Imagine this: it’s a lazy weekend afternoon, and you’re basking in the blissful calm of your home. Suddenly, an unwelcome sound pierces the tranquility – the incessant drip-drip-drip of a pesky leaking copper pipe. Panic sets in as you realize the potential havoc it could wreak on your wallet. But fear not, my friend, for we have the secret weapon that could save you a fortune – the power of the perfect glue.

In this captivating blog post, we’ll dive into the world of plumbing mishaps and unveil the answer to that age-old question: What glue should you use to fix a leaking copper pipe? We’ll guide you through a comprehensive selection of glues specifically designed to tackle those stubborn copper pipe leaks. Get ready to become your own plumbing superhero.

We’ll explore the key characteristics to look for in an adhesive – its ability to withstand high water pressure, resist corrosion, and bond like no other to copper surfaces. And that’s not all – we’ll delve into different types of glues available for copper pipes, from trusty epoxy putty to skilled soldering and even self-fusing silicone tape. Each option has its own unique advantages, and we’ll equip you with insider knowledge on when and how to use them effectively.

Because let’s face it, choosing the right glue is crucial for keeping your plumbing system intact. So get ready to bid farewell to those annoying leaks, sky-high water bills, and sleepless nights worrying about hidden damage – relief is just one little adhesive away.

Gear up and prepare yourself for a transformative journey as we uncover the secret behind becoming a true master of plumbing saving grace. Say goodbye to leaky nightmares as we arm you with all the knowledge needed to conquer those copper pipe conundrums like a pro.

Types of Glue for Fixing Leaking Copper Pipes

Contents

- 1 Types of Glue for Fixing Leaking Copper Pipes

- 2 Advantages and Limitations of Epoxy

- 3 Advantages and Limitations of Copper Pipe Solder

- 4 Advantages and Limitations of Copper Pipe Repair Tape

- 5 General-Purpose Glues vs. Specialized Glues for Copper Pipes

- 6 Steps to Properly Clean the Surface Before Applying Adhesive

- 7 Tips for Choosing the Right Glue or Adhesive

- 8 Conclusion

Leaking copper pipes can wreak havoc in your home, causing damage and increasing your water bill. Fortunately, there are several types of glue that can effectively fix these leaks and restore the integrity of your plumbing system. In this article, we will explore the different options available and provide valuable insights to help you choose the best glue for your specific needs.

Epoxy Resin: The Indestructible Bond

Epoxy resin is a superhero among glues when it comes to fixing leaking copper pipes. This two-part adhesive consists of a resin and a hardener that, when combined, create an incredibly strong and durable bond.

Epoxy resin is renowned for its ability to withstand high water pressure and resist chemicals and corrosion. It is particularly suitable for pipes that come into contact with different substances.

The application process involves mixing the resin and hardener, applying the mixture to the leak, and allowing it to cure. However, it’s important to note that epoxy resin may not be compatible with all types of copper pipes, so always check the manufacturer’s instructions before use.

Soldering Paste: The Precision Fixer

When dealing with small leaks or joining copper pipes together, soldering paste is an excellent option. This glue contains flux and solder particles that melt when heat is applied, creating a tight and reliable bond between the pipe and fitting.

Using a torch or soldering iron, heat up the soldering paste until it melts and flows into the leak or joint, ensuring a watertight connection.

While soldering paste requires some skill to apply correctly, it provides a more permanent solution for larger leaks or critical joints.

Pipe Joint Compound: The Trusty Sealant

Threaded connections often require a sealant to prevent leaks, and pipe joint compound (also known as pipe dope) is an ideal choice for this purpose. This glue is easy to apply and does not require any specialized tools. Pipe joint compound creates a watertight seal, ensuring leak-free connections.

However, it’s worth noting that this type of glue may not be as resilient as epoxy resin or soldering paste, so it’s best suited for smaller leaks or low-pressure applications.

Teflon Tape: The Quick Fix

For a non-adhesive option, Teflon tape is a convenient and effective solution for fixing leaking copper pipes. Made from polytetrafluoroethylene (PTFE), this tape is wrapped around threaded connections to create a tight seal.

Teflon tape is easy to use and doesn’t require curing time, making it a quick fix for minor leaks. However, it may not provide sufficient sealing for more severe leaks and might need to be combined with another type of glue for added security.

Specialized Glues: Tailored Solutions for Specific Leaks

In some cases, specialized glues are designed explicitly for certain types of leaks in copper pipes.

Advantages and Limitations of Epoxy

Leaking copper pipes can turn your home into a watery disaster zone, but fear not, my friends. The superhero of glues, epoxy, is here to save the day and restore your plumbing system to its former glory. Today, I’m going to dive deep into the advantages and limitations of using epoxy for repairing those pesky copper pipe leaks.

Advantages of Epoxy:

- Unbeatable bonding strength: Epoxy is known for its exceptional bonding strength, creating a strong and durable bond that can withstand high pressure and temperature fluctuations. Say goodbye to those pesky leaks once and for all.

- Versatility at its finest: From small pinholes to cracks and joint leaks, epoxy can tackle various types of leaks in copper pipes. It works equally well on both hot and cold water pipes, making it a versatile solution for all your plumbing repair needs.

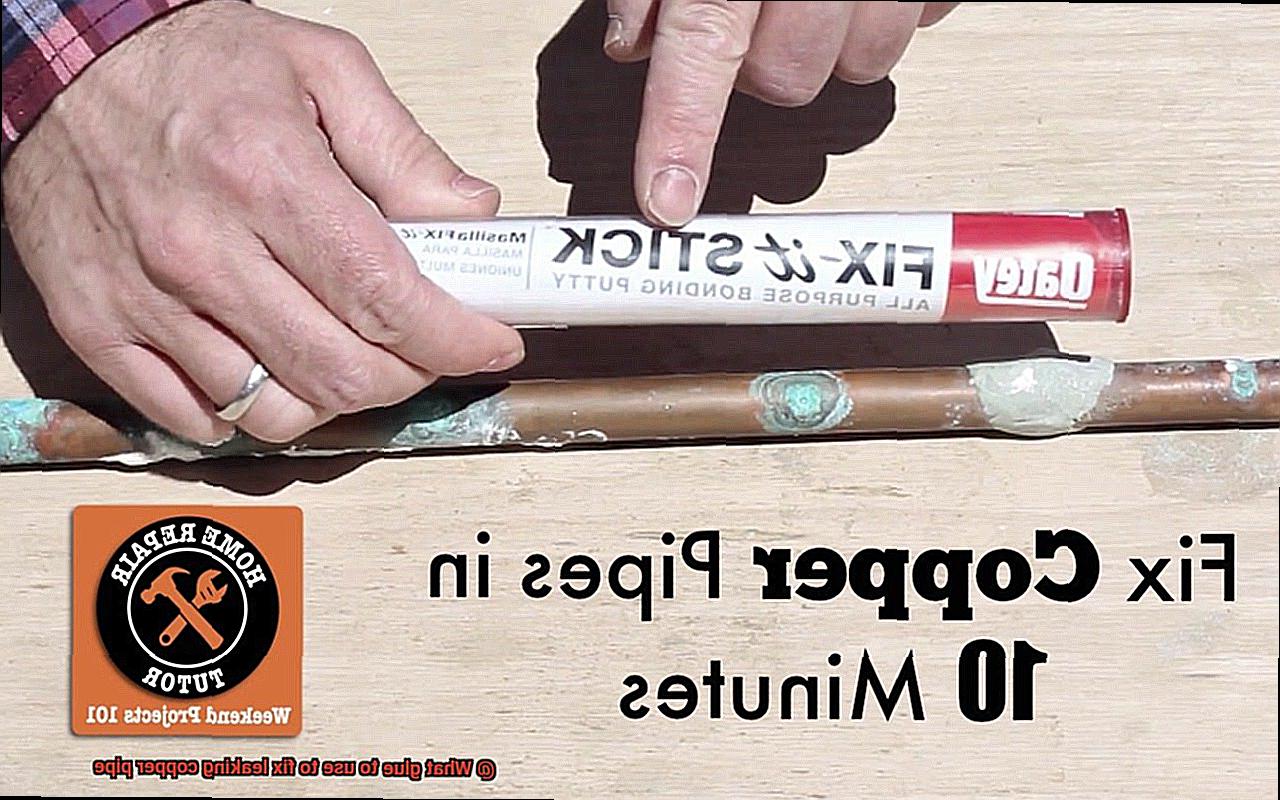

- Easy application for everyone: Even if you’re not a plumbing pro, fear not. Epoxy is relatively simple to apply in different forms like putty or liquid. Just clean the pipe surface, mix the epoxy components if needed, and apply it directly onto the leak area. Easy peasy.

- Warrior against chemicals and corrosion: Epoxy is resistant to a wide range of chemicals commonly found in plumbing systems, like chlorine and cleaning agents. It also provides protection against corrosion, extending the lifespan of your repaired pipe. A win-win situation.

Limitations of Epoxy:

- Temporary fix reminder: While epoxy provides a quick solution for fixing leaking copper pipes, it’s often considered a temporary fix. Depending on the severity of the leak and the condition of the pipe, a more permanent solution like replacing the damaged section may be necessary down the line.

- Large leaks need alternative solutions: Epoxy is most effective for small leaks or cracks. If you’re dealing with a large leak or multiple leaks close together, epoxy may not provide the seal you need. In those cases, exploring alternative repair methods is the way to go.

- Don’t skimp on surface preparation: To ensure a reliable seal, proper surface preparation is crucial. Clean and sand the area around the leak to remove debris or corrosion that could hinder the epoxy’s bond. Don’t skip this important step.

Advantages and Limitations of Copper Pipe Solder

Leaky pipes can be a homeowner’s worst nightmare, but fear not. Copper pipe solder is the superhero solution that can save the day. In this captivating article, we will embark on a journey to explore the incredible advantages and potential limitations of using copper pipe solder. So, roll up your sleeves and prepare to be amazed as we dive deep into the world of copper pipe solder.

Advantages of Copper Pipe Solder:

Ease of Use:

Unlock the simplicity of copper pipe solder. Even if you possess minimal plumbing experience, you can easily master the art of soldering copper pipes. Say goodbye to expensive professional assistance and hello to cost-effective repairs that you can tackle yourself.

Durability:

Unleash the power of durability with copper pipe solder. When applied with precision, this remarkable solder creates an unbreakable bond that seals your pipes tight. No more leaks or disruptions to the smooth flow of water or fluids – just long-lasting, reliable plumbing solutions.

Resistance to High Temperatures:

Ignite the fire within copper pipe solder. With its impressive melting point, it fearlessly withstands scorching hot water and steam coursing through your pipes. This makes it an ideal choice for plumbing systems dealing with high temperatures, such as heating systems or hot water applications.

Versatility and Compatibility:

Unleash the magic of versatility with copper pipe solder. No matter what type of copper pipes you have – rigid or flexible – solder will come to your rescue every time. Its compatibility with various types of copper pipes makes it a convenient solution for different plumbing repairs. Whatever your piping needs may be, rest assured that solder has got you covered.

Limitations of Copper Pipe Solder:

Surface Preparation:

Conquer the challenges of surface preparation when using copper pipe solder. Before diving into the soldering process, it is essential to clean the surfaces of your copper pipes meticulously. Removing debris, oxidation, and corrosion is a vital step to ensure strong joints and prevent potential leaks. Remember, a little preparation goes a long way in achieving flawless repairs.

Advantages and Limitations of Copper Pipe Repair Tape

Imagine a world where fixing leaky pipes is as easy as wrapping them with a magical tape. Welcome to the realm of copper pipe repair tape. In this article, we’ll delve into the captivating advantages and unavoidable limitations of using this versatile tape to conquer those pesky leaks. But before we embark on this adventure, let’s take a moment to appreciate the wonders of traditional copper pipe soldering.

Advantages of Copper Pipe Repair Tape:

Quick and Easy Installation:

Bid farewell to the tedious task of cutting and soldering. Copper pipe repair tape offers a hassle-free installation process that saves you precious time and effort. Simply wrap it around the damaged area, and voila. Your pipes are back in action.

Cost-Effective Solution:

Why spend a fortune replacing an entire section of copper pipe when you can choose a more pocket-friendly option? Copper pipe repair tape is a cost-effective alternative that won’t burn a hole in your wallet. Say hello to savings.

Versatility:

Flexibility is the name of the game when it comes to copper pipe repair tape. Whether you have rigid or flexible copper pipes, this tape has got your back. It seamlessly adheres to various types and sizes of pipes, making it a versatile solution for any plumbing system.

Durability:

Don’t underestimate the resilience of copper pipe repair tape. It is specifically designed to withstand high temperatures and pressure, ensuring a long-lasting fix for those stubborn leaks. No more sleepless nights worrying about drips and puddles.

Temporary Fix:

In times of crisis where immediate action is paramount, copper pipe repair tape can swoop in as your trusty sidekick. It provides a temporary solution to stop leaks until a more permanent fix can be implemented. Consider it your emergency superhero.

Limitations of Copper Pipe Repair Tape:

Compatibility:

While copper pipe repair tape works its magic on copper pipes, it may not possess the same enchanting powers on pipes made from other materials like PVC or steel. To avoid disappointment, double-check if the tape is compatible with the specific type of pipe you’re dealing with.

General-Purpose Glues vs. Specialized Glues for Copper Pipes

Whether you’re dealing with a pesky leak or a full-blown plumbing emergency, it’s crucial to understand the differences between general-purpose glues and specialized glues for copper pipes. So, let’s dive in and explore these options.

General-purpose glues, such as epoxy or super glue, are the versatile workhorses of the adhesive world. Found easily at your local hardware store, they can be used on a variety of materials. These glues offer a quick fix for those annoying small leaks in your copper pipes. Talk about convenience.

However, let’s not overlook the potential downsides of general-purpose glues. Copper pipes are notorious for corrosion and can face high water pressure, which can cause these glues to weaken or fail over time. And let’s face it, nobody wants a plumbing disaster because they opted for a temporary solution.

Now, let’s turn our attention to the superheroes of specialized glues made specifically for copper pipes. These amazing products have some serious advantages that will make you want to give them a standing ovation. Firstly, they’re formulated to bond effectively with copper surfaces, creating a seal that is strong and durable. Say goodbye to those annoying leaks.

Specialized glues are also designed to withstand high water pressure and temperature fluctuations without losing their effectiveness. They’re like the Olympic athletes of the adhesive world, ready to handle any challenge thrown at them. Plus, they have excellent resistance to corrosion, ensuring that your repaired copper pipes will stand the test of time.

One star among the specialized glues family is soldering paste or flux. This powerful adhesive is used alongside solder material to create a tight and secure connection between copper pipes. It’s the go-to method for professional plumbers because it provides a permanent and reliable fix. However, keep in mind that soldering requires some level of skill and experience, so it may not be the best option for DIY beginners.

But fear not, my fellow DIYers. There are copper pipe repair adhesives available that are specifically designed to fix leaks in copper pipes. These incredible adhesives usually come in a two-part formula that needs to be mixed before application. Once applied, they bond strongly with copper surfaces, creating a seal that is watertight and impenetrable. They’re resistant to corrosion and can handle high pressure and temperature fluctuations like champions.

Steps to Properly Clean the Surface Before Applying Adhesive

Get ready to unleash your inner superhero and conquer that pesky leaking copper pipe. But, before you embark on this heroic quest, let’s explore the vital steps to properly clean the surface before applying adhesive. This crucial process ensures a robust and enduring bond. So, grab your tools and prepare to dive into the captivating world of pipe cleaning.

Shut off the water supply to the pipe. We want to avoid any unexpected waterworks while we work our magic.

Use a pipe cutter or hacksaw to remove the damaged section of the pipe. Cutting a clean, straight line is paramount for a seamless connection with the new piece.

It’s time to roll up our sleeves and get cleaning. Equip yourself with emery cloth or sandpaper and start by giving the outside of the pipe some TLC. Employ long, smooth strokes to eliminate dirt, corrosion, and remnants of previous adhesive. Our goal? A surface that gleams with perfection.

Now, let’s venture inside the pipe. Fold a small piece of emery cloth or sandpaper in half and insert it into the pipe. Apply gentle pressure while twisting it back and forth, banishing any debris or corrosion lurking within. Remember, this often overlooked step is key to achieving an impeccable bond.

Once both the interior and exterior of the pipe are spotless, grab a clean cloth or rag to wipe away any remaining residue or dust particles. We want a dry and pristine surface as our canvas for adhesive application.

Keep in mind that different types of adhesives may necessitate specific surface preparations. Consult the manufacturer’s instructions for tailored cleaning recommendations. Following these guidelines guarantees maximum effectiveness.

Smooth out any rough or uneven areas on the surface by utilizing a file or deburring tool prior to adhesive application. This extra step ensures an even stronger connection between the pipe and adhesive. Smooth sailing lies ahead.

Before we proceed, double-check that the cleaned surface is completely dry. Any lingering moisture or water droplets could disrupt our adhesive’s enchanting powers.

And there you have it. With the surface meticulously cleaned and prepared, you’re now ready to become the superhero plumber and apply the appropriate adhesive. Prepare to save the day and bid farewell to that pesky leaking copper pipe.

Tips for Choosing the Right Glue or Adhesive

Don’t let a leaking copper pipe dampen your spirits – with the right glue or adhesive, you can fix it in no time. In this article, we’ll dive into the factors you need to consider when choosing the perfect adhesive for your repair. From understanding the material of the pipe to assessing the severity of the leak, we’ve got you covered.

Material Matters:

When it comes to copper pipes, not all adhesives are created equal. You need an adhesive that is specifically designed for use with copper. Look for products that explicitly state their compatibility with copper materials. Choosing the wrong adhesive can lead to further leaks and even damage to the pipe, so be sure to select one that is suitable for your specific needs.

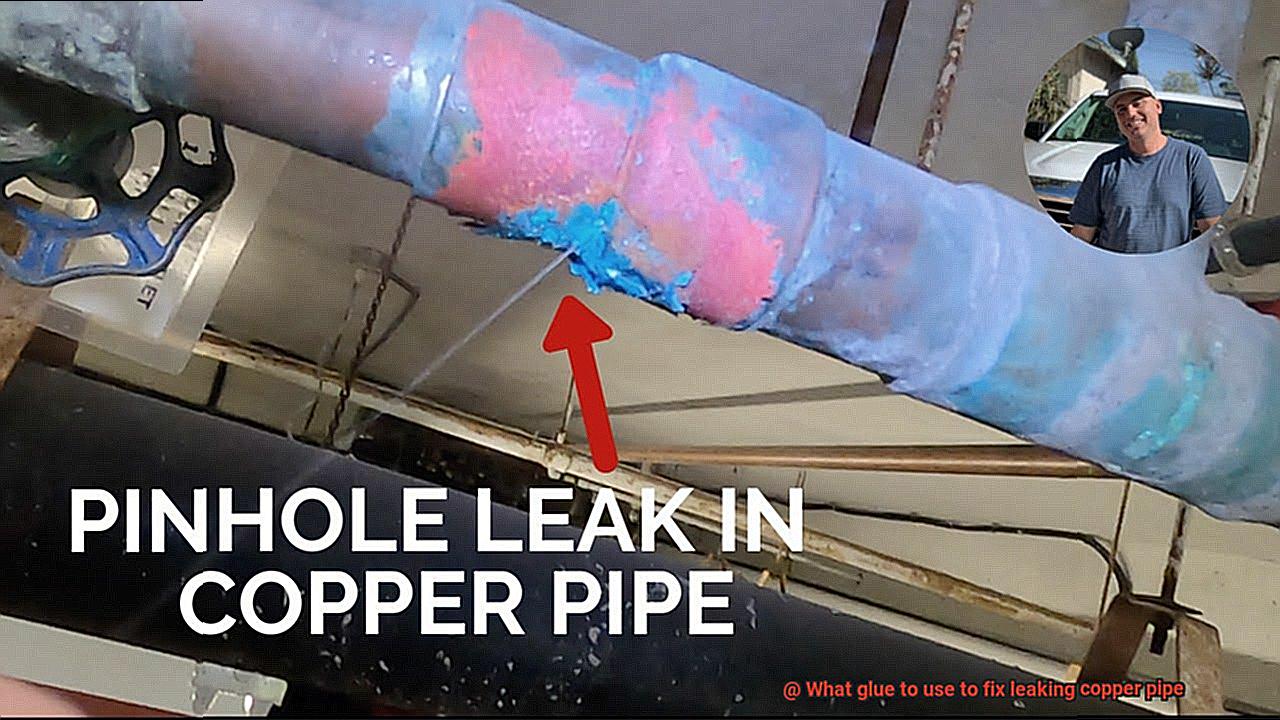

Gauge the Leak’s Magnitude:

Is it a minuscule pinhole leak or a larger, more severe crack? The size and severity of the leak will determine the type of adhesive you need. Different adhesives have varying strengths and properties, so it’s essential to choose one that matches the intensity of your leak. A small pinhole leak may require a different adhesive than a larger crack.

Temperature and Pressure Considerations:

Don’t forget to factor in the temperature and pressure conditions that your repaired pipe will face. If your pipe will be subjected to high temperatures or high-pressure situations, ensure that your chosen adhesive can withstand those conditions. This will guarantee that your repair remains intact and durable, even under challenging circumstances.

Seek Wisdom from Others:

Why go through the trial-and-error process alone? Read reviews and recommendations from other users who have successfully used a particular adhesive for similar repairs. Online forums, DIY websites, and plumbing professionals can provide valuable insights on which glues or adhesives have proven effective in fixing leaking copper pipes. Learn from their experiences to make an informed decision.

Follow Instructions with Precision:

To ensure a successful and long-lasting repair, always follow the manufacturer’s instructions and guidelines for proper application. Neglecting to do so can result in ineffective repairs or further damage to the pipe. Take the time to read and understand the instructions before embarking on your repair journey. Following them meticulously is key to achieving the desired outcome.

rvXEDRS1Neg” >

Conclusion

When it comes to fixing a leaking copper pipe, choosing the right glue is crucial.

You need a strong adhesive that can withstand the pressure and hold the pipe together securely. One option that professionals often recommend is epoxy resin.

This powerful adhesive forms a tight bond, sealing any leaks and preventing further damage. Another effective choice is plumber’s putty, which is easy to apply and creates a watertight seal.

For larger leaks or more complex repairs, soldering may be necessary. This involves melting solder onto the joint to create a permanent connection.

Whichever method you choose, make sure to follow the manufacturer’s instructions carefully and take all necessary safety precautions.