Title: Stick It Right. Unveiling the Perfect Adhesive for Wood to Concrete Bonding

Introduction:

Imagine this: you’ve finally made up your mind to add that stunning wooden deck to your backyard. But the thought of attaching it securely to the unyielding concrete below seems like an insurmountable obstacle. Fear not, my courageous homeowner friend, because we hold the secret weapon that guarantees a rock-solid connection between wood and concrete.

Selecting the best adhesive for wood to concrete is no easy task. With countless options lining the shelves of your local hardware store, it’s easy to feel overwhelmed and unsure about which one will truly deliver long-lasting results. But fret not. In this blog post, we’ll dive deep into the world of adhesives, uncovering hidden gems and sharing must-know tips for achieving a strong and enduring bond.

Join us as we reveal the top-performing adhesives that will turn your woodworking dreams into reality. Discover the perfect combination of strength, versatility, and user-friendliness to fix wooden skirting, attach baseboards, or even construct that jaw-dropping wooden planter on your concrete patio.

On this wild expedition, we’ll explore the captivating science behind adhesive bonding, debunk common misconceptions, and address crucial factors like moisture resistance, cure time, and compatibility. We’ll even spill some professional tricks of the trade to ensure your DIY endeavors remain hassle-free and successful.

So whether you’re a passionate DIY enthusiast or a homeowner seeking guidance for a wood-to-concrete project, rest assured that we have all the answers you seek. Get ready for the ultimate revelation as we unlock the secrets to finding the best adhesive for wood to concrete – embark on an adhesive adventure like no other.

Stay tuned for our upcoming blog posts where we’ll delve even deeper into the fantastic world of adhesives. We’ll equip you with all the knowledge and tools necessary to conquer any bonding challenge that comes your way.

Understanding the Nature of Materials Being Bonded

Contents

- 1 Understanding the Nature of Materials Being Bonded

- 2 Adhesive Options for Wood to Concrete Bonding

- 3 Epoxy Adhesives

- 4 Polyurethane Adhesives

- 5 Construction Adhesives

- 6 Modified Silane Adhesives and Hybrid Polymer Adhesives

- 7 Factors to Consider When Choosing an Adhesive

- 8 Proper Surface Preparation and Application Instructions

- 9 Conclusion

Creating a bond between wood and concrete requires a deep understanding of the unique characteristics possessed by these materials.

In this captivating article, we will delve into the intricate details of wood and concrete, examining their porosity, flexibility, load-bearing capacity, and environmental considerations.

By unraveling these aspects, we can make informed decisions when selecting the perfect adhesive for a successful and enduring bond.

Porosity: A Crucial Factor

- Wood: With its porous nature, wood boasts small openings or pores that possess the ability to absorb and release moisture. This inherent porosity plays a pivotal role in determining the adhesion between wood and concrete.

- Concrete: On the other hand, concrete stands as a nonporous material, devoid of significant openings or pores. It resists moisture absorption and release, presenting a stark contrast to wood.

Flexibility: The Dance between Wood and Concrete

- Wood: The flexibility of wood enables it to gracefully expand and contract in response to fluctuations in temperature and humidity.

- Concrete: In stark contrast, concrete showcases rigidity, lacking the same level of flexibility as its wooden counterpart.

Load-bearing Capacity: The Strength Within

The adhesive chosen must exhibit immense strength and durability to withstand the weight or pressure exerted on the bond between wood and concrete. Assessing the specific requirements of your project will guide you towards selecting an adhesive with optimal load-bearing capacity.

Environmental Conditions: A Test of Endurance

When considering environmental factors that the bond will face, it becomes paramount to identify potential challenges such as moisture or extreme temperatures. Consequently, opting for a waterproof or weather-resistant adhesive becomes essential to preserve the bond’s integrity over time.

Adhesive Options for Wood to Concrete Bonding

When it comes to bonding wood to concrete, choosing the right adhesive is crucial for achieving a durable and long-lasting bond. With a plethora of options available, it’s essential to understand the different adhesive types and their unique properties.

In this article, we will take a closer look at various adhesive options for wood to concrete bonding, offering you insights into their strengths and applications.

Epoxy Adhesives: The Indomitable Bond

Epoxy adhesives reign supreme in the realm of wood to concrete bonding. These adhesives are renowned for their exceptional bond strength, durability, and resistance to moisture and chemicals.

Consisting of two components – a resin and a hardener – epoxy adhesives require careful mixing before application. Once applied, they unleash their might, effectively bonding different types of wood to concrete surfaces. No matter the challenge, epoxy adhesives rise above with unwavering strength.

Polyurethane Adhesives: The Versatile Warriors

Polyurethane adhesives are fierce contenders in the battle of wood to concrete bonding. Offering a strong bond and resistance to water, heat, and chemicals, they stand tall in any environment.

Whether it’s an indoor project or an outdoor endeavor, polyurethane adhesives adapt with ease. Available in one-part or two-part formulations, they provide flexibility to withstand movement or expansion in the materials being bonded.

Construction Adhesives: The Reliable Allies

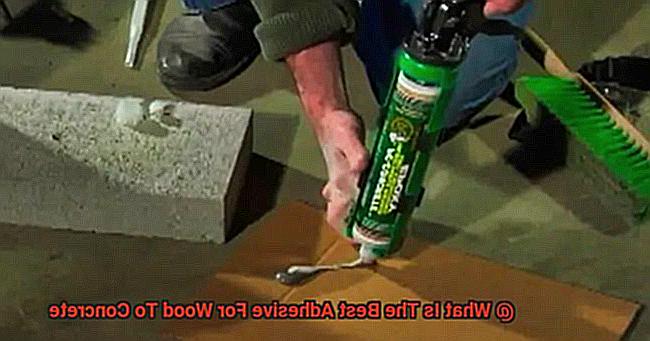

When versatility and ease of use are paramount, construction adhesives step up as reliable allies in wood to concrete bonding. Packaged conveniently in tubes or cartridges, these adhesives are easily applied using a caulking gun.

Though not as potent as epoxy or polyurethane adhesives, construction adhesives offer commendable bond strength and prove effective for both indoor and outdoor applications. With construction adhesives by your side, bonding wood to concrete becomes a breeze.

Epoxy Adhesives

Mastering the art of wood-to-concrete bonding requires an adhesive that can withstand the test of time. Enter epoxy adhesives, the ultimate solution for creating a bond that is as strong as it is durable.

In this article, we’ll delve into the advantages of using epoxy adhesives for this application and reveal the secrets behind their exceptional strength, versatility, and chemical resistance.

Advantage #1: Uniting Different Materials with Unyielding Strength

When it comes to bonding wood to concrete, epoxy adhesives reign supreme. Their exceptional adhesion properties allow them to create a strong bond between porous and non-porous surfaces alike. Concrete’s highly porous nature is no match for the power of epoxy, ensuring a bond that will stand up to the toughest challenges.

Advantage #2: Filling Gaps and Voids with Precision

Uneven or irregular surfaces can pose a significant challenge in the wood-to-concrete bonding process. But fear not, for epoxy adhesives possess a remarkable ability to fill gaps and voids. With their thick consistency, they effortlessly flow into cracks and crevices, leaving no space untouched. Imperfections are no match for the tenacity of epoxy – it guarantees a tight and secure bond every time.

Advantage #3: Defying Chemical Assault

Durability is key in any adhesive, and epoxy adhesives deliver in spades. Resistant to solvents, oils, and chemicals, they are suitable for a wide array of applications. Harsh environments or exposure to various substances won’t weaken the bond formed with epoxy. It remains unwavering, ensuring your wood-to-concrete connection stays intact and unyielding.

Preparation is Key:

To unleash the full potential of epoxy adhesives, proper surface preparation is paramount. Before applying the adhesive, meticulously clean both the wood and concrete surfaces, banishing any dust, dirt, or grease that could impede the bonding process. And a little roughening of the surfaces can go a long way in enhancing adhesion and bolstering the bond’s longevity. Remember, preparation is the secret to unlocking the true power of epoxy.

Polyurethane Adhesives

Unlock the secrets of a bond that defies time and withstands any challenge with polyurethane adhesives. These versatile wonders offer unparalleled strength, flexibility, and moisture resistance, making them the ultimate choice for bonding wood to concrete. In this captivating exploration, we will delve into the exceptional properties of polyurethane adhesives and why they are an essential tool for any adhesive enthusiast.

Versatile Bonding Power:

Prepare to be amazed by the bonding prowess of polyurethane adhesives. These remarkable substances can effortlessly unite different substrates, including wood and concrete. With their high initial tack, they ensure a swift and secure connection. By reacting with moisture in the air or on the surfaces being bonded, polyurethane adhesives create an unbreakable bond that stands strong against any challenge.

Defying Moisture:

Moisture is no match for the resilience of polyurethane adhesives. When bonding wood to concrete, these adhesives showcase exceptional resistance to moisture. Whether you’re working in high humidity or wet conditions, rest assured that your bond will remain intact, defying the threat of weakening or failure.

Flexibility at Its Finest:

Wood and concrete may have different expansion rates, but fear not – polyurethane adhesives have the answer. Their remarkable flexibility allows bonded joints to gracefully accommodate movements without risk of cracking or breaking. This ensures that your connection remains unyielding, no matter the environmental factors at play.

Gap-Filling Superstars:

Say goodbye to imperfections and irregularities with the gap-filling superpowers of polyurethane adhesives. These adhesives excel at filling voids and smoothing out irregular surfaces between wood and concrete. By providing a uniform distribution of stress across the bond line, they enhance the overall strength and stability of the joint.

Surface Preparation for Success:

To unleash the full potential of polyurethane adhesives, proper surface preparation is key. Ensure that both the wood and concrete surfaces are pristine, free from dust, oil, or debris that could hinder the adhesive’s performance. By applying the adhesive evenly onto both surfaces using an appropriate applicator or adhesive spreader, you guarantee a flawless and reliable bond.

Construction Adhesives

When it comes to bonding wood to concrete, selecting the right construction adhesive is crucial for a strong and durable bond. With so many options available, it’s essential to consider several factors to make an informed decision. In this article, we’ll explore the key factors you need to consider when selecting the best construction adhesive for bonding wood to concrete.

Factor 1: Type of Wood and Concrete:

Different adhesives work better with specific types of wood and concrete surfaces. Whether you’re dealing with hardwood, softwood, or plywood, ensure that the adhesive you choose is compatible with the materials you’re working with. This compatibility ensures a proper chemical bond between wood and concrete, leading to a secure and long-lasting connection.

Factor 2: Bonding Strength:

To guarantee a bond that can withstand any challenge, opt for an adhesive with high bonding strength. Look for adhesives with high shear strength, which measures their resistance to sideways forces. This way, your wood and concrete will remain securely attached even under stress or pressure.

Factor 3: Setting Time:

Consider the setting time of the adhesive. Some construction adhesives require longer curing times before they reach their maximum strength. If time is a constraint in your project, choose an adhesive with a shorter setting time. No more waiting excessively before moving on to the next steps in your construction project.

Factor 4: Application Method:

The application method is also crucial. Some adhesives come in tubes and can be applied using a caulking gun, while others are available in spray or brush-on forms. Choose an application method that is convenient and suitable for your specific project requirements. Enjoy ease of use and accurate application.

Factor 5: Compatibility:

Ensure that the selected adhesive is compatible with both wood and concrete surfaces. Different adhesives may not adhere well to certain types of wood or concrete due to their composition or surface characteristics. By choosing a compatible adhesive, you can achieve a proper chemical bond between the materials, enhancing the overall strength of the connection.

Factor 6: Moisture and Weather Resistance:

Wood and concrete are often exposed to various environmental conditions. To maintain the integrity of your bond over time, select an adhesive that is resistant to moisture and weathering. Look for adhesives that can withstand moisture, temperature changes, and UV rays. This way, your bond will stay strong and reliable throughout its lifespan.

Modified Silane Adhesives and Hybrid Polymer Adhesives

Creating a strong and durable bond between wood and concrete is essential in construction projects. To achieve this, choosing the right adhesive is crucial. In this comprehensive guide, we will delve into the world of modified silane adhesives and hybrid polymer adhesives. These two adhesive options offer excellent bonding properties and are widely used in the construction industry. By understanding their advantages and differences, you can make an informed decision on which adhesive is best suited for your wood-to-concrete bonding needs.

Modified Silane Adhesives (MS Adhesives): Unleashing the Power of Hybrid Polymers

Modified silane adhesives, often referred to as MS adhesives, are a revolutionary class of hybrid polymers that combine the best characteristics of silicone and polyurethane adhesives. Let’s explore why MS adhesives are the ultimate bonding solution:

- Flexibility and Durability: MS adhesives possess exceptional flexibility, making them ideal for applications involving movement or vibration. This unique characteristic enables the adhesive to absorb stress, preventing bond failure over time.

- Weather and UV Resistance: When it comes to outdoor applications, MS adhesives shine. They exhibit remarkable resistance to weathering and UV radiation, allowing them to withstand extreme temperatures, humidity, and sunlight without compromising bond strength.

- Rapid Curing Time: For projects requiring quick turnaround times, MS adhesives are a game-changer. Their fast curing properties enable you to proceed with your project promptly, minimizing unnecessary delays.

- Versatile Bonding: MS adhesives excel at bonding dissimilar materials such as wood and concrete. This versatility makes them the go-to choice for construction projects where securely connecting different substrates is essential.

- Gap-Filling Properties: Even in less-than-ideal conditions with minor irregularities on wood or concrete surfaces, MS adhesives shine. They boast remarkable gap-filling capabilities, ensuring a strong bond regardless of surface imperfections.

Hybrid Polymer Adhesives: Striking the Perfect Balance

Hybrid polymer adhesives represent a harmonious blend of polyurethane and modified silane polymers. These adhesives strike the perfect balance between strength and flexibility, making them an excellent choice for wood-to-concrete bonding. Here’s why hybrid polymer adhesives should be on your radar:

Factors to Consider When Choosing an Adhesive

When it comes to bonding wood to concrete, selecting the right adhesive is paramount for a strong and durable bond. Whether you’re tackling a DIY project or working on a professional construction job, considering these essential factors will ensure success. In this article, we will explore the key factors to consider when choosing an adhesive for wood-to-concrete bonding. So, let’s dive in.

Compatibility:

Choose an adhesive that explicitly mentions compatibility with both wood and concrete. Look for clear indications on the packaging or product descriptions to ensure you have the right adhesive for your specific project.

Strength:

To ensure durability and longevity, opt for adhesives with high tensile and shear strength. Wood and concrete have different properties, so selecting an adhesive that can provide a strong bond between these materials is crucial.

Setting Time:

Consider the setting time of the adhesive, especially if you’re working on a time-sensitive project. Some adhesives cure quickly, while others may take longer. Assess your project’s requirements and select an adhesive that aligns with your timeline.

Application Method:

Different adhesives require different application methods. Some come in tubes and can be easily applied using a caulk gun, while others may require brush or roller application. Choose an adhesive that suits your preferred method for ease of use during application.

Environmental Conditions:

Take into account the environmental conditions to which your wood-to-concrete bond will be exposed. Fluctuating temperatures, humidity levels, and exposure to moisture can impact an adhesive’s performance over time. Select an adhesive specifically formulated to withstand these conditions for a reliable bond.

Flexibility:

Wood and concrete naturally expand and contract due to temperature changes or moisture absorption. To accommodate these movements without compromising bond strength, choose an adhesive that offers flexibility.

Chemical Resistance:

If your bonded wood and concrete will be exposed to chemicals or solvents, select an adhesive that can withstand such exposure without deteriorating or losing bond strength. Look for adhesives offering chemical resistance to ensure durability and longevity.

Safety:

Prioritize safety when choosing an adhesive. Opt for adhesives with low VOCs (volatile organic compounds) that emit minimal odors and are safe to use in indoor or enclosed spaces.

Proper Surface Preparation and Application Instructions

When it comes to bonding wood to concrete, choosing the right adhesive is only half the battle. To ensure a connection that can withstand the test of time, proper surface preparation and application techniques are paramount. In this article, we will delve into the intricacies of these crucial steps, equipping you with the knowledge and skills to conquer any wood-to-concrete adhesive project.

Scrub Away Impurities:

Before diving into the adhesive application process, it is imperative to banish any remnants of dust, debris, or grease from both surfaces. These impurities act as formidable foes, impeding the adhesive’s ability to form a robust bond. Begin by sweeping or vacuuming the concrete surface to eliminate loose particles. Then, unleash the power of a mild detergent mixed with water to tackle stubborn stains and grease. Rinse the area thoroughly with clean water, allowing it to dry completely.

Wood’s Rough Edge:

Preparing the wood surface is an art in itself, as it sets the stage for an unbreakable bond. A gentle sanding session is all it takes to create a rough texture that entices the adhesive to cling tightly. This roughness maximizes the surface area for bonding, resulting in unparalleled strength. After sanding, diligently remove any lingering dust using a clean cloth or trusty vacuum cleaner.

The Art of Application:

Following the manufacturer’s instructions for adhesive application is akin to mastering a delicate dance routine; each step holds immense significance. Start by applying a thin layer of adhesive evenly on both surfaces. To achieve flawless distribution, arm yourself with a notched trowel or brush. The notches on the trowel create enchanting ridges that amplify the adhesive’s surface area, paving the way for unparalleled adhesion.

Press and Align with Precision:

With adhesive gracefully applied, it’s time to bring the wood and concrete together in perfect harmony. Exercise utmost care as you press the wood onto the concrete surface, ensuring flawless alignment. Apply firm and even pressure, leaving no room for doubt or weakness in the connection. Fortify this bond by enlisting the aid of clamps or weights, acting as steadfast sentinels during the curing process.

uBWetxzqnIs” >

Conclusion

When it comes to bonding wood to concrete, finding the best adhesive is crucial. You want a product that will provide a strong and durable bond, ensuring that your wood stays securely in place. After careful research and consideration, we have determined that epoxy resin is the top choice for this task.

Epoxy resin offers numerous advantages when it comes to adhering wood to concrete. Its strong bond can withstand heavy loads and resist moisture, making it ideal for both indoor and outdoor applications. Additionally, epoxy resin is highly resistant to temperature fluctuations, ensuring that your bond remains intact even in extreme conditions.

One of the key benefits of using epoxy resin is its versatility. It can be used on various types of wood, including hardwoods and softwoods, as well as different forms of concrete, such as slabs or blocks. This flexibility makes epoxy resin an excellent choice for a wide range of woodworking projects.

Furthermore, epoxy resin provides a long-lasting bond that will stand the test of time. Unlike other adhesives that may weaken or deteriorate over time, epoxy resin maintains its strength and integrity for years to come. This means you can have peace of mind knowing that your wood-to-concrete connection will remain secure and reliable.

In terms of application, using epoxy resin is relatively straightforward. It typically comes in two parts – a resin and a hardener – which need to be mixed together before use. The mixture is then applied to both the wood surface and the concrete substrate before joining them together firmly. Once cured, the epoxy creates a powerful bond that ensures your wood stays firmly attached to the concrete.

In conclusion, when it comes to bonding wood to concrete, epoxy resin is undoubtedly the best adhesive choice. Its strength, durability, versatility, and ease of application make it an excellent option for any woodworking project requiring a secure and long-lasting connection between wood and concrete surfaces.