Title: The Best Epoxy for Fiberglass to Plastic: Your Ultimate Guide

Introduction:

Contents

- 1 What is Epoxy?

- 2 Factors to Consider When Choosing the Best Epoxy for Fiberglass to Plastic

- 3 Two-Part Epoxies: Advantages and Disadvantages

- 3.1 Advantages:

- 3.1.1 Strength that stands the test of time:

- 3.1.2 A bond for all seasons: Versatility is the name of the game for two-part epoxies. No matter if you’re working with fiberglass-reinforced plastic or other types of plastics, these adhesives work their magic seamlessly on various materials. Brave against the elements:

- 3.1.3 Filling in the gaps:

- 3.2 Disadvantages:

- 3.1 Advantages:

- 4 Working Time and Curing Time of the Epoxy

- 5 Temperature Resistance of the Epoxy

- 6 Surface Preparation of Fiberglass and Plastic

- 7 Conclusion

Hey there, DIY enthusiasts and repair wizards. If you’re on a mission to create an unbreakable bond between fiberglass and plastic, you’ve come to the right place. Choosing the perfect epoxy is like finding the missing puzzle piece that completes your project. So, let’s dive into this comprehensive guide and uncover the top contenders for achieving a seamless and long-lasting connection.

Before we jump into the nitty-gritty, let’s talk about why picking the right epoxy is crucial. Fiberglass is like the superhero of materials – lightweight, versatile, and tough as nails. It’s used in everything from cars to boats to spaceships (yes, really.). But when it comes to bonding it with plastic, things can get a little tricky due to their different properties.

Enter epoxy adhesives – the secret weapon in your toolbox. These bad boys are specially formulated to create a bond that would make even Superman proud. They stick like glue (literally.) to both fiberglass and plastic surfaces, ensuring a strong hold that won’t let you down. But with so many options out there, which one should you choose?

In this guide, we’ll walk you through some of the best epoxy choices on the market. We’ll consider factors like adhesive strength, compatibility with different types of plastic, and overall performance. So buckle up and get ready to discover your new favorite epoxy for bonding fiberglass to plastic.

Let’s dive in and find that perfect match.

What is Epoxy?

Prepare to be amazed by the extraordinary world of epoxy. This exceptional adhesive has completely transformed the way we bond materials together. Whether you’re a construction enthusiast, a DIY aficionado, or an automotive expert, epoxy is the go-to solution that will never let you down. Get ready to dive into the fascinating properties, composition, and applications of this versatile adhesive.

Properties and Composition:

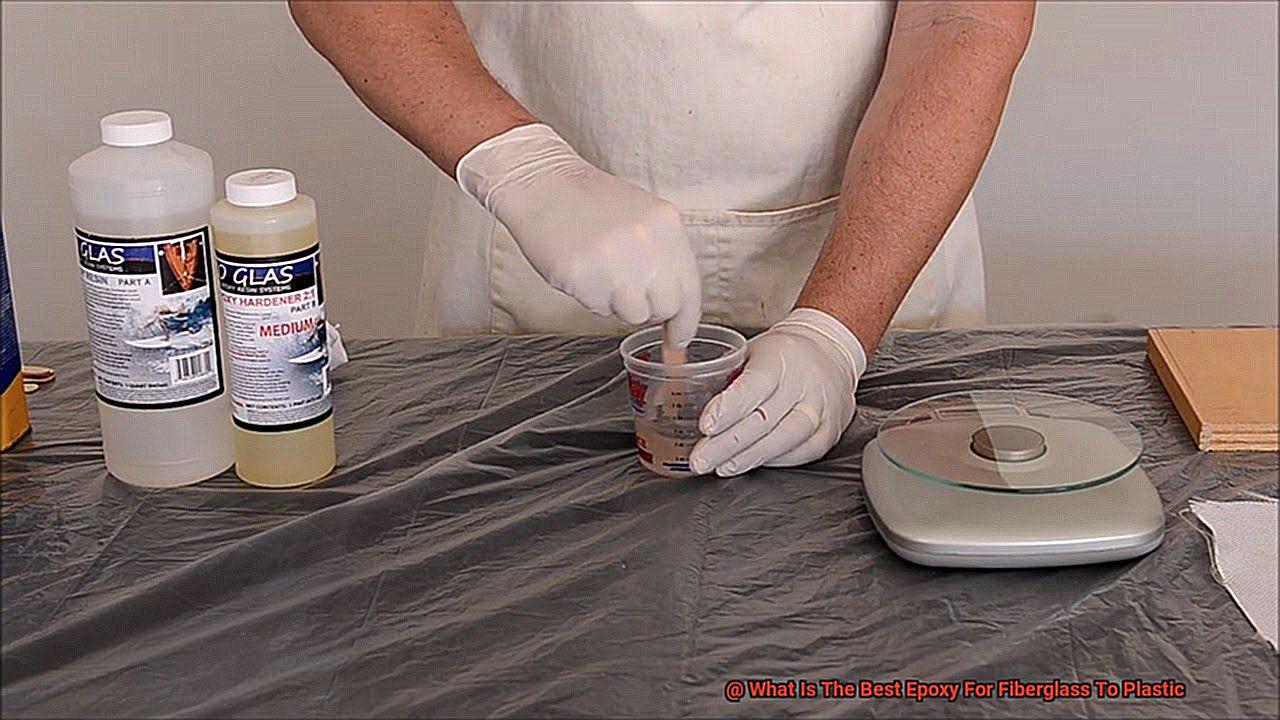

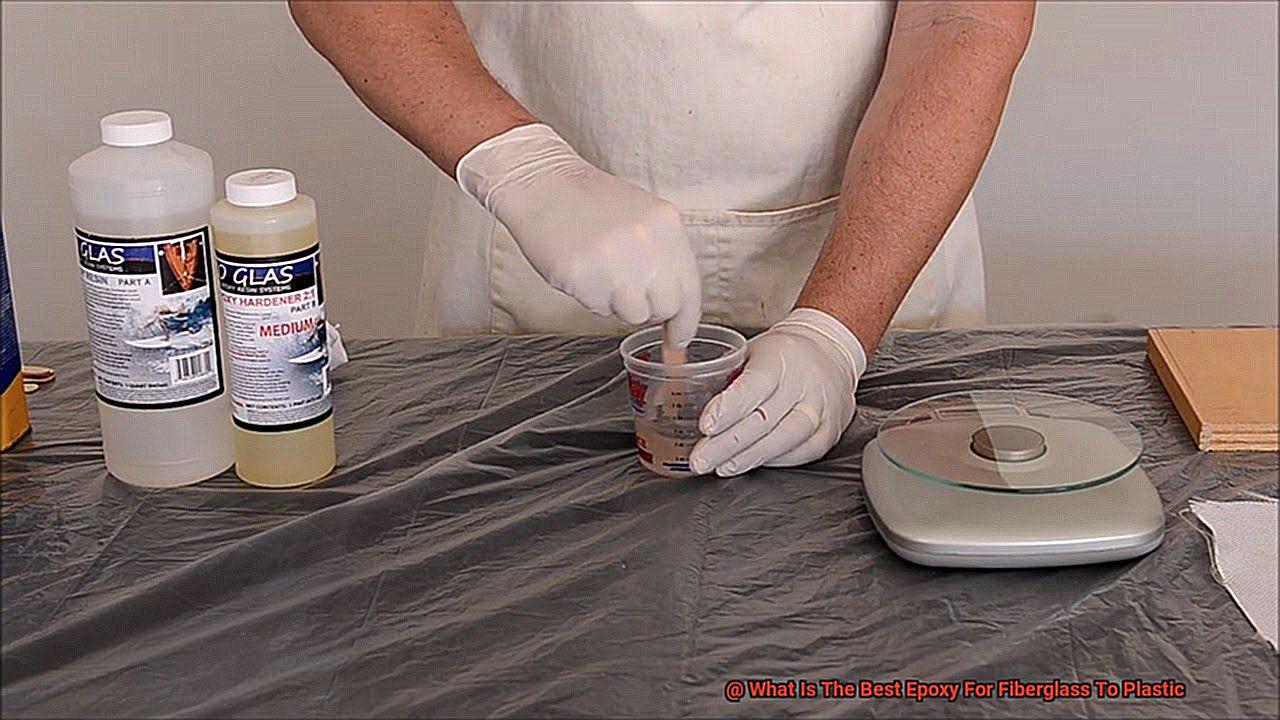

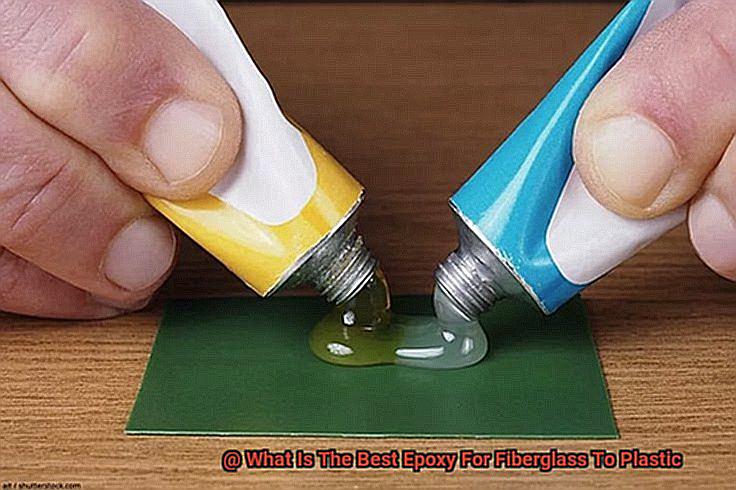

Epoxy has a magical formula consisting of two main components: resin and hardener. When these two ingredients are combined in precise proportions, they create a chemical reaction known as cross-linking. This reaction is what turns the mixture into a powerhouse adhesive with unmatched strength and durability.

The resin component, derived from either petroleum-based sources or renewable resources like plant oils, is the secret behind epoxy’s adhesive properties. It boasts low volatility, exceptional adhesion to various surfaces, and eye-popping strength.

The hardener acts as the catalyst that sets the curing process in motion. Packed with reactive chemicals, it triggers the cross-linking reaction with the resin, transforming the mixture into a three-dimensional network of bonded molecules. Thanks to this transformative process, epoxy gains its superpowers: resistance to heat, chemicals, and moisture.

Applications:

Epoxy’s versatility knows no bounds. Here are just a few examples of its incredible applications:

- Construction Wonder: Epoxy is the hero of the construction world. From bonding concrete, wood, metal, and stone to flooring, tiling, and crack repair, epoxy provides unrivaled adhesion and structural integrity.

- Automotive Marvel: In the automotive realm, epoxy takes center stage. It plays a crucial role in bonding parts together, repairing bodywork, and sealing joints. Its ability to withstand vibrations, impacts, and extreme temperatures makes it indispensable in the automotive industry.

- Electronics Wizardry: Epoxy is a wizard when it comes to electronics. It excels at encapsulating and protecting sensitive components, thanks to its excellent electrical insulation properties, resistance to moisture and chemicals, and impressive thermal stability. Think circuit board assembly and potting.

- Marine Champion: The marine industry’s love affair with epoxy is no secret. Its resistance to water, salt, and UV exposure makes it a champion in the marine world. It’s used for bonding fiberglass, repairing boat hulls, and sealing joints, ensuring strength and durability in the harshest marine environments.

Factors to Consider When Choosing the Best Epoxy for Fiberglass to Plastic

Choosing the right epoxy is vital to ensure a reliable connection between these two materials. Let’s explore the factors that should be at the forefront of your mind when selecting the ideal epoxy:

- Compatibility: The first step is to check the compatibility between the epoxy resin and the plastic substrate. Not all epoxies are suitable for bonding fiberglass and plastic together, so it’s crucial to carefully read the manufacturer’s instructions and product specifications.

- Adhesion: The adhesive strength of the epoxy is paramount. Look for an epoxy that is specifically formulated for bonding different types of plastics, including the specific type of plastic you are working with. Keep in mind that some epoxies have better adhesion to certain plastics than others.

- Curing Time: Consider the curing time of the epoxy. Some epoxies cure quickly, while others may require more time. The curing time should align with your project requirements and timeline. Remember, a longer curing time often results in a stronger bond.

- Temperature Resistance: Think about the temperature range your epoxy will be exposed to. Ensure that the epoxy you choose can withstand those temperatures without compromising its bond strength or structural integrity.

- Flexibility: If flexibility is important for your project, select an epoxy that has some degree of flexibility once cured. This will allow the bonded materials to withstand movements or vibrations without cracking or breaking.

- Chemical Resistance: Depending on the environment in which the bonded materials will be used, chemical resistance may be crucial. Look for epoxies that offer better resistance to chemicals or solvents that might come into contact with the bonded surfaces.

- Ease of Use: Consider the ease of use of the epoxy product. Some epoxies require mixing before application, while others come pre-mixed and ready to use. Choose one that fits your comfort level and skill with handling epoxy products.

- Safety Precautions: Always prioritize safety when working with epoxy. Follow all safety instructions provided by the manufacturer, including proper ventilation requirements and the use of personal protective equipment (PPE).

Two-Part Epoxies: Advantages and Disadvantages

In this article, we will delve into the advantages and disadvantages of using two-part epoxies for this task. Let’s explore the strengths and weaknesses of these adhesives in detail.

Advantages:

Strength that stands the test of time:

Two-part epoxies boast unparalleled durability, ensuring that your fiberglass and plastic remain steadfastly bonded for years to come.

A bond for all seasons:

Versatility is the name of the game for two-part epoxies. No matter if you’re working with fiberglass-reinforced plastic or other types of plastics, these adhesives work their magic seamlessly on various materials.

Brave against the elements:

Extreme temperatures and harsh chemicals are mere obstacles for cured two-part epoxies. They exhibit excellent resistance, making them ideal for demanding environments.

Filling in the gaps:

Imperfect surfaces are no match for the remarkable filling capabilities of two-part epoxies. Uneven surfaces and gaps pose no challenge, as these adhesives ensure a strong bond even in the most challenging areas.

Disadvantages:

Time is of the essence:

Patience is a virtue when it comes to two-part epoxies. Mixing the components and allowing them to cure takes time, which may not be ideal if you’re looking for a quick solution.

Beware of toxic fumes:

Some two-part epoxies emit strong odors due to their toxic chemical composition during the mixing and curing process. Prioritizing safety by working in a well-ventilated area and wearing gloves is crucial.

The ticking clock:

Once mixed, two-part epoxies have a limited working time before they begin to cure. Efficient work and planning are essential to ensure a successful application.

Budget considerations:

While undeniably effective, two-part epoxies may be pricier compared to other adhesives. The cost varies depending on factors like brand, quality, and quantity, so budgeting is important for your specific project.

Working Time and Curing Time of the Epoxy

Today, we explore the fascinating realm of epoxy and its working time and curing time when bonding fiberglass to plastic. Whether you’re a DIY enthusiast or a professional, understanding these crucial factors will help you achieve outstanding results in your projects. So, let’s dive in.

Working Time – The Race Against the Clock:

Working time is the window of opportunity you have to apply and manipulate the epoxy before it starts to harden. Here’s what you need to know:

Definition: Working time refers to the time available for epoxy application and manipulation.

- Product Variations: Different epoxy adhesives offer varying working times, ranging from minutes to an hour or more.

- External Influences: Temperature and humidity affect working time. Warm conditions speed up curing, while cooler temperatures extend it. High humidity shortens working time, while low humidity lengthens it.

- Planning for Success: Adjust your project planning based on epoxy’s working time. With fast-curing epoxies, prep materials beforehand. Longer working times offer flexibility for positioning and adjustments.

Curing Time – The Transformation Process:

Curing time is the duration required for epoxy to fully harden and reach maximum strength. Here’s what you need to know:

Definition: Curing time is the duration for complete epoxy hardening.

Factors at Play: Curing time varies with temperature, humidity, and epoxy formulation.

- Patience is Key: Epoxy provides approximate curing time ranges, but complete drying may take longer as it continues to strengthen over hours or days.

- Manufacturer’s Wisdom: Follow the manufacturer’s recommendations for curing time, including specific temperature ranges and allowing sufficient time before subjecting the bond to stress or load.

Conclusion:

Mastering the delicate balance between working time and curing time is essential for optimal results when bonding fiberglass to plastic with epoxy. By understanding these crucial factors and planning accordingly, you can create durable and robust bonds that stand the test of time. Remember, patience is your best ally when it comes to epoxy curing – rushing the process may compromise bond strength. So, embrace the art of timing and let your epoxy creations shine.

Temperature Resistance of the Epoxy

Epoxy glue is a captivating world that offers endless possibilities for bonding and creating. Today, we will delve into the temperature resistance of epoxy and how it plays a vital role in bonding fiberglass to plastic.

Epoxy resins are renowned for their remarkable ability to withstand a wide range of temperatures. Depending on the specific formulation, they can brave temperatures from -40°C to 150°C (-40°F to 302°F). This exceptional temperature resistance makes epoxy ideal for applications where materials will encounter extreme heat or cold.

When choosing an epoxy for bonding fiberglass to plastic, temperature resistance is paramount. You need an epoxy that can maintain its strength and durability despite temperature fluctuations. To make the right selection, consider the highest temperature that the bonded materials will face. By doing so, you can choose an epoxy that will endure these conditions without compromising its integrity over time.

It is crucial to anticipate any potential temperature extremes that your bonded structure may encounter. If your project will be exposed to outdoor conditions, you must find an epoxy that can withstand scorching summer heat or freezing winter temperatures.

For demanding projects requiring high-temperature resistance, certain epoxies are specially formulated. Industries like automotive or aerospace rely on these epoxies, which can withstand even higher temperatures than standard formulations. These specialized epoxies are perfect for projects where extreme heat is a constant challenge.

Remember that factors like curing processes and additives or fillers in the epoxy formulation can affect its temperature resistance. To ensure optimal performance, it is essential to follow the manufacturer’s guidelines and recommendations.

When selecting the right epoxy for your project, don’t overlook other crucial factors like chemical resistance, adhesion strength, and flexibility. Considering these attributes will contribute to a successful and long-lasting bond between fiberglass and plastic materials.

Lastly, testing your epoxy under simulated or actual operating conditions is crucial. By subjecting the bonded materials to different temperature cycles and measuring any changes in bond strength or integrity, you can gain valuable insights into the epoxy’s performance.

Surface Preparation of Fiberglass and Plastic

Surface preparation is a crucial step when it comes to bonding fiberglass to plastic using epoxy. Properly preparing the surfaces ensures the best adhesion and long-lasting bond between the two materials.

The first step in surface preparation is cleaning the fiberglass and plastic surfaces. Any dirt, grease, or contaminants on the surfaces can hinder the bonding process. Start by wiping the surfaces with a clean cloth or paper towel to remove any loose debris. Then, use a mild detergent or soap mixed with water to clean the surfaces thoroughly. Rinse off the soap residue with clean water and allow the surfaces to dry completely before proceeding to the next step.

Once the surfaces are clean and dry, it is important to roughen them up slightly to enhance adhesion. This can be done using sandpaper or a sanding block with a medium grit (around 120 to 180 grit). Gently sand the surfaces in a circular motion, applying even pressure. The goal is to create a slightly rough texture on both the fiberglass and plastic surfaces, which will provide more areas for the epoxy to grip onto.

After sanding, it is crucial to remove any sanding dust or debris from the surfaces. Use a clean cloth or compressed air to blow away any loose particles. Even the tiniest speck of dust can interfere with the bonding process, so it’s important to ensure that the surfaces are free from any contaminants.

Next, it is recommended to wipe down the surfaces with a suitable solvent before applying epoxy. The choice of solvent depends on the type of plastic being used. For example, if you’re working with polyethylene or polypropylene plastics, which are notoriously difficult to bond, a solvent-based primer specifically designed for these plastics can greatly improve adhesion. On the other hand, if you’re working with other types of plastics like PVC or ABS, acetone or isopropyl alcohol can be used as solvents.

Apply the solvent using a clean cloth or sponge, making sure to cover the entire surface. This will help remove any remaining contaminants and further promote adhesion. Allow the solvent to evaporate completely before applying the epoxy.

lnTTcZv4B54″ >

Conclusion

In conclusion, finding the perfect epoxy to join fiberglass and plastic requires thoughtful consideration of multiple factors. The ideal epoxy will create a bond that is not only robust but also capable of withstanding the test of time.

When selecting an epoxy, it is crucial to take into account its compatibility with the specific type of plastic you are working with. Remember, not all epoxies are created equal, so carefully reading the manufacturer’s instructions and product specifications is paramount. Additionally, adhesive strength plays a vital role in determining which epoxy is best suited for your project. Some epoxies exhibit superior adhesion to certain plastics compared to others.

Consideration should also be given to curing time and temperature resistance. The curing time must align with your project requirements and timeline, while temperature resistance ensures that the bond remains unyielding even in extreme conditions.

Flexibility and chemical resistance may be crucial depending on the application at hand. Certain projects necessitate flexibility to endure movements or vibrations, while others demand resistance against chemicals or solvents.

Ease of use and safety precautions should not be overlooked when selecting an epoxy adhesive. Adhering to the manufacturer’s instructions and employing proper ventilation and personal protective equipment are essential for maintaining a safe working environment.

By comprehending the properties and characteristics of epoxy adhesives and taking these factors into account, you can confidently choose the best epoxy for uniting fiberglass with plastic.

You may also like: