Are you tired of struggling to find an adhesive that can effectively bond plastic surfaces? Look no further than epoxy adhesives. With their impressive bonding power, they have become a popular choice for plastic bonding projects. But with so many brands and variations available, choosing the right epoxy adhesive for your project can be tricky.

That’s where we come in. In this blog post, we’ll explore the best epoxy adhesives for plastic bonding. From discussing the different types of epoxy adhesives available to providing tips and tricks for achieving optimal results, we’ve got you covered.

We’ll also dive into the various plastic materials that can be bonded with epoxy adhesives, including polycarbonate, polypropylene, and PVC. Whether you’re a DIY enthusiast or a professional plastic fabricator, our informative journey will help you discover the perfect epoxy adhesive for your plastic projects.

So say goodbye to traditional adhesives that barely stick and hello to a strong and reliable option. Let’s get started on finding the best epoxy adhesive for your plastic bonding needs.

Types of Plastics and Their Surface Properties

Contents

- 1 Types of Plastics and Their Surface Properties

- 2 Strength Requirements for Different Applications

- 3 Factors to Consider When Choosing an Epoxy Adhesive

- 4 The Best Epoxy Adhesive for Plastic Bonding

- 5 Advantages of Using the Best Epoxy Adhesive for Plastic Bonding

- 6 Disadvantages of Using the Best Epoxy Adhesive for Plastic Bonding

- 7 Different Brands of Epoxy Adhesives Available on the Market

- 8 Conclusion

Plastics are widely used materials in various industries such as automotive, construction, electronics, and packaging. However, not all plastics are created equal, and their surface properties vary depending on the type of plastic. Understanding the surface properties of plastics is crucial in determining the best epoxy adhesive for plastic bonding.

There are two major categories of plastics

thermoplastics and thermosetting plastics. Thermoplastics can be melted and reshaped multiple times without altering their chemical structure. Some examples of thermoplastics include polyethylene, polypropylene, polystyrene, and PVC. On the other hand, thermosetting plastics undergo a chemical reaction during the manufacturing process and cannot be reshaped once they have hardened. Examples of thermosetting plastics include epoxy resins, phenolic resins, and melamine resins.

The surface properties of plastics include their surface energy, polarity, porosity, and roughness. Surface energy refers to the material’s ability to attract or repel other substances. Polarity is a measure of electrical charge distribution. Porosity refers to the presence of small holes or openings on the material’s surface. Roughness refers to irregularities on the material’s surface.

Different types of plastics have different surface properties that can affect their adhesion to epoxy adhesives. For example, high-density polyethylene (HDPE) has a low surface energy and is non-polar, making it difficult for epoxy adhesives to bond to its surface. In contrast, polycarbonate (PC) has a high surface energy and is polar, making it easier for epoxy adhesives to bond to its surface.

When selecting an epoxy adhesive for plastic bonding, it’s essential to consider the strength of the bond required and other factors such as temperature, humidity, and stress on the bond. The compatibility of the adhesive with the plastic’s surface properties is also crucial in achieving a strong bond.

In conclusion, understanding the surface properties of plastics is crucial in determining the best epoxy adhesive for plastic bonding. Different types of plastics have different surface properties that affect their adhesion to epoxy adhesives.

Strength Requirements for Different Applications

The answer lies in understanding the strength requirements for different applications. The strength of an adhesive refers to its ability to hold two surfaces together under stress or force, and the appropriate strength required for your application will depend on various factors.

For heavy-duty applications that require a high level of strength, such as bonding heavy plastic objects or those that will be subjected to constant stress or vibration, a two-part epoxy adhesive is often recommended. This type of adhesive has an incredibly strong bond and can withstand high levels of stress and strain. Additionally, it has excellent chemical resistance and is resistant to water and other environmental factors. If you’re working on a project that requires heavy lifting or constant movement, a two-part epoxy adhesive is the way to go.

However, if your project does not require as much strength, a single-component epoxy adhesive may be more suitable. These adhesives are easier to use since they do not require mixing, and they have a longer working time before they set. They are also more flexible than two-part epoxies, making them ideal for bonding materials that may expand or contract due to changes in temperature.

When selecting an epoxy adhesive for your project, keep in mind that not all epoxies are created equal, and some may work better for specific types of plastic than others. It’s essential to consult with the manufacturer’s recommendations or seek advice from a qualified expert before making a final decision.

Factors to Consider When Choosing an Epoxy Adhesive

There are several crucial factors to consider when choosing an epoxy adhesive for plastic, and I’ll walk you through each one.

Firstly, adhesion strength is a critical factor that determines whether the adhesive is robust enough to hold the plastic parts together. The adhesion strength depends on various factors, such as surface preparation, curing time, and the type of plastic. It’s essential to choose an epoxy adhesive that can provide a strong bond for your specific plastic material.

Secondly, curing time is another essential factor to consider. This refers to the amount of time it takes for the adhesive to harden and reach its full strength. The curing time varies depending on temperature, humidity, and type of epoxy adhesive. It’s crucial to choose an epoxy adhesive with a curing time that suits your application timeline.

Thirdly, consider the chemical resistance of the epoxy adhesive if the plastic parts will be exposed to harsh chemicals or solvents that could weaken or damage the adhesive over time. It’s vital to select an epoxy adhesive that can withstand any chemical exposure it may face.

Fourthly, high-temperature environments require specialized epoxy adhesives that can withstand heat without losing their bonding strength. Be sure to check product specifications before making a purchase and ensure that you choose an epoxy adhesive designed for high-temperature applications.

Lastly, flexibility is another factor to consider when selecting an epoxy adhesive. This is important if the plastic parts will be subjected to stress or movement as a rigid adhesive may crack or break under these conditions.

The Best Epoxy Adhesive for Plastic Bonding

Look no further than epoxy adhesives. These powerful and durable adhesives are the go-to choice for plastic bonding, but not all epoxy adhesives are created equal. To find the best one for your specific needs, consider the following factors:

- Adhesion Strength: The main reason for using an epoxy adhesive is to create a strong and long-lasting bond. Be sure to choose an adhesive with a high strength rating that is suitable for your application.

- Curing Time: Some epoxy adhesives cure faster than others, so consider how much time you have for your project and if a quicker curing time is necessary.

- Chemical Resistance: Depending on what chemicals the adhesive will come into contact with, it may need to have higher chemical resistance to prevent degradation over time.

- High-Temperature Suitability: If the bonded plastic will be exposed to high temperatures, make sure the epoxy adhesive can withstand such conditions without losing its strength or durability.

- Flexibility: Some plastics require a more flexible adhesive to prevent cracking or breaking under stress. Consider if flexibility is necessary for your application.

When it comes to specific products, Gorilla 2-Part Epoxy is one of the best all-around choices with excellent strength and versatility. This adhesive can bond different types of plastics and withstand extreme temperatures and water exposure. Loctite Epoxy Plastic Bonder is specifically designed for bonding plastics and has good resistance to water, chemicals, and impact. It can bond both rigid and flexible plastics. For an eco-friendly option, J-B Weld PlasticWeld Epoxy is non-toxic, easy to use, and can bond even difficult materials like polyethylene and polypropylene.

Advantages of Using the Best Epoxy Adhesive for Plastic Bonding

Plastics are ubiquitous in our daily lives, from household items to industrial components. However, their inherent properties often make them difficult to bond with other materials. This is where the best epoxy adhesive for plastic bonding comes in, offering a range of advantages that make it the go-to solution for various industries.

One of the most significant advantages of using the best epoxy adhesive for plastic bonding is its high strength. Epoxy adhesives create bonds that are stronger than the plastic itself, making them ideal for applications where the joint needs to withstand high stress and strain. Whether you’re dealing with heavy machinery parts or delicate medical devices, epoxy adhesives provide reliable and durable bonding.

Another crucial advantage of epoxy adhesives is their durability. They can withstand a range of environmental factors, including temperature changes, moisture, and chemicals. This makes them suitable for use in harsh environments where other types of adhesives may fail. Additionally, they offer excellent resistance against UV radiation and aging, making them ideal for outdoor applications.

Epoxy adhesives also offer remarkable versatility when it comes to bonding plastics. They can bond a wide range of thermoplastics and thermosetting plastics, as well as dissimilar materials like metals and ceramics. This makes them a popular choice in various industries, including automotive, aerospace, and consumer goods.

In terms of ease of use, epoxy adhesives are straightforward to apply and can be used in various ways, such as a liquid or paste. They also have a long working time, which allows for adjustments to be made before the adhesive sets. This makes them ideal for complex assemblies or projects that require precision and attention to detail.

While epoxy adhesives may be more expensive than other types of adhesives initially, their superior bonding strength and durability make them a cost-effective solution in the long run. By reducing the need for maintenance and repairs, manufacturers can improve the quality and reliability of their products and ultimately save money.

Disadvantages of Using the Best Epoxy Adhesive for Plastic Bonding

When it comes to plastic bonding, epoxy adhesives are often considered the best option due to their superior strength and durability. However, it’s important to be aware of the potential disadvantages associated with this adhesive type.

One major concern is the toxicity of the adhesive. Epoxy adhesives contain harmful chemicals that can be dangerous if inhaled or accidentally ingested. It’s crucial to handle these adhesives with care, wearing protective gear such as gloves and clothing to avoid skin contact.

In addition, epoxy adhesives require a long curing time. Unlike other adhesives that can bond quickly, epoxy adhesives can take several hours or even days to fully cure. This can be frustrating for those who need a quick fix or are working on a tight deadline.

Furthermore, removing epoxy adhesive can be difficult without damaging the plastic surface. If applied incorrectly or in the wrong location, it may require an extensive process to remove without damaging the underlying material.

Lastly, epoxy adhesives tend to be more expensive than other types of adhesives. While they do provide a stronger and more durable hold, the higher cost may not make sense for those on a tight budget or for small-scale projects.

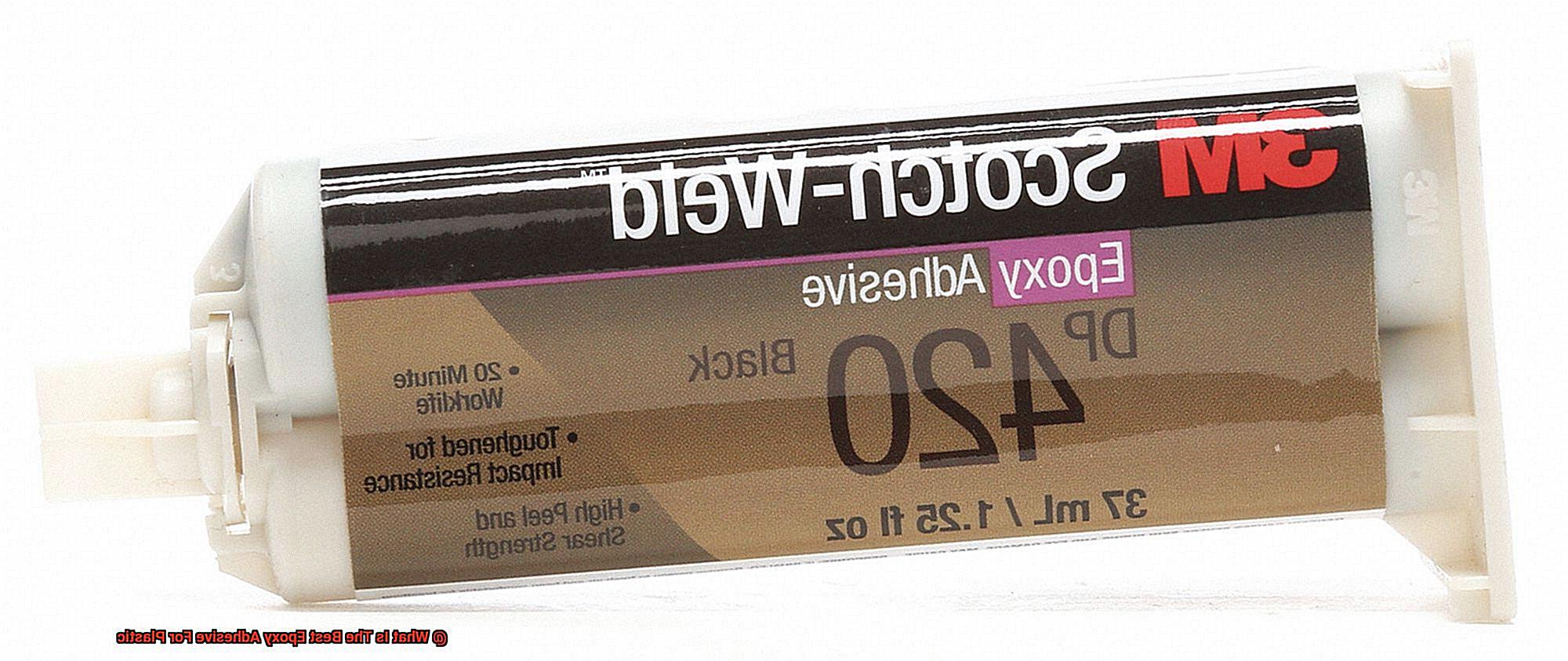

Different Brands of Epoxy Adhesives Available on the Market

If you’re looking for an epoxy adhesive for plastic, you’re in luck – there are plenty of brands to choose from on the market. However, with so many options available, it can be challenging to know which one is right for your project. Fear not, as an expert in this field, I’m here to help guide you through the process.

First on our list is the ever-popular Gorilla Epoxy. This brand is known for its strong and durable bond that can withstand extreme temperatures and harsh chemicals. Its clear finish makes it ideal for use on transparent plastics, ensuring a seamless finish. If you need an adhesive that won’t let you down in tough conditions, Gorilla Epoxy is an excellent choice.

Up next is J-B Weld, a well-known brand famous for its range of epoxy products. Its plastic adhesive sets in just five minutes and is waterproof, heat-resistant, and can handle a fair amount of stress. If time is of the essence and you need an adhesive that can handle heavy-duty wear and tear, J-B Weld should be at the top of your list.

If you’re looking for a specialized product designed specifically for bonding plastics, Loctite Epoxy Plastic Bonder is your go-to brand. Resistant to impact, shock, and vibration, it’s perfect for heavy-duty projects that require strength and durability. Loctite’s Plastic Bonder has been specially designed to work with all types of plastics and will ensure a reliable bond every time.

Another popular choice is Devcon Epoxy Plastic Welder. It forms a strong bond in just five minutes and can be sanded or painted over once cured. This brand offers versatility as it can be used on many types of plastics. If you need an adhesive that can handle everyday wear and tear, Devcon Epoxy Plastic Welder could be the perfect option for you.

Last but not least on our list is Permatex Fabric Repair Adhesive. Although not specifically designed for plastics, it’s still a great option if you need an adhesive that dries clear and waterproof. It’s perfect if you’re working with transparent plastics and need an adhesive that won’t alter the appearance of your project.

K9fXYmMffqs” >

Conclusion

In conclusion, choosing the right epoxy adhesive for plastic bonding may seem overwhelming, but it doesn’t have to be. Armed with the right knowledge and guidance, you can easily find an adhesive that will work perfectly for your project. It’s essential to understand the surface properties of plastics as they play a significant role in determining the best epoxy adhesive to use. Different types of plastics have varying surface properties that affect their adhesion to epoxy adhesives.

When selecting an epoxy adhesive, there are several factors to consider, including adhesion strength, curing time, chemical resistance, high-temperature suitability, and flexibility. The market offers some of the best brands such as Gorilla Epoxy, J-B Weld PlasticWeld Epoxy, Loctite Epoxy Plastic Bonder, Devcon Epoxy Plastic Welder and Permatex Fabric Repair Adhesive.

Epoxy adhesives offer numerous benefits over traditional adhesives such as high strength and durability. They are also versatile and easy to use in various ways. However, there are potential downsides associated with this type of adhesive like toxicity and long curing times.

Overall, using the best epoxy adhesive for plastic bonding guarantees a reliable and long-lasting bond that ensures project success. With careful consideration of all factors involved in selecting an epoxy adhesive brand that suits your specific needs, you can achieve optimal results for all your plastic bonding projects.