Are your beloved leather shoes in need of a little TLC?

Contents

- 1 Types of Adhesives for Leather Shoes

- 2 Advantages and Disadvantages of Contact Cement

- 3 Advantages and Disadvantages of Epoxy Adhesives

- 4 Benefits of Shoe Repair Adhesives

- 5 Different Types of Leather Require Different Adhesives

- 6 Cleaning the Surfaces Before Applying the Adhesive

- 7 Testing the Adhesive on a Small Area First

- 8 Conclusion

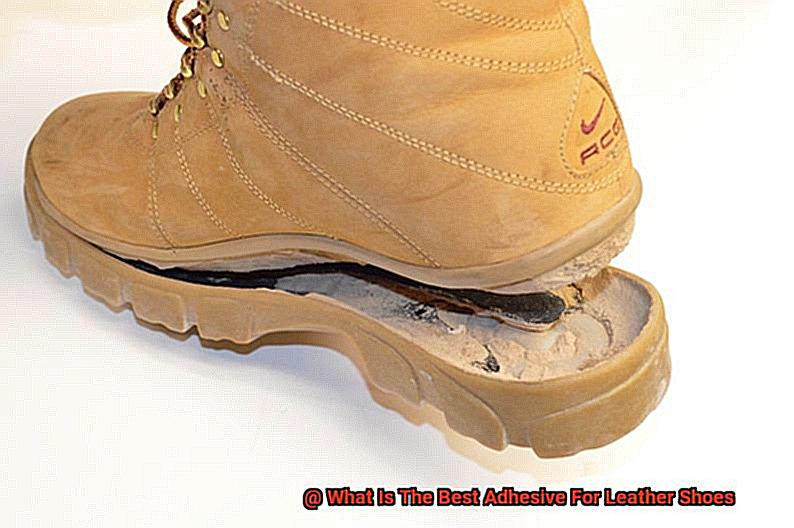

When it comes to fixing those pesky sole separations or patching up worn-out leather layers, finding the best adhesive for leather shoes is crucial.

We’ve all experienced the frustration of investing in a new pair of kicks, only to have them fall apart after a few wears. But fear not, my fellow shoe enthusiasts.

So stick around (pun intended) as we reveal the ultimate adhesive that will have you strutting confidently once again.

Types of Adhesives for Leather Shoes

When it comes to repairing or attaching leather shoes, using the right adhesive is crucial. There are several types of adhesives available, each with its own unique properties and benefits. In this guide, we will explore the different types of adhesives commonly used for leather shoes.

Contact Cement

This adhesive is a favorite among shoe repair enthusiasts. Contact cement is known for its strong and quick bond. It works particularly well for bonding leather to leather or leather to other materials.

To use contact cement, simply apply it to both surfaces, allow it to dry, and then press them together. The bond created by contact cement is permanent and resistant to heat and moisture.

Epoxy

If you need a strong and durable bond for your leather shoes, epoxy is a great choice. Epoxy adhesives consist of two components that need to be mixed together before application. Once mixed, the adhesive cures to form a strong bond that is resistant to heat, chemicals, and water. Epoxy is often used for bonding leather to hard surfaces like rubber soles or metal hardware.

Polyurethane

Polyurethane adhesives are known for their flexibility and resistance to impact. They can bond a wide range of materials, including leather, rubber, and plastic. While polyurethane adhesives require longer curing times compared to other types of adhesives, they provide excellent bond strength and durability.

Solvent-Based Adhesives

For more delicate or thin leather materials, solvent-based adhesives may be the preferred choice. These adhesives are often used in the production of high-end or luxury leather shoes. They provide a strong bond while still allowing some flexibility in the leather.

Shoe Glue

Specifically formulated for repairing shoes, shoe glue is designed to provide a strong and flexible bond. It is often used for fixing loose soles, tears, or detached parts of leather shoes. Shoe glue is a reliable option for quick and easy shoe repairs.

Rubber Cement

Rubber cement is a flexible adhesive that provides a temporary bond. It is useful for temporary fixes or adjustments on leather shoes. Rubber cement allows for easy repositioning and can be removed without causing damage to the leather.

When selecting an adhesive for leather shoes, consider factors such as the materials you are bonding, the intended use of the shoes, and the environment in which they will be worn. It’s also advisable to follow the manufacturer’s instructions for application and curing times to ensure optimal bond strength and longevity.

In conclusion, choosing the right adhesive for your leather shoes is essential for successful repairs and long-lasting results. Whether you opt for contact cement, epoxy, polyurethane, solvent-based adhesives, shoe glue, or rubber cement, make sure to select an adhesive that suits your specific needs and provides a strong and durable bond.

Advantages and Disadvantages of Contact Cement

This adhesive is a game-changer, offering a bond so strong it can withstand the daily rigors of bending and flexing. But like any product, contact cement has its pros and cons, and it’s important to know them before diving in.

Let’s start with the advantages. First and foremost, contact cement is known for its incredible bond. Once applied and dried, it creates a permanent connection that can handle anything your shoes throw at it. No more worrying about your repair or customization coming undone.

Not only does contact cement excel in bond strength, but it’s also incredibly versatile. Leather, rubber, fabric, wood – you name it, contact cement can adhere to it. Whether you’re fixing a sole or adding some flair to your shoes with embellishments, this adhesive has got you covered.

Time is of the essence when it comes to shoe repairs or modifications, and contact cement doesn’t disappoint. Unlike other adhesives that take hours or even days to dry completely, contact cement dries within minutes. That means less waiting time and more time strutting around in your newly transformed kicks.

Now let’s talk about the downsides. One major drawback of contact cement is its toxic fumes. When applying this adhesive, strong solvents are released into the air, which can be harmful if inhaled excessively or in poorly ventilated spaces. So be sure to work in a well-ventilated area or use respiratory protection to keep yourself safe and sound.

Another disadvantage is the difficulty of repositioning once the adhesive has been applied. Once those surfaces are pressed together with contact cement, it becomes quite the challenge to adjust their position. So plan meticulously and measure twice before committing to the bond.

Lastly, contact cement may not be the best choice for shoe parts that require significant flexibility. While it provides a strong bond, it lacks the flexibility needed for certain shoe components that experience bending or flexing. So keep this in mind when deciding whether to use contact cement for specific shoe applications.

Advantages and Disadvantages of Epoxy Adhesives

Choosing the right adhesive for bonding leather shoes is crucial for a successful repair or customization project. Epoxy adhesives have gained popularity due to their strength and versatility. In this article, we will delve into the advantages and disadvantages of using epoxy adhesives for leather shoes, allowing you to make an informed decision.

Advantages of Epoxy Adhesives:

Strong Bonding:

Epoxy adhesives are renowned for their ability to create robust and durable bonds. They chemically bond with the surfaces they are applied to, resulting in exceptional load-bearing capacity. This makes them ideal for leather shoes, as they can withstand the stress and strain experienced during regular use.

Versatility:

One of the remarkable characteristics of epoxy adhesives is their ability to bond various materials, including leather. Whether you’re working with metal, wood, plastic, or fabric, epoxy adhesives offer compatibility and reliability. This versatility ensures a secure bond that can withstand the flexing and movement of shoes.

Temperature Resistance:

Leather shoes often face exposure to high temperatures, whether from direct sunlight or walking on hot surfaces. Epoxy adhesives excel in handling these challenges by retaining their strength and bonding properties even under elevated temperatures. With epoxy adhesives, you can trust that the bonded parts will remain secure.

Chemical Resistance:

Leather shoes may come into contact with oils, solvents, or cleaning agents that could weaken or dissolve other types of adhesives. However, epoxy adhesives exhibit excellent resistance to various chemicals, ensuring the bond remains intact even when exposed to such substances.

Disadvantages of Epoxy Adhesives:

Curing Time:

One drawback of epoxy adhesives is their relatively long curing time. They typically require several hours or even days to fully cure and reach their maximum strength. This can be inconvenient when bonding leather shoes that need to be used or worn immediately after application.

Mixing Process:

Epoxy adhesives come in two parts – a resin and a hardener – which need to be mixed in specific proportions before application. Improper mixing can result in an ineffective bond or an incomplete cure. The mixing process requires careful attention to detail, which may pose a challenge for users who are not familiar with working with epoxy adhesives.

Lack of Flexibility:

While epoxy adhesives provide excellent bonding strength, they can be relatively rigid once cured. This lack of flexibility can become a disadvantage in applications where the bonded parts need to withstand constant movement or flexing, such as in leather shoes. The rigid nature of epoxy adhesives may lead to cracking or failure of the bond if subjected to excessive stress.

Benefits of Shoe Repair Adhesives

We all have that one pair of shoes that we simply can’t bear to part with. Whether it’s a cherished heirloom or a trendy designer piece, shoe repair adhesives are here to save the day. In this article, we will explore the numerous benefits of using shoe repair adhesives, compare different types of adhesives, and provide examples of how they can be used to fix shoes. So, let’s dive in.

Extend the Life of Your Shoes:

Say goodbye to throwing away your favorite shoes due to minor damages like loose soles or peeling leather. With shoe repair adhesives, you can easily fix these issues and extend the lifespan of your beloved footwear. This not only saves you money but also reduces waste and promotes sustainability.

Strong Bonding for Durable Repairs:

Shoe repair adhesives provide a strong bond between different shoe materials, ensuring that your repairs stay secure and durable. No more worrying about your sole falling off mid-stride. These adhesives enhance the structural integrity of your shoes, preventing further damage and allowing you to confidently put your best foot forward.

Versatility for All Shoe Materials:

Regardless of whether your shoes are made of leather, rubber, fabric, or synthetic materials, shoe repair adhesives have got you covered. From dress shoes to sneakers, boots to sandals, these versatile adhesives work their magic on all types of footwear.

Preserve Sentimental Value:

Some shoes hold sentimental value that cannot be replaced. Perhaps they were a gift from a loved one or a reminder of a special occasion. Shoe repair adhesives enable you to maintain the sentimental connection by restoring your cherished pair to its former glory.

Easy DIY Repairs:

You don’t need to be a professional cobbler to use shoe repair adhesives. These user-friendly products come with clear instructions, making it accessible for anyone to perform minor shoe repairs at home. No special tools required – just a little patience and some adhesive magic.

Preventative Measures:

Why wait for your shoes to fall apart? Shoe repair adhesives can be used as a preventative measure to reinforce weak areas before they become major issues. By applying adhesive to potential problem areas, such as seams or edges, you can save yourself from costly future repairs and keep your shoes in top-notch condition.

Quick Fixes for Emergency Situations:

Picture this: you’re about to head out when suddenly your shoe loses its sole. Panic sets in. Fear not, dear reader. Shoe repair adhesives are your lifesaver in such emergencies. They offer a quick and temporary fix until you can make a more permanent repair.

Comfortable and Flexible:

Shoe repair adhesives provide flexibility and elasticity, allowing the repaired area to move naturally with your feet. No more stiffness or discomfort – just comfortable strides all day long.

Different Types of Leather Require Different Adhesives

Leather is a versatile and popular material used in various products, including shoes, bags, and furniture. However, not all leathers are the same, and each type requires a specific adhesive to ensure a strong and durable bond. In this guide, we will explore the different types of leather and the appropriate adhesives that should be used for each, ensuring your leather goods stay intact and beautiful.

Genuine Leather – The King of Leather:

Genuine leather is the highest quality leather, renowned for its strength, durability, and natural beauty. To properly bond genuine leather, it is crucial to use high-quality glues specifically made for leather materials. These adhesives are formulated to provide a strong and long-lasting bond without causing any damage or discoloration to the leather surface. They also have excellent flexibility, allowing the leather to retain its natural movement and integrity.

Suede and Nubuck – Soft and Delicate:

Suede and nubuck leathers have a unique soft and velvety texture that requires special attention when it comes to adhesives. Regular glues may not bond well with these delicate fibers and can leave marks or residue on the surface. Instead, flexible adhesives like rubber cement or specialized suede glue are recommended. These adhesives are designed to be gentle on the delicate fibers of suede and nubuck, providing a secure bond without compromising their soft texture.

Full-Grain Leather – Tough as Nails:

Full-grain leather is known for its thickness, durability, and natural texture. Bonding this type of leather requires a strong adhesive that can withstand its heavy-duty nature. Polyurethane-based glues are often the adhesive of choice for full-grain leather. These adhesives offer excellent strength and durability, ensuring a secure bond that can withstand the rigors of daily use.

Patent Leather – Shiny and Tricky:

Patent leather is characterized by its glossy and reflective surface, which can be challenging to bond with regular adhesives. Using the wrong adhesive can result in a weak bond or even damage the shiny finish. Vinyl cement is specifically designed for bonding patent leather. It provides a strong and durable bond without compromising the glossy appearance.

Synthetic Leather – The Faux Option:

Synthetic leathers, such as PU or PVC, are popular alternatives to genuine leather. These materials have different properties and require specific adhesives for proper bonding. Polyurethane glue or adhesives formulated for synthetic materials are recommended for synthetic leathers. These glues provide a secure bond that is compatible with the unique characteristics of synthetic leather, ensuring your shoes or accessories stay intact and fashionable.

Cleaning the Surfaces Before Applying the Adhesive

Embarking on a shoemaking adventure? Before you dive into repairing your beloved leather shoes with the perfect adhesive, don’t skip an important step – cleaning the surfaces before applying the adhesive. Though it may seem tedious, taking the time to properly clean your leather shoe surfaces will make a world of difference in the strength and longevity of the bond.

Why is it crucial to clean the surfaces before applying the adhesive? Let’s explore two sub-topics that shed light on this matter:

Removing Dirt, Dust, and Oils:

- Dirt and dust may appear harmless, but they form a barrier between the adhesive and the leather surface, hindering a strong connection. By cleaning off these particles, you create a clean slate for the adhesive to work its magic.

- Oils from your skin or other sources can also impede the adhesive’s bonding ability. Cleaning the surfaces ensures there are no oily residues that could compromise the bond’s strength.

Creating an Optimal Bonding Environment:

- Adhesive works best on a clean surface. By removing dirt and oils, you allow the adhesive to directly contact the leather, maximizing its bonding potential.

- Soap residue can interfere with adhesive properties. Ensure thorough rinsing to eliminate lingering substances that could weaken the bond over time.

- Allowing the shoes to fully dry before applying adhesive eliminates moisture that could weaken the bond and lead to separation.

By following these cleaning steps, you set yourself up for success in achieving a strong and durable bond between your leather shoe surfaces. Not only will this extend your shoes’ lifespan, but it will also give you confidence in stepping out in style, knowing your repaired shoes will stay securely intact.

Testing the Adhesive on a Small Area First

Testing the Adhesive on a Small Area First: The Key to Successful Shoe Repair

When it comes to repairing leather shoes, using the right adhesive is essential. But how do you know if the adhesive you’ve chosen will provide a strong and durable bond? That’s where testing the adhesive on a small area first comes in.

Imagine this scenario: you’ve carefully selected an adhesive that claims to be perfect for leather shoe repair. You’re eager to revive your worn-out shoes and bring them back to life. However, what if the adhesive ends up damaging the leather or failing to stick properly? That’s a nightmare no shoe enthusiast wants to experience.

That’s why testing the adhesive on a small area first is so crucial. It allows you to assess its compatibility with the material and its performance before committing to the entire shoe repair process. Let’s delve deeper into why this step is vital:

- Avoid Potential Damage: Different adhesives can have varying reactions with leather. Some may cause staining, discoloration, or even damage to the material itself. By applying a small amount of adhesive to an inconspicuous area, such as the inside of the shoe or a hidden part, you can keenly observe how the adhesive interacts with the leather without risking any visible damage.

- Assess Performance: Testing the adhesive on a small area allows you to evaluate its performance. Does it provide a robust bond between the leather surfaces? Can it withstand pressure and stretching? Gently tugging at the bonded area gives you an idea of whether the adhesive is up to the task or if it falls short.

- Determine Compatibility: Different types of leather may require different adhesives. Genuine leather, synthetic leather, and suede all possess unique properties that may react differently to certain adhesives. By testing the adhesive on a small area, you can ensure that it is compatible with the specific type of leather you are working with.

Now that we understand why testing the adhesive on a small area first is essential, let’s explore how to do it properly.

Begin by thoroughly cleaning the area where you will apply the adhesive. Use a mild soap and water solution to remove any dirt or oils from the leather. Once the area is pristine and dry, apply a small amount of adhesive using a brush or applicator. Spread it evenly and allow it to dry according to the manufacturer’s instructions.

After the adhesive has dried, it’s time to assess its performance. Check if it has created a robust bond between the leather surfaces. Gently tug at the bonded area to see if it holds up well under pressure. Additionally, observe if there are any noticeable changes in color or texture of the leather.

dOS05PbEduM” >

Conclusion

When it comes to finding the best adhesive for leather shoes, there are several options to consider. However, one adhesive that consistently stands out from the rest is Shoe Goo. With its strong and durable formula, Shoe Goo provides a reliable bond that can withstand the toughest conditions.

Not only does Shoe Goo excel in its adhesive abilities, but it also offers additional benefits that make it the top choice for shoe repairs. Its flexible nature allows for natural movement without compromising the bond, ensuring long-lasting results. Whether you’re dealing with a small tear or a complete sole detachment, Shoe Goo has got you covered.

What sets Shoe Goo apart from other adhesives is its ability to create an invisible repair. Once applied, it seamlessly blends into the leather, leaving no unsightly traces of glue behind. You can confidently wear your repaired shoes without worrying about anyone noticing the fix.

Applying Shoe Goo is a breeze as well. The precision applicator makes it easy to control the amount of adhesive you need, minimizing any mess or waste. Simply squeeze out a small amount onto the affected area and let it dry for 24 hours. Once cured, your shoes will be good as new.

Whether you’re an avid hiker or just someone who wants their favorite pair of leather shoes to last longer, choosing the right adhesive is crucial. And when it comes to reliability, durability, and seamless repairs, Shoe Goo takes the crown as the best adhesive for leather shoes on the market.

So don’t let those worn-out soles or torn uppers hold you back from enjoying your favorite pair of leather shoes.