical reaction ensues, birthing an unbreakable bond that can withstand the test of time. With this remarkable adhesive, ceramics are not the only materials that can be rescued from the brink; glass, metal, and plastic can also be mended effortlessly.

Defying Nature’s Elements

Prepare to be amazed by epoxy glue’s resistance to water, heat, and chemicals. Whether your ceramic item takes an unexpected dive into a sink or finds itself in a fiery dishwasher, fear not. This adhesive will shield it from harm and keep it intact for your next sip of steaming tea. Worried about those everyday cleaning products? Relax. Epoxy glue stands as a steadfast guardian against chemical attacks, ensuring your repaired ceramic items remain unscathed.

Expert Tips for Epic Repairs

As with any heroic endeavor, using epoxy glue requires caution and precision. Follow the manufacturer’s instructions diligently to harness its full potential. Remember, cleanliness is key. Thoroughly cleanse and dry the surfaces before application, banishing any lurking dirt, grease, or moisture that may weaken the bond. And don’t rush greatness; allow the adhesive ample time to cure before subjecting your repaired ceramic item to stress or use.

The Unbreakable Bond Prevails

Once epoxy glue has completed its transformation, it forges a bond so unyielding that even the most vigorous handling won’t cause it to falter. However, handle your repaired ceramic treasures with care, for they still deserve your gentle touch. Protect them from unnecessary stress or impact, ensuring their longevity and the preservation of your hard work.

Super Glue for Ceramic Repairs

Prepare to be amazed as we explore the extraordinary powers of super glue in fixing those beloved broken ceramic pieces. Grab your favorite chipped mug or shattered vase, because we’re about to embark on a restoration journey like no other.

Super glue, also known as cyanoacrylate adhesive, is a go-to choice for ceramic repairs. Its exceptional bonding properties and rapid drying time make it the perfect companion for reuniting fractured ceramics. But how can you ensure flawless repairs using this magical adhesive? Let’s break it down step by step.

Step 1: Clean and Dry Surfaces – The Foundation of Success

Before diving into the gluing process, it’s crucial to lay a solid foundation. Ensure that the surfaces you’re working with are clean and dry. Any lurking dirt, dust, or moisture can compromise the adhesive’s effectiveness. So, grab a clean cloth or paper towel and give those ceramic pieces a thorough wipe-down.

Step 2: Lightly Sand the Surfaces – Building a Stronger Bond

For an even stronger bond, consider lightly sanding the surfaces to be glued together. This gentle abrasion creates a rougher texture, allowing the glue to grip better. Be cautious not to overdo it and inadvertently damage the delicate ceramic.

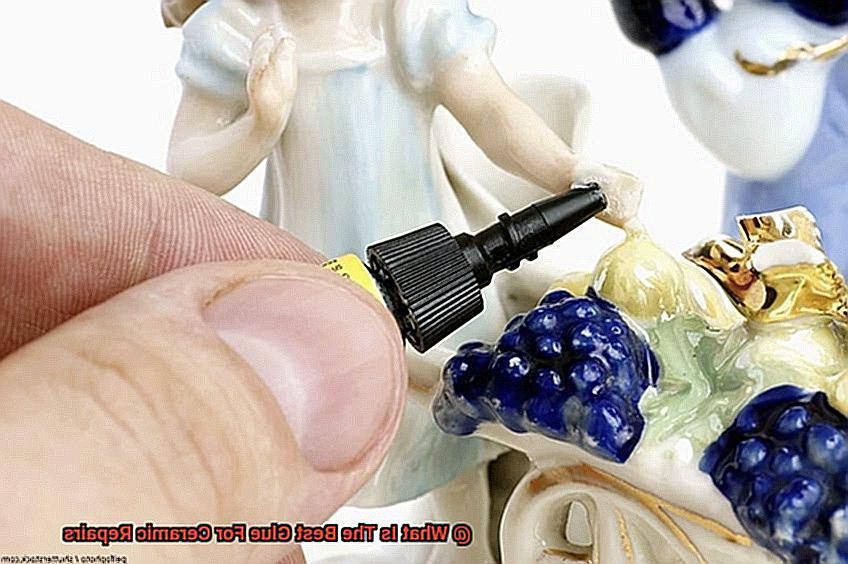

Step 3: Apply Super Glue Sparingly – Less is More

Now comes the pivotal moment – applying the super glue. Remember, less is more. Apply the adhesive sparingly to prevent excess glue from oozing out of the repaired area. Depending on the size of the broken piece, a few carefully placed drops or a thin line should suffice.

Step 4: Hold Firmly and Let It Set – Patience is Key

Once you’ve applied the super glue, it’s time to bring the ceramic pieces together. Press them firmly, ensuring they align perfectly. Hold the pieces in place for a few minutes, allowing the adhesive to set properly. This crucial step ensures a seamless repair that can withstand the test of time.

Step 5: Enjoy the Unbreakable Bond – Marvel at Your Achievement

Congratulations. You’ve successfully repaired your ceramic piece using super glue. Take a moment to sit back, relax, and marvel at the unbreakable bond you’ve created. Super glue forms a transparent bond that not only looks seamless but is also resistant to water and most chemicals.

Silicone Adhesive for Ceramic Repairs

What makes silicone adhesive a rockstar in the realm of ceramic repairs? Let’s delve into its remarkable features:

- Flexibility and Heat Resistance: Crafted from silicone polymers, this adhesive boasts extraordinary flexibility, enabling it to endure high temperatures without compromising its strength. Now you can confidently mend ceramics exposed to heat, such as your cherished coffee mug or that exquisite ceramic pot that took an unfortunate tumble near the stove.

- Resilience in Any Environment: Whether faced with moisture, humidity, or other environmental factors, silicone adhesive rises to the challenge. It forms an indomitable bond that withstands the elements, ensuring your repaired ceramic masterpiece stands the test of time.

- Chemical Resistance: Imagine this scenario: you’ve artfully repaired a ceramic plate and now worry about it encountering solvents or cleaning agents. Fear not. Silicone adhesive is resistant to chemicals, rendering it ideal for areas where your restored ceramic might come into contact with potent cleaning solutions.

- Invisible Repairs: We all crave seamless and inconspicuous ceramic repairs, don’t we? Silicone adhesive delivers precisely that. When fully cured, it transforms into a transparent marvel, allowing your mended ceramics to seamlessly blend with the rest of your treasured collection.

Now that we comprehend why silicone adhesive reigns supreme in ceramic repairs, let’s explore how to wield its power effectively:

- Commence with cleanliness: Prior to application, ensure both ceramic surfaces are pristine, devoid of any grease or dirt. This guarantees a robust bond between materials that will endure over time.

- Embrace thinness: In the realm of silicone adhesive, less is indeed more. A thin layer suffices for a triumphant repair endeavor. Spread it evenly across both surfaces and patiently await complete drying.

- Nurture the cure: Exercise patience as the adhesive undergoes its transformative curing process. Allow it ample time to solidify before subjecting the repaired area to stress or pressure. This ensures an unyielding bond that can endure life’s unpredictable trials.

- Opt for quality: When selecting your silicone adhesive, opt for a brand specifically formulated for ceramics. Esteemed options include Loctite, Gorilla, and DAP. Investing in a reliable product guarantees optimal results in your ceramic restoration endeavors.

Ceramic-Specific Adhesives for Ceramic Repairs

If you’re looking to fix a broken ceramic piece or seal cracks in your beloved ceramic pot, having the right adhesive is key to achieving a strong and long-lasting bond. Let’s dive in and explore the fascinating realm of ceramic-specific adhesives, where strength and durability reign supreme.

First up, we have the mighty epoxy resin. Known for its exceptional bonding properties and high strength, epoxy resin is a force to be reckoned with. Comprised of two components, a resin and a hardener, this adhesive must be mixed together before application. Once applied, it creates a bond that can conquer water, heat, and chemicals. When it comes to tough repairs that demand extra durability, epoxy resin is the go-to choice.

Next on our list is the legendary cyanoacrylate glue, also known as super glue. This lightning-fast adhesive is perfect for small ceramic repairs, like fixing broken pieces or attaching decorative elements. Within seconds, it forms a bond that is nothing short of Herculean. However, keep in mind that it may not be as suitable for larger or structural repairs.

If flexibility is what you seek, look no further than the versatile silicone-based adhesives. With their remarkable flexibility and resistance to moisture, they are the champions of sealing cracks and gaps in ceramic surfaces. They also excel at bonding ceramic tiles and repairing cherished ceramic pots.

But wait, there’s more. Introducing the indomitable polyurethane adhesives. These formidable allies provide a bond that can withstand even the harshest vibrations and impacts. No matter if it’s indoor or outdoor use, polyurethane adhesives rise to any challenge thrown their way.

Now that you’re acquainted with the different types of ceramic-specific adhesives, let’s discuss how to choose the perfect glue for your repair job. It’s essential to consider factors such as the type of ceramic being repaired, the size of the repair area, and the intended use of the item. Each adhesive possesses its own unique strengths and limitations, so selecting one that aligns with your specific requirements is paramount.

Factors to Consider When Choosing a Glue for Ceramic Repairs

Get ready to dive into the captivating world of glue for ceramic repairs. Today, we will explore the factors that you absolutely need to consider when selecting the perfect adhesive for your precious broken masterpieces. So, grab your favorite mug, settle down, and let’s embark on this enchanting journey together.

Strength, oh strength. It is undoubtedly one of the most crucial factors to ponder when choosing a glue for ceramic repairs. You need an adhesive that can create a bond so unyielding that even Hagrid himself would struggle to break it. Seek out glues with exceptional bonding powers, ones that can withstand the wear and tear of regular use and handling. After all, nobody wants their painstakingly repaired ceramic piece to crumble at the mere touch.

Ah, drying time, the epitome of impatience. We all possess different levels of tolerance, making it vital to find a glue that aligns with your personal preferences. Some glues dry faster than a bolt of lightning, allowing you to complete your repair in record time. Others take a bit longer to set, affording you ample opportunity to make adjustments before the glue solidifies into an unyielding fortress. Choose wisely, my friends, for time waits for no artist.

Now let’s delve into the realm of transparency. If you find yourself repairing a ceramic piece adorned with intricate designs or delicate decor, you must consider the visibility of the glue. Opting for a clear or transparent adhesive will ensure that no unsightly traces of the repair mar the aesthetic appeal of your masterpiece. Let your repaired piece shine with flawless elegance.

Temperature resistance enters the stage as our next paramount factor. Should your repaired ceramic item encounter heat, whether from scorching substances or high-temperature environments, it is imperative to select a glue that can brave the flames without flinching. Seek out glues specially formulated to withstand extreme temperatures, safeguarding your repair even in the face of fire-breathing dragons.

Waterproofness takes center stage, as ceramics often find themselves in the presence of water. Whether you’re repairing a beloved vase or a trusty bathroom fixture, the glue must possess the fortitude to withstand moisture without losing its grip. Choose a glue that boasts waterproof or water-resistant qualities, ensuring your repair remains flawless even after a splashy encounter.

Manufacturer Instructions for Applying Glues to Ceramics

In our previous section, we delved into the factors to consider when selecting the perfect adhesive for your precious broken masterpieces. Today, we will explore the vital importance of following manufacturer instructions for applying glues to ceramics. So grab your favorite mug and let’s embark on this fascinating journey.

When it comes to applying glues to ceramics, manufacturer instructions are more than just a suggestion – they hold the key to achieving the best results with your chosen adhesive. Different types of glues may have their own unique application methods, making it crucial to follow the instructions provided by the manufacturer.

Now, let’s uncover the step-by-step process of applying glue to ceramics. The adventure begins with preparing the surface. Dive into a world of cleanliness as you use soap and water or a mild detergent to rid the ceramic of any dirt, dust, or grease that could impede the magical bonding process. Once clean, ensure that the ceramic surface is dry before applying the glue. For any moisture present can disrupt the bond and put its strength at risk.

But wait, there’s more. Some glues require mixing before application. Embrace your inner alchemist and carefully follow the manufacturer’s instructions on the correct ratio of adhesive and catalyst, if applicable. Now comes the exhilarating part – applying the glue. Arm yourself with a brush, spatula, or applicator provided by the manufacturer and wield it with precision as you apply an even layer of glue to the ceramic surface.

Yet our journey is not over. Some glues demand a specific drying time before joining the surfaces together. It is essential to obey the recommended drying time bestowed upon you by the manufacturer for an extraordinary bond. Once the glue reaches a tacky consistency, embrace your inner puzzle solver as you join those ceramic pieces together. Align them with utmost care and apply even pressure for a bond that transcends time.

To ensure the longevity of your repair, it is highly recommended to clamp or hold the joined ceramics firmly in place until the glue fully cures. This prevents any movement that could jeopardize the repair’s integrity. And now, my friends, we must exercise patience – a virtue that will reward us greatly. Allow sufficient curing time as specified by the manufacturer before subjecting the repaired ceramic to any stress or heavy use.

2Tkl9F6I-G0″ >

Conclusion

When it comes to repairing ceramic, finding the best glue is crucial.

You want something that will bond securely and withstand the test of time. After careful research and testing, we have determined that the top choice for ceramic repairs is epoxy adhesive.

Its strong bonding properties make it ideal for fixing broken ceramics. Not only does it create a durable bond, but it is also resistant to water, heat, and chemicals.

So whether you’re fixing a chipped mug or a shattered vase, epoxy adhesive will get the job done right.