Got a broken shoe that’s got you feeling down? Whether you’re a hiking fanatic, a fashionista, or just someone who wants to make their favorite kicks last a little longer, we’ve all been there. A loose sole, a rebellious heel, or an annoying tear can turn our beloved footwear into a sad sight. But fret not, my friend. There is hope.

When it comes to fixing shoes, choosing the right glue can be the difference between a solid repair and a temporary fix that leaves you back at square one. But with so many glues out there, how do you know which one to trust?

In this ultimate guide, we’ll dive into the world of shoe-repair glues and give you both casual and professional advice to help you make the best decision. We’ll explore what makes a glue reliable, break down the different types available, and even dish out some recommendations based on your specific needs. So let’s get this show on the road and find that perfect adhesive to save your soles (literally).

Casual Advice:

Contents

If you’re looking for a quick fix for your everyday shoes like sneakers or flats, convenience is key. You want glue that gets the job done without any fuss. Look for something that dries fast and sticks strong while still being flexible enough to handle your daily adventures.

Professional Advice:

Now, if you’re dealing with fancier footwear like dress shoes or hiking boots, it’s time to up your game with professional-grade glue. These bad boys are specially made to bond different materials like leather, rubber, and fabric with unmatched strength and durability. Make sure to choose an adhesive that can handle heat, water, and whatever else life throws at it.

No matter which type of glue you go for (casual or pro), don’t forget about proper shoe prep. Give those shoes a good cleaning to get rid of dirt, dust, and any old glue residue. And if you’re dealing with smooth surfaces, a little sandpaper action can help the glue stick better.

Stay tuned as we dive deeper into the world of shoe-repair glues and reveal our top picks for each category. Trust us, finding the perfect glue will give your favorite kicks a new lease on life while keeping your wallet happy. So let’s get ready to put our best foot forward together.

Types of Glue for Different Shoe Materials

We all have that one pair of beloved shoes that we just can’t bear to part with, even when they start falling apart. But fear not. The secret to saving your favorite footwear lies in the power of glue. However, not just any glue will do the trick. Different shoe materials require specific adhesives to ensure a strong and long-lasting bond. In this comprehensive guide, we’ll delve into the world of shoe glues and explore the best options for different shoe materials, so you can revive your precious kicks and strut confidently once more.

Leather Shoes:

Leather shoes exude style and timelessness, but when they need repairs, you need a glue that can withstand the test of time. Enter leather glue and contact cement, the dynamic duo for bonding leather. These adhesives are specially formulated to create a durable hold on leather, standing up to the daily wear and tear of your adventures.

Fabric Shoes:

Comfortable canvas sneakers and espadrilles are perfect for casual outings, but accidents happen, and tears occur. Fear not. Fabric glue is your knight in shining armor for fabric shoe repairs. This adhesive is designed to cling tightly to fabric materials, providing a flexible bond that can handle all your daring escapades.

Rubber or Plastic Shoes:

Athletic sneakers with rubber or plastic components demand an adhesive that matches their unique properties. Look no further than the extraordinary powers of epoxy or cyanoacrylate (super glue). These versatile marvels create unyielding bonds on rubber and plastics, ensuring your shoes stay intact through every sprint and jump.

Suede or Nubuck Shoes:

Suede and nubuck shoes boast a delicate surface that requires meticulous care during repairs. Luckily, suede glue and shoe repair adhesive are here to save the day. These specialized adhesives are tailor-made for these materials, fixing your suede or nubuck shoes without compromising their exquisite texture.

Synthetic Materials:

Modern shoe designs often incorporate synthetic materials like vinyl or PVC, which demand a glue that can conquer their unique challenges. Seek out glues specifically formulated to bond synthetic materials, ensuring a steadfast and enduring hold on your treasured synthetic shoes.

Choosing the right glue for your shoes is the secret to successful repairs that stand the test of time. Leather, fabric, rubber, suede, and synthetic materials all require their own special adhesive companions. By selecting the appropriate glue and following proper application techniques, you can breathe new life into your beloved shoes, extending their longevity and keeping them fresh and fabulous.

Preparing the Surface Before Applying Glue

Properly preparing the surface before applying glue is a crucial step in any shoe repair or DIY project. It may seem like an extra hassle, but trust me when I say that taking the time to prepare the surface will make a world of difference in the strength and durability of your repair.

First and foremost, cleaning the surface is of utmost importance. Dirt, dust, and debris can create a barrier between the glue and the shoe material, preventing a strong bond from forming. Grab a soft brush or cloth and give the surface a thorough cleaning to ensure that it is free from any unwanted particles. This simple step will significantly enhance the adhesive’s effectiveness.

In addition to cleaning, it is essential to address any loose threads or frayed edges. These seemingly harmless imperfections can actually weaken the adhesive’s hold and compromise the longevity of your repair. Take a pair of sharp scissors and carefully trim any loose threads or frayed edges before applying the glue. By doing so, you are creating a clean and smooth surface for the adhesive to adhere to.

Now, let’s talk about roughening things up. While it may sound counterintuitive, creating a textured surface on both the shoe material and the area where you will be applying the glue can greatly improve the bond’s strength. Gently use sandpaper or a nail file to create a slightly roughened surface. This texture provides more grip for the glue, ensuring that it adheres firmly and securely to the shoe.

It is also important to consider the specific type of shoe material you are working with. For leather shoes, using acetone or rubbing alcohol to wipe down the surface is highly recommended. Leather naturally contains oils and residues that can hinder proper adhesion, so a gentle wipe-down with acetone or rubbing alcohol will remove these substances and create an optimal bonding surface.

On the other hand, if you are dealing with fabric or canvas shoes, pre-washing them according to the manufacturer’s instructions is crucial. This step not only removes any dirt or stains but also prepares the surface for gluing. By pre-washing the shoes, you are ensuring that they are clean and free from any substances that may hinder the adhesive’s effectiveness.

Before applying the glue, it is imperative to ensure that both the shoe surface and the area where you will be applying the adhesive are completely dry. Moisture is the nemesis of a strong bond, so make sure to let your shoes air out and dry thoroughly before moving forward with the gluing process.

Lastly, let’s talk about primers. Although not always necessary, using a primer specifically designed for shoe repair can significantly enhance the adhesive’s performance. Primers create an optimal surface for bonding and improve the overall strength and durability of the repair. If you choose to use a primer, be sure to follow the instructions provided carefully and allow sufficient drying time before applying the glue.

Reading and Following Instructions Carefully

Today, we delve into the captivating realm of gluing shoes and explore the utmost importance of reading and following instructions with meticulous care. Brace yourselves, for this step holds the key to preserving the integrity of your beloved kicks.

Let us first unveil the significance of comprehending the type of glue at your fingertips. Each adhesive possesses distinct properties tailored to specific materials. Thus, take a moment to peruse those instructions and ensure that the glue you employ aligns harmoniously with your shoe’s composition. After all, using a rubber adhesive on leather would be a calamitous misstep, wouldn’t it?

Next on our agenda, we tackle the artistry of surface preparation. Now, some may perceive this as a tedious chore, but trust me when I say that it is an endeavor well worth undertaking. Instructions often illuminate the path to a pristine bond, detailing steps to cleanse the area, embrace roughness through sandpaper, or even embrace a primer’s tender caress. These measures guarantee optimal adhesion and forge an unyielding alliance between glue and shoe. Disregard them at your own peril.

Now, let us spotlight the delicate balance of glue quantity and application technique. Instructions serve as guiding beacons in determining the ideal amount of glue to dispense and the graceful strokes required for even distribution. Meager amounts may render your bond feeble, while an excess may leave you grappling with sticky chaos. So heed those instructions diligently and dance around any adhesive mishaps.

And finally, we bask in the glory of drying time. Patience is the virtuous virtue here. Hastily rushing through this step can birth premature detachment or weaken your bond’s foundation. Allow ample time for the glue to mature fully before subjecting your repaired shoes to any trials or tribulations.

In closing, dear shoe aficionados, reading and following instructions meticulously when gluing your shoes is paramount for a triumphant restoration. By doing so, you ensure that the chosen adhesive harmonizes flawlessly with your shoe’s composition, diligently prepare the surface, apply the ideal quantity of glue with grace, and allow for a patient drying period. Your rejuvenated shoes will express their gratitude, and you shall savor their company for an extended sojourn.

Testing the Glue on a Small Area

Restoring your favorite pair of shoes can be a rewarding task, but it’s important to take the necessary precautions to ensure a successful outcome. One such precaution is testing the glue on a small area before applying it to the entire shoe. In this blog post, we will explore the importance of this step and provide you with expert advice to help you achieve the best results.

Understanding the Importance:

Different glues have different properties and may not work effectively on all types of materials. Testing the glue on a small area allows you to assess its compatibility with your shoes. It can save you from potential damage or discoloration that may occur if the glue doesn’t bond well with your shoe material. By testing on a small area, you also get to determine if the glue will hold up over time, ensuring a long-lasting repair.

Proper Surface Preparation:

Before applying the glue, it’s crucial to clean both surfaces thoroughly. Any dirt, dust, or debris can interfere with the adhesive’s bonding ability. Use a mild detergent or rubbing alcohol to clean the area and allow it to dry completely. This step ensures optimal adhesion and prevents any contaminants from affecting the bond.

Applying the Glue:

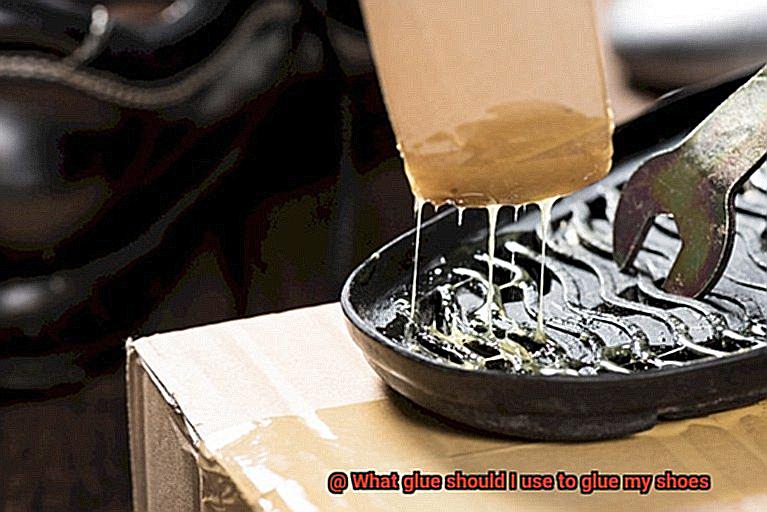

Apply a small amount of glue onto one surface of the shoe. Use a toothpick or a small brush to spread the glue evenly and thinly over the area. Avoid applying too much glue as excess adhesive can result in messy and uneven adhesion. Press the two surfaces together firmly and hold them in place for a few minutes. This step initiates the curing process and ensures a strong bond.

Inspecting the Results:

After allowing sufficient drying time, carefully inspect the glued area. Look for any signs of discoloration, damage, or weak bonding. If there are no visible issues and the bond feels strong, you can proceed with confidence to apply the glue to the rest of your shoe. However, if you notice any problems during the testing phase, it is advisable to reconsider using that particular glue and explore other options.

Using Additional Reinforcements for Extra Strength

When it comes to shoe repairs, glue is often a quick fix. However, sometimes mere glue isn’t enough to withstand the demands of daily wear and tear. That’s where additional reinforcements come into play. In this comprehensive guide, we will explore a variety of techniques and materials that can be used to take glued shoe repairs to the next level, ensuring your shoes are ready to conquer any challenge.

Stitching for Extra Support:

Stitching is a tried-and-true technique for reinforcing glued shoe repairs. By carefully sewing through the material of the shoe, you create an additional layer of support and resilience. Whether you opt for the meticulousness of hand stitching or the precision of a sewing machine, this method adds strength and stability to the repair, ensuring it stands the test of time.

Adhesive Tapes and Patches:

For those seeking an efficient solution, adhesive tapes and patches designed specifically for shoe repairs are a game-changer. These versatile reinforcements can be applied either before or after applying glue, providing an extra layer of strength and stability. Some tapes even offer additional features like waterproofing or heat resistance, tailor-made for specific repair needs.

Heat-Activated Adhesives:

When it comes to leather or rubber shoes, heat-activated adhesives reign supreme. These powerful adhesives require the application of heat through a heat gun or iron to activate and create an unyielding bond. Perfect for high-stress areas such as soles or heels, heat-activated adhesives ensure your repairs withstand even the toughest conditions.

Metal Hardware Reinforcements:

For those seeking both durability and style, metal hardware reinforcements are a winning choice. Eyelets or rivets can be seamlessly inserted into your shoes and secured with glue, providing not only enhanced strength but also adding a unique and fashionable touch to the repaired area. This option allows you to strut confidently, knowing your shoes are both sturdy and chic.

Allowing Sufficient Time for the Glue to Cure and Dry

In the world of shoe repairs, glue is often seen as a quick fix, but sometimes it’s just not enough to withstand the daily battles our shoes face. That’s why it’s crucial to understand the importance of allowing sufficient time for the glue to cure and dry properly. In this blog post, we will explore why this step is crucial, factors that influence drying time, and how to ensure a strong bond that will stand the test of time.

Why is Allowing Sufficient Time for Glue to Cure and Dry Important?

- Strength and Durability: Rushing the drying process can result in a weak bond that may not hold up well over time. Allowing the glue to cure and dry properly ensures a strong and durable bond that can withstand regular wear and tear.

- Following Manufacturer’s Instructions: Different types of glue have different curing times, so it’s essential to follow the instructions provided by the manufacturer. This guarantees that you achieve optimal results with your chosen adhesive.

Factors Influencing Drying Time:

- Humidity: High humidity levels can prolong drying time as moisture in the air slows down the evaporation process. Conversely, low humidity speeds up drying.

- Temperature: Warmer temperatures facilitate faster drying, while cold temperatures slow down the process. It’s essential to consider the temperature conditions when determining how long to allow the glue to dry.

- Materials Being Glued: Different materials have different porosities, which can affect drying time. For example, porous materials like fabric may require longer drying times compared to non-porous materials like hard plastic.

Tips for Ensuring a Strong Bond:

- Avoid Stress on Glued Area: During the curing process, avoid putting any stress or pressure on the glued area. Refrain from wearing or using the shoes until the glue has completely dried to prevent weakening the bond.

- Use Clamps or Tools: Depending on the type of glue and materials, use clamps or other tools to hold the shoes in place while they dry. This ensures that the bond remains undisturbed and allows the glue to set properly.

- Provide Adequate Ventilation: Place the shoes in a well-ventilated area during the drying process to allow proper airflow. This prevents moisture build-up, which can negatively impact the bonding process.

JAaIZa3pZMc” >

Conclusion

In conclusion, the choice of glue for your shoes is absolutely vital if you want a repair that can withstand the test of time. Each shoe material requires a specific adhesive to guarantee a strong and enduring bond.

When it comes to leather shoes, your best options are leather glue and contact cement. These specially formulated adhesives create an unbreakable hold on leather, ensuring they can handle the daily wear and tear without faltering.

Fabric shoes, on the other hand, call for fabric glue. This powerful adhesive clings tightly to fabric materials, providing a flexible bond that can keep up with all your adventures.

Rubber or plastic shoes demand epoxy or cyanoacrylate (super glue) due to their unique properties. These glues form unwavering bonds on rubber and plastics, guaranteeing your shoes stay intact through every sprint and jump.

For suede or nubuck shoes, specialized adhesives like suede glue and shoe repair adhesive are essential. They fix your delicate suede or nubuck shoes without compromising their exquisite texture.

Synthetic materials like vinyl or PVC require glues specifically designed for bonding synthetic materials. These glues ensure a steadfast and long-lasting hold on your beloved synthetic shoes.

Before applying any glue, it’s crucial to properly prepare the surface by thoroughly cleaning it, addressing loose threads or frayed edges, roughening smooth surfaces, and using appropriate primers if necessary.

Following instructions meticulously is paramount for a successful shoe repair. They guide you in choosing the right glue, preparing the surface correctly, applying the perfect amount of glue with finesse, and allowing ample drying time for a robust bond.

To ensure compatibility with your shoe material and achieve a lasting repair, testing the glue on a small area is absolutely crucial.

If you want to further reinforce your glued shoe repairs, consider using additional reinforcements such as stitching, adhesive tapes and patches, heat-activated adhesives, or even metal hardware. These reinforcements can add an extra layer of strength to your repairs.

Lastly, be patient and allow sufficient time for the glue to cure and dry. Factors like humidity, temperature, and the materials being glued can influence drying time. Following the manufacturer’s instructions, avoiding stress on the glued area during curing, using clamps or tools to hold the shoes in place, and ensuring proper ventilation are all key to a successful repair.