Welcome to our blog. Today, we’re diving into the world of creative crafts and DIY projects using everyone’s favorite lightweight material – styrofoam. Whether you’re a seasoned crafter or just starting out on your creative journey, styrofoam is a fantastic material to work with because it’s so versatile.

But here’s the thing: finding the right glue for styrofoam can be a bit tricky. You want something that will bond effectively without causing any damage. Lucky for you, we’ve got all the information you need to make an informed decision.

In this blog post, we’ll explore the different types of glues that are compatible with styrofoam. We’ll dive into their properties and give you some handy tips to help you choose the perfect glue for your next project. So get ready to become a master at gluing styrofoam – let’s go.

White Craft Glue or PVA Glue

Contents

With an array of options available, two contenders rise above the rest: White Craft Glue and PVA Glue. In this captivating article, we will delve into the factors that set these glues apart and unveil the secrets to proper application and handling.

Unraveling the Mysteries of White Craft Glue and PVA Glue:

- These two glues, often used interchangeably, share similar properties and characteristics.

- Both White Craft Glue and PVA Glue are water-based adhesives that dry crystal clear, making them ideal for projects where aesthetics matter.

- Safety is a top priority, as both glues are non-toxic and completely safe for children to use.

The Key Considerations for Using White Craft Glue or PVA Glue on Styrofoam:

- Compatibility: Opt for an adhesive specifically formulated for bonding styrofoam to prevent damage or dissolution of the material.

- Bond Strength: For most arts and crafts projects, both White Craft Glue and PVA Glue provide a robust bond. However, if you require a heavy-duty or larger-scale application, it may be beneficial to explore alternative adhesive options.

- Surface Preparation: To ensure optimal adhesion, thoroughly clean both the styrofoam surface and the material it will be bonded to, eliminating any dust or debris that could hinder the bond.

Mastering Application Techniques and Handling:

- Apply a thin, even layer of glue to both surfaces that require bonding.

- Employ firm pressure when pressing the glued surfaces together to promote a strong and long-lasting bond.

- Allow sufficient drying time before handling the bonded pieces, taking into account the varying drying times indicated by the manufacturer.

Exploring Other Glue Options for Styrofoam:

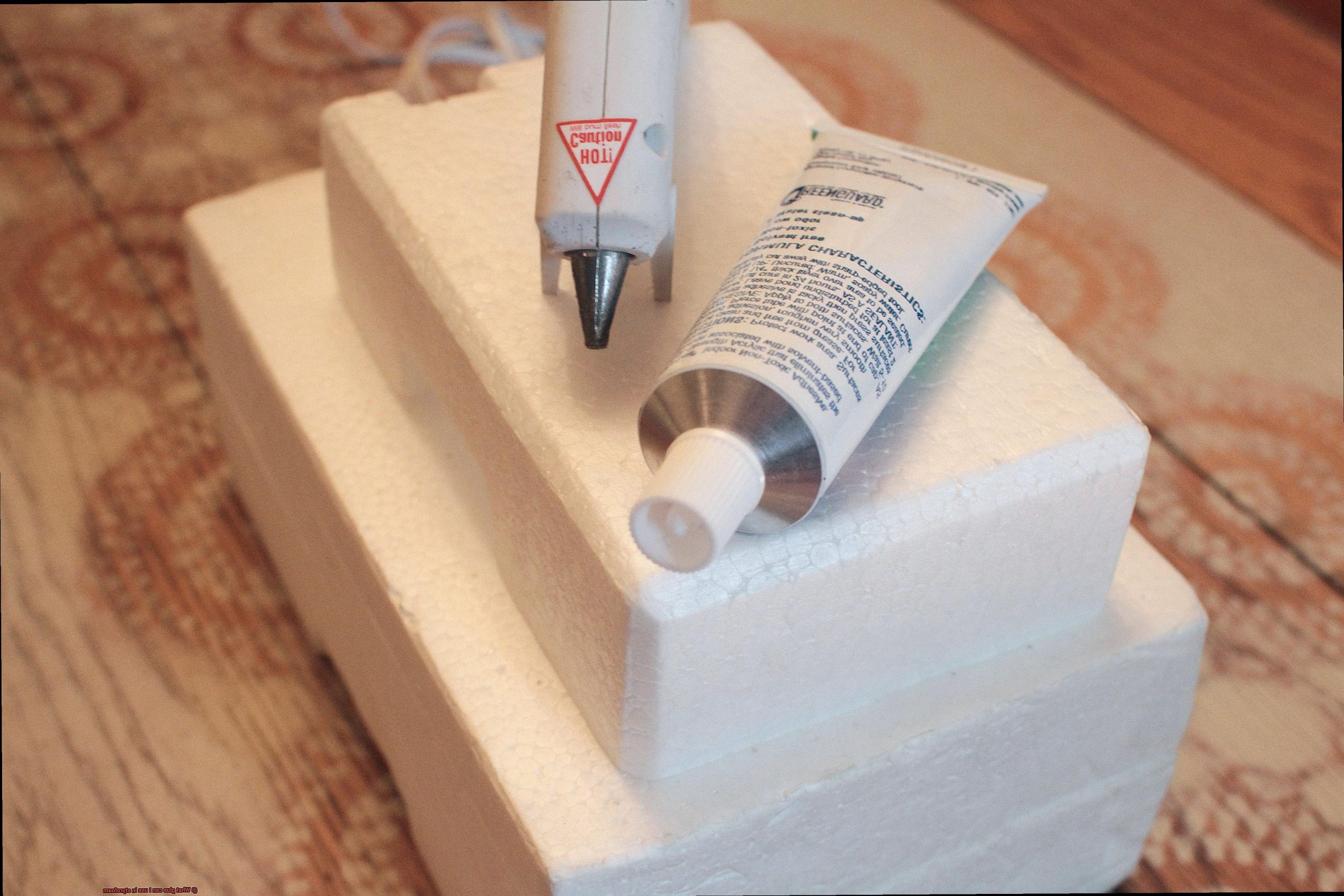

- Styrofoam glue: Specially designed for bonding styrofoam, this adhesive offers a formidable bond without compromising the integrity of the material. It is commonly available in convenient spray form for effortless application.

- Super glue: While it can be used on styrofoam, caution must be exercised. Apply sparingly and work swiftly to avoid dissolving the styrofoam.

- Hot glue: Renowned for its rapid drying time and strong bond, hot glue can be an excellent choice for styrofoam projects. Select a low-temperature setting to prevent accidental melting of the material.

- Epoxy adhesive: Though it may require longer drying times compared to other glues, epoxy adhesive ensures a durable bond for styrofoam projects.

Styrofoam Glue

Look no further. In this comprehensive guide, we will explore the world of styrofoam glue, discussing various types of glues, tips for successful bonding, and precautions to avoid damaging this versatile material.

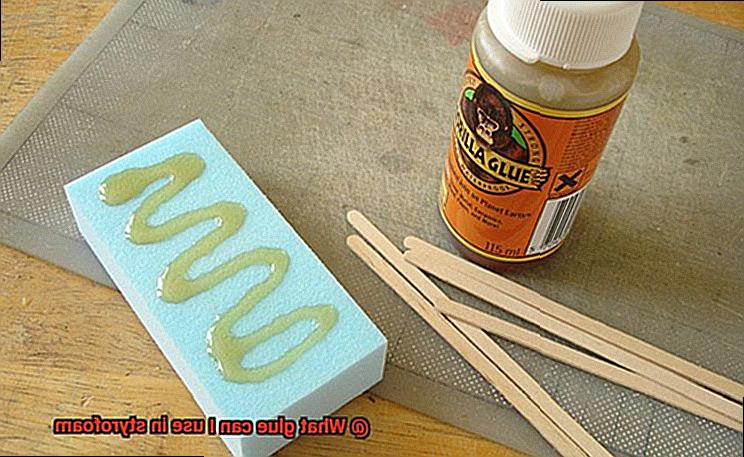

- White Craft Glue or PVA Glue: When it comes to bonding styrofoam, white craft glue or polyvinyl acetate (PVA) glue is a popular and reliable choice. Known for its ease of use and strong bond, brands like Aleene’s Original Tacky Glue and Elmer’s Glue-All come highly recommended. Simply apply an even layer of glue to the surfaces you want to bond and press them together firmly. Allow sufficient drying time as per the manufacturer’s instructions.

- Hot Glue: For quick and secure bonding, hot glue guns are another fantastic option for styrofoam. However, exercise caution as hot glue can melt styrofoam if applied too hot or in excessive amounts. To prevent any mishaps, opt for a low-temperature hot glue gun and apply the glue in small dots or lines instead of spreading it all over the surface.

- Epoxy Glue: If you require a stronger and more permanent bond, epoxy glues should be your go-to choice. These glues consist of two parts that need to be mixed before application. While epoxy provides excellent adhesion, it requires careful handling and longer drying times compared to other glues.

- Specialized Styrofoam Adhesives: To take your styrofoam bonding experience to the next level, consider using specialized adhesives specifically formulated for this material. Brands like StyroGoo and Foam Fusion offer water-based adhesives that provide a strong bond without causing damage.

Now that you have a good understanding of the different types of styrofoam glues available, let’s discuss some essential tips to ensure successful bonding without compromising the integrity of the material:

- Avoid using solvent-based adhesives or super glues (cyanoacrylate) as they can dissolve or melt the styrofoam.

- Always follow the manufacturer’s instructions for proper application and drying times.

- Before applying glue to your entire project, it’s wise to test it on a small, inconspicuous area of the styrofoam to ensure compatibility and prevent unwanted reactions or damage.

Super Glue or Cyanoacrylate Adhesive

Are you in search of the perfect adhesive to bond your styrofoam projects? Look no further. In this comprehensive guide, we will delve into the wonders of Super Glue, also known as Cyanoacrylate Adhesive, and share invaluable tips for achieving a successful bond. Get ready to unleash your creativity with confidence.

Use Sparingly:

When it comes to Super Glue and styrofoam, less is definitely more. Applying an excess amount of glue can spell disaster, as it has the potential to dissolve or melt the styrofoam. Remember, a small amount of Super Glue goes a long way.

Surface Preparation:

To ensure a robust bond, proper surface preparation is key. Lightly sanding the styrofoam with fine-grit sandpaper or a sanding block creates a roughened surface that enhances adhesion. This simple step allows the Super Glue to grip onto the styrofoam with unwavering tenacity.

Apply in Dots or Lines:

Instead of spreading the glue across the entire surface, why not try applying it in precise dots or delicate lines? This technique not only prevents excess glue from seeping out and damaging your styrofoam masterpiece but also grants you greater control during application.

Press and Hold:

Once you have applied the Super Glue, it’s time to work your magic. Gently press the pieces of styrofoam together and hold them in place for a few seconds. This act of patience allows the adhesive to set and form an unbreakable bond. Remember, refrain from moving or disturbing the glued pieces until the glue has fully cured – typically within 24 hours.

Compatibility Check:

While Super Glue works wonders for most styrofoam projects, it may not be a perfect match for all types of styrofoam. Certain high-density or expanded polystyrene foams may not bond well with Super Glue due to their unique composition. As a precautionary measure, always test a small, inconspicuous area before committing to the full application.

Flexibility Matters:

It’s important to consider the end goal of your styrofoam creation. If you require flexibility or impact resistance, keep in mind that Super Glue can be quite brittle once dried. To ensure the longevity and durability of your project, consider alternative adhesives specifically designed for styrofoam or foam-safe glues that offer the desired flexibility.

Hot Glue Guns

Look no further. In this comprehensive guide, we’ll delve into the world of hot glue guns and discover the secrets to effectively bonding styrofoam. With the right tools, techniques, and adhesive options, you’ll be able to create sturdy and long-lasting creations that stand the test of time.

Choosing the Right Hot Glue Gun:

To ensure successful styrofoam bonding, it’s crucial to select the right hot glue gun. Opt for a low-temperature model to prevent any unwanted melting or warping of the delicate styrofoam. This small but significant choice will save you from potential mishaps and provide a solid foundation for your project.

The Perfect Glue Stick:

Not all hot glue sticks are created equal when it comes to bonding styrofoam. Look for adhesive sticks specifically designed for this purpose, labeled as “low-melt” or “low-temperature.” These sticks are formulated to provide a secure and long-lasting bond without damaging the styrofoam. By choosing the perfect glue stick, you set yourself up for success from the start.

Apply Sparingly and Evenly:

To achieve optimal results, less is more when it comes to applying hot glue on styrofoam. Excessive amounts can seep into the porous surface, causing it to dissolve or lose its shape. Instead, apply small dots or thin lines of glue along the areas you want to bond together. This method ensures sufficient coverage for a strong bond without overdoing it.

Speed and Precision:

Hot glue sets rapidly, so it’s essential to work quickly but carefully. After applying the adhesive, align and join the pieces promptly. Avoid exerting excessive pressure on the styrofoam, as it is delicate and can easily dent or deform. Take your time to position the pieces correctly, then gently press them together for a secure bond. By mastering speed and precision, you’ll achieve seamless and professional-looking results.

Alternative Adhesive Options:

While hot glue guns are fantastic for most styrofoam projects, they may not be suitable for all applications. If you’re working with large or heavy pieces of styrofoam, or if the bond will endure significant stress or strain, consider using foam-safe contact adhesives or specialized styrofoam glues. These alternatives are designed to provide a strong bond without compromising the integrity of the styrofoam, giving you peace of mind for more demanding projects.

Epoxy Adhesives

Well, get ready to meet the superheroes of glue – epoxy adhesives. These magical potions, made from a blend of resin and hardener, offer an array of benefits when it comes to bonding styrofoam. Let’s dive into the details and discover why epoxy adhesives are the ultimate solution.

First and foremost, epoxy adhesives are renowned for their unbeatable strength and durability. They can withstand anything that Mother Nature throws at them – from moisture to temperature fluctuations. So whether your styrofoam masterpiece will be displayed indoors or outdoors, you can trust that it will remain intact, even in the harshest conditions.

But that’s not all. Epoxy adhesives also cure to a crystal-clear finish, adding a touch of elegance to your projects. No more worrying about unsightly marks or discolorations on your beautiful styrofoam creations. With epoxy adhesives, your artwork will shine bright and stand out amongst the crowd.

Now, let’s talk about application techniques. To achieve a successful bond with epoxy adhesives, proper surface preparation is key. Start by giving your styrofoam a thorough cleaning to remove any dirt or oils that could hinder the adhesive’s effectiveness. A quick wash with soap and water or a wipe-down with rubbing alcohol should do the trick. Once your styrofoam is squeaky clean, lightly sand it to create a rough texture that will enhance the adhesive’s grip.

When it’s time to apply the epoxy adhesive, follow the manufacturer’s instructions closely. Mix the resin and hardener in the correct ratio (yes, this part is crucial.) and stir them together until they’re perfectly blended. Then, generously apply the adhesive onto one of the surfaces you wish to bond and firmly press the two pieces together.

Now here’s the catch – epoxy adhesives have a longer curing time compared to some other glues. So be patient and hold or clamp the bonded parts together until the adhesive sets completely. The exact curing time can vary depending on factors like temperature and humidity, so it’s best to consult the product’s instructions for specific guidance.

Importance of Testing Glue Compatibility

Unlocking the secret to powerful bonds with styrofoam lies in the realm of glue compatibility. The right adhesive can create unbreakable connections, while the wrong choice can lead to feeble bonds or even disastrous damage. In this blog post, we will embark on a journey to understand why testing glue compatibility is an absolute game-changer and how it paves the way for achieving awe-inspiring results.

Unraveling the Wonders of Styrofoam:

- Lightweight and versatile, styrofoam reigns supreme as a cherished material for insulation, packaging, and artistic ventures alike.

- To forge a successful union with styrofoam, one must employ glues that are specifically designed to bond with its unique surface.

Consequences of the Wrong Glue:

- Feeble and ineffective bonds: An ill-suited glue might not possess the necessary adhesive prowess to create a robust connection between itself and styrofoam.

- Dissolution and destruction: Some glues harbor solvents or chemicals that wreak havoc on polystyrene, causing it to dissolve or crumble into oblivion.

Testing the Boundaries of Compatibility:

- The apply and dry method: A small dab of glue on a test area of styrofoam allows for evaluating bond strength and durability through rigorous stress tests.

- Delving into chemical composition: Different glues boast distinct chemical compositions that interact with styrofoam in diverse ways.

- Adhesion and penetration prowess: Testing unravels which glues possess the ability to adhere flawlessly to the porous surface of styrofoam.

Tailoring to Specific Needs:

- Diverse applications demand varied properties from glue, such as flexibility, water resistance, or heat resistance.

- Testing empowers us to pinpoint glues that meet the specific requirements of our intended purpose.

Unleashing Specialized Glues:

- Some glues are meticulously formulated to forge unyielding bonds with styrofoam, ensuring strength and durability while preserving the material’s integrity.

- Testing these specialized glues guarantees optimal results, giving us the confidence to unleash our creativity without fear.

Unsuitable Glues for Styrofoam

Together, we will navigate the treacherous terrain of adhesive choices and ensure that your styrofoam masterpieces remain unscathed.

Choosing the right adhesive for bonding or gluing styrofoam is not just important—it’s essential. Allow me to shed some light on the matter.

First and foremost, using the wrong type of glue can spell disaster for your cherished styrofoam creations. Imagine pouring hours of love and dedication into crafting a breathtaking sculpture, only to have it crumble before your eyes due to a misguided adhesive choice. The heartbreak would be unbearable.

Not only can the wrong glue lead to destruction, but it can also result in a feeble bond that will inevitably give way over time. We’ve all experienced the disappointment of a project that couldn’t withstand the test of time.

By selecting the right adhesive, you can ensure that your styrofoam creations stand tall and retain their structural integrity.

So, which glues should we avoid when working with styrofoam? Let’s go through a quick checklist:

Solvent-based glues like super glue or epoxy are unequivocally off-limits. These glues contain chemicals that can dissolve or melt the styrofoam, leaving you with nothing more than a mushy mess.

Hot glue, although a staple in the crafting realm, is not suitable for styrofoam. The intense heat required for hot glue application can cause the foam to melt or deform, leaving you feeling deflated instead of delighted.

Water-based glues such as white glue (PVA) may seem harmless at first glance, but they can gradually weaken the structure of styrofoam over time. After investing so much effort into your creation, the last thing you want is for it to crumble into oblivion.

Spray adhesives may appear convenient, but they often contain solvents or chemicals that can dissolve the foam. If you want your styrofoam project to remain intact, steer clear of these like the plague.

Rubber cement and contact cement may have their uses, but they are not friends of styrofoam. These adhesives contain solvents that can damage the foam and result in a feeble bond.

To ensure success on your styrofoam adventures, always read the label or instructions of any adhesive before applying it. Look for glues specifically designed for use with foam materials to avoid any mishaps.

Factors to Consider When Choosing a Glue

Fear not. This guide is here to help you navigate the essential factors to consider when choosing the perfect adhesive for your styrofoam creations. So, grab your supplies and let’s dive into this comprehensive guide.

Compatibility is Key:

When it comes to bonding styrofoam, compatibility is crucial. Not all glues are created equal, so opt for ones specifically formulated for styrofoam. This ensures a strong bond without causing any damage to the material. Choosing the right glue is the first step towards success.

Go Water-Based:

Say goodbye to harsh chemicals that could dissolve or melt your precious styrofoam. Water-based glues are gentle on this delicate material and are generally non-toxic. They are also incredibly easy to work with, making them ideal for various crafting or construction projects. Protect your styrofoam while enjoying a hassle-free experience.

Adhesive Strength:

Consider the nature of your project and determine the required adhesive strength. If you’re working on a heavy-duty creation that needs to withstand stress or weight, opt for glues specifically designed for styrofoam with superior adhesive strength. Don’t let gravity bring your masterpiece down.

Timing is Everything:

In the world of crafting, time is of the essence. If you’re working against the clock or need immediate results, choose a glue that dries quickly. However, if you prefer more flexibility during the assembly process or require additional time for adjustments, opt for glues with longer drying times. Choose a glue that suits your project’s pace.

Application Method:

Precision meets functionality here. Consider the size and intricacy of your project when choosing a glue application method. Precision applicators work wonders for detailed work, ensuring accuracy and control. On the other hand, spray adhesives or adhesive sheets offer an even coverage advantage for larger surface areas. Choose the right tool for the job.

Flexibility Matters:

Styrofoam is known for its lightweight and flexible nature. Ensure your glue choice maintains this flexibility post-curing. This is particularly important for projects that require bending or twisting, such as model airplanes or costume props. Don’t let stiffness cramp your style.

Longevity for the Win:

If your styrofoam masterpiece is meant to endure the elements or become a permanent display, opt for glues that offer enhanced durability. Look for options that can withstand exposure to UV rays, temperature fluctuations, and the test of time. Preserve your creation’s beauty and strength.

G-nNnX_Pvhc” >

Also Read: What Is the Best Glue For Styrofoam? – Glue Things

Conclusion

When it comes to gluing styrofoam, choosing the right adhesive is crucial. You don’t want to risk damaging your project or compromising its structural integrity. So, what glue can you use in styrofoam? Well, fortunately, there are several options available that are specifically designed for this purpose.

One popular choice is a low-temperature hot glue gun. This versatile tool allows you to apply a strong bond without melting or distorting the delicate styrofoam surface. The low-temperature setting ensures that the glue doesn’t get too hot and cause any damage.

Another option is using a specialized styrofoam adhesive. These adhesives are formulated to provide excellent bonding strength while being safe for use on styrofoam. They often come in spray or liquid form, allowing for easy and precise application.

If you prefer a more traditional approach, you can also use white craft glue or polyurethane-based adhesives. However, it’s important to note that these may take longer to dry and may require clamping or holding the pieces together until the glue sets.

No matter which adhesive you choose, it’s essential to follow the manufacturer’s instructions carefully. This will ensure proper application and maximum bond strength.

In conclusion, when working with styrofoam, selecting the right adhesive is crucial for a successful project. Whether you opt for a low-temperature hot glue gun, specialized styrofoam adhesive, or traditional craft glue, make sure to follow instructions diligently and exercise caution throughout the gluing process.