Polyurea, the rising star in the world of coatings, adhesives, and sealants, has taken industries by storm with its incredible properties. Its flexibility, resistance, and durability have made it a top choice for countless applications. But let’s not forget that every superhero has a weakness. In this blog post, we’ll expose the less glamorous side of polyurea – its negatives.

By understanding these downsides, you can make smarter choices when selecting materials for your project. So buckle up as we venture into the dark underbelly of polyurea and reveal its hidden flaws.

Cost: Polyurea is Generally More Expensive than Other Coating Options

Contents

- 1 Cost: Polyurea is Generally More Expensive than Other Coating Options

- 2 Pot Life: Limited Time for Mixing and Application

- 3 Application Challenges: Precise Mixing and Application Techniques Required

- 4 Recoating Difficulties: Removing or Recoating Polyurea is Challenging

- 5 Limited Color Options: Fewer Colors Available than Other Coatings

- 6 Environmental Considerations: Potential Health Risks and Waste Disposal Regulations

- 7 Limited UV Resistance: Susceptible to Degradation When Exposed to Sunlight

- 8 Conclusion

Polyurea coatings have rightfully earned their reputation as the epitome of durability and performance when it comes to protective coatings. However, this exceptional quality comes at a higher price compared to other coating options like epoxy or acrylic. In this article, we will explore the reasons behind the higher cost of polyurea coatings, shedding light on the factors that contribute to its premium price.

Superior Raw Materials:

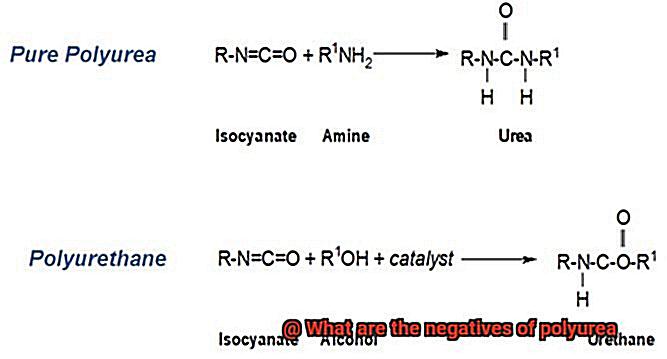

Polyurea formulations rely on a combination of isocyanates and amines, chemical compounds renowned for their high-performance properties. However, these top-notch raw materials come at a premium cost, setting polyurea apart as a more expensive coating option from the outset.

Complex Manufacturing Process:

The production of polyurea coatings entails a sophisticated manufacturing process that demands specialized equipment and expertise. This complexity adds to the overall cost of production and installation, as advanced machinery and skilled professionals are required to meet the exacting standards of polyurea coatings.

Short Pot Life:

Polyurea coatings have a limited pot life, necessitating swift application after mixing. This time constraint can lead to increased labor costs, as more workers may be required to complete the application process within the narrow timeframe. The need for efficiency in application adds to the overall cost of using polyurea coatings.

Enhanced Performance Characteristics:

Polyurea coatings boast exceptional resistance to chemicals, abrasion, and impact, making them the go-to choice for demanding applications like industrial flooring or truck bed liners. However, achieving such high-performance capabilities comes at a higher price point due to the advanced technology and specialized ingredients employed in their formulation.

Long-Term Cost Savings:

Despite the higher upfront cost, it is crucial to consider the long-term benefits and cost savings offered by polyurea coatings. Their unrivaled durability and longevity result in reduced maintenance and repair requirements over time. This not only cuts down on overall costs but also extends the lifespan of the coated surface, minimizing the need for frequent recoating or replacement.

Pot Life: Limited Time for Mixing and Application

Polyurea coatings are highly sought after for their exceptional durability and performance in various industrial and commercial applications. However, one challenge that comes with using polyurea is its limited pot life.

Pot life refers to the amount of time that a polyurea mixture remains workable after it has been mixed. Typically ranging from a few seconds to several minutes, the short pot life of polyurea coatings requires meticulous planning and efficient execution to achieve optimal results in your projects.

The challenges posed by the limited pot life of polyurea coatings are significant and must be carefully managed:

- Time Constraints: The short pot life means that applicators need to work quickly and precisely. There is little room for error or rework once the mixture is applied. Every step must be executed with precision and efficiency.

- Large-Scale Projects: Coating expansive industrial floors or tanks requires coordination and execution within the available pot life. The surface area to be covered must be carefully considered, and batch sizes should be determined accordingly. Smaller batches may be necessary to ensure efficient application.

- High Temperatures: Working in high-temperature environments can further reduce the pot life of polyurea coatings. Extra caution and planning are required to ensure timely application before the mixture becomes too viscous or starts to cure.

To effectively manage the limited pot life of polyurea coatings, implement the following strategies:

- Plan Ahead: Careful planning is crucial when working with polyurea coatings. Ensure that all necessary tools, equipment, and personnel are prepared before mixing the components. This will minimize downtime and maximize productivity during application.

- Batch Size Consideration: Determine appropriate batch sizes based on the surface area to be coated and available workforce. Smaller batches may be necessary for large-scale projects or when working in high temperatures to ensure efficient application within the limited pot life.

- Efficient Mixing and Application: Train applicators to work quickly and accurately, optimizing the available pot life. Utilize efficient mixing equipment and application techniques to minimize wasted time. This will ensure that every moment of the pot life is utilized effectively.

- Simultaneous Mixing: For larger areas or complex shapes, consider simultaneous mixing and application of multiple batches of polyurea. This approach ensures complete coverage within the limited pot life, reducing the risk of incomplete or uneven coating.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s guidelines and recommendations regarding pot life and application techniques. These guidelines are formulated based on extensive research and testing, ensuring optimal results and avoiding potential issues during the application process.

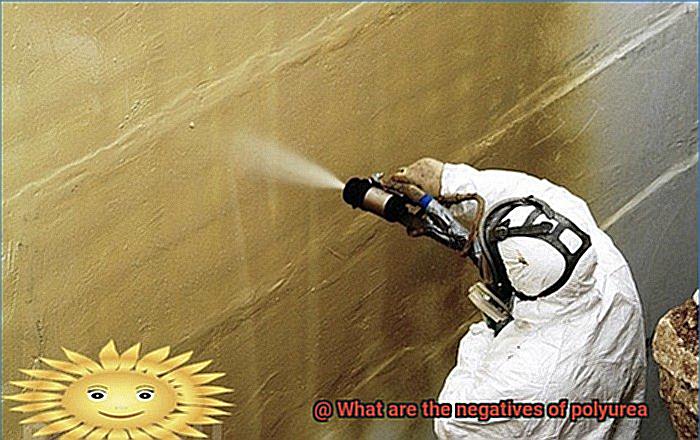

Application Challenges: Precise Mixing and Application Techniques Required

Today, we delve into the fascinating world of polyurea coatings – a versatile solution that has revolutionized industries like automotive, construction, and marine. However, to truly unlock the potential of this remarkable material, we must navigate the challenges of precise mixing and application techniques. So, grab your gear and let’s embark on a journey to master the art of polyurea application.

The Dance of Precision Mixing:

Polyurea is no ordinary coating; it requires a delicate balance of components for optimal performance. The isocyanate component must flawlessly mingle with the amine or polyol component, ensuring a tough and durable coating. However, improper mixing can lead to weak or brittle results. To conquer this challenge, specialized equipment and training are essential. Manufacturers provide guidelines for precise mixing ratios, as well as instructions on calibration and maintenance of mixing devices.

To achieve precise mixing, consider using simultaneous mixing techniques that allow you to prepare multiple batches simultaneously. This approach saves time and ensures consistency in the coating’s properties. Additionally, batch sizes and the working environment’s temperature should be taken into account to maximize the coating’s pot life.

Time is of the Essence:

Picture this – a coating that cures within seconds or minutes. Yes, that’s polyurea for you. This rapid cure time demands impeccable surface preparation to guarantee adhesion and minimize issues like blistering or delamination. The surface must be clean, dry, and free from contaminants. In some cases, additional steps like sandblasting or priming may be necessary for optimal results.

To tackle this challenge effectively, meticulous planning is crucial. Prepare all necessary tools and materials in advance to ensure a seamless workflow. Establish a step-by-step process for surface preparation, ensuring that each stage is completed efficiently and thoroughly. By doing so, you can minimize the risk of adhesion failures and achieve a flawless finish.

The Skillful Application:

Like an artist wielding a brush, skilled operators must work swiftly and efficiently to apply polyurea coatings effectively. Specialized spray equipment is often employed for this task, requiring proper training and experience. Moreover, with the fast cure time, multiple coats may need to be applied in quick succession – a true test of coordination and timing.

To overcome the challenges of skillful application, invest in operator training programs offered by manufacturers or industry experts. These programs cover topics such as equipment operation, spray techniques, and troubleshooting common issues. With proper training, operators can confidently navigate the intricacies of polyurea application, resulting in consistent and high-quality coatings.

Conquering the Challenges:

To surmount these challenges, planning ahead is paramount. Consider batch sizes and the working environment’s temperature to maximize the coating’s pot life. Simultaneous mixing can be a game-changer, allowing you to prepare multiple batches simultaneously. And remember, always follow the manufacturer’s guidelines – they hold the secrets to success.

Furthermore, maintaining equipment and ensuring its proper calibration is crucial for achieving precise mixing ratios. Regular maintenance checks and calibration adjustments will guarantee accurate results and prevent coating failures due to equipment malfunction.

Recoating Difficulties: Removing or Recoating Polyurea is Challenging

Recoating polyurea is no easy task. Its strong adhesion properties make it a stubborn coating to remove or recoat. The challenges associated with this process are numerous and require careful consideration.

First and foremost, the bond that polyurea forms with the substrate is incredibly strong. Breaking this bond and removing or recoating polyurea requires thorough surface preparation. Any contaminants or loose material left on the surface can compromise the adhesion of the new coating. So, before even thinking about recoating, ensure that the surface is squeaky clean.

Finding compatible coatings is another hurdle to overcome when recoating polyurea. Polyurea has specific formulations that it likes to play nicely with. Using incompatible coatings can result in poor adhesion, blistering, or delamination of the new coat. So, extensive research is necessary to find a coating that will be a good match for your polyurea.

One of the trickiest aspects of recoating polyurea is its fast-curing nature. This stuff dries faster than paint on a hot summer day. Within seconds or minutes of application, polyurea starts to cure. This means you have a limited window of time to recoat before it forms an unbreakable bond with the substrate. Talk about pressure.

In some cases, complete removal of polyurea may be necessary before applying a new coating. But let me tell you, removing polyurea is no walk in the park. It can be a labor-intensive and time-consuming process. Mechanical abrasion, chemical stripping, or high-pressure water blasting are some methods used to remove polyurea, but caution must be exercised to avoid damaging the underlying substrate.

And last but not least, let’s talk money. Recoating polyurea can be quite costly compared to other coating systems. The challenges involved in surface preparation and finding compatible coatings can drive up the overall cost of the project. So, be prepared to open your wallet if you’re looking to recoat polyurea.

Limited Color Options: Fewer Colors Available than Other Coatings

Limited Color Options: Fewer Colors Available than Other Coatings

When it comes to choosing the perfect coating for your project, aesthetics play a significant role in creating the desired visual impact. However, if you’re considering polyurea coatings, you may find yourself faced with a narrower range of color options when compared to other types of coatings. The reasons behind this limitation lie in the manufacturing process and the curing characteristics of polyurea coatings.

Polyurea coatings derive their color from pigments that are added during manufacturing. Unfortunately, the availability of these pigments can be somewhat limited, resulting in a more restricted color palette for polyurea coatings. While popular colors like white, gray, black, and various shades of these colors are readily available, more specific or unique colors may not be as easily accessible.

Another contributing factor to the limited color options of polyurea coatings is the curing process. During curing, some colors may shift or change slightly, further narrowing down the range of available colors. This means that even if a particular color is initially available, it may not maintain its exact shade after curing.

Despite these limitations, polyurea coatings are highly sought after in various industries due to their exceptional durability and other positive attributes. Performance often takes precedence over aesthetics when it comes to choosing polyurea coatings.

However, if you have your heart set on a specific color that isn’t readily available in polyurea coatings, you may need to explore alternative coating options. Some manufacturers may offer custom color matching services for polyurea coatings, allowing you to achieve a more specific color. It’s important to note that this customization process may come with additional costs and longer lead times.

Environmental Considerations: Potential Health Risks and Waste Disposal Regulations

This versatile polymer finds its place in various industries, but let’s not forget about the crucial environmental considerations that come with it. Today, we’ll be exploring the potential health risks and waste disposal regulations associated with polyurea. So, hold on tight as we delve into this important topic.

Health Risks:

- Respiratory Irritants: Brace yourself for a not-so-fresh air experience. Polyurea contains isocyanates, which can irritate your respiratory system, causing coughing, wheezing, and chest tightness. Prolonged exposure may even lead to conditions like asthma or occupational lung diseases.

- Safety First: Protect yourself. When working with polyurea, ensure you wear personal protective equipment (PPE) like respirators, gloves, and coveralls. Adequate ventilation systems are also essential to keep airborne particles at bay.

Waste Disposal:

- Time is Ticking: Polyurea has a limited pot life. Once it’s mixed, you’ve got to use it within a specific timeframe. Any leftover or waste material needs proper disposal according to local regulations.

- Follow the Rules: Consult local environmental agencies or waste management professionals to ensure compliance with waste disposal regulations specific to polyurea. Key considerations include segregation, suitable containers, and appropriate treatment or disposal methods.

Environmental Impact:

- Contamination Concerns: Improperly managed polyurea coatings can contaminate nearby water bodies or soil if applied outdoors without containment measures. This can harm aquatic life and disrupt ecosystems in the long run.

- Be Responsible: Minimize environmental impact by following best practices for application and cleanup. Use containment systems during application to prevent overspray or runoff, clean equipment properly after use, and dispose of excess material responsibly.

Limited UV Resistance: Susceptible to Degradation When Exposed to Sunlight

Polyurea, a versatile and durable material widely used across industries, has a potential downfall that deserves attention. In this blog post, we will explore one of its major limitations – limited UV resistance and its consequences. Let’s delve into the science behind this issue and understand the impact it can have.

Photodegradation: The Silent Saboteur:

When polyurea is exposed to prolonged sunlight, it undergoes a process known as photodegradation. The high-energy photons in UV radiation trigger chemical reactions within the polyurea molecules, giving rise to highly reactive free radicals.

Loss of Physical Properties:

UV degradation causes the deterioration of polyurea’s physical properties. The material becomes brittle, less flexible, and loses its elasticity. These changes make it more susceptible to cracking or breaking under mechanical stress.

Discoloration Woes:

Another consequence of UV degradation is the unsightly discoloration of polyurea surfaces. Over time, vibrant colors may fade or change, posing a significant challenge for applications where aesthetics matter, such as architectural coatings or automotive finishes.

Chemical Composition Changes:

UV exposure can also alter the chemical composition of polyurea. The breakdown of molecular bonds can result in the release of volatile organic compounds (VOCs), which are harmful to both human health and the environment.

Additives and Their Limitations:

To combat UV degradation, manufacturers often incorporate additives or UV stabilizers into polyurea formulations. These additives act as a protective barrier, absorbing or reflecting UV radiation. However, even with these measures in place, polyurea’s resistance to UV degradation remains limited.

02agu77PPcY” >

Conclusion

In conclusion, while polyurea coatings boast unparalleled durability and performance, they do come with a few drawbacks that demand careful consideration. Firstly, the price tag of polyurea is higher compared to other coating options due to its top-notch raw materials and intricate manufacturing process. Moreover, the fleeting pot life of polyurea coatings necessitates swift and efficient application within a tight timeframe, potentially escalating labor costs and requiring meticulous planning for large-scale projects.

Furthermore, achieving optimal results with polyurea coatings demands precise mixing and application techniques. The lightning-fast cure time of polyurea also presents challenges in terms of surface preparation and coordination during multiple coat applications.

Recoating polyurea can be arduous due to its tenacious adhesion properties. Additionally, there are limited color options available compared to other coatings, potential health risks associated with exposure to isocyanates in polyurea, as well as stringent waste disposal regulations that must be adhered to. Lastly, when exposed to sunlight, polyurea exhibits limited UV resistance leading to degradation.

Despite these downsides, it is crucial to acknowledge that polyurea coatings still offer myriad benefits such as exceptional durability, resistance against chemicals and abrasion, reduced maintenance requirements over time, and an extended lifespan for coated surfaces.