Laminate surfaces are everywhere these days, from the kitchen to the office. But finding a glue that will stick to them can be a real headache. If you choose the wrong adhesive, your laminate could start peeling or slipping, and before you know it, your beautiful surface is ruined. That’s why it’s essential to pick the right glue for your project.

The good news is that there are many types of adhesives that can bond successfully with laminate surfaces. You’ve got cyanoacrylate, contact cement, epoxy, and PVA glue – each with its own unique strengths and weaknesses. The key is choosing the one that will work best for your specific application.

In this blog post, we’ll go over all the different types of glue that can bond with laminate surfaces in detail. We’ll talk about their pros and cons and give you tips on how to choose the best adhesive for your project. Plus, we’ll share some expert advice on preparing your laminate surface correctly, applying the glue properly, and ensuring a long-lasting bond.

Whether you’re a seasoned pro or just starting out with DIY projects, this guide has everything you need to know about what glue will stick to laminate. So get ready to become an expert at bonding those pesky laminates once and for all.

Different Types of Laminate

Contents

- 1 Different Types of Laminate

- 2 Adhesives for High-Pressure Laminate (HPL)

- 3 Adhesives for Low-Pressure Laminate (LPL)

- 4 Manufacturer’s Recommendations for Adhesives

- 5 Preparing the Surfaces Before Applying the Adhesive

- 6 Proper Application of the Adhesive

- 7 Pros and Cons of Solvent-Based and Water-Based Adhesives

- 8 Tips for Choosing the Right Glue for Laminate

- 9 Conclusion

Laminate is a popular flooring option that is made from synthetic materials. From commercial buildings to residential homes, it’s available in various types, each with its own unique characteristics.

Here, we’ll take a closer look at the different types of laminate and what sets them apart.

High-Pressure Laminate (HPL)

High-pressure laminate (HPL) is the most durable type of laminate available. It’s created by layering multiple sheets of kraft paper impregnated with resin and bonding them together under high pressure and heat. HPL is known for its strength and scratch resistance, making it ideal for heavy-duty applications in public buildings, hospitals, and schools.

Low-Pressure Laminate (LPL)

Low-pressure laminate (LPL) is commonly used in residential settings such as houses and apartments. It’s made by fusing a thin layer of decorative paper onto a fiberboard using heat and pressure. LPL is less durable than HPL but is also cheaper and easier to install.

Direct Pressure Laminate (DPL)

Direct pressure laminate (DPL) is similar to LPL but has a thicker resin layer that makes it more durable. DPL is often used for residential applications and comes in a wide range of colors and patterns.

Waterproof Laminate

Waterproof laminate is designed to resist moisture, making it ideal for use in bathrooms and kitchens. It won’t buckle or warp when exposed to water, making it an excellent choice for areas with high humidity levels.

Anti-Bacterial Laminate

Some laminates come with anti-bacterial properties that make them suitable for use in healthcare facilities or other environments where hygiene is critical. These laminates are easy to clean and help prevent the spread of harmful bacteria.

Melamine

Melamine is a type of laminate commonly used in the manufacturing of furniture, shelving, and kitchen cabinets. It’s known for its moisture resistance, durability, and easy-to-clean surface.

When selecting the right type of laminate for your project, it’s essential to consider factors such as durability, appearance, and maintenance requirements. Each type of laminate has its unique properties, which make them suitable for different settings.

Adhesives for High-Pressure Laminate (HPL)

HPL is a laminate made of several layers of paper or fabric impregnated with resin and compressed under high pressure, resulting in a dense and hard-wearing material.

When it comes to choosing the right adhesive for HPL, there are various options available, including contact adhesives, PVA adhesives, and epoxy adhesives. Each type of adhesive has its own unique advantages and disadvantages, which must be considered before making a decision.

Contact adhesives are commonly used because they provide an instant bond and do not require clamping. However, they can be challenging to work with due to their strong initial tack, and any mistakes during application cannot be corrected easily. So, if you’re comfortable working with strong adhesives and require an instant bond, contact adhesives might be the best choice for your project.

PVA adhesives are another popular option that is easy to use and clean up with water. They have a longer open time than contact adhesives, allowing for adjustments before the bond sets. However, they require clamping for at least one hour, which may be inconvenient for some projects.

Epoxy adhesives provide an incredibly strong bond and are suitable for bonding HPL to various substrates, including metal and concrete. They offer excellent resistance to impact and moisture, making them ideal for high-stress applications. However, they have a longer curing time than other adhesives.

When selecting an adhesive for HPL, it’s essential to consider the substrate’s compatibility, the strength of the bond required, and the application method. It’s also crucial to follow the manufacturer’s instructions carefully to ensure a successful bond.

Adhesives for Low-Pressure Laminate (LPL)

When it comes to Low-Pressure Laminate (LPL), you want an adhesive that will provide a strong and lasting bond. LPL is a thin layer of decorative paper or vinyl that is bonded to a substrate using heat and pressure. It’s commonly found in furniture, countertops, and flooring. As an expert in the field, I’m here to guide you through the different types of adhesives available for LPL.

The most popular adhesive for LPL is contact cement. This versatile adhesive is applied to both the substrate and the back of the LPL. Once it dries, the two surfaces are pressed together, creating a strong bond. The advantage of contact cement is that it provides an instant bond without clamping, making it a convenient and efficient option. However, it’s important to note that contact cement may not hold up well in high-moisture environments.

Another widely used adhesive for LPL is PVA glue. This water-based adhesive is easy to apply and dries clear. It’s not as strong as contact cement but allows for adjustments before the bond sets. PVA glue is also more affordable than contact cement and can be found at most hardware stores. However, it’s not recommended for high-moisture environments.

Epoxy and cyanoacrylate (super glue) adhesives can also be used for LPL, but they are generally less popular due to their higher cost and more difficult application process. Epoxy adhesives offer excellent resistance to impact and moisture but require a longer curing time. Super glue dries quickly but may not provide a strong enough bond for larger LPL projects.

It’s essential to remember that not all adhesives will work with LPL. Some types of adhesive, such as silicone or acrylic, may not adhere properly or may damage the surface of the laminate. It’s always best to consult with the manufacturer or a professional before selecting an adhesive for LPL.

Manufacturer’s Recommendations for Adhesives

In our previous section, we explored the different types of adhesives available for Low-Pressure Laminate (LPL). But today, we’ll be discussing why it is crucial to follow the manufacturer’s recommendations for adhesives when installing laminate.

To ensure a strong and durable bond between the laminate and substrate, it is always essential to check the manufacturer’s recommendations. These recommendations are usually found on the packaging or in the instructions provided with the laminate. Following them will prevent any damage to the laminate or substrate and ensure a successful installation.

Most importantly, using the wrong type of adhesive can lead to a weak bond between the laminate and substrate. This could result in the laminate peeling or lifting over time, making it necessary to replace it sooner than expected. By following the manufacturer’s recommendations, you can ensure a robust and long-lasting bond that can withstand everyday use.

Manufacturers typically recommend using a solvent-based adhesive like contact cement or rubber cement. These adhesives provide a strong and durable bond that can withstand significant wear and tear. However, solvent-based adhesives should be used in a well-ventilated area, and proper safety precautions should always be taken.

In some cases, manufacturers recommend using a specific type of adhesive based on the type of laminate being used. High-pressure laminates may require a different type of adhesive than low-pressure laminates. Following these specific recommendations will ensure optimal performance and longevity of the laminate.

Lastly, some manufacturers may recommend using a specific brand of adhesive because certain adhesives may have different properties or ingredients that could potentially damage the laminate or substrate. Using a recommended brand will ensure compatibility and prevent any potential issues.

Preparing the Surfaces Before Applying the Adhesive

Preparing the surfaces before applying the adhesive is a crucial step in ensuring that your laminate flooring or any other project stays put for years to come. The following steps will guide you on how to prepare the surfaces effectively to make sure that the glue will stick to your laminate.

Firstly, cleaning the surface is an essential step in preparing surfaces. It is essential to remove any dirt, dust, or debris on the surface as it can prevent the adhesive from sticking correctly. Using a clean, dry cloth or a soft-bristled brush, remove any loose particles and dirt from the surface.

Next, use a mild detergent solution to clean the surface thoroughly. This will help remove any grease, oil, or other contaminants that may be present on the surface. Rinse the surface well with clean water and allow it to dry completely before proceeding.

Once the surface is clean and dry, it’s time to roughen it up a bit. This will help the adhesive bond more effectively to the surface. Use a fine-grit sandpaper or sanding block to lightly sand the surface. Be sure to sand in the direction of the grain of the laminate.

After roughening up the surface, it’s time to prime it. Applying a thin layer of primer using a brush or roller will help improve the bond between the laminate and adhesive. Allow it to dry completely before proceeding.

Finally, before applying any adhesive, make sure that both surfaces are at room temperature. Temperature can affect the performance of adhesives, so it’s essential to ensure that both surfaces are at the same temperature before applying any glue.

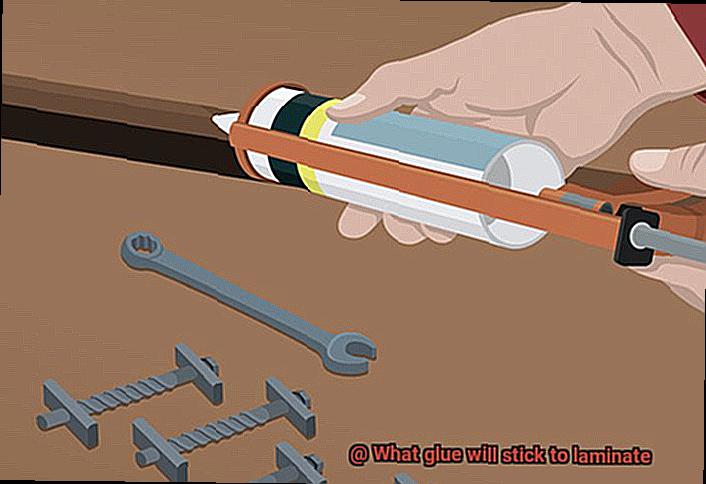

Proper Application of the Adhesive

If you’re planning to install laminate flooring or stick laminate onto a surface, then you need to know how to apply adhesive properly. Proper application of adhesive is essential to ensure that laminate adheres correctly to a surface and stays put for years to come. Here are some tips to help you get it right.

Prepare the Surface:

Before applying the adhesive, make sure that your surface is clean and free of debris. Use a cleaning solution recommended by the manufacturer and let the surface dry completely before proceeding with the adhesive application.

Use a Notched Trowel:

When applying the adhesive, use a notched trowel to spread it evenly across the surface. The size of the notches on the trowel will depend on the thickness of the laminate being used. Apply enough adhesive to ensure full coverage, but avoid over-applying as this can cause air pockets and bubbles under the laminate.

Align Correctly:

Once the adhesive has been applied, carefully place the laminate onto the surface, making sure that it is aligned correctly. Proper alignment is key, as it will affect the overall look and feel of your project.

Eliminate Air Pockets:

Use a roller or similar tool to press down firmly on the laminate, ensuring that it adheres properly to the surface and that any air pockets are eliminated. Over-applying adhesive can cause air pockets and bubbles under your laminate that will undermine the integrity of your project.

Allow Sufficient Drying Time:

It is important to allow sufficient time for the adhesive to dry completely before subjecting the surface to any stress or pressure. This can take anywhere from several hours to a full day depending on the type of adhesive used and environmental factors such as temperature and humidity.

Pros and Cons of Solvent-Based and Water-Based Adhesives

Solvent-based adhesives are renowned for their incredible bonding capabilities. They dry quickly and can be used in various temperatures, making them ideal for outdoor projects. However, there is a significant drawback to using solvent-based adhesives; they emit toxic fumes that can pose serious health risks.

For this reason, it’s crucial to use them in well-ventilated areas and with proper safety equipment.

Additionally, they require special storage conditions and need careful handling.

Water-based adhesives are an excellent alternative to solvent-based adhesives. They are environmentally friendly and have a longer shelf life. One of the most significant benefits of water-based adhesives is that they do not emit toxic fumes, making them safe to use in enclosed spaces.

They can also be easily cleaned up with water and do not require any special ventilation during use. However, they may take longer to dry up and may not create a bond as strong as solvent-based adhesives.

When choosing between solvent-based and water-based adhesives, several factors must be considered. If you require a highly robust bond, solvent-based adhesives are the best option. However, you must ensure that they are used in an open space with proper ventilation and safety precautions. If your project is in an enclosed space or environmental concerns are a priority, then water-based adhesives are the way to go.

Tips for Choosing the Right Glue for Laminate

When it comes to choosing the right glue for your laminate project, there are several factors to consider. Here are some tips to help you make an informed decision:

Label Check

The first step is to check the label of the glue. It’s crucial to choose a glue specifically designed for use with laminate materials. Not all adhesives available in hardware stores are suitable for bonding laminate surfaces. So, make sure the label mentions that it can be used on laminate surfaces.

Consider the Type of Laminate

Laminate surfaces come in different textures and finishes. High-pressure laminate (HPL) has a smooth surface, while low-pressure laminate (LPL) has a more textured surface. It’s essential to consider the type of laminate you will be working with and choose a glue that is suitable for that particular surface.

Adhesive Properties

Different types of glue have different adhesive properties. Some are better suited for porous surfaces, while others work better on non-porous surfaces. It’s crucial to choose a glue that is appropriate for the surface you will be bonding.

Drying Time

The drying time of the glue can vary depending on the type of glue you use. Make sure to choose a glue that dries within a reasonable amount of time so that you can work efficiently. Waiting too long for the glue to dry can be frustrating and delay your project.

Ease of Use

Some glues require special tools or techniques for application, while others are more straightforward. Consider how easy it is to use the glue and whether it requires any special equipment before making your choice. Choosing a user-friendly glue will save you time and effort in the long run.

Testing

Before starting any major project, it’s always best to do a small test to ensure that the glue works as expected and provides a strong bond. A small test will prevent you from making costly mistakes and ensure that your project turns out exactly as planned.

xyKG5sAtNJo” >

Conclusion

To sum it up, the search for the perfect glue for your laminate project can be overwhelming. But fret not, as there are numerous options available that can provide a sturdy and durable bond. Be it high-pressure laminate (HPL) or low-pressure laminate (LPL), you can choose from a variety of adhesives like contact cement, PVA glue, epoxy, and cyanoacrylate.

However, selecting an adhesive is not as simple as picking one off the shelf. You need to consider factors such as substrate compatibility, drying time, ease of use, and adhesive properties. Don’t forget to follow the manufacturer’s instructions precisely and prep the surfaces correctly before applying any adhesive.

In conclusion, finding the right glue for your laminate project is crucial to ensure longevity. By following our expert advice on what glue will stick to laminate and taking into account all the different variables involved in selecting an adhesive, you’ll be well-equipped to tackle those pesky laminates with confidence.