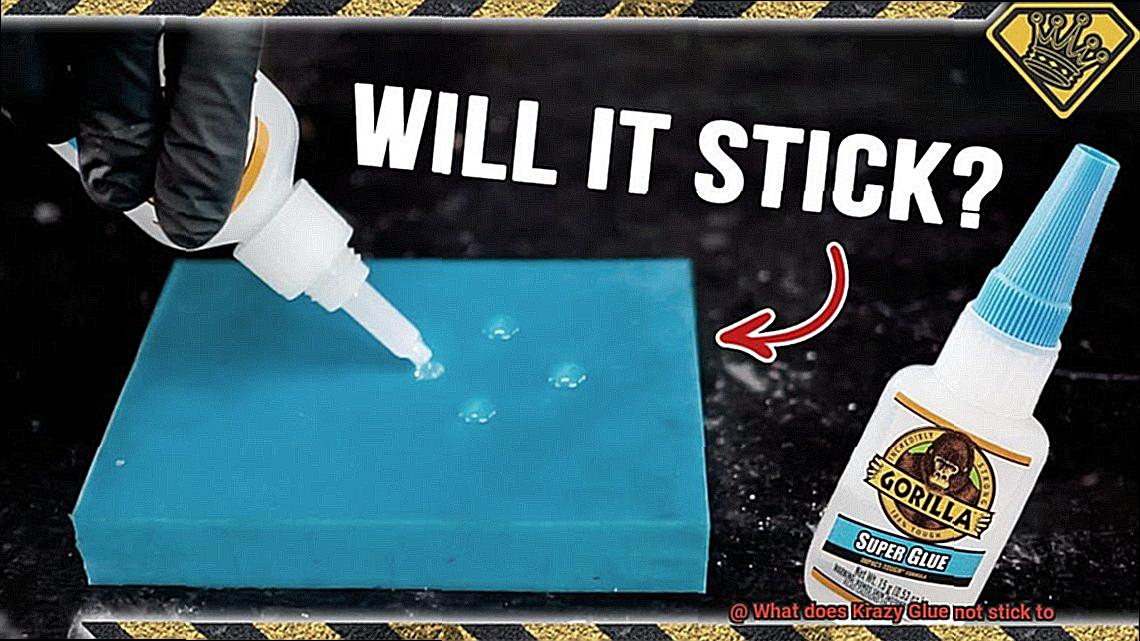

We’ve all been there – that moment when something we love breaks, and panic sets in. Whether it’s a cherished ceramic figurine or a trusty household tool, the desire to fix it is overwhelming. That’s where Krazy Glue comes in, the superhero of adhesives, promising to restore our treasures with an unbreakable bond.

But let’s face it, even superheroes have their kryptonite. And for Krazy Glue, there are a few materials that refuse to be tamed by its sticky powers. These stubborn substances leave us scratching our heads and reaching for Plan B. In this blog post, we’re going to dig deep into the world of Krazy Glue and uncover the materials that just won’t succumb to its adhesive charm.

So whether you’re curious about the limits of this sticky wonder or simply want to avoid any glue-related mishaps, join us as we explore the materials that remain untouchable by Krazy Glue’s embrace.

Get ready because together, we’re about to unearth some secrets.

What is Krazy Glue?

Contents

When it comes to adhesive solutions that offer quick and reliable bonds, Krazy Glue is a name that stands out. This exceptional brand of adhesive has become a go-to choice for DIY enthusiasts, hobbyists, and professionals alike.

In this comprehensive post, we will delve into the world of Krazy Glue, exploring its features, applications, and limitations.

Quick-Drying Powerhouse:

Krazy Glue’s claim to fame lies in its lightning-fast drying time. This adhesive sets in seconds, creating an almost instantaneous bond. No more waiting around for glue to dry or cure. Krazy Glue’s quick-drying property makes it the perfect choice for urgent repairs or time-sensitive projects.

Versatile Bonding Capabilities:

One of the standout features of Krazy Glue is its remarkable versatility. It boasts exceptional adhesive properties that allow it to bond various materials with ease. Whether you’re working with metal, ceramic, rubber, plastic, wood, or even certain fabrics, Krazy Glue has got you covered.

Its ability to provide strong bonds across diverse materials makes it an invaluable tool in any toolbox.

Resilience That Lasts:

Krazy Glue not only bonds quickly but also withstands challenging conditions. Its resistance to water and most solvents ensures that the bond remains strong and durable even in harsh environments.

Temperature variations, impact, and vibration pose no threat to the reliability of Krazy Glue’s bonds.

Limitations to Consider:

While Krazy Glue excels in many applications, it does have some limitations. It may not effectively bond polyethylene and polypropylene plastics due to their low surface energy. Similarly, Teflon’s nonstick properties make it resistant to adhesives like Krazy Glue.

Rubber surfaces with high oil content or plasticizers may also pose challenges.

Additionally, certain fabrics and metals, such as synthetic fibers and aluminum/stainless steel, may not bond well with Krazy Glue.

What Materials Does Krazy Glue Not Work On?

Krazy Glue, the renowned adhesive with its impressive bonding capabilities and rapid drying time, is a true superhero in the world of adhesives. However, even this mighty glue has its limitations. It’s important to understand which materials may pose a challenge for Krazy Glue to adhere effectively. By knowing its kryptonite, you can select the right adhesive for your specific application.

Let’s begin with plastics. Krazy Glue may struggle to bond with polyethylene and polypropylene plastics. These tricky materials have a low surface energy, making it difficult for any adhesive to establish a strong bond. But fear not. There are specialized adhesives available that excel in bonding these slippery plastics.

Next up is rubber. Some rubber materials can be as stubborn as a mule when it comes to bonding with glue. Their porous and flexible nature makes it challenging for Krazy Glue to penetrate and create a reliable bond. If you find yourself in a sticky situation with rubber, consider using an adhesive specifically formulated for this material.

Ah, Teflon, the nonstick wonder. Unfortunately, Krazy Glue might slide right off Teflon surfaces. With its low surface energy and nonstick properties, Teflon is notorious for resisting adhesives. When it comes to bonding Teflon, it’s best to seek out alternative adhesives specifically designed for this slippery surface.

Now, let’s talk metals. While Krazy Glue excels at bonding most metals, certain smooth and non-porous metals like aluminum and stainless steel can pose a challenge. These shiny surfaces don’t leave much room for the adhesive to work its magic. To conquer these metals, reach for an adhesive formulated specifically for metal bonding.

Last but not least, fabrics and textiles. While Krazy Glue may work wonders on other materials, it’s not the best choice for fabrics. Its inability to effectively penetrate fibers and the risk of leaving behind residue can compromise both the appearance and functionality of your favorite fabrics.

For fabric bonding adventures, look for adhesives that are specially designed for textiles.

Polyethylene and Polypropylene Plastics

Polyethylene and polypropylene plastics, renowned for their resilience and resistance to chemicals, are commonly employed in a diverse range of industries. However, when it comes to bonding these plastics with adhesives like Krazy Glue, challenges arise due to their smooth and non-porous surfaces.

In this informative article, we will delve into the intricacies of polyethylene and polypropylene plastics, exploring their unique properties and discussing alternative adhesion methods that offer more robust bonding solutions.

The Slippery Surface Challenge:

Polyethylene and polypropylene plastics possess low surface energies, rendering them resistant to traditional forms of adhesion. Krazy Glue, a cyanoacrylate adhesive, necessitates a porous surface to establish a secure bond.

Unfortunately, the inherent smoothness and non-porosity of these plastics make it arduous for Krazy Glue to achieve an enduring grip.

Specialized Adhesives to the Rescue:

Thankfully, specialized adhesives tailored specifically for polyethylene and polypropylene plastics are readily available in the market. These adhesives incorporate additives that facilitate enhanced adhesion by generating a rougher surface for the glue to adhere to. When working with these plastics, it is highly recommended to utilize these specialized adhesives instead of Krazy Glue to ensure optimal results.

Surface Preparation Techniques:

In situations where specialized adhesives are unavailable, there exist techniques that can be employed to augment the bond strength between Krazy Glue and polyethylene or polypropylene plastics. One such technique involves surface preparation. By abrading the plastic surface using sandpaper or other abrasive materials, one can create additional contact points for the adhesive to gain traction. Additionally, cleaning the surface with isopropyl alcohol or a mild detergent can effectively eliminate contaminants that may impede adhesion.

Alternative Bonding Methods:

While Krazy Glue may not be the ideal choice for bonding polyethylene and polypropylene plastics, alternative bonding methods can be explored. Heat welding, solvent bonding, and mechanical fastening are all viable options when it comes to joining these plastics together. These techniques offer stronger and more reliable bonds compared to adhesives alone.

Teflon

Teflon, the magical material known for its non-stick properties, is a tough nut to crack when it comes to adhesive bonding. Its chemically inert nature, low surface energy, and exceptional chemical resistance make it quite the challenge for adhesives like Krazy Glue.

The non-porous nature of Teflon is one of the main reasons Krazy Glue struggles to bond with it. Teflon has a smooth surface that repels most liquids, including glue. Without moisture to initiate the curing process, Krazy Glue can’t form a strong bond with the Teflon surface.

But that’s not all. Teflon’s exceptional chemical resistance also plays a role in hindering adhesion. Even if Krazy Glue contains chemicals that enable it to bond with various materials, these chemicals may not have much effect on Teflon due to its chemical inertness.

To make matters even trickier, Teflon has an extremely low surface energy. This means it repels most substances, including adhesives. Krazy Glue may struggle to spread evenly on the Teflon surface, resulting in weak or no bonding.

But fear not. There are alternatives to Krazy Glue that are specifically designed for bonding Teflon surfaces. These specialized adhesives roughen up the smooth surfaces of Teflon and create a stronger bond. Additionally, surface preparation techniques like abrasion and cleaning can improve adhesion.

If adhesive bonding is still not possible, there are other options available. Heat welding, solvent bonding, and mechanical fastening can provide a more robust solution for joining Teflon surfaces together.

Certain Types of Rubber

While Krazy Glue is renowned for its strong bonding properties, there are certain types of rubber materials that pose challenges for this adhesive. In this article, we will delve into the reasons behind these challenges and explore alternative solutions for bonding rubber.

Slippery Secret of Natural Rubber:

Rubber derived from the sap of rubber trees, also known as natural rubber, can be a tricky material to bond with Krazy Glue. The presence of natural oils and moisture in the rubber creates a slippery surface that hinders the establishment of a strong bond. Consequently, while Krazy Glue may work wonders on other materials, it may not be the optimal choice for natural rubber.

Synthetic Rubber Surprises:

Synthetic rubbers, including neoprene, nitrile, and silicone rubber, also present challenges for Krazy Glue. These types of rubber often contain additives or coatings that interfere with the adhesive’s effectiveness. Silicone rubber, with its low surface energy and non-polar nature, especially proves difficult for Krazy Glue to form a lasting bond. To tackle this issue, alternative adhesives specifically designed for these materials should be considered.

The Energy Conundrum:

Rubbers with low surface energy are less receptive to bonding with adhesives like Krazy Glue. Consequently, the glue may struggle to adhere strongly to these materials. To overcome this challenge, it is recommended to thoroughly clean the surface and slightly roughen it before applying any adhesive. This helps improve the adhesive’s ability to create a durable bond.

Specialized Solutions:

While Krazy Glue may not be the best option for bonding certain types of rubber, specialized adhesives are available that are designed specifically for this purpose. These rubber-specific adhesives often contain ingredients that enhance their compatibility with various rubber materials. If you’re working with rubber and require a strong and long-lasting bond, it’s worth considering these alternative glue options.

Testing Is Key:

Before applying any adhesive to rubber, it is always prudent to test a small inconspicuous area first. This ensures compatibility and desired results before committing to a larger project. By conducting a simple test, you can save time and prevent any disappointments in the bonding outcome.

Certain Fabrics

In the world of fabric bonding, Krazy Glue is renowned for its strong hold. However, not all fabrics are compatible with this adhesive powerhouse. In this article, we will delve into the fascinating realm of fabric adhesive compatibility, exploring the advantages and disadvantages of certain fabrics when it comes to Krazy Glue.

By understanding these nuances, we can uncover alternative solutions and ensure successful bonding projects.

Slippery Smoothness: Nylon

Nylon fabrics, commonly found in apparel and outdoor gear, possess a sleek and slippery nature that poses a challenge for Krazy Glue. This adhesive struggles to penetrate the surface and create a robust bond on nylon. To conquer this obstacle, we suggest exploring adhesives specifically formulated for nylon materials to achieve a firm and lasting bond.

Synthetic Complexities: Polyester and Acrylic

Synthetic fabrics like polyester and acrylic, often encountered in clothing and upholstery, present their own set of challenges for Krazy Glue. The smooth texture and water-repellent properties of these fabrics hinder proper adherence of the adhesive. To overcome this hurdle, one should venture beyond Krazy Glue and explore alternative adhesives that are tailor-made for synthetic materials.

Delicate Luxury: Silk

Silk, renowned for its delicate and luxurious feel, demands special attention when it comes to bonding. Krazy Glue may seep into the silk fibers, leading to discoloration or damage. Moreover, silk is sensitive to solvents present in some adhesives, including Krazy Glue itself. When handling silk fabrics, exercise caution and consider alternative adhesives specifically designed for delicate fabrics.

Stretching Boundaries: High-Spandex or Lycra Content

Fabrics boasting high spandex or lycra content, such as sportswear and swimwear, pose a unique challenge for Krazy Glue due to their inherent stretchiness. The elasticity of these fabrics prevents the adhesive from creating a durable bond that withstands stretching and movement. To conquer this issue, explore fabric glue or adhesives specially formulated for flexible materials when working with stretchy fabrics.

Certain Metals

Certain metals pose challenges when it comes to bonding with Krazy Glue, a popular adhesive known for its versatility. Aluminum, for example, has a thin layer of oxidation that prevents Krazy Glue from adhering properly. Its smooth, nonporous surface also makes it difficult for the glue to form a strong bond.

Stainless steel, on the other hand, presents bonding difficulties due to the presence of chromium oxide on its surface. This oxide hinders the adhesion process and requires alternative adhesives like specialized metal bonding adhesives or epoxy adhesives.

Copper is another metal that may not play well with Krazy Glue. Like aluminum, copper often has an oxide layer on its surface that interferes with the adhesive’s ability to create a strong bond. Additionally, copper’s high conductivity affects the curing time and overall effectiveness of the glue.

Zinc and galvanized metals are also problematic when it comes to Krazy Glue bonding. These metals have a protective coating of zinc or zinc alloy that makes it difficult for the glue to adhere properly.

However, don’t despair. While Krazy Glue may not be the best option for these metals, there are alternative adhesives available. Epoxy adhesives or specialized metal bonding adhesives are designed specifically for bonding these tricky metals.

When using Krazy Glue on metals, it’s crucial to ensure that the surfaces are clean and free from any contaminants. Roughening the surface slightly with sandpaper or using a primer specifically designed for metal bonding can also improve the adhesive’s performance.

Alternatives to Krazy Glue for Different Materials

When it comes to bonding different materials, Krazy Glue is often the go-to adhesive for many DIYers and professionals alike. However, there are instances where Krazy Glue may not be the ideal choice due to the nature of the materials involved. In this blog post, we will explore alternative adhesives that can conquer the bonding challenges posed by various materials. So, let’s dive in and unleash the power of these alternative adhesives.

Conquering Metals:

Metals, with their smooth and non-porous surfaces, can be notoriously difficult to bond. But fear not. Enter epoxy adhesive, a two-part adhesive consisting of a resin and a hardener. This powerhouse creates an unbreakable bond on metals like steel, aluminum, and copper. Just make sure to clean the surfaces thoroughly before applying epoxy for optimum results.

Taming Plastics:

Plastic materials possess low surface energy, making them a tricky surface for traditional adhesives like Krazy Glue. However, there are cyanoacrylate adhesives specifically formulated for plastics. These adhesives provide strong bonds without damaging the delicate plastic surfaces. Say goodbye to frustration and hello to successful plastic bonding.

Woodworking Wonders:

Wood surfaces require an adhesive that can penetrate and bond effectively due to their porous nature. Enter wood glue or carpenter’s glue, tailor-made for woodworking projects. These adhesives offer exceptional bonding strength on various types of wood and create a durable bond that withstands the test of time. Embrace the wonder of woodworking with these reliable alternatives.

Fabric Bonding Bliss:

Delicate fabrics demand an adhesive that is flexible, residue-free, and stain-resistant. Fabric glue or textile adhesive is designed precisely for this purpose. These adhesives create strong bonds between fabrics without causing damage or compromising flexibility. Let your creativity flow with the assurance of a reliable fabric bond.

Ceramics and Glass Magic:

Smooth and non-porous surfaces of ceramics and glass pose a challenge for regular adhesives. Luckily, clear silicone adhesive comes to the rescue. This adhesive offers a robust and long-lasting bond on ceramics and glass, even resisting high temperatures, water, and chemicals. Achieve magical results with this powerful alternative adhesive.

Rubber and Flexibility:

Rubber surfaces can be challenging to bond due to their flexibility and low surface energy. The solution? Rubber adhesives or contact cement specifically designed for bonding rubber and other flexible materials. These adhesives provide a strong and flexible bond that can withstand the test of time. Embrace the versatility of rubber bonding with confidence.

QthlA8A8G3s” >

Also Read: Does Krazy Glue Work on Metal?

Conclusion

Krazy Glue, with its remarkable bonding power, seems like a miracle worker for all your sticking needs. But alas, there are some surfaces and materials that even this mighty adhesive cannot conquer. It’s important to know the limitations of Krazy Glue to avoid disappointment and frustration in your DIY projects.

Firstly, Krazy Glue does not work well on porous materials such as wood or fabric. The glue’s thin consistency makes it difficult to penetrate these surfaces effectively, resulting in weak bonds that may easily break. So if you’re planning to mend a wooden chair or sew up a tear in your favorite shirt, Krazy Glue is not the ideal choice.

Secondly, Krazy Glue struggles with bonding certain plastics. While it can work on many types of plastic, it may not adhere properly to those with low surface energy or high flexibility. So don’t expect miracles when trying to fix your flexible phone case or repair a toy made from challenging plastic materials.

Furthermore, Krazy Glue is not designed for use on wet surfaces. Water creates a barrier that prevents the glue from properly adhering to the intended surface. So make sure your project is completely dry before attempting any repairs with Krazy Glue.

Lastly, extreme temperatures can also affect the performance of Krazy Glue. If you’re working in freezing cold conditions or scorching hot environments, the adhesive properties may be compromised. It’s best to choose an alternative adhesive specifically formulated for extreme temperature applications.

In conclusion, while Krazy Glue is undoubtedly a fantastic adhesive for many purposes, it does have its limitations. Avoid using it on porous materials like wood and fabric, certain types of plastics, wet surfaces, and extreme temperature conditions.