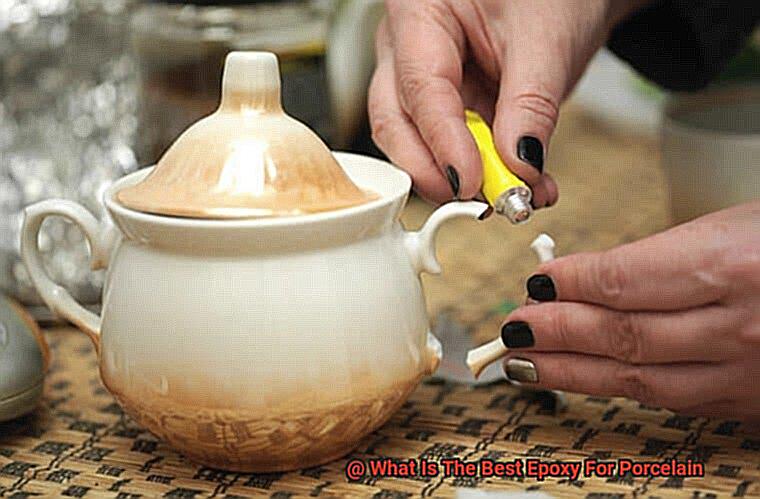

Imagine the heartbreak of seeing a cherished porcelain heirloom shattered into countless fragments. It’s enough to bring tears to your eyes. But fret not. Thanks to cutting-edge technology, we now have a solution that can breathe new life into these delicate works of art – the best epoxy for porcelain.

In this all-encompassing guide, we’ll take a deep dive into the captivating realm of epoxy and uncover the holy grail adhesive that will nurture and resurrect your beloved porcelain treasures. From vintage chinaware to fragile figurines, we’ll unravel the key qualities you should seek in an epoxy superhero.

But why opt for epoxy, you might wonder? Unlike ordinary glues, epoxy boasts an unparalleled bond that is both robust and everlasting – perfectly suited to meet porcelain’s unique demands. Its exceptional adhesion properties make it an ideal choice for repairing shattered or chipped porcelain items. Whether you’re a restoration enthusiast or simply enamored with fine porcelain, this blog post is your ultimate go-to resource.

Throughout this enthralling journey, we’ll delve into the crucial factors to consider when selecting an epoxy for porcelain. Transparency, strength, moisture resistance, and heat endurance are just a few of the remarkable features we’ll explore. Equipped with this knowledge, you’ll feel empowered to restore your most treasured porcelain possessions back to their former glory.

So buckle up, dear reader. Let’s embark on this exhilarating adventure together as we uncover the perfect sidekick in our quest for porcelain restoration excellence. Prepare to be astounded by the transformative powers of this extraordinary adhesive and witness one-of-a-kind porcelain masterpieces rise from their broken state like phoenixes from the ashes.

What is Porcelain?

Contents

Porcelain, a captivating ceramic material cherished for its strength and beauty, has graced homes for centuries. Its delicate dishes and exquisite decorative pieces bring elegance to any space. But what makes porcelain so enduring? The secret lies in choosing the ideal epoxy adhesive for bonding porcelain. In this article, we will delve into the distinctive characteristics of porcelain and provide insights on selecting the best epoxy for your porcelain projects.

Unyielding Strength:

Porcelain is renowned for its robustness, allowing for the creation of thin and delicate pieces that can withstand daily use. Unlike earthenware or stoneware, porcelain achieves remarkable strength without sacrificing its structural integrity. This resilience must be considered when selecting an epoxy adhesive.

Translucency and Grace:

Hold a slender piece of porcelain up to the light, and be captivated by its ethereal translucency. This exceptional quality enhances the allure and sophistication of porcelain objects, particularly when used as decorative items or in lighting fixtures. When choosing an epoxy, opt for one that preserves this delicate translucence.

Heat Resistance:

Porcelain’s ability to endure high temperatures without cracking or melting makes it ideal for cooking utensils and ovenware. Whether baking or serving piping hot dishes, your porcelain vessels remain unharmed. Seek an epoxy adhesive capable of withstanding high temperatures without compromising the bond.

Impenetrable Non-Porousness:

One of porcelain’s greatest advantages lies in its non-porous nature. Its dense structure repels liquids, ensuring hygiene and effortless cleaning. Stains and odors are thwarted, making porcelain perfect for food preparation and bathroom applications. When choosing an epoxy, consider its ability to maintain porcelain’s non-porousness.

Key Factors to Consider When Selecting an Epoxy for Porcelain:

- Strength and Longevity: Opt for a two-part epoxy adhesive specifically formulated for ceramics or porcelain. These epoxies provide exceptional adhesion and enduring bonds.

- Curing Time: Depending on your project, evaluate the epoxy’s curing time. Fast-curing options cater to swift bonding, while longer curing times suit larger or more intricate endeavors.

- Color Matching: Porcelain is often white or off-white, so selecting an epoxy adhesive that seamlessly blends with its color is crucial.

Advantages of Using Epoxy for Porcelain

Porcelain, with its delicate beauty and enduring strength, deserves an adhesive that can match its elegance. Enter epoxy, the unsung hero of porcelain preservation. But what sets epoxy apart? What are the advantages of using epoxy for porcelain? Let’s dive into the details.

First and foremost, epoxy boasts exceptional bonding power. It forms an unbreakable bond with porcelain surfaces, ensuring that any repairs or joins remain steadfast for years to come. This is crucial for delicate porcelain, as it requires a secure bond to withstand the test of time.

Versatility is another feather in epoxy’s cap. From fixing chipped porcelain tiles to restoring cracked sinks or broken figurines, epoxy has your back. It adheres effortlessly to both glazed and unglazed porcelain surfaces, making it a versatile adhesive for a wide range of applications.

But what use is an adhesive if it’s difficult to apply? Fear not, for epoxy prides itself on easy application. With its two-component formula – resin and hardener – simply mix them together before use. The beauty of epoxy lies in its relatively long working time, allowing you to meticulously apply and make adjustments before it sets. Whether you’re a professional or a DIY enthusiast, epoxy makes the process a breeze.

Now let’s talk about water resistance. Porcelain often finds itself in moisture-prone areas like bathrooms and kitchens. That’s where epoxy shines. Its excellent water resistance prevents seepage and protects the underlying structure from moisture-induced damage. Your porcelain repairs will stay strong and secure, even in wet environments.

Durability is another ace up epoxy’s sleeve. Porcelain items endure daily use and wear, from dishes being washed to tiles being walked upon. Epoxy rises to the challenge with exceptional strength, ensuring that the bonded or repaired porcelain surface can withstand whatever life throws at it. Impact, temperature changes, and general wear and tear are no match for epoxy’s resilience.

Last but certainly not least, let’s not forget about aesthetics. When repairing or joining porcelain items, appearance matters. Epoxy adhesives often dry clear or can be tinted to match the color of the porcelain, resulting in seamless and nearly invisible repairs. This is particularly crucial for highly visible areas like kitchen countertops or decorative porcelain pieces. Epoxy’s ability to provide a visually appealing finish enhances the overall beauty of your porcelain creations.

Types of Epoxy for Porcelain

Porcelain, a material renowned for its delicate beauty and strength, deserves nothing but the best when it comes to repairs. Enter epoxy, the superhero of adhesive solutions.

In this comprehensive guide, we will explore the diverse world of epoxy for porcelain surfaces, unveiling their unique attributes and applications.

So, let’s embark on this journey and unlock the true potential of epoxy for porcelain.

Two-Part Epoxy: The Unbreakable Bond

Picture a dynamic duo in action – that’s exactly what you get with two-part epoxy adhesive. This remarkable epoxy consists of a resin and a hardener that join forces through a chemical reaction, creating a bond that can withstand any challenge. Its unrivaled strength and durability make it the go-to choice for bonding porcelain surfaces subjected to heavy loads or constant stress. From restoring shattered porcelain figurines to fixing chipped tiles, two-part epoxy is your ultimate ally.

Fast-Curing Epoxy: Where Time Meets Convenience

In a fast-paced world where time is of the essence, fast-curing epoxy swoops in as the hero we need. With its lightning-fast curing time, sometimes as short as 5 minutes, it caters to projects that demand immediate results. However, keep in mind that while fast-curing epoxies offer quick fixes, they may not possess the same level of strength and durability as their two-part counterparts. Choose wisely based on your project’s specific requirements.

Specialized Porcelain Epoxy: A Bond Beyond Compare

When it comes to bonding porous porcelain surfaces, specialized epoxies take center stage. These exceptional epoxies boast enhanced adhesion properties specially formulated to conquer the challenges posed by porous porcelain. They often feature unique additives or fillers that fortify the bond, ensuring it stands the test of time without any unsightly discoloration or yellowing. Prepare to witness a bond beyond compare.

Clear Epoxy: The Art of Invisible Repairs

For those imperfections demanding a seamless repair, clear epoxy emerges as the master of invisibility. Its transparent nature allows the natural beauty of the porcelain to shine through, leaving no trace of the repair. Bid farewell to those unsightly eyesores on your cherished porcelain pieces and embrace the art of invisible repairs.

Colored Epoxy: A Symphony of Harmony

When faced with larger damaged areas or missing pieces, colored epoxy steps up to create a symphony of harmony. Custom-tinted to match the color of your porcelain, it effortlessly blends into the surrounding surface, creating a repair that is both visually pleasing and structurally strong. Get ready to witness a splash of perfection on your beloved porcelain treasures.

Strength and Durability of Two-Part Epoxies

Prepare to be amazed as we delve into the remarkable world of two-part epoxies and unlock the secrets behind their unmatched strength and durability. Curious about why these adhesives reign supreme when it comes to bonding porcelain? You’ve come to the right place. So grab your lab coats and join us on this exhilarating epoxy adventure.

The Chemistry of Strength:

Let’s start by unraveling the chemical composition that gives two-part epoxies their extraordinary might. These dynamic duos consist of a resin and a hardener that, when combined, undergo a mesmerizing transformation known as curing. This alchemical reaction magically converts the liquid mixture into a solid material with awe-inspiring adhesive properties.

Tensile Strength: The Power to Resist:

Porcelain, delicate as it may be, is no match for the superhero strength of two-part epoxies. These adhesives boast unparalleled tensile strength, allowing them to triumphantly resist pulling forces. With their ability to distribute applied forces evenly, two-part epoxies shield precious porcelain surfaces from the perils of cracks and chips.

Shear Strength: Keeping It All Together:

Durability That Defies Expectations:

Strength alone is futile if an adhesive crumbles under environmental pressure. Luckily, two-part epoxies are formidable foes that stand up to the harshest conditions. Once cured, they form an unyielding, resilient bond capable of defying the elements. Temperature fluctuations, moisture exposure, and even chemical assaults pale in comparison to the indomitable durability of these epoxies. So whether your porcelain creation endures daily use or resides in a humid environment, rest assured that the bond will remain unbreakable.

Considerations When Choosing the Best Epoxy for Porcelain

In our previous section, we delved into the extraordinary world of two-part epoxies and their remarkable bonding abilities. Today, we’re going to unravel the mysteries behind choosing the best epoxy for porcelain. So, put on your detective hats and join me as we explore the key considerations that will help you make an informed decision. Let’s dive in.

Know Your Porcelain:

Porcelains are as diverse as people, each with its own unique composition and surface characteristics. Whether it’s fine china or a sturdy bathroom fixture, understanding your porcelain’s personality is crucial in selecting an epoxy that is compatible and tailored to its specific needs.

Purpose Matters:

Are you fixing a small chip or crack? Or do you need to bond two porcelain pieces together? The intended use of the epoxy plays a vital role in determining which product to choose. Consider the strength and adhesion properties of different epoxies, aligning them with your project goals.

Strength and Durability:

Porcelain may be delicate, but it doesn’t mean it can’t be tough. Prioritize strength and durability when selecting an epoxy. Seek out epoxies specially formulated for bonding porcelain, boasting high tensile strength. After all, you want a bond that can withstand the test of time.

Timing is Everything:

Time waits for no one. Consider the curing time of your epoxy. Some epoxies cure faster than others, perfect for quick projects. However, if you’re working on a complex or intricate piece, opt for an epoxy with a longer curing time. Remember, patience is a virtue in creating masterpieces.

Aesthetics Matter:

We know appearances matter. Not all epoxies dry clear, so choose wisely if blending seamlessly with your porcelain’s color is a priority. Select an epoxy that matches or complements your porcelain, ensuring a flawless finish. No one wants a noticeable epoxy line marring their beautiful masterpiece.

Ease of Use:

Whether you’re a seasoned epoxy veteran or a newbie in the craft, ease of use is essential. Consider your skill level and project requirements when choosing an epoxy that suits your expertise. Some epoxies require mixing two components together, while others come pre-mixed for your convenience.

Curing Time

Today, we embark on a thrilling expedition into the realm of curing time. Brace yourself as we unravel the secrets behind this essential factor in choosing the perfect epoxy for porcelain. Prepare to be awestruck as we explore how curing time, environmental conditions, and the thickness of the epoxy layer can influence the hardening process. Let’s dive right in.

The Essence of Curing Time:

Curing time is the transformative moment when your epoxy attains its maximum strength and solidifies into a rock-hard bond. It is the ultimate objective of any bonding endeavor. However, different epoxy products have varying curing times. While some may cure within minutes, others might require hours or even days.

The Dance of Environmental Factors:

Prepare to be captivated by the interplay between your surroundings and the speed at which your epoxy cures. Temperature and humidity form a dynamic duo that either hastens or delays the curing process.

Higher temperatures ignite an accelerated reaction, while lower temperatures extend the waiting period. Likewise, high humidity levels apply brakes to curing, while low humidity presses down on the accelerator.

Unlocking the Thickness Riddle:

Ah, the enigma of thickness. It holds sway not only over our preference for steaks but also over epoxy’s curing time. Thicker layers demand more patience during the hardening process compared to their slimmer counterparts. How? Well, heat generated during curing disperses more leisurely in thicker layers, causing a deceleration in reaction and an elongated overall curing time. Thus, when working with porcelain, strike a balance between applying enough epoxy for durability without crossing into excessive territory.

Manufacturer’s Instructions: Your Holy Grail

The manufacturer’s instructions hold the key to unraveling the mysteries of your epoxy’s exact curing time. They are the ultimate guide to ensuring optimal bonding and durability. Devoutly follow their wisdom to shield your repaired or bonded porcelain item from premature stress or load.

Color Matching Epoxies

Prepare to be captivated as we delve into the enchanting world of color matching epoxies for porcelain surfaces. If you’ve ever yearned for flawless repairs and invisible bonds that seamlessly blend with your porcelain, you’ve come to the right place. So don your goggles and join us on a journey to uncover the secrets of selecting and applying the perfect color matching epoxy.

Selecting the Perfect Shade:

The first step in this mesmerizing process is to choose an epoxy that harmonizes flawlessly with your porcelain surface. Manufacturers have embraced the challenge, offering a kaleidoscope of colors ranging from ethereal whites and creamy creams to sophisticated greys and earthy browns. Embrace your inner artist, scrutinize your porcelain canvas, and discover the hue that will make your repairs vanish like a magician’s rabbit.

Consistency is Key:

Now that you’ve unlocked the mystery of the perfect shade, it’s time to delve into the realm of consistency. Some epoxies take on a gel-like form, providing you with unrivaled precision during application. Imagine yourself as a master painter, delicately dabbing and blending until your repairs become indistinguishable from the original surface. Alternatively, if you’re tackling expansive areas, opt for an epoxy with a more liquid nature. This fluid consistency will effortlessly spread over those wide spaces, guaranteeing a breathtakingly seamless finish.

Porcelain-Specific Formulation:

Porcelain surfaces deserve only the utmost care, so why settle for generic epoxies that may betray you in the long run? Seek out specialized epoxies explicitly formulated for use on porcelain surfaces. These magical elixirs possess extraordinary adhesive properties tailored exclusively for porcelain, resulting in bonds that stand the test of time. Don’t let mediocrity tarnish your porcelain projects – embrace the power of purpose-built epoxies.

Waterproof or Water-Resistant Epoxies

Today, we embark on an exhilarating journey into the realm of waterproof and water-resistant epoxies. These remarkable concoctions possess the power to safeguard our treasured porcelain creations from the clutches of water damage, ensuring their longevity and strength. But what sets these epoxies apart, and how can we choose the perfect one for our specific projects? Brace yourselves as we unearth the answers.

Waterproof vs. Water-Resistant Epoxies:

Unveiling the Heroes:

In this epic battle, waterproof and water-resistant epoxies emerge as the valiant protectors of porcelain against water damage. Although porcelain itself repels water due to its non-porous nature, utilizing a compatible epoxy is essential for establishing a robust adhesive bond.

The Mighty Waterproof Epoxies:

Imagine a world where your porcelain masterpiece faces relentless exposure to moisture or even submersion in water. Fear not. Enter waterproof epoxies, equipped with the extraordinary ability to repel water entirely. These formidable formulations shield your project from any harm that H2O might attempt.

The Trusty Water-Resistant Epoxies:

Not every porcelain endeavor necessitates a superhero capable of deflecting every droplet. For projects involving occasional or minimal contact with water, let water-resistant epoxies take center stage. While not completely impervious to water’s advances, they provide ample protection for most porcelain applications.

Choosing the Right Epoxy for Your Project:

Tailoring to Your Project’s Needs:

Before selecting an epoxy, consider the unique requirements of your project. If your porcelain creation will face frequent or prolonged encounters with water, the invincibility of waterproof epoxy is your best bet. However, if sporadic or minimal water exposure is expected, a water-resistant epoxy shall rise to the challenge.

Timing and Technique:

Every superhero possesses distinctive traits, and epoxies are no exception. Some waterproof and water-resistant epoxies demand longer curing periods or specific application methods. To unlock their full potential, heed the manufacturer’s instructions diligently, ensuring your chosen hero can unleash its powers.

2Tkl9F6I-G0″ >

Conclusion

When it comes to finding the best epoxy for porcelain, there are a few factors to consider. One of the most important things to look for is an epoxy that is specifically designed for use on porcelain surfaces. This ensures that it will adhere properly and provide a strong bond.

In terms of performance, a high-quality epoxy should have excellent adhesion properties, allowing it to bond securely to the porcelain surface. It should also be able to withstand heat and moisture, as these are common conditions that porcelain may be exposed to.

Another important consideration is the curing time of the epoxy. A fast-curing epoxy can be beneficial, as it allows for quicker project completion. However, it’s essential to ensure that the epoxy still provides sufficient working time before it sets.

Furthermore, durability is key when choosing an epoxy for porcelain. You want a product that will stand up to everyday use and resist chipping or cracking over time. Look for epoxies with high tensile strength and impact resistance for optimal results.

Lastly, ease of use should not be overlooked. The best epoxy for porcelain should be easy to mix and apply, providing smooth and even coverage. It’s also helpful if it has a low odor and easy cleanup options.

In conclusion, when searching for the best epoxy for porcelain, prioritize finding one specifically formulated for this material. Consider factors such as adhesion properties, resistance to heat and moisture, curing time, durability, and ease of use.