Sick of your glued items falling apart in freezing temps? Well, worry no more.

Today, we’re diving into the world of glue and uncovering which types can withstand the icy grip of freezing. Whether you’re fixing a shattered ornament, patching up outdoor decor, or securing parts on your trusty snowboard, we’ll reveal the glues that won’t let you down when the mercury drops.

Let’s stick together.

What is Glue?

Contents

- 1 What is Glue?

- 2 Different Types of Glue

- 3 Epoxy Resin – A Glue That Can Withstand Freezing Temperatures

- 4 Cyanoacrylate (Super Glue) – Another Glue That Can Withstand Freezing Temperatures

- 5 Specialty Glues Formulated for Low Temperatures

- 6 Factors to Consider When Choosing a Glue for Freezing Temperatures

- 7 Surface Preparation and Proper Application for Maximum Adhesive Strength in Cold Conditions

- 8 Conclusion

Glue, the unsung hero of the adhesive world, is a versatile substance that bonds materials together with remarkable strength and durability. From delicate crafts to heavy-duty industrial projects, glue plays a vital role in our daily lives. But what exactly is glue? In this captivating exploration, we will delve into the art and science behind this miraculous adhesive.

The Magic of Molecular Bonds:

At its core, glue is a blend of polymers – long chains of molecules that possess a unique ability to form strong intermolecular bonds. These bonds enable glue to create unyielding connections between different surfaces. When applied, glue undergoes a transformative process known as curing, transitioning from a liquid or gel-like state to a solid state. This metamorphosis occurs through mechanisms like solvent evaporation, chemical reactions, or cooling.

Types of Glue:

- PVA (Polyvinyl Acetate) Glue: A widely-used water-based adhesive, PVA glue exhibits exceptional bonding prowess with porous materials such as wood, paper, and fabric. However, it may succumb to freezing temperatures, becoming brittle or losing its adhesive properties.

- Epoxy Glue: Renowned for its unmatched strength and durability, epoxy glue consists of two components – resin and hardener – that blend together to form an unbreakable bond. It excels at bonding metal, glass, ceramics, and plastic, making it a formidable choice for freezing conditions.

- Cyanoacrylate Glue: Known as super glue or instant glue, cyanoacrylate glue wields rapid adhesion power. Triggered by moisture in the air or on surfaces being bonded, it creates instantaneous chemical reactions. While its ability to withstand freezing temperatures varies with formulations, it serves as an excellent choice for quick and strong bonds.

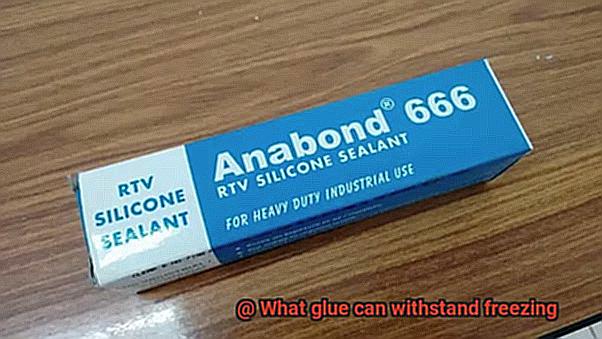

- Silicone Glue: A flexible adhesive with resistance to water, heat, and chemicals, silicone glue is ideal for applications requiring flexibility or extreme condition resilience. While some formulations may not thrive in freezing temperatures, silicone glue generally exhibits admirable temperature resistance.

Selecting the Perfect Glue:

When choosing glue for freezing temperatures, several factors must be considered:

- Material Compatibility: Different glues have varying affinities for specific materials. It is crucial to ensure compatibility between the glue and the substances being bonded.

- Temperature Range: Evaluate the expected temperature range the glue will encounter and select a glue that can withstand those conditions.

- Bond Strength and Flexibility: Determine the desired strength and flexibility of the bond to choose the most appropriate glue.

Different Types of Glue

In this blog post, we’ll explore different types of glue and discover which ones can brave the icy cold and still keep things stuck together.

Epoxy Resin – The Superhero Glue:

Epoxy resin is like the superhero of glues. It doesn’t get scared of freezing temperatures. This glue is a two-part adhesive that creates a super strong bond when its resin and hardener are mixed together. Whether it’s metal, plastic, or ceramics, epoxy can handle it all, even in the coldest conditions.

Epoxy glue is known for its incredible strength and versatility. It forms a bond that can withstand extreme temperatures, making it ideal for use in freezing conditions. Whether you’re repairing a broken pipe or creating an outdoor sculpture, epoxy glue will hold everything together, no matter how icy it gets.

Super Glue – Quick but Cold-Resistant:

Super glue is like a speedy superhero. It dries fast and forms a strong bond. Although it can become a bit brittle in freezing temperatures, it still holds its ground when it comes to staying stuck. Just be careful not to pull too hard on objects bonded with super glue in the cold.

Super glue, also known as cyanoacrylate adhesive, is a popular choice for quick fixes and small projects. While it may lose some of its flexibility in freezing temperatures, it still maintains its adhesive properties. So whether you’re repairing a broken ornament or sticking together frozen decorations for a winter wonderland, super glue can handle the cold.

Specialty Glues – Made for Cold Adventures:

Some glues are specially made to conquer freezing temperatures. These glues are designed for outdoor use or in places where it gets really chilly. They stay flexible and strong even when everything else freezes around them. So, if you’re planning an icy adventure, look for these special glues.

Specialty glues come in various formulations, including some specifically engineered to withstand freezing temperatures. These glues are perfect for outdoor applications such as repairing frozen pipes or securing outdoor decorations in cold climates. With their ability to remain flexible and strong in freezing conditions, specialty glues ensure that your projects stay intact, no matter how cold it gets.

White Glue – Not So Frosty Friendly:

White glue, also known as PVA glue, is great for crafts and woodworking projects. It dries clear and is safe for kids to use. However, it’s not the best choice for freezing temperatures. When things get frosty, the bond may weaken or even break. So save the white glue for warmer days.

Epoxy Resin – A Glue That Can Withstand Freezing Temperatures

Well, fret no more because epoxy resin is here to save the day. This extraordinary adhesive is renowned for its unyielding strength and unwavering durability, making it the ultimate choice for projects in frigid climates.

So, what sets epoxy resin apart from its feeble counterparts? It all boils down to a remarkable chemical reaction. Comprised of two components – a resin and a hardener – epoxy resin undergoes a transformative process when combined. This reaction creates a bond that can withstand even the most bone-chilling temperatures, defying the icy grip of winter.

Unlike other glues that surrender their effectiveness when confronted with freezing conditions, epoxy resin remains unfazed by the cold. Its curing process remains unimpeded by sub-zero temperatures, allowing it to form robust bonds even in the harshest of winter environments. This makes it an ideal choice for outdoor repairs or construction projects in the midst of a frosty landscape.

But there’s more. Epoxy resin boasts exceptional resistance against moisture and chemicals, further augmenting its suitability for freezing realms. It triumphs over the expansion and contraction caused by temperature fluctuations without relinquishing its adhesive properties. This means that as the mercury rises and falls, your materials will steadfastly remain bonded together.

Strength alone doesn’t define epoxy resin; it also boasts flexibility. It can endure the strain inflicted by relentless cycles of freezing and thawing without succumbing to breakage or weakening its bond. This flexibility becomes invaluable in environments where materials are perpetually subjected to dramatic temperature changes.

One can’t overlook the versatility of epoxy resin either. It exhibits extraordinary adhesion to a vast array of materials – metals, plastics, ceramics, and wood – making it an adhesive superhero for diverse applications. Its powers find purpose in industries ranging from construction, automotive, aerospace, to marine, where it emerges as the adhesive of choice to combat the harshest environmental conditions.

Cyanoacrylate (Super Glue) – Another Glue That Can Withstand Freezing Temperatures

Cyanoacrylate, also known as super glue, is here to save the day. In this blog post, we will delve into the fascinating world of super glue and uncover why it can withstand freezing temperatures. So, if you’re someone who wants to learn more about glue and its performance in cold environments, keep reading.

The Power of Super Glue:

Super glue is renowned for its strong and fast bonding properties. Made up of cyanoacrylate monomers, this adhesive polymerizes rapidly in the presence of moisture. But what sets it apart from other glues is its ability to remain stable and effective even in freezing temperatures. This makes it a reliable choice for outdoor constructions and equipment used in cold climates.

The Secret Behind Super Glue’s Resilience:

The chemical composition of cyanoacrylate and its unique bonding mechanism are the reasons behind its resilience in freezing temperatures. When super glue comes into contact with moisture, whether in the air or on the surface being bonded, it undergoes rapid polymerization to form a strong bond. And guess what? Low temperatures don’t affect this process. The adhesive sets and bonds materials together effectively, even in freezing conditions.

Tips for Optimal Performance:

While super glue is a winter warrior, it’s important to note that repeated freeze-thaw cycles or extreme temperature fluctuations can weaken the bond over time. To ensure optimal bonding strength and durability in freezing conditions, follow these tips:

- Clean and dry surfaces: Before applying super glue, make sure the surfaces are clean and free from any contaminants or moisture that could interfere with the bonding process.

- Give it time: Allow sufficient curing time for the adhesive to fully set before subjecting it to freezing temperatures. Patience is key.

Cyanoacrylate, or super glue, is a glue that truly lives up to its name. Withstanding freezing temperatures like a champ, it’s a reliable adhesive for various applications in cold environments.

Its ability to bond materials together effectively, even in extreme cold, is a testament to its unique chemical composition.

Specialty Glues Formulated for Low Temperatures

Specialty glues formulated for low temperatures are here to save the day. These glues have been specifically designed to withstand freezing conditions and maintain their adhesive properties, even in extreme cold.

So, what makes these specialty glues so effective and reliable in freezing conditions? Let’s take a closer look.

One key feature of these glues is that they are made from a special polymer that remains flexible and resilient, even in the harshest cold temperatures. This means that they won’t become brittle or lose their bond strength when exposed to freezing conditions.

There are several different types of specialty glues for low temperatures that you can choose from. One popular option is cyanoacrylate glue, also known as super glue. This stuff is famous for its fast bonding and strong adhesive properties, making it perfect for outdoor repairs and construction projects in cold climates.

Another excellent option is epoxy glue. This type of adhesive consists of two components that need to be mixed together. Once cured, epoxy creates a strong bond that can withstand freezing temperatures. It’s great for bonding materials like metal or plastic.

Polyurethane adhesives are another versatile choice. They have excellent resistance to low temperatures and can maintain their adhesive properties even in freezing conditions. These glues can be used in a wide range of applications, from automotive repairs to construction projects.

To get the best results from these specialty glues, it’s important to follow the manufacturer’s instructions for proper application and curing times. Additionally, make sure to properly prepare the surfaces to be bonded by cleaning them thoroughly and removing any dirt, grease, or moisture.

With specialty glues formulated for low temperatures, you can tackle outdoor repairs and projects with confidence, even in freezing conditions. These glues provide a reliable bonding solution that will stand the test of time.

Factors to Consider When Choosing a Glue for Freezing Temperatures

When it comes to choosing a glue for freezing temperatures, there are several factors that need to be taken into consideration. These factors will ensure that you select the right glue that can withstand the cold and provide a strong bond. Here are the key factors to consider:

- Temperature Range: Not all glues are designed to handle extreme cold temperatures. It is important to select a glue that can remain adhesive even in sub-zero temperatures. Look for glues that have a specified temperature range on their labels, ensuring they can withstand the freezing conditions you will be working in.

- Flexibility: Materials contract and expand in freezing temperatures, which can put stress on the bond created by the glue. Choosing a flexible glue will allow it to accommodate these changes without cracking or breaking, ensuring your bond remains intact. Look for glues that offer good flexibility properties.

- Cure Time: In freezing temperatures, some glues may take longer to cure or may not cure at all. This can be problematic if you require a quick and strong bond. Opt for glues with relatively fast cure times, ensuring that the bond forms effectively even in freezing temperatures.

- Water Resistance: Freezing temperatures often come with moisture and water exposure. It is important to choose a glue that is water-resistant or waterproof. This will prevent any weakening or degradation of the bond due to moisture penetration. Additionally, a water-resistant glue will also be more resistant to the freeze-thaw cycle, which can further compromise the bond.

- Material Compatibility: Different glues have different adhesive properties and work better on specific materials. Ensure that the glue you choose is compatible with the materials you’re working with and can form a strong bond even in freezing temperatures. Consider the specific materials you will be bonding and choose a glue that is suitable for those materials.

- Application Method: Some glues may require specialized equipment or techniques for application, which may not be practical in freezing conditions. Opt for a glue that is easy to apply and doesn’t require complex procedures or equipment. Look for glues that have user-friendly application methods, making it convenient to bond materials even in cold weather.

- Longevity: Choose a glue that can maintain its adhesive properties over an extended period, even in harsh winter conditions. Look for glues specifically designed for long-term durability and can withstand freezing temperatures without deteriorating. This will ensure that your bond remains strong and intact for a longer period of time.

Surface Preparation and Proper Application for Maximum Adhesive Strength in Cold Conditions

Unlocking maximum adhesive strength in cold conditions requires a combination of meticulous surface preparation and precise application techniques. In this article, we explore the importance of these factors, offering insights to those seeking to harness the full potential of glue in freezing temperatures.

The Cleanliness Factor:

Before applying glue, it is imperative to eliminate contaminants that can impede bonding. Dirt, dust, and grease become formidable foes, weakening adhesive strength. To combat this, conduct a thorough cleaning using suitable solvents or mild detergents to prepare the surface for a robust bond.

The Drying Game:

Moisture poses a significant challenge when bonding in cold conditions as it freezes and forms a barrier between the glue and surface. Thus, complete drying of the surface before applying adhesive is vital to avoid compromised adhesion caused by moisture-related issues.

The Art of Application:

Achieving maximum adhesive strength involves precise and even glue application. Excessive glue weakens bonds and extends drying time, especially in freezing temperatures. Applying an optimal amount guarantees a strong connection without unnecessary delays or compromise.

Temperature Limitations:

Different adhesives possess varying temperature ranges for effective bonding. Some are specialized for cold weather applications, maintaining adhesive strength even in freezing temperatures. Follow manufacturer instructions regarding temperature requirements for both application and curing phases.

Time is Your Ally:

Curing time is crucial for achieving maximum adhesive strength. In cold temperatures, adhesives may require longer curing periods than in warmer conditions. Patience is key; allow ample time for the adhesive to achieve its full strength before subjecting it to stress or load.

1nEgFzKl60g” >

Conclusion

In conclusion, when it comes to choosing a glue that can brave the icy grip of winter, you have several options to consider. Epoxy resin emerges as the superhero adhesive, unyielding and unfazed by freezing temperatures. It forges unbreakable bonds in even the harshest winter environments, shrugging off moisture and chemicals with ease.

Another contender is cyanoacrylate, also known as super glue. This adhesive possesses a unique chemical composition and lightning-fast bonding properties that keep it stable and effective in extreme cold conditions. It remains steadfast even when faced with freezing temperatures.

For those seeking glues specifically formulated for low temperatures, specialty options are available. These remarkable adhesives are crafted from special polymers that maintain flexibility and resilience in freezing realms. They are perfect for outdoor repairs and projects in cold climates, ensuring your creations withstand the chill.

When selecting a glue for freezing temperatures, it’s crucial to consider various factors: temperature range, flexibility, cure time, water resistance, material compatibility, application method, and longevity. Proper surface preparation and precise application techniques are also vital for achieving maximum adhesive strength in cold conditions.

So whether you’re mending shattered ornaments or securing outdoor decorations amidst frigid temperatures, choosing the right glue is paramount.