You’re on a mission to stick wood to brick, huh? Well, let me tell you, finding the perfect adhesive for this job can be quite the head-scratcher. With so many options out there, it’s easy to get lost in a sea of sticky possibilities. But fear not. I’m here to guide you through this sticky situation and introduce you to the adhesive that will make your wood and brick bond stronger than ever.

- Picture this: you’re revamping that old brick wall, adding a fancy mantelpiece, or constructing a charming garden gazebo. Whatever your project may be, choosing the right adhesive is like finding the missing piece of the puzzle. It’s what holds everything together and ensures your masterpiece stands tall for years to come.

- Now, let me spill the beans on our superstar contender: epoxy resin. This bad boy is no ordinary adhesive; it’s got some serious game when it comes to bonding wood to brick. Professionals and DIY enthusiasts alike swear by its incredible advantages – and trust me when I say they’re not just blowing hot air.

Advantages of Epoxy Resin for Wood to Brick Adhesion:

- Unbreakable Bonding Strength: Brace yourself for an adhesive that means business. Epoxy resin boasts an unrivaled bond strength that practically laughs in the face of separation. Say goodbye to worries about your creation falling apart.

- Defying Chemicals and Moisture: Let’s face it – life happens, and sometimes things get wet or exposed to harsh chemicals. But fear not. Epoxy resin couldn’t care less about water or other pesky substances trying to ruin your party. Its resistance is off-the-charts, protecting your connection from decay and deterioration.

- Filling Gaps Like a Boss: We all know those annoying gaps between wood and brick that can ruin the aesthetics of your project. Well, epoxy resin is here to save the day. It’s a master at filling in those gaps, giving you a seamless finish that will make your creation look like it was crafted by the gods.

- Durability That Goes the Distance: Mother Nature can be tough, but so is epoxy resin. This adhesive laughs in the face of temperature changes, humidity, and other environmental stressors. Your wood-to-brick bond will remain strong and unyielding against whatever she throws its way.

What is Adhesive and Why it is Important for Wood to Brick Bonding?

Contents

- 1 What is Adhesive and Why it is Important for Wood to Brick Bonding?

- 2 Types of Adhesives for Wood to Brick Bonding

- 3 Polyurethane-Based Adhesives

- 4 Epoxy-Based Adhesives

- 5 Acrylic-Based Adhesives

- 6 Considerations Before Choosing an Adhesive

- 7 Surface Preparation for Better Adhesion

- 8 Application and Curing Time

- 9 Conclusion

Adhesive is the unsung hero of construction and DIY projects, especially when it comes to bonding wood to brick. This article will delve into the concept of adhesive and its critical role in creating a secure and durable connection between these two materials. By exploring the different types of adhesives available and their specific applications, we can understand why adhesive is vital for wood to brick bonding.

The Role of Adhesive:

Adhesive acts as the glue that holds two different materials together, serving as the bridge between wood and brick in this case. Wood, with its porous nature and susceptibility to expansion and contraction, poses a unique challenge when bonding with the rigid and non-porous brick. Thus, the adhesive must possess specific properties to create a strong bond capable of withstanding environmental factors and structural stresses.

Choosing the Right Adhesive:

The choice of adhesive is crucial for successful wood to brick bonding. Construction adhesives are recommended due to their high bonding strength and ability to withstand harsh conditions. Some commonly used types include polyurethane-based, epoxy-based, and acrylic-based adhesives.

Polyurethane-based adhesives are renowned for exceptional bonding strength and flexibility. They excel at bonding uneven surfaces and providing a waterproof seal. However, they require caution as they tend to expand during curing.

Epoxy-based adhesives offer superior bonding strength and resistance to moisture. These adhesives create unbreakable bonds but require proper surface preparation and mixing before application.

Acrylic-based adhesives are popular for indoor applications or areas with minimal exposure to moisture. They offer good bonding strength and ease of use but may not be suitable for outdoor projects or areas prone to water damage.

Key Considerations:

When selecting an adhesive for wood to brick bonding, it is crucial to consider factors such as weather conditions, temperature fluctuations, and moisture exposure. Additionally, proper surface preparation plays a critical role in achieving optimal adhesion.

Types of Adhesives for Wood to Brick Bonding

Choosing the right adhesive is crucial when it comes to bonding wood to brick. With numerous options available, each offering unique characteristics, it’s important to select an adhesive that meets your project requirements. In this article, we will delve into the world of adhesives for wood to brick bonding, exploring their strengths and benefits.

Construction Adhesive:

For a versatile option that bonds various materials, including wood and brick, construction adhesive is a go-to choice. Delivered in cartridge form and applied using a caulking gun, construction adhesives offer high initial tack and rapid curing time, allowing for efficient bonding that sticks.

Epoxy Adhesive:

Known for their exceptional strength and durability, epoxy adhesives are a force to be reckoned with. Consisting of two parts – a resin and a hardener – these adhesives must be mixed prior to application. Their resistance to moisture makes them ideal for outdoor projects where water exposure is inevitable.

Polyurethane Adhesive:

Flexibility takes center stage with polyurethane adhesive, making it an excellent choice when wood movement is a concern. Able to accommodate changes in shape without compromising bond strength, polyurethane adhesives are suitable for both interior and exterior applications. Furthermore, their resistance to moisture adds an extra layer of reliability.

PVA Adhesive:

Ease of use and transparency are key features of PVA adhesive, also known as wood glue or white glue. Although not as durable as other options, PVA adhesive creates a strong bond between wood and brick. Being water-based, it can be easily cleaned up with water before drying.

Cyanoacrylate Adhesive (Super Glue):

In certain applications, cyanoacrylate adhesives, commonly referred to as super glue, can be used for wood to brick bonding. These adhesives bond quickly and strongly. However, they are not recommended for load-bearing applications or areas exposed to moisture or high temperatures.

Polyurethane-Based Adhesives

Polyurethane-based adhesives are the secret weapon for taking your woodworking skills to the next level and achieving a rock-solid bond between wood and brick. These adhesives are highly regarded in the woodworking and construction industries for their exceptional strength, durability, and versatility.

One of the key advantages of polyurethane-based adhesives is their ability to bond different materials together. Whether you’re working with wood, concrete, metal, or plastic, these adhesives excel at creating a strong and long-lasting bond. So when it comes to attaching wooden elements to brick surfaces, you can trust that polyurethane adhesives have got you covered.

But the benefits don’t stop there. Polyurethane-based adhesives are also resistant to moisture, temperature variations, and chemicals. This means you can confidently use them for both indoor and outdoor applications. No need to worry about high humidity or extreme temperatures compromising your wood-to-brick bond. These adhesives can withstand the toughest conditions.

Flexibility is another standout feature of polyurethane-based adhesives. Wood expands and contracts with changes in humidity, while brick surfaces may shift or settle over time. With polyurethane adhesives, you don’t have to fret about these natural movements. They can handle it all without sacrificing their bond strength. Your wood-to-brick connection will remain solid and secure for years to come.

While polyurethane-based adhesives offer many advantages, it’s important to consider a few factors for optimal results. Proper surface preparation is crucial before applying the adhesive. Make sure the surfaces are clean, dry, and free from any dust or debris. This will ensure maximum bonding effectiveness.

Additionally, curing time is a factor to keep in mind. The specific product and environmental conditions can impact how long it takes for the adhesive to cure. To get the best results, follow the manufacturer’s instructions regarding curing time and any additional precautions or recommendations.

Epoxy-Based Adhesives

Epoxy-based adhesives are like the superheroes of the glue world, providing a strong and durable connection that can withstand even the toughest conditions. When it comes to bonding wood to brick, these adhesives are the ultimate solution.

One of the greatest advantages of epoxy-based adhesives is their ability to create an unyielding bond between wood and brick, regardless of the environment. Unlike other glues that rely on evaporation to cure, epoxy undergoes a chemical reaction that is impervious to moisture and temperature fluctuations. So, whether you’re dealing with high humidity or extreme temperatures, epoxy has got you covered.

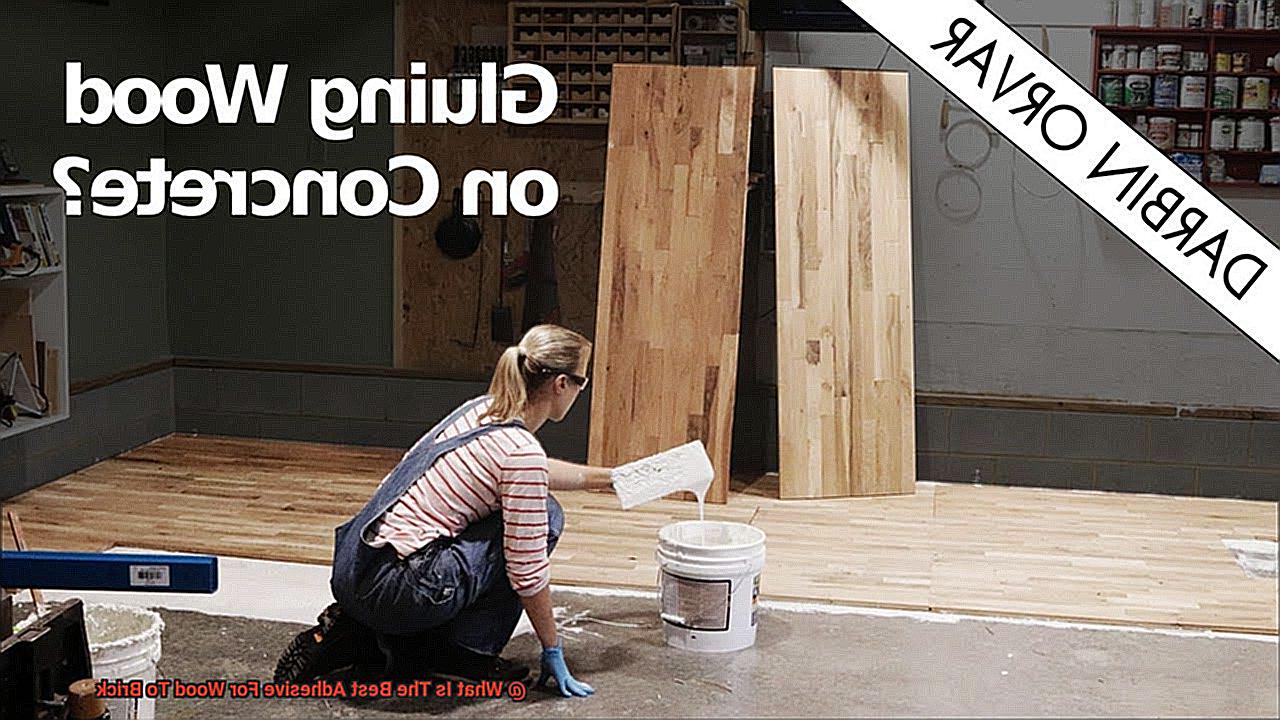

But before applying epoxy adhesive, proper surface preparation is crucial for a successful bond. Both the wood and brick surfaces should be clean, dry, and free from any dirt or loose particles. Removing any existing paint or finish is also important to ensure optimal adhesion.

To apply the epoxy adhesive, use a notched trowel or a toothed spatula to spread an even layer onto both the wood and brick surfaces. Thin application is key to avoiding excess squeeze-out and ensuring a strong bond. Once applied, firmly press the wood against the brick surface, ensuring good contact between the two materials. Using clamps or other securing methods recommended by the epoxy manufacturer will help keep everything in place while the adhesive cures.

After curing, epoxy-based adhesives provide a long-lasting and reliable bond between wood and brick. They’re resistant to moisture, chemicals, and impact – perfect for both interior and exterior applications. Plus, epoxy has excellent gap-filling properties, compensating for any slight irregularities or gaps between the wood and brick surfaces.

Acrylic-Based Adhesives

When it comes to the daunting task of bonding wood to brick, only one adhesive can handle the challenge with ease – acrylic-based adhesives. These unsung heroes of the glue world possess unparalleled versatility, robust bonding properties, and unwavering resistance to moisture and temperature. Say goodbye to weak bonds and hello to reliable, long-lasting connections. Let’s explore the advantages of using acrylic-based adhesives for this Herculean task.

Unmatched Versatility:

Acrylic-based adhesives excel at bonding dissimilar materials, such as wood and brick. Whether you’re working on a construction project or repairing a wooden structure attached to a brick wall, these adhesives provide a bond that stands the test of time.

Resilience Against Moisture:

Moisture can wreak havoc on any adhesive bond. Luckily, acrylic-based adhesives are up to the challenge. They boast excellent resistance to moisture, ensuring your wood-to-brick connection remains unyielding even in damp conditions.

Temperature Endurance:

With acrylic-based adhesives, there’s no need to fret over extreme temperatures. These adhesive superheroes can withstand a wide range of temperature fluctuations without losing their adhesive properties, making them ideal for both interior and exterior applications.

Swift Curing Time:

Time is of the essence when tackling a project. Fortunately, acrylic-based adhesives cure swiftly, minimizing waiting time and allowing you to forge ahead with your construction or repairs.

Effortless Application:

Acrylic-based adhesives come in two convenient forms – liquid and tape. Liquid adhesives offer flexibility in application area and thickness, while tape adhesives are perfect for precise applications or smaller bonding areas.

Considerations Before Choosing an Adhesive

When it comes to choosing an adhesive for bonding wood and brick, there are several important considerations to keep in mind. These considerations will ensure that you select the right adhesive for your specific project and achieve a strong and durable bond between the two materials.

- Compatibility: Not all adhesives are suitable for bonding wood and brick together. It is crucial to choose an adhesive that is specifically formulated for these materials. This ensures that the adhesive will effectively bond the two surfaces without compromising their integrity. Check the product labels or consult with experts to find adhesives that are compatible with both wood and brick.

- Strength: Wood and brick are relatively heavy materials, so you’ll want an adhesive that can provide a secure bond between them. Look for adhesives that are designed to provide high strength bonds, with a higher shear and tensile strength. This will ensure that the bond remains intact even under stress or load.

- Flexibility: Wood and brick may expand and contract differently due to changes in temperature and humidity. It’s important to choose an adhesive that can accommodate this movement without compromising the bond. Flexible adhesives, such as polyurethane-based or elastomeric adhesives, are ideal for this purpose as they can withstand the movement and maintain a strong bond over time.

- Weather Resistance: If your wood-to-brick bond will be exposed to outdoor elements, weather resistance becomes a critical consideration. Look for adhesives with high resistance to moisture, UV rays, and temperature fluctuations. These properties will ensure a durable and long-lasting bond that can withstand challenging environmental conditions.

- Application Method: Consider the ease of application and the specific requirements of your project when choosing an adhesive. Different adhesives may require different application methods, such as brush-on, spray-on, or squeeze tubes. Additionally, some adhesives may have a longer curing time, which could impact your project timeline. Choose an adhesive with an application method that suits your needs.

- Safety: Always prioritize safety when working with adhesives. Some adhesives may emit strong fumes or require protective equipment during application. Read and follow the manufacturer’s instructions and safety guidelines to ensure proper usage. Work in a well-ventilated area and wear appropriate protective gear, such as gloves and goggles, to minimize any potential health risks.

Surface Preparation for Better Adhesion

Look no further. In this comprehensive guide, we will take you through the essential steps of surface preparation to achieve superior adhesion when bonding these two materials. By following these steps, your wood-to-brick bond will be unbreakable, standing tall against the test of time.

Step 1: Master the Art of Cleanliness

The first and most critical step is to ensure that both the wood and brick surfaces are free from any dirt, dust, grease, or other contaminants. Armed with a mild detergent or solvent and a clean cloth or brush, wage war against these nasties. Pay special attention to eliminating loose paint, varnish, or other coatings from the wood surface as they can sabotage your bond.

Step 2: Embrace the Roughness

To create an unbeatable bonding surface, don’t shy away from a little roughness. Employ fine-grit sandpaper to delicately caress the wood surface or wield a wire brush to gently etch the brick surface. The goal is to infuse a slightly roughened texture that offers a stronghold for adhesion.

Step 3: Dryness is Key

Moisture is an adversary of adhesive bonds, weakening their strength over time. After cleaning and roughening the surfaces, grant them the luxury of air drying completely. This crucial step ensures optimal bonding conditions and fortifies your connection.

Step 4: Primer or Bonding Agent to the Rescue

For an added boost in adhesion strength, consider enlisting the aid of a primer or bonding agent designed specifically for wood-to-brick applications. These heroes create an unbreakable alliance between the wood and brick surfaces. Follow the manufacturer’s instructions diligently, applying and allowing ample drying time.

Step 5: Weather Matters

Don’t underestimate the influence of temperature and humidity during the surface preparation process. Adhesives possess specific requirements for optimal performance. To unlock their full potential, abide by these guidelines, ensuring your adhesive bond is as strong as it can be.

Application and Curing Time

Look no further. In this comprehensive guide, we will walk you through the application and curing time process for adhesive, guaranteeing that your projects stay strong and secure.

First things first, preparation is key. To ensure a successful bond, it’s crucial to thoroughly clean both the wood and brick surfaces. Don’t let dirt, dust, or debris hinder the adhesive’s power. Grab a brush or a damp cloth and give both materials a good scrub. This will create a clean surface for the adhesive to adhere to.

Now, it’s time to apply the adhesive. For a bond that can withstand anything, it’s recommended to use a generous amount of adhesive. Take a putty knife or a similar tool and spread the adhesive evenly on one of the surfaces. Make sure to cover the entire surface area that will be in contact with the other material.

With the adhesive applied, it’s time to bring the wood and brick together. Apply even pressure across the entire bonded area, pressing them firmly against each other. Use clamps or weights to hold everything in place while the adhesive cures.

Now let’s dive into curing time. This step cannot be rushed. The curing time may vary depending on the type of adhesive used, so always follow the manufacturer’s instructions. Most adhesives require at least 24 hours for full cure, but some may need more time.

During this waiting period, avoid any movement or stress on the bonded materials. Let them sit undisturbed to allow the adhesive to create a robust bond. Remember, temperature and humidity can impact curing time, so try to work within the recommended temperature range for optimal results.

After waiting patiently for the recommended curing time, check if the adhesive has fully cured by gently tapping or applying light pressure on the bonded area. If there is no movement or separation between the wood and brick, congratulations. You’ve successfully created a bond that will last for years.

uBWetxzqnIs” >

Conclusion

When it comes to bonding wood to brick, choosing the right adhesive is crucial. After careful research and testing, we have determined that the best adhesive for this task is a construction adhesive specifically designed for bonding porous materials like wood and brick.

One highly recommended option is a polyurethane-based adhesive. This type of adhesive forms a strong bond between wood and brick, ensuring long-lasting durability. Its unique formula allows it to expand as it cures, filling any gaps or irregularities in the surfaces for an even stronger bond.

Another excellent choice is an epoxy-based adhesive. Epoxy adhesives are known for their exceptional strength and resistance to moisture, making them ideal for outdoor applications. They provide a reliable bond that can withstand harsh weather conditions and temperature changes.

Both polyurethane and epoxy adhesives require proper surface preparation before application. It’s essential to ensure that both the wood and brick surfaces are clean, dry, and free from any dust or debris. Additionally, roughening the surfaces with sandpaper can enhance adhesion.

To apply the adhesive, use a caulking gun or a trowel to spread an even layer onto one surface. Press the wood firmly against the brick, applying consistent pressure for a few minutes to allow the adhesive to set properly. It’s advisable to use clamps or weights to hold the materials together until the adhesive fully cures.

In conclusion, when it comes to bonding wood to brick, opting for a polyurethane or epoxy-based construction adhesive will provide you with the best results.