Ever pondered over the mystical glue that can effortlessly adhere to acrylic sheets? Well, wonder no more. Brace yourself for an awe-inspiring journey into the captivating realm of adhesion, where we uncover the hidden truths behind bonding these mesmerizing transparent wonders.

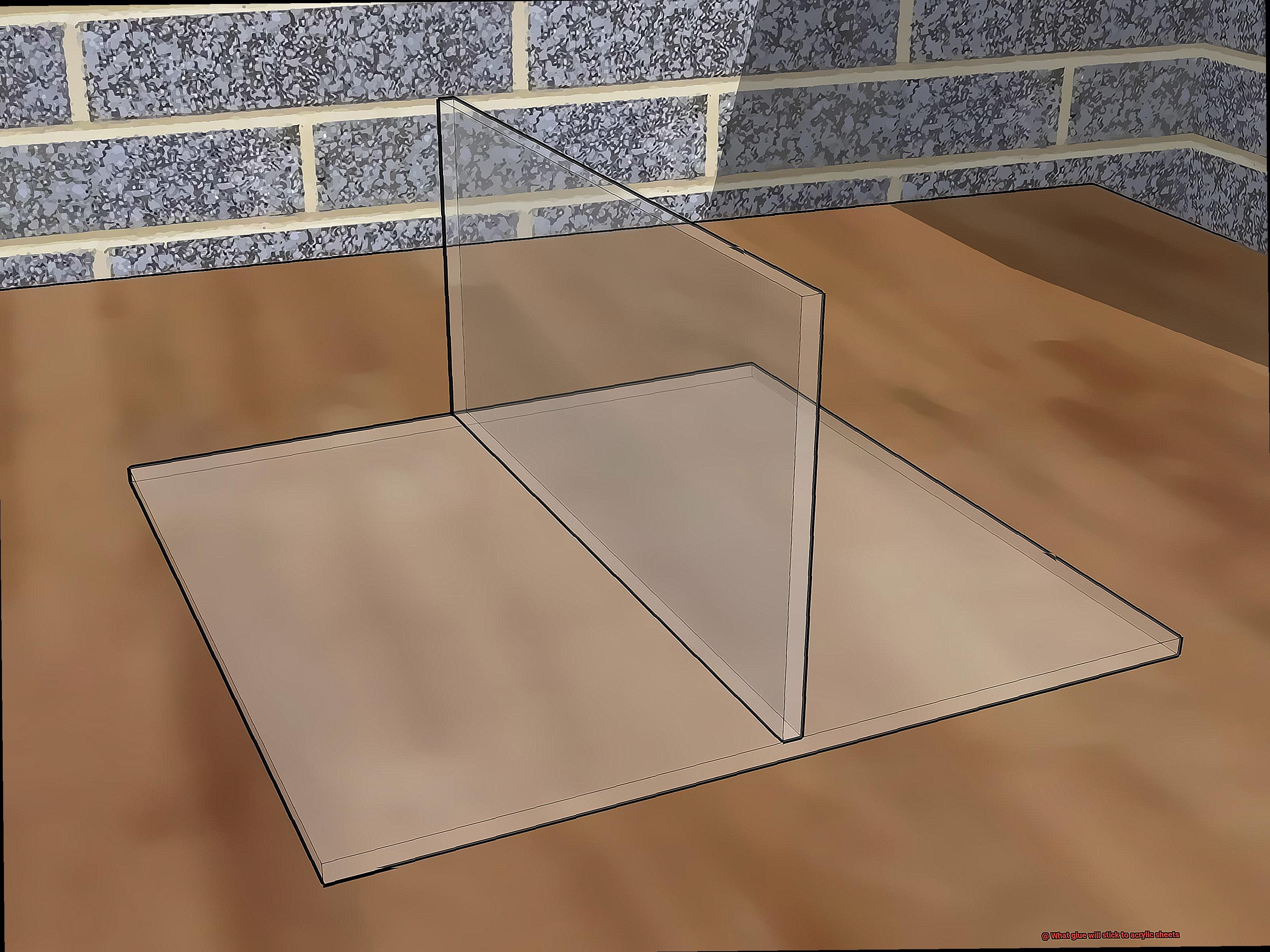

Picture this: seamlessly connecting acrylic sheets to create jaw-dropping displays, attention-grabbing signs, or even crafting magnificent works of art. The possibilities are limitless with the right adhesive in hand. But beware, dear reader, for finding the perfect glue can be a perplexing expedition due to acrylic’s sleek and non-porous surface that defies conventional bonding methods.

But fret not. Today, we dare you to embark on an adventure through the world of acrylic adhesives – where science intertwines with creativity and dreams come alive in vibrant hues.

In this exploration, we shall delve deep into crucial aspects that will lead you towards discovering your holy grail of glues for acrylic sheets. Let us unravel the primary adhesive types commonly employed, ranging from solvent-based options to high-performance alternatives. Witness how these glues’ molecular composition forms an unbreakable bond with the slick surface of acrylic, ensuring a connection that lasts and withstands the test of time.

Yet wait. There’s more. We shall also examine the upsides and downsides of different adhesives, considering vital factors like drying time, transparency levels, and resistance against moisture and temperature. Equipped with this knowledge arsenal, you’ll make informed choices when creating your next masterpiece using acrylic.

So brace yourselves to unlock the enigmatic universe of adhesion. Buckle up tight, fellow enthusiasts, as we navigate through a labyrinthine web of glues that cling onto acrylic sheets. Prepare to join ranks with imaginative minds who have mastered this artistry – igniting imaginations one bond at a time.

What is Acrylic and its Uses?

Contents

- 1 What is Acrylic and its Uses?

- 2 Solvent-Based Cement for Bonding Acrylic Sheets

- 3 Two-Part Epoxy Adhesive for Bonding Acrylic Sheets

- 4 Cyanoacrylate (Super Glue) for Bonding Acrylic Sheets

- 5 Acrylic Adhesives for Bonding Acrylic Sheets

- 6 Water-Based Glues and Solvents to Avoid

- 7 Tips for Choosing the Right Glue

- 7.1 Material Compatibility:

- 7.2 Acrylic is a unique material with specific characteristics, such as lightweight, transparency, and impact resistance. Not all glues are suitable for bonding acrylic effectively, so it is crucial to choose a glue specifically designed for this purpose. Acrylic adhesives are specially formulated to create robust bonds with acrylic surfaces while maintaining excellent clarity.

- 7.3 Bond Strength:

- 7.4 Drying Time:

- 7.5 Application Method:

- 7.6 Glues come in various forms, such as liquid, gel, or adhesive tape, each offering unique advantages during application. Liquid glues are versatile and can be applied with precision using a brush or syringe, making them ideal for intricate projects or small areas. Gel glues have a thicker consistency and can be easily dispensed from a tube, providing convenience for larger areas. Adhesive tapes offer a mess-free application but might not provide the same level of bond strength as liquid or gel glues. Consider the size and nature of your project and choose an application method that suits your preferences and requirements.

- 7.7 Environmental Considerations:

- 8 Conclusion

Acrylic, derived from polymethyl methacrylate (PMMA), is a remarkable material known for its transparency, strength, and durability. In this article, we will explore the versatility of acrylic and its diverse range of applications, highlighting its key characteristics and benefits.

Unparalleled Optical Clarity:

With its exceptional light transmission properties, acrylic allows up to 92% of light to pass through. This makes it the perfect choice for applications requiring transparency, such as windows, display cases, and striking signage.

Moreover, acrylic’s availability in an array of colors and finishes offers endless creative design possibilities.

Resilience Against Impact and Weathering:

Unlike glass, acrylic is highly resistant to impact, reducing the risk of shattering. It can withstand even the harshest outdoor conditions without discoloration or degradation caused by UV radiation. As a result, acrylic is widely used in skylights, protective barriers, and architectural elements that demand both durability and aesthetic appeal.

Embracing Lightness:

Acrylic’s lightweight nature sets it apart from heavier materials like glass or metal. Its reduced weight not only makes it easier to handle during installation but also enhances its resistance to breakage. This makes acrylic an ideal choice for applications where weight needs to be minimized, such as aircraft windows or sleek automotive components.

Limitless Possibilities in Fabrication:

One of acrylic’s most impressive advantages lies in its versatility in fabrication techniques.

Through injection molding or vacuum forming, acrylic can be effortlessly molded into various shapes and sizes. Furthermore, it can be cut, drilled, bent, and bonded together to create intricate designs and complex structures.

This flexibility drives cost-effective production and enables customization according to specific requirements.

Solvent-Based Cement for Bonding Acrylic Sheets

Acrylic sheets have taken the world by storm, captivating us with their unparalleled clarity and remarkable durability. But what’s the secret behind their seamless union? Enter solvent-based cement, the wizardry that creates invisible and unbreakable bonds between acrylic surfaces. In this captivating exploration, we will uncover the steps and precautions involved in using this magical adhesive to bond acrylic sheets.

Step 1: Prepare for Perfection

Before embarking on this enchanting journey, ensure that your surfaces are pristine. Rid them of any impurities like dirt, dust, or grease. A clean canvas sets the stage for a flawless masterpiece.

Step 2: Thin is In

With a stroke of precision, apply a delicate layer of solvent-based cement onto one of the surfaces. Remember, less is more in this realm. Excessive glue can disrupt the delicate balance, causing excessive melting and jeopardizing the bond’s strength. Embrace moderation as your guiding principle.

Step 3: Align with Precision

The dance of alignment begins. Gently bring the two surfaces together, ensuring they harmoniously align. Once bonded, repositioning becomes a perilous feat that may lead to irreparable damage or an uneven union. Take your time and let the elegance of perfect alignment unfold.

Step 4: The Power of Pressure

Now, channel your inner sorcerer and apply even pressure across the entire bonded area for a few moments. This act empowers the glue to work its magic, securing a tight and steadfast bond. Imagine your hands as wands, infusing the acrylic sheets with strength and resilience.

Step 5: Patience Pays Off

Ah, patience, the virtue that brings forth perfection. Resist the urge to test the bond’s strength prematurely. Allow your creation to cure for an appropriate duration, granting the solvent ample time to evaporate and solidify the bond. Seek guidance from the adhesive manufacturer’s instructions, as curing times may vary depending on the mystical forces of temperature and humidity.

Two-Part Epoxy Adhesive for Bonding Acrylic Sheets

Today, we shall unveil the secrets of two-part epoxy adhesive, a mystical potion that transforms mere sheets into a formidable force. Prepare to be captivated as we explore the science behind this adhesive sorcery and discover how it defies the test of time.

Chapter 1: The Potent Blend – Unraveling the Magic of Two-Part Epoxy Adhesive

- Enter the realm of enchantment: Two-part epoxy adhesive, the magician’s secret weapon for bonding acrylic sheets.

- The dynamic duo revealed: A resin and a hardener, uniting in perfect harmony to create an unbreakable bond.

- The chemistry behind the sorcery: When these components combine, they release a spellbinding reaction that forges an unyielding connection.

- Defying the elements: This powerful bond endures extreme temperatures and defies environmental challenges.

Chapter 2: Preparing for the Magic – Creating a Flawless Canvas

- Setting the stage for greatness: Ensuring both acrylic surfaces are pristine, free from dirt, dust, and any interferences.

- The brushstroke of perfection: Skillfully applying the adhesive using a brush or spatula to achieve flawless coverage.

- No crevice left untouched: An even coat is crucial, ensuring every corner and crevice is embraced by this magical adhesive.

Chapter 3: The Dance of Fusion – Uniting Acrylic Sheets

- Embracing harmony: Firmly pressing the acrylic sheets together to maximize contact and unleash the full potential of their bond.

- A symphony of pressure: Enlisting clamps or other forms of pressure to perform their role during the curing process.

- Timing is everything: The duration of the curing process may vary, typically ranging from a few hours to an enchanting overnight wait.

Cyanoacrylate (Super Glue) for Bonding Acrylic Sheets

Today, we shall unlock the secrets of using cyanoacrylate, or as we fondly know it, super glue, to forge an unyielding bond between acrylic sheets. Get ready to witness the power of polymerization and discover the art of achieving a flawless bond that defies time and environmental challenges.

Chapter 1: The Wizardry Behind Super Glue’s Power

Prepare to be spellbound as we delve into the magical properties of cyanoacrylate, the mighty adhesive known as super glue. This enchanting substance works its wonders through a process called polymerization. With just a touch of moisture in the air, it springs into action, creating bonds that are virtually indestructible against even the most formidable forces.

Chapter 2: Preparing for the Alchemical Bonding Ritual

Cleanliness is our ally on this mystical quest. To ensure a successful bond, banish any lurking dust, dirt, or contaminants from both acrylic sheets. Employ a gentle touch with a mild detergent or acrylic cleaner to purify their surfaces. But there’s more to this ritual. Let us invoke the power of fine-grit sandpaper to delicately roughen the acrylic’s surface. By doing so, we create a larger canvas for our super glue to weave its binding magic upon.

Chapter 3: Applying Super Glue – The Dance of Precision

With grace and precision, it is time to apply the super glue. Dispense a measured amount onto one of the acrylic surfaces, for moderation is key in this mystical art. Too much glue may disrupt our delicate dance and lead to messy and uneven bonding – an outcome we seek to avoid. A gentle touch, a steady hand, and a controlled amount of super glue will ensure our bond remains seamless and strong.

Chapter 4: The Sacred Ritual of Bonding

As we embark on the sacred ritual of bonding, let us honor the connection between our acrylic sheets. Gently bring them together, forging a firm and unyielding union. Hold them in place for a few minutes, allowing the glue to set and weave its spell. Should you desire an even stronger bond, call upon clamps or weights to amplify the magic.

Acrylic Adhesives for Bonding Acrylic Sheets

Today, we shall unlock the secrets of using acrylic adhesives to forge an unyielding bond between acrylic sheets. Prepare to witness the power of polymerization and discover the art of achieving a flawless bond that defies time and environmental challenges.

Types of Acrylic Adhesives:

When it comes to bonding acrylic sheets, not all adhesives are created equal. Let’s delve into the different types available and explore how to choose the best one for your specific needs.

Solvent-Based Adhesives:

Picture a wizard dissolving the surface of an acrylic sheet, magically creating a strong bond when it dries. That’s precisely what solvent-based adhesives do. These popular adhesives work their magic by dissolving the surface of the acrylic, ensuring a quick drying time and high bond strength. Perfect for projects that demand speed without compromising durability.

UV Curing Adhesives:

If transparency is paramount in your application, UV curing adhesives are your secret weapon. These adhesives cure when exposed to UV light, creating an invisible yet formidable bond between acrylic sheets. Say goodbye to residue or discoloration – these adhesives leave behind nothing but pure magic.

Two-Part Systems:

For those seeking the pinnacle of strength and versatility, two-part acrylic adhesives are here to answer the call. By combining a resin and a hardener, these adhesives provide exceptional bond strength and are ideal for large surfaces or applications requiring gap filling. The perfect choice when you need to conjure up a bond that stands the test of time.

Choosing the Right Acrylic Adhesive:

Now that we’ve explored the magical properties of acrylic adhesives, it’s time to choose the perfect one for your project. Consider these factors:

- Temperature Resistance: Is your application faced with scorching heat or bone-chilling cold? Fear not. Select an adhesive that can withstand extreme temperatures, ensuring your bond remains unyielding even in the harshest conditions.

- Flexibility: Some projects require a touch of elasticity in their bonds. Look for an adhesive that can gracefully handle movement without sacrificing strength. After all, a bond that bends but never breaks is the epitome of magical mastery.

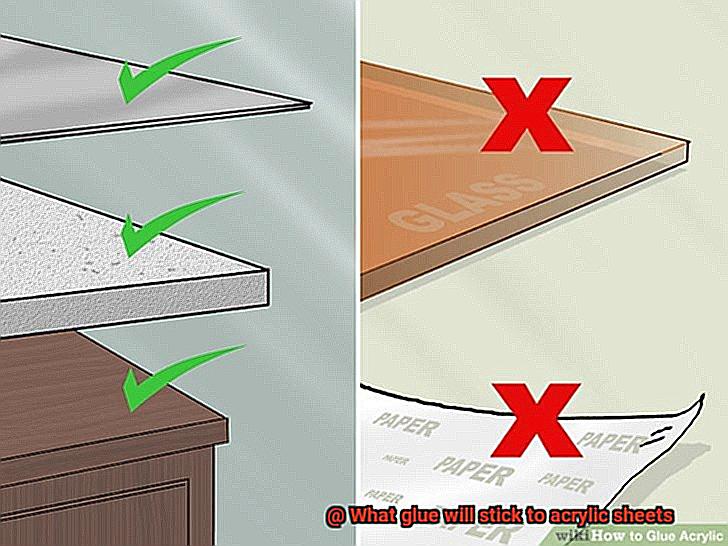

Water-Based Glues and Solvents to Avoid

Prepare to be enchanted as we delve into the mystical world of acrylic adhesives and uncover the secrets to achieving flawless bonds that defy time and environmental challenges. Today, we embark on a crucial quest: discovering the water-based glues and solvents to avoid when working with acrylic sheets.

Acrylic, a material of wonder, renowned for its transparency, durability, and versatility. However, finding the perfect adhesive that will bond effectively to acrylic surfaces without causing harm can be a daunting task. Fear not, for we shall guide you through the treacherous waters of water-based glues and solvents that should be shunned.

Ah, water-based glues, known for their ease of use and environmental friendliness. But beware, dear sorcerers, for when it comes to bonding acrylic sheets, certain types of these glues can prove disastrous. Why, you ask? These glues harbor a hidden danger – a high concentration of moisture that can unleash havoc upon your precious acrylic.

Let us begin with the mischievous ordinary white school glue or craft glue. Oh, how they flourish on porous materials like paper or fabric. But alas, their power wanes in the face of non-porous surfaces like acrylic. Feeble in strength, these glues fail to provide the robust bond required. And beware, for their moisture-laden hearts can render your acrylic sheet brittle over time. A fate no sorcerer desires.

Next on our list of forbidden water-based glues is wood glue or carpenter’s glue. Ah, these glues possess great power in the realm of woodworking projects. Yet, they are ill-suited for the delicate dance with acrylic. Why? Their cure lies in moisture absorption, a perilous path for acrylic. Should you dare to unite wood glue with acrylic, prepare for warping and discoloration to mar your exquisite sheets. A tragedy no sorcerer should endure.

Tips for Choosing the Right Glue

Acrylic sheets are versatile and widely used in various applications, but finding the right glue is essential for creating durable and reliable bonds. In this article, we will explore key factors to consider when selecting a glue for bonding acrylic sheets.

By understanding these tips, you can confidently choose the perfect adhesive for your projects, ensuring exceptional results.

Material Compatibility:

Acrylic is a unique material with specific characteristics, such as lightweight, transparency, and impact resistance. Not all glues are suitable for bonding acrylic effectively, so it is crucial to choose a glue specifically designed for this purpose.

Acrylic adhesives are specially formulated to create robust bonds with acrylic surfaces while maintaining excellent clarity.

Bond Strength:

Consider the type of bond you want to achieve with your acrylic sheets. Some glues create permanent bonds that cannot be easily undone, providing maximum strength and durability.

On the other hand, if you require flexibility and the ability to disassemble the bond if needed, opt for glues that offer more versatility. Assess your project’s requirements and select a glue that provides the desired level of bond strength.

Drying Time:

The drying time of the glue can significantly impact your project timeline and assembly process. Quick-drying adhesives can expedite assembly, reducing waiting time and allowing you to move forward swiftly.

However, some glues require longer curing times to achieve optimal bond strength. Consider your project’s timeline and select a glue that aligns with your specific needs regarding drying time.

Application Method:

Glues come in various forms, such as liquid, gel, or adhesive tape, each offering unique advantages during application. Liquid glues are versatile and can be applied with precision using a brush or syringe, making them ideal for intricate projects or small areas. Gel glues have a thicker consistency and can be easily dispensed from a tube, providing convenience for larger areas.

Adhesive tapes offer a mess-free application but might not provide the same level of bond strength as liquid or gel glues. Consider the size and nature of your project and choose an application method that suits your preferences and requirements.

Environmental Considerations:

Take into account any specific environmental factors that may affect the performance of the glue. Some glues may not withstand extreme temperatures or high humidity levels, compromising the bond’s strength.

If your project will be exposed to such conditions, ensure you select a glue specifically designed to withstand them. This will guarantee that your bond remains strong and reliable, even in challenging environments.

hT6Ow_cBTps” >

Conclusion

Acrylic sheets are a popular choice for various projects, but finding the right glue to stick them together can be a challenge. Luckily, there are a few options that will do the job effectively.

One reliable adhesive for acrylic sheets is solvent cement. This powerful glue creates a strong bond by chemically melting the surfaces of the acrylic together. It’s important to note that solvent cement specifically designed for acrylic should be used, as other types may not work as effectively.

Another option is epoxy resin. This versatile adhesive forms a durable bond and can be used on various materials, including acrylic. Just make sure to choose an epoxy that is compatible with plastics.

If you’re looking for a quick fix or temporary solution, double-sided adhesive tapes can also work well. These tapes have a strong adhesive backing that adheres to both surfaces and provides a secure hold.

When applying any glue to acrylic sheets, it’s essential to clean the surfaces thoroughly beforehand. Any dirt or residue can prevent the glue from sticking properly.

In conclusion, when it comes to sticking acrylic sheets together, choosing the right glue is crucial. Solvent cement and epoxy resin are excellent options for creating strong and long-lasting bonds. Alternatively, double-sided adhesive tapes offer convenience and temporary solutions.