Ever had that heart-stopping moment when your favorite plate slips from your hands and shatters into a million pieces? It’s enough to make you want to cry over spilled milk, or in this case, broken china. But fear not, my friend, because I’ve got the secret sauce to fix it all. And it all starts with finding the perfect glue to bring those shattered shards back together. So buckle up and join me on this glue-tastic journey as we explore the world of plate repair.

First up on our glue extravaganza is epoxy glue. This bad boy is like a superhero for your broken plates. It swoops in with its two-part chemical formula and creates an unbreakable bond that would make even Superman jealous. Plus, it dries clear and can withstand water like a champ, making it perfect for those plates you actually plan on using again.

But wait, there’s more. Enter super glue, also known as cyanoacrylate adhesive. This little wonder works its magic by reacting to moisture and creating a bond so strong it could probably hold up a skyscraper (okay, maybe not that strong, but you get the idea). Just be careful because super glue can leave behind some residue and isn’t as water-resistant as our buddy epoxy glue.

Now, if you’re thinking about fixing plates that will come into contact with food (because who wants to eat off broken dishes?), then listen up. We’ve got something special just for you – food-safe adhesive. This stuff is designed specifically for repairing plates used for serving food. It’s non-toxic, odorless (no funky smells ruining your dinner party), and safe for contact with food. And guess what? It’s even dishwasher-safe. Talk about convenience.

Before you go gluing willy-nilly though, let me drop some wisdom on you. Consider the purpose of your plate and any potential drawbacks of each type of glue. It’s always a good idea to do a little test run on a small, hidden area before slathering that glue all over your precious broken pieces. We wouldn’t want any unexpected surprises, would we?

So there you have it, my plate-repairing friend. Armed with this newfound knowledge, you’re ready to conquer the world of broken plates and bring them back to their former glory. Now go forth and resurrect those beloved dishes like the glue guru you were born to be.

What is Glue?

Contents

- 1 What is Glue?

- 2 Types of Glue for Plates

- 3 Advantages and Disadvantages of Epoxy Resin

- 4 Advantages and Disadvantages of Food-Safe Adhesives

- 5 Advantages and Disadvantages of Silicone Adhesive

- 6 Preparing the Plates Before Gluing

- 7 Following Manufacturer’s Instructions

- 8 Dishwasher Safety Considerations

- 9 Conclusion

Glue, a captivating substance with the remarkable ability to unite. It is the faithful companion of artists, craftsmen, and everyday DIY enthusiasts, allowing them to create, repair, and construct with ease. But what exactly is glue and how does it work its magic?

At its essence, glue is a bonding agent that brings surfaces together. It comes in various forms – liquid, gel, or solid – and is a staple in every household and workshop. Its purpose is simple yet vital: to create a robust and enduring bond between different materials.

There are several types of glue available, each tailored for specific applications and materials. Let’s explore some of the most commonly used ones:

- PVA Glue: This water-based adhesive is beloved by crafters and woodworkers alike. It dries clear and is ideal for porous materials such as paper, fabric, cardboard, and wood.

- Epoxy Glue: When you need an incredibly strong bond that can withstand heat, water, and chemicals, epoxy glue is your go-to. It consists of resin and hardener that are mixed together before application.

- Super Glue: In need of a quick fix? Super glue is the answer. This fast-drying adhesive bonds almost instantly upon contact with the surface and is perfect for small repairs on plastic, metal, rubber, and ceramics.

- Contact Cement: This adhesive requires both surfaces to be coated before joining them together. It creates a robust bond when the coated surfaces are pressed firmly against each other. It’s commonly used in woodworking and upholstery.

- Hot Glue: As the name suggests, hot glue is melted using a hot glue gun and quickly solidifies upon cooling. It’s versatile and great for crafts, DIY projects, and temporary bonding.

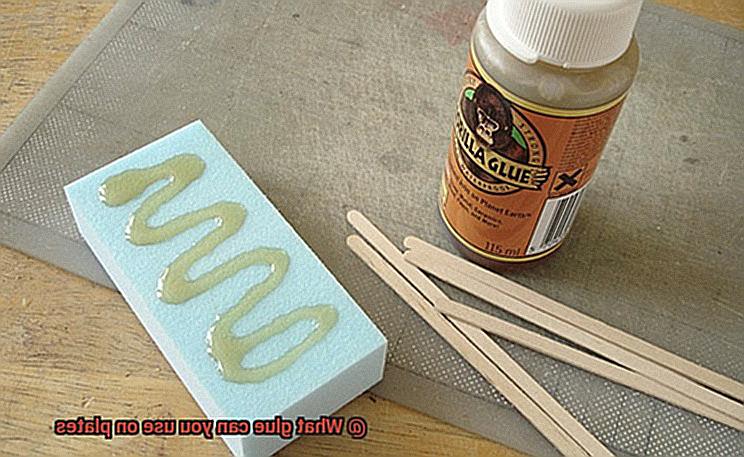

Now that we’ve covered the fundamentals of glue, let’s dive into a specific application: gluing plates together. When it comes to bonding plates, it is crucial to use a glue that is food-safe and non-toxic. Epoxy resin, a two-part adhesive, is a popular choice as it forms a strong bond and is resistant to heat, water, and chemicals. There are also food-safe adhesives designed specifically for ceramics and glass, providing a strong bond that can withstand washing and normal use. Silicone adhesive is another suitable option as it’s safe for use with food, flexible, and resistant to high temperatures.

Remember to ensure the surfaces are clean and free from dirt or grease when using any adhesive on plates. Follow the manufacturer’s instructions carefully, allowing the adhesive to dry or cure fully before using the plates. While some adhesives may be safe for use on plates, they may not be dishwasher safe. Therefore, handwashing is often recommended.

Types of Glue for Plates

In this article, we will dive into the world of plate adhesives and explore the various types of glues that are ideal for different plate materials and purposes. From the superhero-like strength of epoxy glue to the delicate touch of craft glue, we’ve got all the information you need to make your plates as good as new.

Epoxy Glue: The Superhero Adhesive

If you’re in need of a glue that can withstand the toughest challenges, epoxy glue is your go-to option. Known for its incredible strength and durability, this adhesive creates a bond that’s as tough as nails. Perfect for repairing broken plates or attaching decorative elements, epoxy glue can handle high temperatures, making it ideal for oven-safe plates. Its superhero-like qualities ensure that your plates will be sturdy and long-lasting.

Ceramic Glue: A Match Made in Pottery Heaven

When it comes to bonding ceramic plates, ceramic glue is a match made in pottery heaven. This specialized adhesive provides a strong and long-lasting bond, even when faced with heat and water. Say goodbye to those pesky chips and cracks that can ruin the beauty of your ceramic plates. With ceramic glue, you can restore their original charm and ensure they withstand everyday use.

Multipurpose Plastic Adhesive: Plastic Fantastic.

Plastic plates require a special kind of adhesive, and multipurpose plastic adhesive is just the magic you need. Specially formulated to bond plastic materials, this adhesive creates a strong and flexible connection that can handle any dining experience. Whether you’re using it for picnics or formal dinners, multipurpose plastic adhesive will keep your plastic plates intact and looking fantastic.

Glass Glue: Clear as Crystal

Working with glass plates or glass-like materials? Glass glue is your best friend. This adhesive forms a clear and sturdy bond that can withstand both heat and water, ensuring your glass plates remain as crystal-clear as ever. Whether you’re repairing glass plates or adding decorative elements, glass glue will blend seamlessly with the material, creating an invisible bond that’s as strong as it is beautiful.

General-Purpose Adhesives: The Jack-of-All-Trades

Don’t worry if you have plates made of different materials – general-purpose adhesives have got your back. These versatile glues can bond ceramic, plastic, or glass plates, making them the ultimate jack-of-all-trades. Just make sure you choose one that’s suitable for your specific plate material to ensure optimal adhesion and longevity.

Advantages and Disadvantages of Epoxy Resin

Epoxy resin, a superhero-like adhesive, offers numerous advantages when it comes to bonding plates.

Its strong and durable bond can handle even the toughest wear and tear, ensuring no more cracked or peeling plates. Additionally, epoxy resin is resistant to moisture and chemicals, making it perfect for plates that may come into contact with liquids or chemicals in kitchens or laboratories.

Its versatile application allows it to be used on a variety of materials such as ceramics, glass, porcelain, and metals, eliminating the need for multiple glues. Furthermore, epoxy resin dries clear and transparent, preserving the original appearance of valuable or decorative plates.

However, epoxy resin does have its drawbacks. It requires careful mixing of two components and has a longer curing time compared to other glues.

This means you’ll have to wait for it to fully dry before handling the glued plates. Moreover, working with epoxy resin can release potentially toxic fumes during mixing and curing, necessitating a well-ventilated area or protective equipment.

Finally, once epoxy resin has cured, undoing or removing it without damaging the plates can be challenging.

Advantages and Disadvantages of Food-Safe Adhesives

When it comes to repairing plates, using a food-safe adhesive is not just important but crucial in maintaining the safety and integrity of the repaired item. In this article, we will delve into the advantages and disadvantages of utilizing food-safe adhesives, providing you with a comprehensive understanding of their benefits and limitations.

Advantages:

- Safety: Food-safe adhesives are specifically formulated to meet stringent food safety regulations. They do not contain any harmful substances that could potentially leach into the food, ensuring the utmost safety for the end consumer.

- Non-Toxic: Crafted from non-toxic materials, these adhesives guarantee that no harmful fumes or chemicals are released when exposed to heat or moisture. This feature is essential in preventing any contamination of the food.

- Temperature Resistance: Food-safe adhesives can withstand a wide range of temperatures, making them suitable for plates that may be subjected to extreme temperature changes. This versatility allows for seamless transitions from the refrigerator to the microwave or oven without compromising the adhesive bond.

- Versatility: Food-safe adhesives can be used on various materials commonly found in kitchenware, including ceramic, glass, porcelain, and certain types of plastics. This flexibility allows for effortless repairs on different types of plates without compromising their food safety.

Disadvantages:

- Limited Bond Strength: Compared to regular adhesives, food-safe adhesives may have slightly lower bond strength. This is because they are formulated to be easily removable, ensuring no residue is left behind when removing the adhesive from the plate.

- Longer Drying Time: Food-safe adhesives often require a longer drying time compared to regular adhesives. This may be inconvenient when attempting to repair plates quickly or in a commercial kitchen setting where time is of the essence. However, allowing the adhesive to fully cure is crucial to ensure its effectiveness and safety.

- Limited Availability: Food-safe adhesives may not be as readily available as regular adhesives. They are typically sold in specialized stores or online retailers catering to the needs of the food industry. This limited availability may pose challenges when searching for the right adhesive for specific plate repair needs.

- Cost: Food-safe adhesives may be slightly more expensive compared to regular adhesives due to their specialized formulation and compliance with food safety regulations. While the cost difference may not be significant for occasional repairs, it could accumulate for frequent or commercial use.

Advantages and Disadvantages of Silicone Adhesive

Silicone adhesive, a go-to choice for bonding plates, offers several advantages that make it a versatile and reliable option. However, like any product, it also has its downsides. In this article, we will explore the advantages and disadvantages of using silicone adhesive for bonding plates in greater detail.

Let’s dive into the advantages first. Firstly, silicone adhesive is incredibly versatile. It can bond various materials, including ceramic, glass, metal, plastic, and even porous surfaces like wood and fabric. This versatility makes it an ideal choice for repairing or bonding plates made from different materials.

Additionally, silicone adhesive exhibits exceptional heat resistance. It can withstand extreme temperatures ranging from -40°C to 200°C or even higher depending on the specific product. This makes it perfect for bonding plates that may be exposed to heat-intensive environments such as ovens or microwaves.

Another advantage is its waterproof and weatherproof properties. Silicone adhesive forms a strong bond that is resistant to water, moisture, and humidity. This means you can confidently use it for indoor or outdoor applications without worrying about the bond weakening over time.

Furthermore, silicone adhesive offers flexibility and durability. Its unique composition allows it to absorb shocks or vibrations without cracking or breaking the bond. This makes it ideal for plates that may experience frequent handling or slight movement. Plus, silicone adhesive is known for its long-lasting durability and resistance to aging.

Now let’s turn our attention to the disadvantages. One drawback of silicone adhesive is its longer curing time compared to other types of adhesives. It may take several hours or even days for it to fully cure and reach its maximum strength. So if you need to use the bonded plates immediately after application, this could be inconvenient.

Another disadvantage is the limited initial bond strength of silicone adhesive. While it offers excellent long-term bonding strength, the initial bond may not be as strong. Additional support or clamping may be necessary during the curing process to ensure a secure bond.

Additionally, silicone adhesive is not as effective in filling larger gaps or uneven surfaces compared to some other adhesives. It works best on smooth and clean surfaces with minimal gaps between the plates. So if you’re trying to bond plates with significant gaps or irregularities, silicone adhesive may not be the most suitable option.

Lastly, once silicone adhesive is fully cured, it can be challenging to remove or separate the bonded plates without causing damage. This is because silicone forms a strong and resilient bond that is resistant to solvents or mechanical forces. If you anticipate the need for future disassembly or repair, it’s important to consider alternative adhesives that offer easier removal options.

Preparing the Plates Before Gluing

Today, we’re diving into the nitty-gritty details of preparing plates before gluing. Whether you’re fixing a broken ceramic dish or creating a stunning mosaic masterpiece, these steps will ensure a strong and long-lasting bond. So grab your sandpaper and let’s get started.

Step 1: Clean the surfaces

First things first, we need to make sure those plates are squeaky clean. Grab a mild detergent or dish soap and warm water, and give those surfaces a good scrub. This will remove any dirt, dust, grease, or residue that could interfere with the adhesive bond. Once they’re sparkling clean, make sure to dry them thoroughly before moving on to the next step.

Step 2: Roughen the surfaces

To really amp up that adhesive power, we need to roughen the plate surfaces. Grab some fine-grit sandpaper or a sanding block and lightly sand the areas that will be glued together. This roughened texture will provide more surface area for the glue to adhere to. Remember, gentle is the name of the game here – we don’t want to damage those precious plates.

Step 3: Apply a primer (if necessary)

Depending on the type of plates and glue you’re using, it might be necessary to apply a primer. Primers can work wonders on materials like porcelain or ceramic plates, improving their adhesion properties. Be sure to carefully follow the instructions provided with the primer product – different primers may have specific application methods and drying times.

Step 4: Align and secure the plates

Now that our plates are clean, roughened (if needed), and primed (if necessary), it’s time to align them properly. Use alignment guides or marks if available to ensure accurate placement. And to keep things in place while the glue works its magic, use clamps or tape to securely hold the plates together.

Step 5: Protect surrounding areas

Before we bust out the glue, let’s take a moment to protect any surrounding areas that may accidentally come into contact with it. We’ve all had those “oops” moments where glue ends up where it shouldn’t be – trust me, it’s not fun. Use masking tape or plastic sheets to cover adjacent surfaces, preventing any unwanted adhesive marks or damage.

And there you have it, folks – a comprehensive guide on preparing plates before gluing. By following these steps, you’ll increase your chances of achieving a strong and durable bond. Just remember, the specific instructions may vary depending on the type of plates and glue you’re using, so always refer to the manufacturer’s guidelines for the best results.

Following Manufacturer’s Instructions

In this blog post, we’ll explore why it’s essential to pay attention to those instructions and how doing so can help you achieve perfectly bonded plates. So, put on your apron and get ready to dive into the art of glue.

Read and Understand the Instructions

To begin your journey towards perfectly bonded plates, start by carefully reading and understanding the instructions provided by the glue manufacturer. These guidelines will help you determine which surfaces are suitable for gluing, the recommended drying time, safety precautions, and more. By familiarizing yourself with these instructions, you’ll be equipped to choose the right glue for your specific plate material and ensure a successful bonding process.

Clean and Prepare the Surface

A solid foundation is essential for a strong bond between your plates. Before applying any glue, take the time to clean and prepare the surface thoroughly. Eliminate dirt, grease, or other contaminants that could compromise the adhesive properties of the glue. Use a mild detergent or dish soap to give the surface a thorough cleaning, rinse it well, and pat it dry. This step sets the stage for a flawless bond.

Apply the Glue Correctly

The application of glue is an art in itself. Follow the manufacturer’s instructions on how much glue to use and how to apply it evenly across the bonding area. Remember, less is often more when it comes to glue application. Applying too much can result in excess seepage or uneven drying, compromising both the appearance and durability of your bonded plates.

Allow Sufficient Drying Time

Patience is a virtue when it comes to gluing plates. Rushing the drying time can lead to premature handling or movement of the plates, jeopardizing the bond. Follow the manufacturer’s instructions on the recommended drying time and resist the temptation to touch or move the plates until they are fully dry. This ensures a secure and long-lasting bond.

Curing Time

Some glues require additional curing time to reach their maximum bonding strength. Even if the glue appears dry to the touch, it may not have fully cured. It’s crucial to allow the glued plates to cure for the specified duration mentioned by the manufacturer. This step guarantees optimal adhesion and longevity of your bonded plates.

Handle with Care

Once your plates are glued and fully cured, handle them with utmost care. Avoid subjecting them to extreme temperatures, excessive moisture, or rough handling, as these factors can weaken the adhesive properties over time. By treating your bonded plates gently, you’ll ensure their beauty and durability for years to come.

Dishwasher Safety Considerations

Dishwasher safety considerations are of utmost importance when it comes to using glue on plates. Not all glues are created equal, and the high heat and moisture in the dishwasher can wreak havoc on certain adhesives. To ensure the longevity of your dishes and the safety of your food, here are some key points to keep in mind.

First and foremost, choose a glue that is specifically labeled as dishwasher-safe or heat-resistant. These glues are specially formulated to withstand the rigorous conditions inside a dishwasher, maintaining their adhesive properties even after multiple cycles. By selecting a suitable glue, you can bid farewell to broken plates and unsightly glue residue.

Consider the material of your plates when selecting a glue. Different materials require different adhesives for optimal results. Ceramic or porcelain plates may require a different type of glue than glass or plastic plates. Take a moment to assess the composition of your dishes and choose a compatible glue accordingly.

Safety should always be a top priority, particularly when it comes to items that come into contact with food. Ensure that the glue you use is food-safe and non-toxic. Some glues contain harmful chemicals that can leach into your food when exposed to heat. Look for glues that are specifically labeled as food-safe or non-toxic to avoid any potential health hazards.

Proper application is also key to dishwasher safety. Follow the manufacturer’s instructions carefully, including using the recommended amount of glue and allowing it to dry completely before using the plate again. Rushing this step can result in poor adhesion or even contamination of your food—a risk you definitely want to avoid.

Even with dishwasher-safe glues, regular exposure to high heat and moisture can weaken the adhesive bond over time. It’s a good idea to periodically inspect your plates for any signs of loosening or damage. If you notice anything amiss, simply reapply the glue according to the manufacturer’s instructions.

5NEP4LCahXc” >

Conclusion

In conclusion, when it comes to gluing plates together, there are a few options that work well.

One reliable choice is epoxy adhesive, which provides a strong bond and is resistant to heat and moisture. Another option is food-safe ceramic glue, specifically designed for bonding ceramics and safe for use on plates.

It’s important to choose the right glue based on the material of your plates and consider factors like heat resistance and food safety.