Ever wondered how electronic components stick together while keeping the electricity flowing? The answer lies in electrically conductive glue – a mind-blowing solution that combines the stickiness of regular glues with the power of electrical conductivity. In this blog post, we’ll dive into the captivating world of conductive glues, exploring their unique characteristics and properties. Get ready to discover different types of conductive glues and learn when they’re the ultimate adhesive choice.

What glue is electrically conductive

Contents

- 1 What glue is electrically conductive

- 2 Types of Conductive Glue

- 3 Adhesive Matrix and Electrical Conductivity

- 4 Application Methods for ECA

- 5 Factors Affecting Electrical Conductivity

- 6 Industries Where ECA is Used

- 7 Considerations When Choosing an ECA

- 8 Advantages of Using Electrically Conductive Glue

- 9 Disadvantages of Using Electrically Conductive Glue

Carbon-Based Conductive Glue:

Picture this: tiny carbon particles mixed with binders to create a glue that conducts electricity. These carbon-based glues have varying levels of conductivity and are perfect for intricate electronic circuits, fixing damaged traces, and attaching components to PCBs (Printed Circuit Boards). Talk about sticking it to technology challenges.

Silver Epoxy Glue:

Imagine silver particles suspended in an epoxy resin, creating a glue that not only bonds like crazy but also conducts electricity like lightning. This silver epoxy glue is a superhero in high-frequency bonding, chip packaging, and die attachment in the semiconductor industry. It’s like having a powerful electric current running through your adhesive.

Nickel and Copper Conductive Adhesives:

Say goodbye to traditional soldering techniques. Nickel and copper conductive adhesives offer an alternative way to make electrical connections without the hassle of soldering. These adhesives can bond substrates with different thermal expansion coefficients, making them perfect for delicate microelectronic assemblies or heat-sensitive components. Who needs solder when you’ve got these versatile adhesives?

Graphene-Based Conductive Adhesives:

Enter graphene – the superstar material revolutionizing multiple industries. Now imagine combining its exceptional properties with adhesive magic – that’s graphene-based conductive glue. These glues boast excellent electrical conductivity, impressive thermal properties, and unmatched flexibility. They’re the go-to choice for wearable electronics, smart textiles, and flexible circuits. It’s like sticking technology to your skin.

Conclusion:

Electrically conductive glues are where adhesive technology meets electrical conductivity in a mind-bending fusion. With a range of options available, each with its own superpowers, don’t forget to consider conductive glues when you need to bond electronic components. From carbon-based and silver epoxy glues to nickel, copper, and graphene – these glues will electrify your adhesive game.

Types of Conductive Glue

It lies within a remarkable adhesive known as conductive glue. This extraordinary substance not only bonds components together but also allows the flow of electricity. In this article, we will explore the world of conductive glue and its diverse applications.

The Enchanting World of Conductive Glue:

Conductive glue, also called electrically conductive adhesive (ECA), is a unique adhesive with the ability to conduct electricity. It acts as a secret ingredient that brings electronic devices to life. This extraordinary glue finds its applications in industries such as electronics, automotive, aerospace, and medical devices.

Unveiling the Different Types of Magic:

Similar to the variety of magic spells, conductive glue comes in different types. Let’s delve into a few:

- Silver-Based Conductive Glue: This variety contains silver particles, making it highly conductive. It is ideal for bonding electrical contacts and shielding components.

- Carbon-Based Conductive Glue: With carbon particles as its secret ingredient, this glue is cost-effective and commonly used for grounding applications.

- Copper-Filled Conductive Glue: This glue contains copper particles that provide excellent conductivity and thermal properties. It is perfect for power electronics and heat sinks.

A Closer Look at Applications:

Now that we understand the different types of conductive glue, let’s explore where they work their magic:

- Electronic Devices: Conductive glue bonds components in electronic devices, establishing reliable connections while ensuring electrical conductivity.

- Circuit Board Repair: Conductive glue comes to the rescue when a circuit board needs fixing, repairing damaged traces and reconnecting broken pathways.

- Grounding Wires: Conductive glue is perfect for attaching grounding wires, guaranteeing electrical safety and preventing shocks.

- Flexible Circuits: Certain conductive glues adhere to flexible substrates like fabrics or plastics, making them ideal for wearable electronics and flexible circuits.

Choosing the Perfect Glue:

Selecting the right conductive glue is vital for a successful application. Factors to consider include electrical conductivity, thermal properties, adhesion strength, and material compatibility. Always follow the manufacturer’s instructions for proper application and curing.

Conductive glue possesses the magical ability to bond and conduct electricity. Its various types find applications in electronics, automotive, aerospace, and medical devices. From bonding components to repairing circuit boards, conductive glue plays a crucial role in the world of technology.

Adhesive Matrix and Electrical Conductivity

In this article, we will embark on an electrifying journey as we explore the profound influence of adhesive matrix on electrical conductivity. So, prepare for an adventure that unveils the secrets behind this magical phenomenon.

The Adhesive Matrix:

At the core of conductive glue lies the adhesive matrix, also known as the base material or binder. This matrix serves as the backbone that holds the glue together, providing it with structural integrity. It can be crafted from an array of materials, ranging from polymers to metals and ceramics. The choice of adhesive matrix plays a pivotal role in determining whether the glue possesses electrical conductivity.

Conductive Fillers – The Powerhouses:

To transform regular glue into a conductor, the adhesive matrix must be infused with conductive fillers. These fillers are typically composed of materials with exceptional electrical conductivity, such as silver, copper, carbon nanotubes, or graphene.

The concentration of these fillers within the adhesive matrix is crucial for creating a pathway through which electrons can flow, thereby enhancing the overall conductivity of the glue.

Uniform Dispersion – The Key to Success:

Achieving electrical conductivity necessitates uniform dispersion of conductive fillers within the adhesive matrix. This ensures efficient electron transport by establishing a network or pathway for electron flow.

Techniques like blending, mixing, or compounding are employed during the manufacturing process to ensure even distribution.

Size and Shape – Matters that Count:

The size and shape of conductive fillers significantly impact the electrical conductivity of the glue. Smaller filler particles or nanoparticles offer superior conductivity due to their increased surface area. Moreover, fillers with a higher aspect ratio, such as elongated carbon nanotubes, facilitate electron transfer along their length, further enhancing conductivity.

Balancing Act – Beyond Conductivity:

While electrical conductivity is the primary objective, achieving a balance between conductivity and other desirable adhesive properties is essential. The choice of adhesive matrix must consider factors like mechanical strength, flexibility, and adhesion performance to ensure that the glue meets the specific requirements of its intended application.

Application Methods for ECA

Electrically Conductive Adhesives (ECAs) are supercharged heroes in the world of adhesives, providing both bonding and electrical conductivity. They are conquering industries like electronics, automotive, aerospace, and medical devices. Let’s explore the exciting methods for applying ECAs and unlock their full potential.

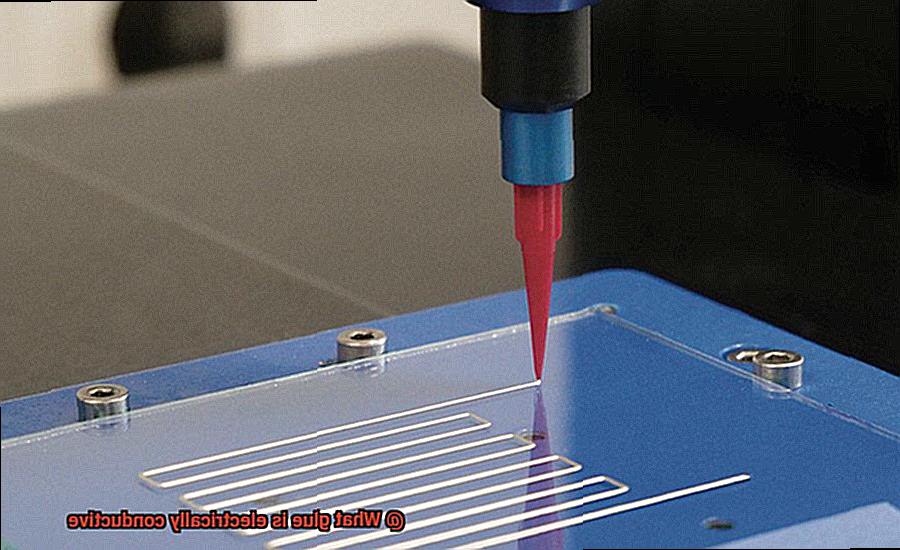

- Dispensing: This method allows for precise control over the amount and location of the adhesive. It’s perfect for intricate patterns and aligning components just right. You can manually dispense with a syringe or go high-tech with an automated system.

- Screen Printing: Transfer the adhesive onto a substrate through a fine mesh screen, like creating a work of art. It’s quick and efficient for large-scale production. Specialized screens adapt to curved or irregular shapes.

- Stenciling: Use a cut-out pattern on the substrate to apply the adhesive through open areas. It’s like drawing with glue. Stenciling is ideal for precise adhesive placement, such as in circuit board assembly.

- Tape/Film Application: Some ECAs come in tape or film form for ultimate convenience. Peel off the backing and stick it where you need it. This method is great for small-scale applications or quick repairs.

When choosing an application method, consider factors like substrate material, adhesive properties, required bond strength, and environmental conditions. Some adhesives may need specific curing methods like heat or UV light for optimal conductivity.

Factors Affecting Electrical Conductivity

In this article, we will explore the intriguing factors that influence the electrical conductivity of glue. Whether you’re an electronics enthusiast or simply curious about the science behind these adhesive superheroes, get ready for an exciting journey.

Material Composition:

Let’s begin with the composition of the glue itself. Electrically conductive glues are crafted from materials with high electrical conductivity, such as metals or conductive polymers. These remarkable substances allow electric charges to effortlessly flow through them, transforming ordinary glue into a conductor of electricity.

Particle Size and Distribution:

Size matters when it comes to electrical conductivity. Smaller conductive particles provide a larger surface area for electrical charges to traverse, ultimately enhancing conductivity. Moreover, an even distribution of these particles throughout the glue ensures a consistent pathway for electrical current, further augmenting its conductivity.

Concentration of Conductive Particles:

In the realm of electrical conductivity, more is indeed merrier. Higher concentrations of conductive particles typically result in increased conductivity since they provide more pathways for electric charges to travel. However, striking the right balance is crucial, as excessively high concentrations can lead to clumping or aggregation of particles, impeding conductivity.

Adhesive Properties:

While electrical conductivity is vital, let us not forget that the primary purpose of glue is adhesion. It is essential to consider factors such as bonding strength, flexibility, and compatibility with different surfaces when selecting an electrically conductive glue. After all, we need our adhesive superhero to excel in both electrical and adhesive applications.

Temperature and Environmental Conditions:

Just like us, glues can be influenced by their surroundings. Some glues may experience changes in their conductivity when exposed to extreme temperatures or varying humidity levels. It is crucial to evaluate the stability and reliability of the glue’s electrical conductivity under different environmental conditions to ensure its suitability for specific applications.

Curing Process:

Last but certainly not least, the curing process utilized for the conductive glue can significantly impact its electrical conductivity. Different glues require varying curing methods, such as heat curing or room temperature curing. The specific curing process employed can influence the arrangement and bonding of conductive particles within the glue, ultimately affecting its electrical properties.

Conclusion:

By considering these six factors, you can unlock the full potential of electrically conductive glue. Whether you require precise placement or swift repairs in industries like electronics, automotive, aerospace, or medical devices, these adhesive superheroes are here to save the day. Just remember to carefully assess your requirements and select a glue that offers both reliable electrical conductivity and strong adhesion properties.

Industries Where ECA is Used

Electrically conductive adhesive (ECA) is a specialized adhesive that has the remarkable ability to conduct electricity. This unique characteristic makes it an indispensable component in several industries where electrical conductivity is crucial. Let’s explore some key industries where ECA is commonly utilized:

- Electronics Industry: The electronics industry heavily relies on ECA for bonding various electronic components together, such as integrated circuits, transistors, and resistors. It ensures a strong and reliable electrical connection between these components, enabling smooth electrical flow in electronic devices. ECA is particularly favored in the manufacturing of printed circuit boards (PCBs), where it securely attaches components to the board’s surface.

- Aerospace and Aviation Industry: The aerospace and aviation industry demands high-performance materials capable of withstanding extreme conditions while providing reliable electrical connections. ECA is extensively used for bonding electrical connectors, sensors, and other critical components in aircraft and spacecraft. Its ability to maintain conductivity under harsh environments, including high temperatures, vibrations, and electromagnetic interference, makes it an ideal choice for these applications.

- Automotive Industry: In the automotive sector, ECA plays a vital role in various applications. It is commonly used in the assembly of electronic control units (ECUs), which are essential for the proper functioning of modern vehicles’ electrical systems. By ensuring secure connections between ECUs and other electronic components, ECA enables efficient communication and control within the vehicle’s network. Additionally, ECA finds applications in bonding sensors, antennas, and other electrical components in automotive systems.

- Medical Devices Industry: Medical devices require not only secure electrical connections but also biocompatibility and resistance to sterilization processes. ECA fulfills these requirements and finds extensive use in medical device manufacturing. It bonds electrodes, sensors, and other electrical components in devices like pacemakers, defibrillators, and diagnostic equipment. ECA’s ability to maintain conductivity even after repeated sterilization cycles makes it an ideal choice in the medical field.

- Renewable Energy Industry: With the rising emphasis on renewable energy sources, ECA has become a crucial adhesive in this industry. It is used in the assembly of solar panels to provide electrical connections between photovoltaic cells, ensuring efficient electricity generation. ECA is also utilized in the manufacturing of wind turbines, where it bonds electrical components together, enabling the smooth transmission of electricity generated by the turbine’s blades.

Considerations When Choosing an ECA

When selecting an electrically conductive adhesive (ECA), there are several critical considerations to evaluate. These factors will ensure that the chosen ECA is the most suitable for the particular application and requirements at hand.

First and foremost, it is essential to consider the electrical conductivity requirements of the application. Different ECAs possess varying levels of electrical conductivity, so selecting an adhesive that meets the desired level is crucial. High conductivity may be necessary for efficient electrical transfer in certain applications, while others may suffice with lower levels.

Next, the substrate materials involved in the application must be taken into account. ECAs can bond to a wide range of materials, including metals, plastics, ceramics, and composites. However, not all adhesives are compatible with every type of substrate material. It is vital to choose an ECA specifically designed for the intended substrates to ensure optimal bonding performance.

Cure time and process are also important considerations. ECAs typically require curing to achieve their full electrical conductivity and strength. Cure time can vary depending on the adhesive and curing method employed. Some ECAs necessitate heat curing, while others cure at room temperature or with UV light. It is essential to ensure that the cure time aligns with production requirements and capabilities.

Mechanical properties should not be overlooked when choosing an ECA. The adhesive must be strong and flexible enough to withstand stresses and vibrations encountered during operation. Thermal stability, chemical resistance, and moisture resistance are also vital factors to consider if the adhesive will be exposed to harsh environments.

Lastly, ease of application and compatibility with the manufacturing process should be evaluated. ECAs come in different forms such as liquids, pastes, and films. Selecting a form that works well with the application method and equipment is crucial. Additionally, considering shelf life and storage conditions ensures the adhesive remains in optimal condition.

Advantages of Using Electrically Conductive Glue

Are you tired of dealing with complicated and messy electrical bonding techniques? Well, say goodbye to your soldering iron woes because electrically conductive glue is here to save the day. This revolutionary adhesive offers a range of advantages that will leave you electrified. Let’s dive right into the perks of using this sticky wonder in your electrical bonding applications:

- Enhanced Electrical Connectivity: Electrically conductive glue creates a conductive path between surfaces, ensuring a strong and reliable electrical connection. Say goodbye to unreliable connections and hello to seamless conductivity.

- Simplified Assembly Process: Forget about fumbling with complex equipment and high temperatures. Conductive glue simplifies the assembly process, making it safer and easier to use. Just grab a syringe or an automated dispenser, apply the glue, and voila. Quick and efficient bonding at your fingertips.

- Improved Flexibility: Unlike rigid solder joints or welds, conductive glue can handle stress and vibrations without losing its electrical conductivity. It’s perfect for applications that require flexibility, like wearable electronics or flexible circuit boards.

- Compatibility with Various Substrates: Whether it’s metal, ceramics, glass, or plastics, conductive glue plays well with a wide range of materials. No more worrying about thermal stress-induced damage when bonding different substrates together.

- Cost-Effective Solution: Conductive glue offers a cost-effective alternative to traditional methods like soldering or welding. It’s not only the materials that are less expensive but also the simplified assembly process that reduces labor costs. Say hello to savings.

- Repairability: Need to fix or replace components? Conductive glue has got you covered. Unlike soldered or welded connections that can be a nightmare to repair or remove without causing damage, conductive glue allows for easy disassembly and rework. Maintenance just got a whole lot easier.

- Environmental Friendliness: If you care about the environment, conductive glue is your eco-friendly hero. It doesn’t require harmful fluxes or lead-based solders, reducing the risk of environmental contamination. Plus, it can be formulated to be free of volatile organic compounds (VOCs), making it a safer and more sustainable option.

Also Read: Is Hot Glue Conductive?

Disadvantages of Using Electrically Conductive Glue

Today, we will explore the realm of electrically conductive glue, a remarkable innovation with its own set of drawbacks. Before embarking on the journey of electric bonding, it is imperative to understand the potential disadvantages that come with this adhesive.

So, put on your safety goggles as we delve into the limitations of using electrically conductive glue.

Limited Conductivity:

Let’s start with conductivity. Despite offering some level of electrical conductivity, electrically conductive glue may fall short in high-power applications or situations that demand a robust electrical connection.

Factors such as glue composition, curing process, and environmental conditions can impact the glue’s conductivity. Therefore, project requirements must be carefully considered to ensure that the glue can handle the electrical load.

Weaker Bond Strength:

Bond strength is another concern when it comes to electrically conductive glue. Unfortunately, this type of adhesive often exhibits weaker bonding compared to traditional methods like soldering or welding. This weakness becomes problematic in applications involving mechanical stress or vibrations. Joint failure, connection instability, and signal interruptions can all arise when relying solely on electrically conductive glue. Thus, it is crucial to evaluate the mechanical strength required for each project before making adhesive decisions.

Temperature Limitations:

Beware of temperature limitations. Many electrically conductive glues have low melting points or may degrade when exposed to high temperatures. If your application involves sizzling conditions, your glue may lose conductivity or fail altogether. Understanding the operating temperature range of your chosen adhesive is vital to prevent melting away your electrical connections.

Sensitivity to Environmental Factors:

Like humans, electrically conductive glue can be sensitive to its surroundings. Humidity, moisture, and chemicals can all wreak havoc on the conductivity and reliability of your electrical connection. Before bonding, it is crucial to consider the environmental conditions your glue will encounter and choose an adhesive that can withstand these factors. Don’t let your adhesive get all hot and bothered.

Difficult Repair and Maintenance:

Uh-oh, what happens when things go wrong? Repairing or modifying electrically conductive glue connections can be a sticky situation. Unlike soldering, once the glue is cured, it forms a permanent bond that is not easily reversible. This poses a challenge in reworking or replacing components without damaging existing connections. Specialized tools or techniques may be required to remove or replace the glue, adding complexity to repair and maintenance procedures.

Cost Considerations:

Lastly, let’s talk about everyone’s favorite topic: cost. Electrically conductive glue often comes with a heart-stopping price tag compared to traditional adhesives or soldering materials. The specialized nature of these glues, their unique properties, and precision formulations contribute to higher costs. Therefore, before getting carried away with the allure of electrically conductive glue, consider whether its benefits are worth the extra expense.

nxa4LddIb0o” >