Rockets have always been the backbone of our quest to conquer the stars. But hidden beneath their mesmerizing thrusters and mind-boggling engineering lies a secret ingredient that holds it all together – plastic cement. Don’t let its humble name fool you, because in the world of rocket construction, plastic cement is a force to be reckoned with.

In this blog post, we’re diving headfirst into the fascinating realm of plastic cement for rockets. We’ll explore its purpose, perks, and how it’s revolutionized the way we design and build these jaw-dropping machines. Whether you’re a space geek, a hobbyist on the lookout for insider knowledge, or just someone hungry for insights into interstellar travel’s intricate mechanics, this exploration of plastic cement’s role in rocketry will leave you spellbound.

Plastic cement, also known as styrene cement or polystyrene cement, has become an absolute must-have tool in today’s aerospace industry. Its superpowers make it the go-to adhesive for securing vital rocket components, ensuring unshakable structure integrity and fuel efficiency that’s out of this world. While other bonding agents may have their merits, plastic cement reigns supreme thanks to its unrivaled versatility and unwavering reliability in space’s unforgiving conditions.

So strap in tight as we embark on an epic odyssey through the transformative power of plastic cement in rockets. We’ll unravel the mysteries behind this unsung hero of rocket construction – from its role in assembling thrusters to its impact on payload capability. Get ready to be captivated by the extraordinary wonders lurking beneath the surface as we journey beyond ordinary cement and into the extraordinary realm of space exploration.

What is Plastic Cement for Rockets?

Contents

- 1 What is Plastic Cement for Rockets?

- 2 Benefits of Using Plastic Cement for Rockets

- 3 How to Apply Plastic Cement for Rockets

- 4 Different Types of Adhesives Used in Rocketry

- 4.1 Epoxy Adhesives:

- 4.2 Epoxy adhesives consist of two parts – the resin and the hardener. When these two components are mixed together, a chemical reaction occurs, creating a strong and rigid bond. This makes epoxy ideal for bonding structural components like rocket fins, body tubes, and nose cones. Epoxy adhesives are also resistant to high temperatures, making them suitable for use in rocket engines.

- 4.3 Super Glue (Cyanoacrylate Adhesive):

- 4.4 Have you ever used super glue to fix something quickly? Well, rockets use it too. Super glue, also known as cyanoacrylate adhesive, is famous for its fast-drying properties. It bonds quickly and securely, making it perfect for small-scale repairs or attaching lightweight components.

- 4.5 Plastic Cement:

- 5 Factors to Consider When Selecting an Adhesive

- 6 Quick-Drying Formulas of Plastic Cement

- 7 Resistance to Vibrations and Shocks During Flight

- 8 Compatibility with Different Materials

- 9 Conclusion

The art and science of building and launching model rockets demands meticulous attention to detail, especially when it comes to selecting the ideal adhesive. Enter plastic cement for rockets, a specialized adhesive that plays a pivotal role in this exhilarating hobby. In this article, we will embark on an exploration of the world of plastic cement, uncovering its nature, functionality, and why it reigns supreme in rocketry.

What is Plastic Cement?

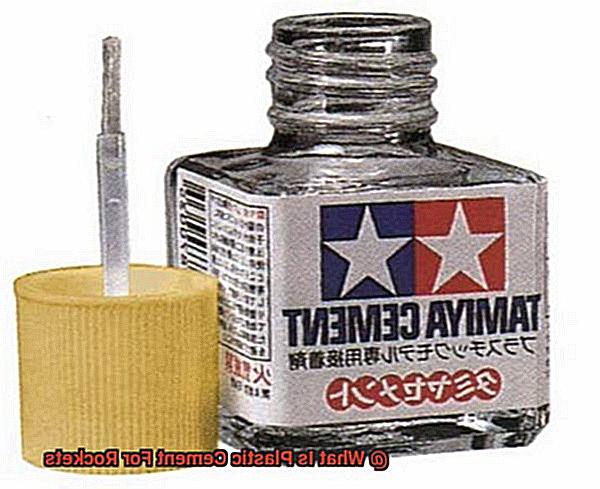

Plastic cement for rockets is a mesmerizing adhesive concoction designed to fuse plastic components together. Delivered in a liquid form, it is expertly applied using a brush or applicator. This adhesive wields solvents that work their magic by gently softening the plastic surfaces, allowing them to meld seamlessly when pressed firmly. When dried, plastic cement transforms into an unyielding bond capable of withstanding vibrations and shocks.

The Benefits of Plastic Cement:

- Strength and Durability: By creating robust and enduring bonds between plastic components, plastic cement ensures the rocket remains intact during launch and flight, unwavering even under the most intense forces and vibrations.

- Lightweight Solution: In the pursuit of optimal flight performance, weight plays a pivotal role. Plastic cement’s lightweight properties enable enthusiasts to keep their rockets as feather-light as possible, enabling them to soar to greater heights and achieve superior overall performance.

- Quick-Drying Formula: Time is of the essence in rocket assembly, and plastic cement rises to the occasion with its quick-drying formula. This accelerates the bonding process while minimizing the chances of misalignment or displacement, ensuring precision with each application.

- Compatibility: While plastic cement shines in bonding plastic parts, it may not be compatible with all materials employed in rocketry. It becomes vital to consider the adhesive’s compatibility with other materials like wood or metal and select suitable alternatives accordingly.

Safety Considerations:

When working with plastic cement, adherence to the manufacturer’s safety guidelines is paramount. Adequate ventilation in a well-ventilated area is essential due to the presence of solvents. Inhalation of large quantities of solvents should be avoided, as they can potentially pose harm.

Benefits of Using Plastic Cement for Rockets

Rocketry is an exhilarating field that demands precise construction and assembly for successful launches and safe flights. One of the unsung heroes in this realm is plastic cement, an extraordinary adhesive with a range of benefits for rocket builders. In this blog post, we will delve into the advantages of using plastic cement for rockets, including its seamless bonding abilities, versatility, rapid drying time, flexibility, and user-friendly application.

Seamless Bonding:

Plastic cement possesses a true mastery in creating secure and seamless bonds between plastic components. Unlike other adhesives, it chemically melts the plastic surfaces it encounters, forming a robust molecular bond. This results in joints that can endure the vibrations and shocks experienced during rocket launches, ensuring the rocket’s durability and structural integrity.

Versatility:

Rocket components often consist of various types of plastics, such as polystyrene, polypropylene, and PVC. Fortunately, plastic cement is a versatile adhesive that can bond these different materials together. This eliminates the need for multiple types of adhesives, streamlining the construction process and saving valuable time.

Rapid Drying Time:

Time is of the essence in rocket construction projects. Plastic cement comes to the rescue with its quick-drying formula. Once applied, it typically dries within minutes. This means less waiting around for the adhesive to cure, allowing for efficient assembly and reducing overall project duration. It’s perfect for time-sensitive projects or when working on multiple rockets simultaneously.

Flexibility:

Rockets endure intense stress and strain during flight. Plastic cement’s flexibility is a vital attribute in this regard. It enables the joints to withstand these forces without cracking or breaking, ensuring the overall structural integrity of the rocket. With plastic cement as your adhesive hero, you can confidently watch your rocket soar through the skies.

User-Friendly Application:

Whether you’re a seasoned rocket builder or a beginner, plastic cement is your trusty sidekick. It’s easy to use, requiring no mixing or special application techniques. Simply apply it directly from the tube or bottle using a brush or nozzle. This accessibility encourages greater participation and innovation in rocketry, ensuring that everyone can experience the thrill of building and launching their own rockets.

How to Apply Plastic Cement for Rockets

Building model rockets is an exciting hobby that combines science, engineering, and creativity. To ensure a strong and secure bond between plastic rocket components, it is essential to know how to apply plastic cement correctly. This specialized adhesive is designed specifically for bonding plastic parts together. In this step-by-step guide, we will walk you through the process of applying plastic cement for rockets, ensuring a sturdy and reliable connection for your rocket parts.

Step 1: Gather Your Materials

Before you begin, gather all the necessary materials. You will need plastic cement (available at hobby stores or online), the rocket parts you plan to assemble, sandpaper or a file, and clamps or tape if required.

Step 2: Prepare the Surfaces

To create a robust bond, take the time to prepare the surfaces that will be bonded. Start by cleaning the plastic parts to remove any dirt or grease. Then, use sandpaper or a file to roughen up these surfaces. This rough texture enhances the adhesive’s grip on the plastic, ensuring a secure bond.

Step 3: Apply the Cement

Squeeze a small amount of plastic cement onto one of the prepared surfaces. Using a toothpick or a small brush, spread an even layer of cement on this surface. Be mindful not to apply excessive glue, as it can result in messy bond lines.

Step 4: Joining the Parts

Carefully align and position the other plastic part onto the surface with applied cement. Press the parts firmly together and hold them in place for a few moments to ensure a secure bond. For larger or more complex rockets, you may need to use clamps or tape to hold the parts together while the cement sets.

Step 5: Drying Time

Patience is key. Allow the cement to dry according to the manufacturer’s instructions. Usually, this takes around 24 hours, but it’s always best to check the specific drying time for the plastic cement you’re using. Avoid rushing this step, as proper drying ensures a strong and durable bond.

Step 6: Finishing Touches

Once the cement has fully dried, use sandpaper or a file to remove any excess glue or rough edges. This will give your rocket a clean and professional appearance, ready for launch.

Different Types of Adhesives Used in Rocketry

They rely on a special kind of glue called adhesive. In this blog post, we will explore the different types of adhesives used in rocketry and how they help keep those rockets soaring through the sky.

Epoxy Adhesives:

Imagine a glue that is as tough as a superhero. That’s epoxy adhesive for you. Epoxy is known for its incredible strength and durability. It’s like the Hulk of adhesives. Rockets use epoxy to bond components that experience a lot of stress and vibrations during launch and flight. Once mixed, epoxy creates a super-strong bond that can withstand the harsh conditions of space travel.

Epoxy adhesives consist of two parts – the resin and the hardener. When these two components are mixed together, a chemical reaction occurs, creating a strong and rigid bond. This makes epoxy ideal for bonding structural components like rocket fins, body tubes, and nose cones. Epoxy adhesives are also resistant to high temperatures, making them suitable for use in rocket engines.

Super Glue (Cyanoacrylate Adhesive):

Have you ever used super glue to fix something quickly? Well, rockets use it too. Super glue, also known as cyanoacrylate adhesive, is famous for its fast-drying properties. It bonds quickly and securely, making it perfect for small-scale repairs or attaching lightweight components.

Cyanoacrylate adhesives work by reacting with moisture in the air to form a strong bond. They are commonly used in rocketry for bonding smaller components like electronics, wiring, or decorative elements. However, it’s important to note that super glue may not be as strong as epoxy, so it’s not suitable for heavy-duty applications or components that experience high levels of stress.

Plastic Cement:

Just like LEGO blocks, rockets have plastic parts that need to stick together. That’s where plastic cement comes in. This special adhesive is designed specifically for bonding plastic components. It works by dissolving the surface of the plastic, creating a chemical bond that fuses the pieces together. Plastic cement ensures that rocket fins and other plastic parts stay securely in place.

Plastic cement is often used in rocketry because it provides a strong and durable bond between plastic materials. It is particularly effective for bonding polystyrene plastic, which is commonly used in rocket construction. Plastic cement creates a chemical reaction with the plastic, resulting in a tight and long-lasting connection. It is also easy to apply and dries quickly, making it convenient for rocket builders.

Factors to Consider When Selecting an Adhesive

Rocket construction is a complex process that requires careful consideration of various factors, and selecting the right adhesive is no exception. Whether you’re a seasoned rocket scientist or just a curious space enthusiast, understanding the factors to consider when choosing an adhesive can help you appreciate the complexity and precision involved in building these incredible machines.

First and foremost, bond strength is crucial. Rockets experience intense forces and vibrations during launch, so the adhesive must be able to create a strong and durable bond between the materials being joined. A weak bond could lead to catastrophic failure, which is definitely not what you want to happen during a rocket launch.

Compatibility is another key factor. Different adhesives are designed to bond specific materials, so it’s important to ensure that the adhesive you choose is compatible with the materials you’re working with. Using an incompatible adhesive can result in weak bonds or even damage to the materials.

The application method of the adhesive also needs to be considered. Some adhesives come in liquid form, while others may be in the form of tapes or films. The application method should be suitable for the specific requirements of rocket construction, and factors like cure time and ease of application should also be taken into account.

Environmental conditions play a significant role in adhesive selection as well. Rockets are exposed to extreme temperatures, pressures, and humidity levels during their lifecycle. The selected adhesive should have good resistance to these environmental factors to ensure its performance and longevity.

Safety is always a top priority, especially when working with adhesives. Some adhesives may emit harmful fumes or require special precautions during application. It’s essential to carefully follow safety guidelines provided by the manufacturer to prevent accidents or health risks.

Last but not least, cost is an important consideration. While it’s crucial to choose an adhesive that meets the necessary requirements, cost-effectiveness should also be taken into account. Comparing different options and evaluating their performance, durability, and price can help make an informed decision.

Quick-Drying Formulas of Plastic Cement

Quick-drying formulas of plastic cement are a game-changer in the world of model rocketry. These adhesives are designed to dry rapidly, allowing for efficient and speedy assembly of rocket components. Unlike traditional glues that require lengthy drying times and clamping, plastic cement can be applied directly to the surfaces to be bonded and sets within minutes.

The key to the quick-drying nature of plastic cement lies in its unique formulation. Typically, these formulas consist of a mixture of solvents like acetone or toluene, along with a thermoplastic resin. When applied, the solvents evaporate rapidly, leaving behind a sticky residue that bonds the plastic parts together. The thermoplastic resin acts as a binder, providing strength and durability to the bond.

One of the major advantages of quick-drying plastic cement is its immediate handling capability. After application, you don’t have to wait around for hours or even days for the glue to set. You can continue working on your rocket right away. This is particularly beneficial in rocketry, where time is often of the essence during assembly and launch preparations.

Convenience and ease of use are also significant perks of quick-drying plastic cement. Its ability to be applied with precision and efficiency makes it ideal for small-scale projects like model rockets, where every second counts. You can easily and quickly bond the various components together without the need for clamping or excessive waiting.

However, it is important to note that while quick-drying formulas of plastic cement offer expedient bonding, they may not provide the same level of strength as slower-drying alternatives. So, if you prioritize maximum strength in your model rocket, you may need to sacrifice some speed and opt for a different adhesive.

Resistance to Vibrations and Shocks During Flight

Today, we delve into the fascinating world of resistance to vibrations and shocks during flight. Rockets face intense challenges, with vibrations and shocks threatening their structural integrity. But fear not, for there is a hero in this tale – plastic cement. This adhesive, designed specifically for bonding plastic components, plays a crucial role in ensuring the safety and stability of rockets during their thrilling flights.

So how does plastic cement work its magic? Let’s explore its remarkable qualities. First and foremost, it forms a strong and durable bond between plastic parts. Chemically bonding with the surfaces, it creates a connection that can withstand even the most intense vibrations and shocks. Talk about strength.

But that’s not all – plastic cement is also a master at absorbing and dissipating energy from these vibrations and shocks. By doing so, it reduces the impact on the rocket’s overall structure, safeguarding against potential damage or failure. It’s like having a trusty shield.

Flexibility is another fantastic quality of plastic cement. It absorbs and distributes stress throughout the bonded areas, minimizing localized points of strain. This flexibility ensures that the rocket can handle dynamic forces without compromising its structural integrity. It’s like having an acrobat on board.

Now let’s address temperature extremes. Rockets experience rapid heating during ascent and cooling during descent, posing a challenge for adhesives. But fear not. Plastic cement is formulated to withstand these fluctuations without losing its adhesive properties or undergoing deformation. It’s as resilient as an astronaut.

To achieve optimal performance, proper application techniques are key. Surface preparation is crucial – ensure those plastic parts are clean and free from contaminants. And don’t forget to use the right amount of cement and allow sufficient curing time. Patience pays off in the end.

Engineers and manufacturers continuously strive to improve plastic cements for rocket applications. They conduct rigorous experiments and simulations, testing different formulations under various flight conditions. It’s all about making rockets more reliable and durable. Kudos to those rocket scientists.

Compatibility with Different Materials

Rocket modeling is a captivating world of precision and creativity. It’s a hobby that demands attention to detail, especially when it comes to the compatibility of different materials used in the construction and assembly of rocket models. From plastics to metals and wood, each component plays a vital role in creating a successful rocket.

Plastic cement is the go-to adhesive for bonding plastic components in rocket modeling. It’s specifically formulated to create robust connections, ensuring the structural integrity of the model. However, not all materials are created equal, and it’s essential to consider compatibility to avoid any damage or weakening of the components.

When working with plastic cement, selecting the correct type is crucial. Different plastics have different properties, requiring specific adhesives. For example, polystyrene, with its smooth surface, can be bonded using regular plastic cement. But ABS, with its slightly rough surface, may need a more aggressive cement or some surface preparation like sandpaper roughening.

But rocket models aren’t just made of plastics; they embrace other materials too. Metal or wood components add diversity and challenge to the construction process. However, plastic cement might not be suitable for bonding these materials together. That’s when specific adhesives designed for metal or wood come into play, ensuring proper adhesion and compatibility.

To navigate this intricate web of compatibility considerations, manufacturers provide recommendations on which adhesive to use for specific materials or components. By carefully following these instructions, you can ensure that your rocket model is built to withstand the forces of its thrilling flights.

Of course, safety should always be a priority when working with plastic cement. Proper ventilation is essential, as the solvents present in the adhesive can be harmful if inhaled or exposed to the skin for prolonged periods. Additionally, it’s crucial to handle the adhesive with care and avoid contact with eyes or ingestion.

55-lQ2-5dgI” >

Conclusion

In conclusion, plastic cement for rockets is a crucial component in the construction and assembly of these powerful space vehicles.

Its unique properties make it an ideal adhesive for joining various parts of a rocket together, ensuring structural integrity and stability during launch and flight. With its strong bonding capabilities, plastic cement creates a reliable seal that prevents leakage of fuel or other vital fluids.

Whether it’s securing fins, attaching payloads, or reinforcing joints, plastic cement plays a vital role in the success and safety of rocket missions.