Are you a DIY enthusiast who loves to tinker with electrical wires? Have you ever found yourself in a sticky situation where you need to glue wires together, but have no clue what type of adhesive to use? If yes, then this blog post is for you.

Working with electrical wires can be tricky, especially when it comes to selecting the right adhesive. Not all glues are created equal, and not all of them can withstand the heat and pressure that come with electrical wiring. But don’t worry, we’ve got your back.

In this post, we’ll be exploring the world of glues that can be used on wires. We’ll take a deep dive into the different types of adhesives available and which ones work best for specific situations. From hot glue to epoxy, we’ll give you all the information you need to successfully glue wires for your DIY projects.

But before we get started, let’s get one thing straight – gluing wires may seem easy, but it’s not as simple as slapping some glue on and calling it a day. A bad glue choice can lead to electrical issues or even a fire. So sit back, grab your favorite beverage and let’s explore the wonderful world of glues and wires together.

What is Glue?

Contents

Glue is a remarkable adhesive that has the power to bond surfaces together and form a strong, unbreakable connection. This sticky substance is typically made from a combination of natural or synthetic polymers, solvents, and additives. With the diversity of materials and applications out there, you can find many types of glue on the market, each with its own distinct features and characteristics.

Some commonly used adhesives for wiring projects include cyanoacrylate (super glue), epoxy, hot glue, and silicone. Cyanoacrylate glue is a fast-setting adhesive that can bond to a variety of surfaces, including wires. Though it may not be the best choice for high-stress applications, it dries quickly and forms a strong bond that can withstand vibrations and impacts.

On the other hand, epoxy resin is an ideal option for wiring exposed to heat or harsh environments. It’s a two-part adhesive that consists of a resin and hardener. When mixed together, they form a permanent bond that can handle high temperatures and corrosive substances.

Silicone adhesive is another flexible option that’s suitable for electronic devices or automotive wiring. It’s perfect for applications that require flexibility as it can withstand high temperatures and resist water and chemicals.

When selecting a glue for your wiring project, several factors need consideration. These include strength, flexibility, and electrical conductivity. It’s vital to choose an adhesive that’s strong enough to hold the wires together but also flexible enough to allow movement without breaking. Additionally, you want to select an adhesive that doesn’t interfere with the conductivity of the wires.

Cleanliness is crucial when using adhesives on wires. You must ensure that the wire surface is free from dirt, grease or other contaminants as adhesives will not bond correctly if the surface is dirty or oily. Always follow the manufacturer’s instructions when using adhesives on wires to achieve the best results.

Types of Glue Used on Wires

When it comes to gluing wires, there’s no one-size-fits-all solution. The type of glue used will depend on the wire’s material, the intended use, and the environment it will be exposed to. Here are some of the most common types of glue used on wires and their unique properties.

Epoxy is a two-part adhesive that’s renowned for its strength and durability. It’s an excellent choice for wires that will be exposed to severe conditions, such as those used in marine or automotive applications. It’s also resistant to water and chemicals, making it ideal for outdoor use.

Cyanoacrylate glue, also known as superglue, is a fast-drying adhesive that forms a strong bond between surfaces. Although it may not be the best option for all types of wires, it’s useful for small-scale projects or temporary repairs.

Silicone adhesive is a flexible adhesive that can be used on wires that need to move or bend. It can also withstand high temperatures, making it perfect for use in applications where the wire will be exposed to heat.

Polyurethane adhesive is a waterproof adhesive that can bond a wide range of materials, including wires. It’s particularly useful for heavy-duty projects where maximum strength is required.

Finally, hot glue is a fast-drying adhesive that can be applied using a hot glue gun. While it may not be the strongest option, it can be useful for small-scale projects or temporary repairs.

When selecting a glue for use on wires, it’s essential to consider the specific needs of the application. Temperature fluctuations, exposure to water or chemicals, and flexibility should all be taken into account when deciding which type of glue to use. By choosing the right glue for your project, you can ensure that your wires will stay securely bonded together for years to come.

Cyanoacrylate Glue

This versatile adhesive can be used on a variety of wire materials, including copper, aluminum, and steel. However, before bonding your wires together, it is essential to ensure that the surfaces are clean and dry. Even the slightest dirt or moisture can weaken the bond and cause the wire to detach.

One of the advantages of using cyanoacrylate glue for wires is its ease of application and versatility. Despite its usefulness, it is not recommended for wires exposed to high temperatures or chemical exposure as it may lose its strength over time. In such cases, epoxy may be a better option.

When applying cyanoacrylate glue to wires, use a small amount evenly across the surface. Overuse of glue can cause the wire to become brittle and break. It is also important to avoid getting the glue on your skin as it can bond quickly and cause irritation or injury.

To sum it up, cyanoacrylate glue can be a suitable adhesive for bonding wires when used correctly. Make sure that surfaces are clean and dry and use a small amount of glue evenly across the surface. However, it may not be suitable for wires exposed to high temperatures or chemical exposure. Consider all factors before choosing the right adhesive for your wires.

Remember to proceed with caution when working with cyanoacrylate glue. It may be tiny, but its strength should not be underestimated. A small drop of this powerful adhesive can create a strong bond that lasts long after your project is complete.

Epoxy Resin

Look no further than epoxy resin. As an expert in this field, let me tell you all about the advantages and considerations of using this powerhouse adhesive.

Epoxy resin is a two-part adhesive consisting of a resin and hardener that, when mixed together, create a bond that’s strong enough to withstand almost anything. It can be used on a variety of surfaces, including metal, plastic, and rubber, making it an excellent choice for bonding wires of different materials.

Before applying epoxy resin to your wires, ensure that they are clean and free from debris or oils. A small amount of mixed epoxy should be applied to the wires and pressed together firmly. The epoxy should then be left to cure for the recommended time, typically between 24-48 hours.

One significant advantage of using epoxy resin is its ability to create a waterproof seal that’s perfect for outdoor applications or areas exposed to moisture. It’s also heat-resistant, making it ideal for use in electronic devices or other applications where heat may be present.

It’s essential to remember that once cured, epoxy resin can be challenging to remove. Therefore, care should be taken when applying it to wires. Also, ensure you wear gloves and work in a well-ventilated area when working with epoxy resin.

Silicone Adhesive

Look no further than silicone adhesive. As an expert in this field, I can tell you that silicone adhesive is the go-to choice for bonding wires due to its numerous advantages.

Silicone adhesive provides a strong and durable bond, making it ideal for electrical wires. You won’t have to worry about your circuit failing due to a loose connection. Additionally, its flexibility allows it to move with the wires without cracking or breaking, even with movement or vibration.

Heat resistance is another significant advantage of silicone adhesive. With the ability to withstand temperatures up to 500 degrees Fahrenheit, it’s perfect for high-temperature applications like electronic devices or automotive wiring. No more worrying about your adhesive melting.

It’s important to note that there are different types of silicone adhesives available. One-part formulations are easier to use, while two-part formulations provide a stronger bond. Make sure to choose the appropriate type for the specific application to ensure the best results.

Silicone adhesive isn’t just reliable; it’s also water-resistant, making it perfect for outdoor applications or areas exposed to moisture. You can trust that your wires will remain securely attached even in wet conditions.

Preparing the Wires for Glue Application

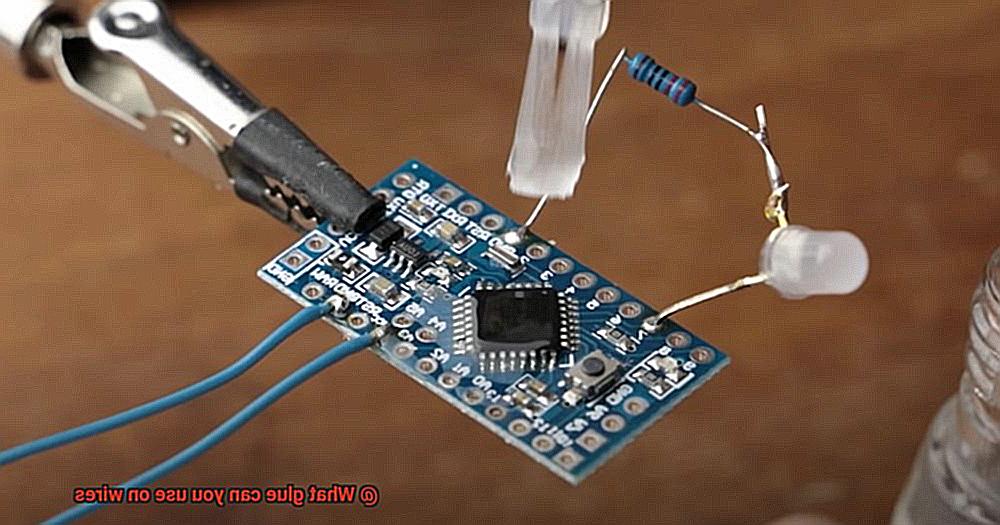

When it comes to gluing wires together, preparation is key. Properly preparing the wires for glue application ensures a strong and lasting bond. Let’s walk through some steps involved in preparing wires for glue application.

First things first, clean those wires. Dust, dirt, and debris can interfere with the bonding process. A clean cloth or wire brush can be used to wipe the wires down.

Next up, strip off any insulation or coating. This step is crucial as it allows the glue to come into direct contact with the metal wire, creating a stronger bond. Be sure to use wire strippers or a sharp knife to carefully remove the insulation without damaging the wire.

Now it’s time to roughen up the surface of the wire. This step may seem counterintuitive, but creating tiny scratches on the surface of the wire actually helps the glue adhere better. Sandpaper or a wire brush can be used for this step. Be careful not to scratch too deeply though, as this can weaken the wire.

Lastly, make sure that your wires are straight and properly aligned before applying any glue. Twisted or bent wires can cause uneven pressure on the glue, resulting in weaker bonds and potential failure.

Benefits of Using Glue on Wires

If you’re tired of dealing with loose wires that seem to move around and cause electrical issues, using glue to secure your wires in place can provide numerous benefits. As an expert in this field, I have compiled some research notes on the advantages of using glue on wires.

Firstly, using glue can prevent wire movement. This is crucial because when wires start to move around, they can become disconnected or even cause electrical fires. By using glue to secure your wires in place, you can prevent these dangerous issues from occurring and ensure that your wiring is safe and secure.

Moreover, using glue on wires provides additional insulation. This is especially beneficial in harsh environments or situations where your wires may be exposed to extreme temperatures. The glue acts as a protective layer, keeping your wires safe and secure from external elements.

In addition, using glue on wires can improve wire organization. By securing your wiring with glue, you can keep them neat and tidy, making it easier to identify and troubleshoot any issues that may arise. Plus, it just looks better overall and enhances the overall aesthetic of your wiring setup.

Last but not least, using glue on wires can save you time and money. Instead of constantly checking and re-securing your wiring, using glue provides a long-lasting solution. This means less time spent troubleshooting and repairing faulty wiring, ultimately saving you time and money in the long run.

Disadvantages of Using Glue on Wires

Glue may seem like the perfect option, but before you proceed, consider the disadvantages.

Firstly, glue can be messy and challenging to work with, especially when dealing with small wires. The glue may end up in the wrong places or even on other components, causing damage or interference. Additionally, it can make it hard to make changes or repairs to the wiring in the future.

Secondly, it’s essential to choose an adhesive that is specifically designed for use on wires. Some adhesives may be too weak and not provide enough hold, while others may be too strong and cause damage to the wire’s insulation or even cause the wire to break. Using the wrong adhesive can lead to unreliable connections and potential hazards.

Thirdly, using glue on wires can increase the risk of electrical shorts or fires if not applied correctly. This risk is even higher when using flammable adhesives. Electrical shorts and fires can cause significant damage and pose a safety hazard.

F19YVfOrbv8″ >

Conclusion

In conclusion, selecting the appropriate adhesive is vital when it comes to gluing wires together. It’s crucial to consider essential factors such as strength, flexibility, and electrical conductivity before making a final decision. Cyanoacrylate glue is an ideal fast-setting adhesive that can bond to various surfaces, while epoxy resin is perfect for wiring exposed to heat or harsh environments. For electronic devices or automotive wiring, silicone adhesive offers a flexible option.

Before applying any glue to wires, proper preparation is necessary. Cleaning the wires and stripping off any insulation or coating is critical. Roughening up the wire’s surface can also improve the glue’s adhesion. However, using glue on wires has its disadvantages such as potential damage to insulation or wires if using the wrong adhesive, messiness and increased risk of electrical shorts or fires if not applied correctly.

Overall, gluing wires provides numerous benefits such as preventing wire movement and improving wire organization while providing additional insulation.